BLOODBORNE PATHOGENS EXPOSURE CONTROL PLAN CALIFORNIA STATE UNIVERSITY, FRESNO

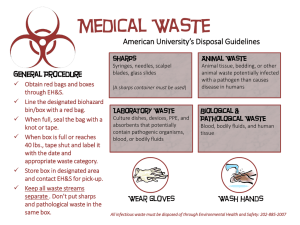

advertisement