Document 13078117

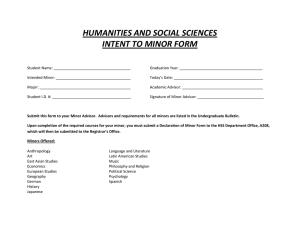

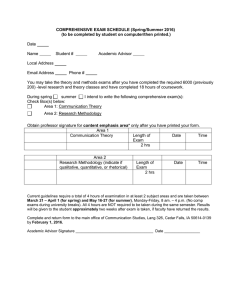

advertisement