Technical Support for Development of an Attic Simulation Model for the

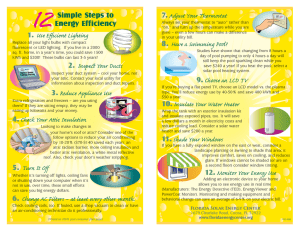

advertisement