Document 13050443

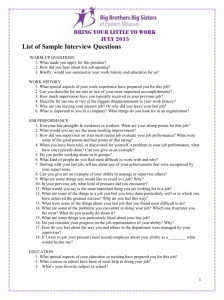

advertisement