APPENDIX A Inspection Reports

advertisement

APPENDIX A

Inspection Reports

r\lovemoer ,jU, LUUtt

_ _ _ _ _ _ _ _ _ _ _ _ Sta\e Information

BDEPT#="

047 CASEY OVERPASS

_ _ _ _ _ _ _ _ Code

_ _ _ _ _ _ _ _ _ _ _ _ Classificalion

Agency Br,No,

816367

047

B.f.N=

4EX

AASHTO=

_ _ _ _ _ _ _ _ _ _ _ _ Identification

(104) Highway System

031.2

FHWA Select list:::

(8) Structure Number

(100) Defense Highway

B163674EXDOTNBI

(101) Parallel Structure

131002030

(5) Inventory Route

04

07000

COMB WASH ST&AMTK&ORNG

(6) Features intersected

ST203 MONSGR CASEY

.5 MI E OF BUSSEY ST

(9) LocaUon

(11) l(lIomelerpoint

0001.979

(12) Base Highway Network

y

(13) LRS Inventory Route & Subroute

(26) Functional Class-

Y

(2) State Highway Department District

(3) County Code

025

(4) Place code

(7) Facility Carried

Y

Y

(112) NBIS Bridge Length

L.O. MDC

Town= Boston

Urban Arterial

14

o

N

2

2-waytraffic

(102) Dlrectfon of Traffic -

N

(103) Temporary Struclure

(105) Federal Lands Highways

o

(110) Designated NaUonal Network

N

3

On free road

(20) TolI(21) Maintain -

State Highway Agency

01

(22) Owner-

State Highway Agency

01

built after 1949 presumed to be not eligil Z

(37) Historical Significance

_ _ _ _ _ _ _ _ _ _ _ _ _ Condilion

Code

000000000000

(16) Latitude

420EG 18 MIN

04.99 SEC (58) Deck

5

(17) Longitude

71 DEG 06 MIN

49.86 SEC (59) Superstructure

(60) Substructure

5

(98) Border Bridge State Code

%

(99) Border Bridge Structure No. #

_ _ _ _ _ _ _ _ _ _ Structure Type and Material

(43) Structure Type Main:

N

(61) Channel & Channel Protection

N

(62) Culverts

_ _ _ _ _ _ Co<Ie

_ _ _ _ _ _ _ _ _ _ Load Rating and Posting

Code

Steel

Stringer/Girder

4

JoinUess bridge type:

302

Not applicable

(44) Structure Type Appr:

2

2

H 15"M 13.5

(31) Design Load -

(63) Operating Rating Method -

Allowable Stress (AS)

35,6

(64) Operating Rating

Other

Code

(45) Number of spans in main unit

(46) Number of approach Spans

(107) Deck Structure Type-

000

(65) Inventol)' Rating Method -

020

(66) Inventory Rating

0000

15.9

5

(70) Bridge Posting

for other

restrict

(41)

_

_Structure·

_ _ _ _ _ _ _Posted

___

Appraisal

_ _ _ _ _ _ _ _ _ CodeR

Code

Concrete Cast·in-Place

2

Allowable Stress (AS)

(108) Wearing Surface 1 Protective System:

A} Type of wearing surface -

Latex Concrete

8) Type of membrane -

3

Code

None

0

Code

C) Type of deck protection·

None

Code

0

_ _ _ _ _ _ _ _ _ _ _ .Age and Service _ _ _ _ _ _ _ _ _ __

(57) Structural Evaluation

2

(68) Deck Geometry

4

N

N

(69) Underclearances, vert, and hafIz,

(71) Waterway adequacy

(72) Appto3ch Roadway Alignment

(27) Year Built

1951

(106) Year Reconstructed

1991

(42) Type of Service: OnUnder-

HIghway

Code

HWY-RR

(28) Lanes: On Structure

05

(29) Average Daily Traffic

1997

(30) Year of ADT

14

Under structure

04

N_

(113)

_

_Scour

_ _CriUesl

_ _Bridges

_ _ _ _ _ Inspeclions _ _ _ _ _ _ _ _ _ _

01/30/08

(90) Inspection Date

MOA)

%

00

MOB)

00100100

Y

06

MOC)

07127/09

00509.0 M

02.9

M

RI9ht

02.9 M

(51) Bridge RoadwayWfdlh Curb to Curb

016.5 M

(52) Deck Width Out 10 Out

024.4 M

(32) Approach Roadway Width (w/shoulders)

020.7 M

(33) Bridge Median(34) Skew

Closed median (no barrier)

00

DEG

(e) Other Special Inspection

N

00

MO")

00/00100

(") Closed Bridge

N

00

MO~)

00100100

(.) UW Special Inspection

N

00

MO")

00/00100

0

08.2 M

(53) Min Vert Clear Over Bridge Rdwy

(54) Min Vert Underclear ref

H

(55) Min Lat Underclear RT ref

N

(56)

Lal

T _ _ Navigation Data

_

_ Min

__

_Underclear

_ _ _ _L_

(38) Navigation Control-

Not applicable, no watelWay

(39) Navigation Vertical Clearance

(116) Vert-lift Bridge Nav Min Vert Clear

(40) NavIgation Horizontal Clearance

N

_(0)

_Damage

_ _ _Inspection

_ _ _ _ _ _ _ Raling Loads _ _ _ MO")

_ _ _ _ _ _00100/00

_ __

04/02179

Report Date

Operating

H20

Type 3

Type 352

Type HS

0.0

0.0

0,0

0.0

Inventory

0.0

0,0

0.0

0.0

_ _ _ _ _ _ _ _ _ _ _ FleldPosling _ _ _ _ _ _ _ _ __

Status

Posting Date

POSTED

99.99 M

(47) Inventory Roule Total Horlz Clear

(111) Pier Protection

2

Code

(35) Structure Flared

(10) Inventory Route MIN Vert Clear

00/00/00

00

N

0029.0 M

Left

MO

N

000 KM

(49) Structure Length

06

(93) CFI DATE

(A) Fracture Critical Detail

(") Other Inspection

(50) Curb or sIdewalk:

(91) Frequency

(92) CrlUcal Feature InspecUon:

(B) Underwater Inspection

01

(48) Length of maximum span

6

0 0 0

032600

(109) Truck ADT

(19)

length

_

_Bypass,

_ _ _detour

___

_ _ _ _ 'Geometric Data

o

(3S) Traffic Safety Features

2 Axle

16

Actual

04/19179

5 Axle

2S

3 Axle

21

99.99 M

Recommended

02.99 M

MiSSing

Signs

N _ _ _ _ _ ,Mlsc. ....:._ _ _ _ _ _ _ _ __

_

__

___

00.0 M

01.BM

Code

N

Code

000.0 M

M

0000.0 M

Bridge Name

N

047 CASEY OVERPASS

Anti-missile fence

N

Acrow Panel

N

Jointless Bridge

Freezeffhaw

Accessibility (Needed/Used)

NIN

liftbucket

NIN

Rigging

N/N

Ladder

N 1N

Staging

N/N

80at

NIN

Traffic Control

N/N

Wader

NI N

RR Flagperson

NIN

Inspector 50

N/N

Police

Inspection

Hours:

006

MASSACHUSETTS DEPARTMENT OF TRANSPORTATION

1 2 - OIS1 1

fB1.N.l

S.-STRUCTURE NO.

BOSTON

07-F ACILITY CARRIED

26·FUNCTIONAL CLASS

COMB WASH ST&AMTK&ORNG

Urban Arterial

43-STRUCTURE TYPE

302 : Steel Stringer/Girder

f:~~v

J07-DECK TYPE

WEATHER

1 : Concrete Cast-in-Place

11

!

27-YR BUILT

047 CASEY OVERPASS

06-FEATURES INTERSECTED

~tate

DEF

"'8@Cd,'

0

SUPERSTRUCTURE

DEF

S-A

2.0eck Condition

5

Sop

2.Floorbeams

N

'. ~ •. 'in place forms

3

M-P

3.Floor System Bracing

N

-

6

M-P

4.Girders or Beams

5

M-P

N

-

..

4

M-P

•

7

M-A

I.

5

M-P

a.Railing

9.Anti Missile Fence

7

M-P

N

-

5.Trusses ~ General

a. Upper Chords

N

b. Lower Chords

N

c. Web Members

N

d. Lateral Bracing

N

e. Sway Bracings

N

f. Portals

N

g. EndPosts

N

-

-

4

Sop

4

Sop

12. Utilities

4

Sop

6.Pin & Hangers

N

13.Deck Joints

4

Sop

7.Conn Pit's, Gussets & Angles

5

110.

111.' ,_ ••,.

,System

Standards

14.

N

-

a.Cover Plates

15.

N

-

N

16.

5

N

CURB REVEAL

(In millimeters)

1

254

1

1

254

APPROACHES

1

5

M-P

b. Appr. Roadway

5

M-P

I c. Appr. Sidewalk

7

-

N

d.

-

M-P

5

M-P

9.Bearing Devices

5

M-A

10. Diaphragms

3

S-A

11. Rivets & Bolts

12. Welds

5

M-P

13. Member Alignment

5

M-P

14. PaintlCoating

4

Sop

5

DEF

a. Appr. pavement condition

15.

M-P

N

I

1Year Painted

INone (

ILOAD

) Minor (

-

I

X

p,., •• ..... /.

1nn ".'n •• DAMAGE:

)

PROJ MGR HNTB Corporation

B. O'ARTISTA, M. BEINTUM

_1°C

3

.

0000

D. J. Consentino

TEAM MEMBERS

TEMP. (air)

1.Stringers

-..

1991

TEAM LEADER J. Carney

M-P

_._L

I06-YR REBUILT YR REHAB'O (NON 106)

1951

5

surface

JAN 29,2010

Highway

IIiDi1BI

0

90-ROUTINE INSP. DATE

O:OPEN

DISI. BRIDGE INSPECTION ENGINEER

21-MAINTAINER

Varied

41-STATUS

001.979

MEMORIAL NAME/LOCAL NAME

ST203 MONSGR CASEY

B-16-367

II-Kilo. POINT

B16367 -4EX-OOT -NBI

DECK

BR. DEPT. NO.

ROUTINE & SPECIAl. MEMBER INSPECTION

CITyrroWN

IIiii11D

I

STRUCTURES INSPECTION FIELD REPORT

~

04

PAGE_1_ OF 70

,( X)Severe(

I

Please explain

) Minor ( X ) Moderate (

) Severe (

)

0

SUBSTRUCTURE

11. ""u,

IDiv,lcu,

1 a.

N

N

I b. a,idae Seats

I c.

N

N

N

6

6

6

6

N

6

H

H

N

7

m.

N

N

a.

N

3

b, CaDS

c

N

5

N

i

N

d.

N

N

N

N

' e.

f. .,-

a. Pointina

h.

N

i. Piles

I / Seou,

N

6_

M-P

M-P

M-P

M-P

M-P

-

.. ..

i k

' I

12. Piers or Bents

I d.

I e. Pointino

I f. Footinn

I a. Piles

I h.Seou,

Ii

N

N

N

H

N

7

5

5

1 a. PII. "an<

N

N

I b. Piles

I c, n'

Irl

I e.

N

N

N

N

~Bents

M_P

H

N

,S"cko

M_P

N

N

N

N

' "',

M_P

•6

N

/

3~

M_P

N.-

,/ anJeina

UNDERMINING (YIN)

N

N

N

N

-

-

If YES please explain

I

N

nl:'l:'l

OVERHEAD SIGNS

(Attached to bridge)

(YIN)

0

DEF

,fWelds

i

I a.

I b. Condition of Bolts

N

c. Condition of Signs

N

N

X=UNKNOWN

RTN(1)7-9S

§

INone (

ILOAD VIBRATION:

INone ( ) Minor ( X

Please explain

) Moderate (

) Severe (

Any Fracture Critical Member: (YIN)

Any Cracks:

(YIN)

0

N=NOT APPLICABLE

0

)

)

COLLISION DAMAGE:

None (X ) Minor (

) Moderate (

) Severe (

)

SCOUR: Please eXl2iain

None (X ) Minor (

) Moderate (

) Severe (

)

/·60 (Dive Report):

0

93B-UIW (DIVE) Insp

H=HIDDENIINACCESSIBLE

/·60 (This Report):

1

0

00/00/00

R=REMOVED

1

PAGE

B.l.N.

BR. DEPT. NO.

8.-STRUCTURE NO.

4EX

B-16-367

B16367 -4EX-DOT -NBI

BOSTON

2

OF

70

INSPECTION DATE

JAN 29, 2010

(V/N/P)

ACCESSIBILITY

0

~~13~21Isin~le I

Not Applicable

Actual Posting

Recommended Posting

Waived Date:

I

00100100

~~~~

IEJDMT Date: I

00100100

Signs In Place

(y=Yes,N=No,

NR=NotRequired)

Legibility/

Visibility

TOTAL HOURS

PLANS

Not Applicablf ~

Actual Field Measurement

STREAM FLOW VELOCITY:

Tidal (

) High (

) Moderate (

) Low (

) None (

(V.C.R.)

Posted Clearance

X

(yIN):

(Y/N)~

TAPE#:

ITEM 61 (Dive Report):

~

93b-UIW INSP. DATE:

Rating Report (YIN)

Date:

I

ITEM 61 (This Report)

I

00100100

G

List of field tests performed:

Visual, Hands-On; D-Meler

I

(To be filled out by DBIE)

~

04/19/1979

Signs In Place

f'{=Yes,N=No,

NR=NotRequired)

Request for Rating or Rer.ting (YIN):

I

~

If YES lease ive riori :

HIGH (

) MEDIUM (

REASON:

Inspection data at time of existing rating

158: - 159: - 160: Date :01/02/1979

CONDITION

CONDITION

C

2

c

T NG GUIDE

DEFECTS

CRITICAL

"IMMINENT' FAILURE

o

FAILED

Qut of service - beyond corrective action.

DEFICIENCY REPORTING GUIDE

CATEGORIES OF DEFICIENCIES:

M= Minor Deficicncy- '~:I:.e~~osr ::~~~ ;;Ii~IO:~,~ ~~~~~e$.;;,cu~~g~I~:;~ I~~~~~~~ e~~~c1ural integrity of the bridge and could easily be mpaTrnd. Examples Include but arc not !imilml 10: Spalled concrete, Minor pol

S= Severc/M aj or Dcficicncy- ~~~:~::d~j~r:,~~n~~:~;I~S!~~I~;:~~~~~~~I~:~~;;~:~~nngn~?u~~~:~~n~~ ~~:rn~~:;:~:~~i~~::~::;: t~O~I~m~I::~;:;:;mV:I~~!~~~~;~d~:~~~;~o~i~~~~~te.

Exposed

C-S= Critical Structural Deficiency _ ~t:~~yC~~rh~ ~~I~~ural element of a bridge thai poses an exlmme unsafe cond~ion due \0 the failure or ImmInent failure a/the element which will affect the structural

e-H= Cri ti cal Hazard Defi deney - ~~~:~~~fu~e~~Pao~e~~t,f~~:~~~; ~~~s~~:!~! k~~~n~nd~:~~V~~~~~~ ~~ ~~~:~~IiC:n~~~o~~I~ ti~e/su~!a~~~~;t~~~t:1s~;~fueli:~~~~~~~~:~~;:Z ~I~~rn~~eg~ion of

bridge railing, etc.

URGENCY OF REPAIR:

I = Immediate-

[Inspector(s) Immediately contact District Bridge InspecHon Engineer (DalE) 10 reporlthe Deficiency and 10 receive further instruction from hlmlhcr].

A=ASAP~

!Actlon/Rcpairshould be Initiated by Dislrict Mainlenunce Engineer orlhe Responsible Party (if not a Stale owned bridge) upon receipt ollhe Inspection Report].

P = Prioritize-

[Shall be prioriltzcd by D~lrict Maintenance Engineer or Ihc Responsible Party (if not a Siale owned bridge) and repairs mude when funds and/or manpower is available].

RTB(2)04-07

PAGE

MASSACHUSETTS DEPARTMENT OF TRANSPORTATION

12-DIS11~ STRUCTURES INSPECTION FIELD REPORT

04

~

3

BR. DEPT. NO.

ROUTINE & SPECIAL MEMBER INSPECTION

CITvrroWN

S.-STRUCTURE NO.

BOSTON

B16367 -4EX-DOT -NBI

07-FACILIrY CARRIED

B-16-367

II-Kilo. POINT

90-ROUTfNE INSP. DATE

001.979

Jan 29, 2010

93*-SPEC. MEMB. INSP. DA

Jan 29, 2010

MEMORIAL NAl\I1EILOCAL NAME

ST203 MONSGR CASEY

*YR REHAB'O (NON 106)

047 CASEY OVERPASS

06-FEATURES INTERSECTED

26-FUNCTIONAL CLASS

COMB WASH ST&AMTK&ORNG

Urban Arterial

1951

1991

0000

D. J. Consentino

DIST. BRIDGE INSPECTION ENGINEER

TEAM LEADER J. Carney

43-STRUCTURE TYPE

OF 70

PROJ MGR

HNTB Corporation

302 : Steel Stringer/Girder

I07-DECK TYPE

TEAM MEMBERS

1 : Concrete Cast-in-Place

B. D'ARTISTA, M. BEINTUM

WEIGHT POSTING

At brid e

Signs In Place

(y=Yes,N=No,

Actual Posting

Waived Date:

NR=NotRequired)

Legibilityl

Visibility

iru;m;;-;n;;=r;

Advance

8Si@Si

RATING

Rating Report (YIN)

158: _

~

Request for Rating or Rerating (YIN):

Date:

1L-_O_4_'_19_'_19_7_9_-,

Inspection data at time of existing rating

159: _ 160: _

162: _

Date :01/02/1979

MEMBER

CRACK

(YIN):

N

N

N

REASON:

0

PLANS

(V.C.R.)

TAPE#:

If YES please give priority:

IHIGH (

) MEDIUM (

I

LOCATION OF CORROSION, SECTION LOSS ("ho), CRACKS,

COLLISION DAMAGE, STRESS CONCENTRATION, ETC.

See remarks in comments

section.

See remarks in comments

section.

See remarks in comments

section.

INV. RATING OF

MEMBER

Deficiencies

3

3

Not Rated

S-A

3

3

Not Rated

S-A

6

3

Not Rated

C-S-I

I-58

List offield tests performed:

Visual, Hands-On; D-Meter

) LOW (

(Overall Previous Condition)

(Overall Current Condition)

I-59

1-60

1-62

QJ~~D

0000

CA TEGORIES OF DEFICIENCIES:

1\:1= Minor Deficiency- '~:I~~~e~~~~~:Si~r:: ::;~t~~:~ ~f~~~~g,~~r;:;.lItl~~;:j ~~i~~9~.ee~~~ctura! integrity of the bridge and could easily be repaired. Examples include but are notlimiled to: Spalled concrete. Minor pot

S= Severe/Maj or Defi cien cy- ~:~:=:dw~~~~.r~:~~:::I~S!~~U~;:~~,~~~~i~:~tl~~~~~an~n~~u~~~~~~~n~~ ~:~~7:~:~~:~~le~:~~I~~ t~O!t~~t:lt~e~~~t~~!~s~~~~ed::~~~~o~i~~~rc~te, Exposed

C-S= Critical Structural Deficiency _ ~1~~~~e~ITh~ :~I~~tum! element of a bridge that poses an extreme unsafe condition due 1(1 the I~ilure or imminenl failure of the element which will affect the structural

C-H= Critical Hazard Deficiency-

A deficiency In a component or element of a bridOfl that poses an extreme hazaro or unsafe condnion to the publiC, but does nol impair the structural integrity olthe bridge.

Examples include but are not limited to: Loose concrete hanging down over Imffic or pedestrians, A hole in a sidewalk Ihat may cause Injuries to pl!deslrians, Mtssing section of

bridge raUing, etc.

URGENCY OF REPAIR:

I = Immediate-A = ASAPP = Prioritize--

Iinspector(s) Immediately contact Dtstrict Bridgo Inspection Engineer (DBIE) to report Ihe Deficiency and to receive further instruction from himJher].

[ActionlRepair should be

X=UNKNOWN

F.C.(1)7-96

In~iated

by District Maintenance Engineer or the Responsible Party (if not a Slate owned bridge) upon receipt olthe Inspection Report].

IShall be prioritized by District Maintenance Engineer or the Responsible Party (if not a Slate owned bridge) and repairs made when fundS and/or manpower is available].

N=NOT APPLICABLE

H=HIDDEN/INACCESSIBLE

R=REMOVED

PAGE

CITyrrOWN

B.I.N.

BR. DEPT. NO.

S.-STRUCTURE NO.

BOSTON

4EX

B-16-367

B16367 -4EX-OOT -NBI

4

OF

70

INSPECTION DATE

JAN 29, 2010

REMARKS

aRID~<1E~OJ~LEf>lIATIQI:lI

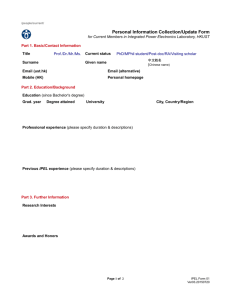

This bridge carries State Route 203 in an east/west direction over several city streets, a parking lot for the

West Roxbury Municipal Court and the MBTA in the City of Boston. This bridge is a twenty span structure

and each span consists of fourteen rolled steel beams, two built-up steel fascia girders, two rolled steel

sidewalk stringers and two rolled steel median stringers (see sketches 1 and 2). The spans are numbered

east to west and the beams are numbered south to north. The fascia girders, sidewalk stringers and

median stringers are designated as south or north. The piers are lettered A to U from east to west (omitting

letters I and 0) and the abutments are labeled east and west. The piers consist of two solid stem piers,

twelve concrete hammerhead piers and five two column concrete bents. Span 3 spans over a turnaround

roadway for the Arborway. Spans 4 through 9 are over the courthouse parking lot. Spans 10 and 11 span

over Washington Street and an associated turn for the Arborway. Spans 12 through span 17 are over the

MBTA Forest Hills subway station property. Span 18 spans over South Street. The bridge labeling system

follows the convention set in the previous inspection reports.

{iENEBAI.J~I;MABKS

At the time of this inspection, a contractor (SPS New England, Inc.) was performing repairs to this structure

which included the installation of fabric wrapping around whole U/S deck including the fascia girders and

parapets above roadways that pass under the bridge and some repairs to the concrete wearing surface.

The area beneath span 1 is being used as a dwelling for homeless people; refer to Item 60.1.d. The spans

located above the courthouse parking lot should be inspected on weekends or at night as the lot fills to

capacity when the court is in session (coordinate with Chief Court Officer, Jack Cahill). The spans located

above Forest Hill Station and the approaching busway lanes were inspected at night using a UB-60

snooper. The MBTA required a bus inspector to be on site until termination of MBTA service at about 1:15

am.

ItjlI!L5Jl.j-,,-W~e~a.J:i ng~s~llrfac~e

The concrete filled steel grating is overlain with a latex modified concrete (LMC) wearing surface. There are

numerous locations of hairline to 1/8" transverse cracks (up to 3/16" wide in a few locations) in the wearing

surface. These cracks are typically about 4' to 6' on center and become more closely spaced at the ends of

the spans adjacent to the deck joints (see photo 1). Span 9, eastbound roadway, was noted to have the

highest concentration of transverse cracks extending over the majority of the span. The grid deck is

noticeably bowed upward approximately 1 1/2" to 2" adjacent to the deck joints which creates an uneven

riding surface (see photo 2); this condition was most prevalent on the eastbound roadway. See Item 58.13

for additional comments.

Extensive concrete repairs have been performed to the wearing surface, many of which extend the full width

and length of the spans. Some of these concrete repairs contain hairline to 1/16" wide transverse and

longitudinal cracks and some minor deterioration along the edges. There are scattered longitudinal cracks,

up to 1/8" wide, and also some widely scattered 6" diameter by 1/2" deep minor spalls in the wearing

surface.

Below the deck, there is a visible longitudinal gap of 1" to 4" between the outer edge of the grid deck and

the cast-in-place concrete of the center median. A 2" wide strip of the concrete wearing surface above this

gap, adjacent to the median curb, is typically heaved and in the process of breaking up or has spalled (see

photo 3). In many locations this 2" wide portion has become punky and is filled with sand allowing for water

infiltration to the superstructure below (see photo 4). The localized wearing surface deterioration was

noted to be prevalent along the median curb of the eastbound roadway and occurring in scattered locations

along the median curb of the westbound roadway.

REM.(2)7-96

PAGE

CITyrrOWN

B.I.N.

BR. DEPT. NO.

S.-STRUCTURE NO.

BOSTON

4EX

B-16-367

B16367 -4EX-DOT -NBI

5

OF

70

INSPECTION DATE

JAN 29, 2010

REMARKS

The following is a summary of additional specific locations of deterioration:

Span 2, E.B. Roadway: There is an 8" long by 2'-2" wide by 1 1/2" deep spall, left lane, at the 1/3 point from

east.

Span 5, E.B. Roadway: There is a 2'-9" long by 3'-3" wide by 2" deep spall at a location of a partial spall

repair.

Span 7, E.B. Roadway: There is a 3/16" wide by 11'-0" long longitudinal crack in the left lane at the 1/4 point

from east.

Span 7, E.B. Roadway: There is a 4'-0" long by 6'-0" wide by 1" high heave of the concrete repair adjacent

to the median near midspan.

Span 11, E.B. Roadway: There is a local 2'-0" long by 3 1/2" wide by 1 1/2" deep spall, left lane, adjacent to

the median curb near the east end of the span.

Span 12, E.B. Roadway: There is a 15'-0" long by 5'-6" wide by 1 1/2" high heave of the concrete repair

adjacent to the median at pier L. Additionally, there is a 3'-0" long by 14" wide bituminous concrete patch

adjacent to this concrete repair.

Span 12, W.B. Roadway: There are two 18" diameter by 3" deep spalls with exposed reinforcing welded

wire fabnc and mounded frozen debris in the right lane adjacent to the curb; one spall is located at pier M

and the other approximately 12' east of pier M (see photo 5).

Span 13, W.B. Roadway: There is local concrete breakup in the left lane, 2'-6" wide by 2'-6" long, along the

median curb at pier N. Epoxy coated wire mesh is exposed and protruding into the roadway.

Span 15, W.B. Roadway: There is a local 18" long by 12" wide by 1" deep spall in the right lane at midspan.

Span 20, E.B. Roadway: There is a 6'-8" long by up to 6 1/2" wide by full depth spall with exposed epoxy

coated welded wire fabric, in the left lane adjacent to the median curb (see photo 6).

U~_m 5Jic2-,,--lLe_cJL~Qtu:!.i.!:1cm.

Underside of Deck: The deck is comprised of concrete filled steel grating. The condition of the stay in place

forms vary from minor surface rusting at interior regions (away from deck joints and curb lines) (see photo

7) to complete loss of the stay-in-place forms in many locations; particularly near the deck joints and curb

lines. In locations where the stay-in-place forms have rusted away, there is typically some visible salt

efflorescence on the bottom surface of the exposed concrete and rust delamination on the bottom surface

of the exposed steel grating with some minor section loss (approximately 1/32" loss) (see photo 8).

There is typically impacted rust between the top flange of the beams and the underside of the deck which

appears to be causing the deck to be bowed upward above the beams in many locations. The worst case is

at the westerly end of span 12, eastbound roadway, where the deck is bowed up to 1 3/4" above beams 2

through 5 (see photo 9) from pier M to the 1st interior diaphragm. The maximum upward bow at these

beams occurs about 5 feet off pier M. Approximately 1/8" of live load deflection was observed to the deck

above beam 5. The remaining intenor beams at the west end of the eastbound roadway exhibit similar but

less severe gaps. Similar but less severe gaps occur in scattered areas throughout the underside of deck,

most of which appear to be approximately 1/2" or less with pack rust filling the gap between the underside

of deck and the beam flange.

The concrete along the top exterior flange of the fascia girders typically exhibits scattered loose thin

concrete fragments and areas of spalling where concrete fragments have fallen out of place or have been

removed (see photo 10). Visible gaps, 1/4" to 9/16", are evident between the top flange of the south

exterior girder and the underside of the concrete deck along the south fascia where corner spa lis exists

(see photo 11).

REM.(2)7-96

PAGE

CITYITOWN

B.I.N.

BR DEPT. NO.

8.-STRUCTURE NO.

BOSTON

4EX

B-16-367

B16367 -4EX-OOT -NBI

6

OF

70

INSPECTION DATE

JAN 29,2010

REMARKS

In span 9, three locations of local delamination were noted along the north fascia of the deck slab at the

lower corner (see photo 12). These delaminations occur above the outer edge of the courthouse parking

lot. The deck overhangs and concrete parapets have recently been wrapped with fabric netting where they

pass over roadways, entranceways to the courthouse parking lot and over the MBTA busways.

lt~m_5_8~3_____SJ_ay in pl<l~e forms.

The stay-in-place forms for the concrete filled grating have large areas of 100% section loss exposing the

underside of deck (see photo 8). See Item 58.2 for additional comments.

lt~m_5_8.4 - C_UJ:l:ts

The granite curbs are generally in good condition. There are local sections of concrete curb, typically 2'

long, at the deck joints. N. several locations the concrete sections of curb are spalling, particularly at piers

Q, Rand S. The heaviest spalling occurs at the pier R deck joint in span 16, which has a 2' long by full

height by 5" deep spall in the concrete median curb.

Just off the bridge, a 10' long section of granite median curb is protruding 1" into the left westbound lane of

the west approach (see photo 13).

!Jem_5_8~.s - r~'Le_d ian

There are hairline to 1/32" wide vertical shrinkage cracks throughout the length of the concrete median.

The concrete median on the approach roadways leading up to the bridge have areas of spalling at the east

and west abutments. There is a 9' long by 18" wide by 2" deep spall in the east approach concrete median

at the east abutment (see photo 14). There is a 4'-0"long by 1'-6" wide by 1" deep spall in the west

approach concrete median at west abutment. See Items 58.4 and 58.13 for additional comments .

.IJeJJL5Jl.9_____S1djl_waJl5s

The concrete sidewalks are generally in good condition (see photo 18). N. the time of this inspection there

were 17' long by full width sections of the south and north sidewalks in span 14 that were covered with ice

due to ponding as a result of plugged sidewalk scuppers (see photo 15). There is moderate concrete

debris accumulation on the south sidewalk in span 16. The deck joints in the sidewalks have heaved

upward in several locations. See Item 58.13 for additional comments.

lt~m_5_8~_~e.arap_e_ts

Fabric wrapping has been installed around the parapets and fascia girders above Washington Street, South

Street, the MBTA busway, the courthouse parking lot south entrance and the turnaround for the Arborway

(see photo 16).

There is a horizontal misalignment of 1 1/2" at the south parapet at the expansion joint between spans 19

and 20 at pier U (see photo 17).

U~m_5JUL-_Bai1lng

The pedestrian railing has peeling and chipping paint exposing the underlying galvanized coating. There

are a few locations of missing fasteners at the locations where the horizontal pipe rails connect to the pipe

sleeves at the rail posts. Some tree growth is encroaching through the pickets of the north pedestrian

railing in spans 5 and 6 (see photo 18).

See Item 36a for comments on the traffic railing.

REM.(2)7-96

PAGE

CITYffOWN

B.I.N.

BR. DEPT. NO.

S.-STRUCTURE NO.

BOSTON

4EX

B-16-367

B16367-4EX-DOT-NBI

7

OF

70

INSPECTION DATE

JAN 29,2010

REMARKS

It.e-')1_5~8. to-,,--Draina~.e_sy_s.t.e~m

The roadway scuppers are typically nearly completely plugged (80% to 95% plugged) at the scupper grates

however the discharge pipes below generally appear to be unobstructed and functioning properly. There

are fully plugged roadway scuppers in the westbound and eastbound lanes of span 2 at pier A (see photo

19), in the westbound and eastbound lanes of span 4 at pier C, in the eastbound lane of span 16 at pier R

and in the eastbound lane of span 19 at pier U.

The sidewalk scupper gratings are partially full of leaves. There are plugged sidewalk scu ppers with minor

vegetation growth in several locations along both sidewalks. Water is ponding on the surface of both

sidewalks in span 14 due to plugged scuppers (see photo 15).

The drainpipes are heavily rusted, and leaking at some locations (see photo 20). Scattered drainpipe

hangers are not properly adjusted leaving gaps between the bottom of the support saddle and the pipe and

are not providing active support to the pipes. There are also a number of drainpipe hangers which have

become disconnected from the structural supports and are ineffective and are hanging down from the pipes

(see photo 21).

Jj.e_m_5_a.J.:I-,,--Ljgb.tln~_SJ.an_d_ards

Highway lighting standards on concrete poles are in place along the center median. A few of the lighting

standard poles exhibit 1/32" to 3/16" wide vertical cracking with surrounding delamination and local spalling

along the lower 3' of the pole (see photo 22). The hand hole covers on the lighting standard poles are

typically loose and missing a fastener. The bolts are typically missing from the galvanized steel electrical

pull box covers for the lighting standards. The original pull box covers had been replaced with temporary

plywood covers in spans 1 through 5 and these covers have become heavily weathered (see photo 22).

A few of the anchor bolt nuts are not fully tightened leaving slight gaps between the anchor bolt nut and

washers. There is an 1/8" gap between the southwest anchor bolt nut and the washer for the lighting

standard in span 8. The northeast anchor bolt is missing for the lighting standard in span 10 (see photo

23). The lighting standards in spans 12 and 15 have been removed.

There is under-bridge lighting in the spans above the courthouse parking lot and the turnaround for the

Arborway. Most of the covers for the under-bridge lighting are missing. The under-bridge lighting attached

to beam 8 at pier F in span 7 has a tie wire connection replacing a broken connection clip (see photo 24).

This light is loose and District Maintenance has been notified.

tt.e.m_S.8~.t2-,,-UJltLtle~s

There is a 1" diameter electrical conduit connected to the bottom flange of beam 8 which serves the underbridge lighting in the spans above the courthouse parking lot and the turnaround roadway for the Arborway.

There are two consecutive broken connection clips causing an 8" sag to the electrical conduit at the east

half of span 5 and ten consecutive broken connection clips causing a 12" sag to the electrical conduit at the

east half of span 9 (see photo 25). There are two broken connection clips for the electrical conduit at the

under-bridge lighting at pier E in span 6. The electrical conduit at pier G is disconnected. There are

scattered areas of heavy rust to the electrical conduit.

The electrical conduit junction box on the east face of pier C in span 3 is open with exposed wires (see

photo 26).

REM.(2)7.95

PAGE

CITY/TOWN

B.I.N.

BR. DEPT. NO.

S.-STRUCTURE NO.

BOSTON

4EX

B-16-367

B16367 -4EX-OOT -NBI

8

OF

70

INSPECTION DATE

JAN 29, 2010

REMARKS

Ltftm_5_8.13-,"-Qe_cJLJ_oiO.tS

The deck joints are in poor condition overall. The majority of the deck joints are leaking allowing infiltrating

water to pond on many of the pier caps in the center region between the raised pedestal walls and allowing

corrosion of the steel superstructure elements below. There is moderate sand and debris accumulation in

the deck joints. The joint seals are becoming dislodged from joint angles in several locations and local

sections of missing joint seals were noted in a couple locations (see photos 27 & 28). Additionally, the joint

seals extend vertically up the face of the curbs at the median and the sidewalks. These vertical sections of

joint seal have become dislodged and torn by plows in numerous locations throughout the length of the

structure and project upwards at the curb lines at numerous locations (see photo 28). The eastbound deck

joint angle at pier L has cracked through in the left lane and the section of angle to the south of the crack

has separated from the concrete and rotated inward (see photo 29).

The eastbound deck joint at pier U is overly compressed with only a 5/8" opening remaining between the

joint angles. The east joint angle of the west abutment deck joint, eastbound roadway, has rotated inward

at the south end leaving a 1/4" gap between the joint angle and the concrete wearing surface.

In many locations, particularly along the eastbound roadway, the deck joints are set 11/2" to 2" lower than

the adjacent wearing surface of the grid deck, creating a bump as traffic passes over the joints. This

condition was most noticeable at piers M, Q and U of the eastbound roadway (see photo 2).

The joints in the sidewalks consist of 2" compression seals with elastomeric concrete headers. The

elastomeric concrete joint headers are delaminating and are heaving upward in several locations,

particularly at the west half of the north sidewalk. The joint headers and joint seals project up to 2 1/4"

higher than the adjacent sidewalk surface where the headers have heaved (see photo 30).

ARPLO_a_~b.!ts_a-,,-ARR.r:._R.aVeme_I1Lc_ondltloo

There are 3/16" wide longitudinal cracks with some surrounding break-up of the east approach bituminous

concrete pavement. There are 1/4" wide longitudinal and transverse cracks with surrounding break-up,

rutting and settlement of the eastbound west approach pavement.

ARRroa_c_he_s-'>-"...ARRr.

Roadway~S_eJ.tJ.!tment

There is 2" deep settlement in the west approach for the eastbound roadway along the west abutment deck

joint. See "Approaches a" for additional comments.

ARPLoa_clHtS_c-"...ARPL._SJde'KalIL5e_tlLerneo.t

The previously reported puddling at the northeast, southeast and southwest sidewalk approaches was not

observed during the current inspection and appears to have been rectified. No significant settlement of the

approach sidewalks was observed.

Ltftrn~5_a.·L:_SJting~m;

Median Stringers: There is extensive water infiltration from the median curb line above the median stringers.

This water infiltration is causing severe rusting and section loss to the north median stringer. There is up to

3/16" web loss to the north median stringer ends and up to 5/16" flange loss to the north median stringer at

midspan (see photo 31 and sketch 4). The south face of the north median stringer is encased in concrete.

The south median stringer has been replaced in all spans throughout the length of the bridge (see photo

32). The south median stringers are in good condition however gaps were noted between the top flange of

the replacement stringers and the original concrete surface due to apparent lack of complete grouting. The

REM.(2)7-96

PAGE

CITyrrOWN

B.I.N.

BR. DEPT. NO.

8.-STRUCTURE NO.

BOSTON

4EX

B-16-367

B16367 -4EX-DOT -NBI

9

OF

70

INSPECTION DATE

JAN 29, 2010

REMARKS

It~J),L5_9. L::JitrJIJ-9I~I.S~(.c_onl'dL

shielding in span 18 under the median stringers noted in the previous inspection report has been removed.

See Item 59.14 for additional comments.

Sidewalk Stringers: There is extensive water infiltration from the sidewalk curb line above the sidewalk

stringers. This water infiltration is causing severe deterioration and rusting to the sidewalk stringers. See

sketches 3 & 4 and photo 33 for the most severe sidewalk stringer conditions and locations. See Items

59.13 and 59.14 for additional comments.

IJ~JIL5_9A_::_mId_e.r.s_QLB_e.am.li

Beams: The beams under the median (beams 7 and 8) and under the sidewalk curb lines (beams 2 and 13)

are heavily rusted at the ends with deterioration of the web varying from minor to moderate due to water

infiltration from the curb lines (see photos 34 & 35). Beams 2,7, 8 and 13 typically exhibit approximately

1/8" average section loss to the web at the bearings. The beams under the median (beams 7 and 8)

typically have rust de-lamination with minor to moderate section loss to the top surface of the flanges and

lower web, on the side of the beam facing the median joint, throughout the midspan region (see photo 36).

Beams 7 & 8 typically exhibit approximately 1/8" loss to the top flange and 1/4" loss to the bottom flange on

the joint side of the flanges. The opposite side of these beams, away from the median joint, typically

exhibits no appreciable section loss. Beams 2 and 13 also exhibit areas of flaky rust and minor section loss

to the flanges in the midspan region (see photo 37 & 38). These beams typically exhibit approximately 1/8"

loss to the top surface of the top flange and 1/16" section loss to the top surface of the bottom flange. See

sketches 5, 6 and 7 for field measurements of beams exhibiting the most severe section loss. See Item

59.14 for additional comments.

Fascia Girders: There is moderate rusting to the fascia girders, particularly along the bottom flange. There

are numerous local bends and dings in the bottom flanges of the fascia girders. Most of these result in 3/8"

downward bends over a length of about 6" (see photo 39); the worst case was noted to the north girder in

span 5 where the flange is bent 3" downward over a 30" length on the exterior face at the 1/3 point from

east. The local bends in cover plates are most prominent in the spans over the court house parking lot and

in span 19. The top surface of the bottom flange cover plate typically exhibits areas of rust de-lamination

with approximately 1/16" section loss where it is exposed, from the edge of the flange angle to the exterior

edge of the cover plate (see photo 40). The bottom flange cover plates are connected to the flange angles

with intermittent fillet welds. Some localized pitting (4" long by 3/4" wide by 1/8" deep) often occurs on the

top surface of the cover plate, in the region between fillet welds along the interior side of the bottom flange.

The north and south fascia girders have numerous bends, dents and gouges in the bottom flange from

vehicle impact damage in span 3, over the turnaround roadway. Both fascia girders have been recently

wrapped with fabric wrapping over the turnaround roadway which prevents hands-on access in this region.

The impact damage has been noted in previous inspections and there was no sign of recent impact

damage. The turnaround roadway is posted for 9'-10" vertical clearance; a minimum vertical clearance of 9'11" was measured beneath the north girder at the east curb line.

ltem_5.9 J - C_QlJn.£Jj~s_,_Qu.s_s.eJ~L&"'AngJ~J:;

There is heavy rusting to the connection angles below the leaking deck joints and the curb lines for the

median and the sidewalks.

J

ltem_5.9...!I-=-C_O_'l.e.I:J~J.ate.li

There are areas of moderate to heavy rusting to the cover plates on beams below the curb lines for the

median (beams 7 and 8) and the sidewalks (beams 2 and 13). There are numerous locations of 3/8" deep

by 6" long local bends in the cover plates for the fascia girders. See Items 59.4 and 59.12 for additional

comments.

REM.(2)7·95

PAGE

CITYITOWN

B.I.N.

BR. DEPT. NO.

S.-STRUCTURE NO.

BOSTON

4EX

B-16-367

B16367 -4EX-DOT -NBI

10

OF

70

INSPECTION DATE

JAN 29, 2010

REMARKS

It~!lL5_9~_9--"Jle_ariJlg_D_evi!:jts

Numerous rocker bearings exhibit impacted rust between the curved surface of the rocker and the masonry

plate (see photo 41). The impacted rust appears to be jacking the bearings upward with noted gaps of 3/8"

to 1/2" occurring very commonly with a maximum gap of 3/4" between the rocker and the masonry plate and

exposing the pintels (see photo 42).

The rocker bearings are not centered beneath the rolled beams in several locations with up to 1 1/2" of

lateral misalignment noted (see photo 43). At some locations where lateral misalignment of the bearings

occurs, the 1/4" thick keeper plates in place along the sides of the upper sole plate (to trap top surface of

rocker) were noted to have cracked welds or had fallen off and were missing (see photo 44).

At several locations the rocker bearings were noted to be overly extended to the west, particularly at piers

C, E, Land N (see photo 44). Based upon temperatures in the low 30's (fahrenheit) at time of inspection

the rocker bearings would be expected to be retracted in the opposite direction at these piers.

There is heavy rusting to the bearings and some section loss to the anchor bolts below the leaking deck

joints, particularly beneath the curb lines. One of the anchor bolt nuts for the beam 8 bearing in span 20, at

pier U, is backed off and the north anchor bolt for the beam 5 bearing at the east abutment is missing a nut.

See Item 59.14 for additional comments.

The bearings for beams 8 through 10 at pier Q in span 15 have serious undermining due to spalling of the

supporting concrete pedestals. See Item 60.2.a for additional comments.

IteJIUi9~.:LO--,,-Djapbn~gm~

The interior diaphragms exhibit surface rusting but are in satisfactory condition overall. The end

diaphragms are not encased in concrete and are in poor to serious condition with heavy rusting and section

loss due to leaking deck jOints. There are numerous locations of severe deterioration to the end

diaphragms including large rust holes in the webs which reduce the effectiveness of the diaphragms (see

photos 45 & 46).

The diaphragms are cantilevered off of beams 7 and 8 to support the median stringers. The majority of the

cantilevered diaphragms which support the north median stringers are in poor to serious condition due to

water infiltration from the median curb line. There is advanced deterioration at these diaphragms including

rust holes in the webs and major section loss to the flanges; the rust holes in the web typically occur in the

lower web near the ends of the cantilevers and occasionally in the upper web along the stringer connection

angle (see photo 47). The flanges of the cantilevered diaphragms are typically reduced to a thickness of

approximately 1/8" with knife edge flanges and some scattered rust holes noted. The worst case was noted

at the 3rd diaphragm bracket from east, in span 12, where the bottom flange is completely missing and the

diaphragm is completely ineffective due to rust holes in the web surrounding the sidewalk stringer

connection angle (see photo 48). The cantilevered diaphragms which support the south median stringers

have been replaced throughout the length of the bridge and are in good condition (see photo 32).

It~IJUi!!'j_:L=-Riy_eJs_a,-B_oJts

There is heavy rusting and up to 50% section loss to the rivets at connection angles and plates below the

leaking deck joints and in areas of similar leakage beneath the curb lines at the median and sidewalks.

lt~m_5_!!...:1.2-,,-v.v_eld_s

The bottom cover plates for the rolled beams and fascia girders are connected with intermittent welds; there

are areas of moderate rusting to the welds near the curb lines. The end diaphragm channels are connected

to the connection angles with partial length welds. In span 19, at pier U, there are broken welds at the end

diaphragm connections to beams 7, 13 and 14, apparently due to pack rust (see photo 49).

REM.{2)7-96

PAGE

CITyrrOWN

B.I.N.

BR. DEPT. NO.

S.-STRUCTURE NO.

BOSTON

4EX

B-16-367

B16367 -4EX-OOT-NBI

11

OF

70

INSPECTION DATE

JAN 29, 2010

REMARKS

lt~t!LS.9.,.t3-,,-M_em_b_en'),Ug.!1IJJJtlJJ

There is a 1 1/2" lateral misalignment between the ends of spans 19 and 20 along the south parapet at pier

U (see photo 17). The granite curbs at the sidewalk at this location are offset a similar amount.

It.!!J1L5.9...:I.4-''...E'.aloJIJ::_Qa.tlag

The paint system is generally in fair condition throughout the interior portions of the spans but is in poor

condition in areas beneath the deck joints and near the curb lines. The beam ends and bearings at the

median (beams 7 and 8) and the sidewalks (beams 2 and 13) exhibit severe paint loss. The sidewalk

strtngers and the north median stringer also exhibit severe paint deterioration with minimal paint remaining

in many of these areas. There is moderate paint loss to the fascia girders.

S_up_eLS.tnlcJJKe_G..oJ.UsLQ!l.lLoJ.!!A

The north and south fascia girders have moderate collision damage to the bottom flange between piers B

and C across from the court house at the Arborway turnaround.

It.!!m_6_0.1 - AbJJtme.llts

It.!!m 60.1.b - Brid.Q~LS...!!ats

There is typically up to 5" deep debris accumulation on the west abutment bridge seat. There is a vertical

jog at the ends of the seats due to the increased depth of the fascia girders. There is up to 16" of pigeon

debris accumulating between the north fascia girder and the jog in the west abutment seat which completely

covers the bearing and lower portion of the girder web at this location. There is an 11" diameter by 3" deep

spall on the west abutment bridge seat adjacent to the south side of the beam 6 beartng. See item 60.1.d

for additional information.

U.!!.m_6Jl....~.c--=-a.aJ~kllol.aJJA

There are a few 1/16" wide vertical cracks in both backwalls. The vertical cracks in the backwalls typically

align with vertical cracks in the breastwalls. There is a 3' long by 18" high by 3" deep spall in the north end

of the east abutment backwall. There is a 5" wide by full height by 1 1/2" deep spall with some exposed

reinforcing steel in the west abutment backwall between the south girder and beam 1.

It~m3Jl.1.d-"'-BrEta.sJl"!Lalls

There are a few 1/16" wide vertical cracks with rust staining in both breastwalls, typically at weephole

locations. Between beams 9 and 10, at the west abutment, there is a full height vertical crack which is 1/16"

wide at the base and increases to 1/8" wide at the bridge seat. There is 3/8" of lateral differential movement

at the top of this crack with the seat to the south side of the crack showing outward movement relative to

the north side (see photo 50).

There is extensive debris accumulation adjacent to the east abutment breastwall due to use of space

beneath span 1 by homeless people (see photo 51).

JJ~m_6.o~j...!!___1Illi.ogw.aIJ5

The wingwalls are faced with brick for the majority of the wall height with the brick supported on granite

headers atop a concrete base at ground level. Two sections of granite headers (23" and 3'-4" long

sections) are missing at the base of the northwest wingwall, located approximately 100 feet from the

breastwall corner (see photo 52). The concrete base for the wingwalls has numerous hairline horizontal

and vertical cracks with efflorescence and minor to moderate spalls. There is a 9' long by 5" to 2'-6" high by

3" deep spall with exposed reinforcing steel in the concrete base of the east end of the southwest wingwall.

There is also a 7' long by 5" high by 1 1/2" deep spall in the concrete base of the southwest wingwall

REM,(2)M6

PAGE

CITyrrOWN

B.I.N.

BR. DEPT. NO.

S.-STRUCTURE NO.

BOSTON

4EX

B-16-367

B16367 -4EX-DOT -NBI

12

OF

70

INSPECTION DATE

JAN 29, 2010

REMARKS

IijlJ)1_6~0~jJjl___Wingl!\LallJL(.c~ont'dL

located approximately 50' from the breastwall corner. There is a 3' long by 2' high by 3" deep spall near the

concrete base of the northwest wingwall where it meets the west abutment breastwall (see photo 53).

There is a 1/4" wide separation between the brick facing of the northwest wingwall and concrete of the west

abutment breastwall at the interface of the wingwall and breastwall, where the brick appears to have heaved

slightly outward. There is also a 1/8" wide by 12' long horizontal crack in the mortar joint of the upper brick

course of the northwest wing wall , just beneath the granite cap stone, at the east end where it meets the

bridge rail. The mortar between the granite headers and the concrete base is typically deteriorated and

spalled.

Iijlmj;_OJ1.g~ojntlng

The mortar joints for the brick facing are generally in satisfactory condition with evidence of repointing

throughout. There are scattered areas of minor mortar deterioration in the brick fascia of the wing walls,

particularly in the upper courses beneath the granite cap stones.

li~m_6_0~2---PieJ:JLQL~nJs

.IJEl.!!L6_0J.2.._a~e_cLe_sjals

There are raised, variable height, concrete pedestal walls atop the main section of the pier caps which

support the bearings for the rolled beams. These pedestal walls appear to be non-reinforced, and in many

cases there is little or no edge distance between the masonry plate and the face of the pedestal walls.

Water and debris is collected between the pedestal walls at several piers due to the leaking deck joints.

The retained water was most severe at piers E, J and N with a maximum water depth of up to 4" noted at

pier E (see photo 54).

At numerous locations, wide longitudinal cracks/splits (typically 1/4" to 3/8" wide) were observed along the

top surface in these pedestal walls. These cracks extend beneath the bearing devices (and often extend

behind the anchor bolts near the rear of the masonry plates) and jeopardize the bearing capacity of the

beams where this occurs. The raised concrete pedestals for piers K, Q and S are in serious condition due

to the formation of the above mentioned longitudinal cracks/splits in the pedestal walls. See sketches 1 &

2 for locations of piers where these conditions exist and sketches 8 through 10 for plan view of the

pedestals indicating the widths and locations of these cracks.

During this inspection a critical deficiency was discovered at the bearing for beam 8, in span 15, at pier Q.

At this location the concrete pedestal exhibited a wide split extending behind the bearing anchor bolts with

the concrete at the front face of the pedestal heaving outward resulting in serious undermining and minimal

effective bearing remaining (see photos 55 & 56). The large section of delaminated pedestal concrete was

situated close to the edge of the pier cap and in danger of potentially falling onto the brick plaza for the

Forest Hills Station where there is heavy pedestrian activity due to the adjacent bus stops. 3/8" wide

cracks/splits were also observed along the top surface of the pedestal extending the entire length from

beam 8 to beam 13 (see sketch 9 and photos 57 through 59). The concrete at the front face of the

pedestals for adjacent beams 9 and 10 exhibited a distinct hollow tone when tapped indicating that this

concrete was likely not load bearing. At beams 11 through 13 the face of the concrete directly beneath the

bearings was not hollow sounding, however the region between the masonry plates was hollow sounding

when tapped. MassDOT was immediately notified of the serious undermining of concrete beneath beams 8

to 10 and the left lane for the westbound roadway was closed to traffic and the loose section of concrete

pedestal was removed at beam 8. Additionally, timber blocking was installed beneath the ends of the

beams, adjacent to all pedestals exhibiting the wide cracks/splits. This timber blocking is intended to

remain until the necessary concrete repairs are performed.

REM.(2)1-96

PAGE

CITyrrOWN

B.I.N.

BR. DEPT. NO.

S.-STRUCTURE NO.

BOSTON

4EX

B-16-367

B16367 -4EX-DOT-NBI

13

OF

70

INSPECTION DATE

JAN 29, 2010

REMARKS

Lt.e~6Jl._2--,,-E'ijlJ~LQLE!.el1tl>

!tjlm 6_0.2.~a - Pedes_tals_(C_QIJ.t'-dl

Similar but less severe cracks were noted on the top surface and front face of pedestals at beams 2 through

7, in span 16, at pier Q. The cracks were typically 3/16" wide and broke out on the front face of the

pedestals approximately 18" each side of the centerline of bearing (see sketch 9 and photos 60 & 61).

The face of the concrete pedestal typically emitted a hollow tone when tapped within the limits of the cracks.

Major longitudinal cracks/splits also exist along the pedestals for support of the span 18 beams extending

nearly the entire length of the pedestal at pier S, from beam 2 through 13. The cracks are typically 1/4" to

3/8" wide on the top surface and most often extend to the anchor bolts at the center of the masonry plate, or

just behind the anchor bolts, but were noted to extend to the back edge of the masonry plates for beams 4

and 11 (see sketch 8 and photos 62 through 66). In between the bearing locations the crack migrates to

within about 2" to 3" of the face of the pedestal but does break out on the front face. In general the face of

the concrete pedestals between the bearings emitted a hollow tone when tapped but the section directly

below the bearings emitted a relatively solid tone (apparently due to the thickness of the delaminations and

the load from the bearings). Several local spa lis occur along the upper portion of the pedestal wall for

support of the span 17 bearings along the east side of pier S. These spalls are typically about 2 feet long

by 8" to 12" high and extend to the front edge of the masonry plate but do not undermine the bearings (see

photo 67).

At pier K there are major cracks/splits (1/2" wide to 1" wide) extending beneath three of the bearings. On

the east (span 10) side of the concrete cap these cracks/splits in the pedestal occur at beams 7 and 8. A

1/2" wide crack was noted along the top surface of the concrete pedestal to the south side of the beam 7

bearing and propagated towards the rear end of the masonry plate (see photo 68). The concrete on the

front face of the pedestal exhibited a hollow tone and fell off with a light hammer tap. Upon removal of the

delaminated section of concrete, the shear plane could be observed extending beneath the bearing of beam

7 and a metal ruler could be readily probed into the shear plane to the full 6" limit of the ruler (see photo

69). The front face of the pedestal exhibits an 8" wide by 5 1/2" deep by 14" high (full height) spall beneath

the north edge of the masonry plate for beam 7 which exposes the north anchor bolt which appears to be

debonded with a slight void surrounding it. At beam 8 (span 10) there is a major 1" wide split in the top

surface of the concrete pedestal along the north side of the bearing, which extends completely through the

12" width of the pedestal and is visible as a 1/4" wide vertical crack on the back surface (see photo 70).

On the west (span 11) side of pier K there are 5/8" wide splits extending about 2' each side of the bearing

for beam 11. These cracks breakout along the rear face of the pedestal and the section of concrete

beneath the bearing has shifted approximated 3/4" to the east (see photo 71). The front face of the

concrete pedestal at beam 11 generally appears in satisfactory condition, with some occasional hairline

vertical cracks and with no signs of distress. A 7/8" gap is visible between the front edge of the masonry

plate for beam 11 and mortar that was originally placed against the masonry plate. This gap corresponds to

the lateral movement noted to the back face of the pedestal (see photo 72). This condition was only

observed at beam 11 and no other sections of concrete pedestal along the west side of pier K exhibited this

pattern of deteri oration.

The concrete pedestals at the remaining piers typically exhibit numerous hairline to 3/16" vertical cracks and

local spalls along the top edge of the pedestals in scattered locations.

REM.(2)7.96

PAGE

CITyrrOWN

B.I.N.

BR. DEPT. NO.

8.-STRUCTURE NO.

BOSTON

4EX

B-16-367

B16367 -4EX-DOT -NBI

14

OF

70

INSPECTION DATE

JAN 29, 2010

REMARKS

IJ~JJL6_Q.2,J;L:_G.ap-s

There is evidence of recent concrete repairs at most of the piers. There are some areas of up to 3/8" wide

horizontal cracks with surrounding delamination and rust staining in the pier caps of piers M, N, P, Q and R,

particularty near the bottom corners of the caps (see photo 73). There are also scattered areas of

delaminated and spalled concrete in the faces of the caps. The following are notable locations of pier cap

deficiencies:

Pier M: There is a 6'-0" long by 15" high by 4" deep corner spall at the seat with exposed reinforcing steel

and rust staining, west face, below beam 12 (see photo 74). There is also a 4' high x 5' wide hollow

sounding section which is beginning to spall, west face, between beams 12 & 13 at the seat.

Pier N: There is a 4'-0" long by 12" high by 3" deep top corner spall with exposed reinforcing steel and rust

staining, west face, below beam 7. There is 12" long by 12" wide by 18" high spall with rust staining in the

northeast corner of the cap atthe seat.

Pier P: There is a 4'-6" long by 6'-0" high delamination, west face, below beam 5 and a 10" long by 5'-0"

high delamination, east face, at the south end.

Pier Q: There is a 4'-0" long by 12" high by 3 1/2" deep corner spall with exposed reinforcing steel and rust

staining in the west face at the bottom of the cap near midspan.

Pier R: There is a 4'-0" long by 12" high by 3 1/2" deep spall with exposed reinforcing steel and rust

staining, west face, at the north end.

The leaking deck joints allow for considerable water infiltration onto the pier caps below. See Item 60.2.j for

hammerhead pier cap comments.

.c - CQlumn.s

tt~!JL6_Q.2 .

There are some scattered areas of surface delamination (up to 5' high by 3' wide) with some efflorescence

and rust staining in the columns. See Item 60.2.j for hammerhead stem comments.

tt~IJL6_Q,2.JL:_eLeJw.al.ls

There are some hairline to 1/16" wide vertical cracks with surrounding delamination on pierwalls A and B.

There is a 5'-0" long by 2'-10" high area of delamination with a 20" long by 4" high by 1 1/2" deep spall on

the east face of pierwall B at the south end (see photo 75). There is a 7/16" wide crack on the top surface

of the pierwall at this location.

There is extensive debris accumulation adjacent to the east face of pier A due to the use of the area

beneath span 1 by homeless people.

IJ~IJL6_Q.2.j - Hitmme.r.bl'tad..Pie.L!;

All of the hammerhead piers have had post tensioning repairs made to them (1990 repairs) due to structural

shear cracks. These cracks started at the top center of the pier and traveled down diagonally to the base of

the cantilevered arms. The post tensioning repairs generally appear to be secure and in satisfactory

condition. Galvanized steel plates form a protective cabinet enclosure which completely encloses the post

tensioning ducts and anchorages; therefore, these elements were not able to be visually inspected.

There are scattered areas of delaminated concrete on the stem, cap and cantilevers of the hammerhead

piers. The following are notable locations of hammerhead pier deficiencies:

REM.(2J7-96

PAGE

CITYffOWN

B.I.N.

BR. DEPT. NO.

S.-STRUCTURE NO.

BOSTON

4EX

B-16-367

B16367 -4EX-DOT -NBI

15

OF

70

INSPECTION DATE

JAN 29, 2010

REMARKS

Pier C: There is evidence of previous fire damage on the east face (surface charring & soot) due to

homeless people that were living along the base of the pier.

Pier D: Some delaminated concrete was noted along the north and south cantilevers, west face, just below

the post tensioning cabinet (see sketch 9 and photo 76).

Pier G: There is a 12" diameter by 2 1/2" deep spall in the cap on the west face and a 3' long by 12" wide by

3" deep spall with scaling on the top of the pier below the median.

Pier J: There is a 5" wide by 14" high by 1 1/2" deep spall with surrounding 4" wide by 19" high delamination

on the west face of the cap. There is a 41/2" wide by 41/2" high by 1 112" deep spall with surrounding 3"

wide by 16" high delamination in the stem, west face, at the south cantilever. There is a 2' wide by 10" high

delamination in the stem on the north face and a full width by 12" high delamination in the stem on the south

face.

Pier K: There is a 2'-6" wide by 3'-6" high delamination and a full width by 3'-6" high delamination in the

stem on the north face.

Pier L: See sketch 11.

Pier S: There is an 11' long by 4'-6" high delamination in the stem on the east face and a 10' long by 5' high

delamination in the stem on the west face. There is a 4' wide by 4' high delamination in the stem on the

north face.

Pier T: There is a 14" long by 18" high by 1 1/2" deep spall with exposed reinforcing steel and a 3'-9" long

by 16" high delamination in the north cantilever on the west face. There is a 10' long by 5' high

delamination in the stem on the west face and a 2'-6" long by 5'-6" high delamination and 8' long by 4' high

delamination in the stem on the east face. There is an 18" long by 18" high by 3" deep spall with exposed

reinforcing steel in the stem on the north face.

Pier U: There is a 2' long by 6' high delamination in the stem on the east face.

The leaking deck jOints allow for considerable water infiltration onto the pier caps below with water

becoming trapped and ponding on the caps between the raised concrete pedestals in several locations. A

number of the deficiencies noted in the last inspection (July 2009) have been repaired.

tteJJ:L6_Q.2.J5-,,-~a nmeveL/,tEtarn_BJ]u:J5eJs

There are heavy rolled steel cantilevered beam brackets (14WF246 or 14WF287) which extend beyond the

pier caps to support the fascia girders (see photo 77). Most of these cantilevered beams are surrounded

by a heavy build-up of sand and debris which covers the bottom flange and lower web, particularly where

raised concrete pedestal walls are in place. There is typically up to 1/4" loss to the lower 6" of the web and

up to 1/4" loss to the flanges.

The cantilevered beam brackets are held down by a group of six anchor bolts (1 1/2" diameter) at the

interior end (see photo 78). There is typically heavy rust delamination to the lower 6" of the anchor bolts

and the web stiffeners associated with the hold-down point of the beams. The debris was cleared from the

base of numerous anchor bolts and rust delamination chipped away (where accessible to swing of hammer)

and the anchor bolts were typically noted to be necking down within the lower region. The majority of the

anchor bolts have a remaining diameter between 1 1/32" to 1 3/16" with the minimum remaining anchor bolt

REM.(2)7-96

PAGE

CITYITOWN

BOSTON

B.I.N.

BR. DEPT. NO.

8.-STRUCTURE NO.

4EX

B-16-367

B16367 -4EX-DOT -N BI

16

OF

70

INSPECTION DATE

JAN 29, 2010

REMARKS

Lte_m_6_Q.2.JL,,-.kantiJ~jLeLB_ean:U:~ra_~~ejlL(kQ!Jj~dl

diameter of 7/8" noted to a hold down bolt for span 14 at pier P (see photo 79). The lower 6" of the web

stiffeners adjacent to the hold-down anchor bolts are typically reduced to a remaining thickness of 7/16" vs.

3/4" original thickness.

Lt~JlL2_6jt.::_BJ:idgfLRaiJjl19

The traffic rail along the outer edges of the roadway consists of a single rail pipe rail on a reinforced

concrete wheel guard base which is generally in good condition but does not meet current standards. The

concrete base section has random minor vertical cracking. The previously reported collision damage in span

4 has been repaired.

The traffic rail at the inside edge of the roadway consist of a raised concrete median which is generally in

satisfactory condition but does not meet current standards. Refer to Item 58.5 for additional comments

1!~11L3J~b-=-"D:.am;ltl(ms

The traffic rail and raised concrete median in place on the bridge extend continuously onto the approach

roadways.

1!~!JJ-.3Jtc - ApPLoach G_QaLdrail

The traffic rail and raised concrete median in place on the bridge continue onto the approach roadways. As

noted under Item 36a above, these systems do not meet current standards. At the fourth traffic rail post

from the east abutment, south rail, 3 out of the 4 anchor bolts nuts are backed off over 1" from the base

plate (see photo 80).

Ue!JL3_6_d - App~oji_cJLG_I.ta~dxalLE_!J_dl!

Impact attenuators are in place at each approach to the leading ends of the approach traffic rails. The

impact attenuators are generally in satisfactory condition. The heavy collision damage previously reported

to the attenuator of the east approach has been repaired since the last inspection.

S~~_t!:hLel,-oJ(Ll.p-9

Sketch 1:

Sketch 2:

Sketch 3:

Sketch 4:

Sketch 5:

Sketch 6:

Sketch 7:

Sketch 8:

Sketch 9:

Sketch 10:

Sketch 11:

Photo 1 :

Photo 2:

Photo 3:

Photo 4 :

REM.(2)7.95

Framing Plan (1 of 2)

Framing Plan (2 of 2)

Stringer Condition Details (1 of 2)

Stringer Condition Details (2 of 2)

Beam Condition Details (1 of 3)

Beam Condition Details (2 of 3)

Beam Condition Details (3 of 3)

Pier K Part Plan View - Beam Pedestal Conditions

Pier Q Plan View - Beam Pedestal Conditions

Pier S Plan View - Beam Pedestal Conditions

Piers D and L Conditions

Numerous transverse cracks in concrete wearing surface, spans 8 & 9, eastbound roadway at

pier H.

Pier Q Deck Joint, EB Roadway, Looking South- Deck joint is approx. 1 1/2" lower than

adjacent deck causing uneven surface.

1 1/4" wide gap between median granite curb and wearing surface filled with heaved concrete

and/or sand, span 2, eastbound roadway.

1 1/4" wide x 4' long open gap between median granite curb and concrete wearing surface,

span 14, eastbound roadway.

PAGE

CITyrrOWN

B.I.N.

SR. DEPT. NO.

S.-STRUCTURE NO.

BOSTON

4EX

B-16-367

B16367 -4EX-DOT -NBI

17

OF

70

INSPECTION DATE

JAN 29, 2010

REMARKS

Photo 5:

Photo 6:

Photo 7:

Photo 8:

Photo 9:

Photo 10:

Photo 11 :

Photo 12:

Photo 13:

Photo 14:

Photo 15:

Photo 16:

Photo 17:

Photo 18:

Photo

Photo

Photo

Photo

19:

20:

21 :

22:

Photo 23:

Photo 24:

Photo 25:

Photo 26:

Photo 27:

Photo 28:

Photo 29:

Photo 30:

Photo 31 :

Photo 32:

Photo 33:

Photo 34:

REM.(2)7-96

18" diameter x 3" deep spall with exposed wire mesh reinforcement adjacent to north curb,

span 12, westbound roadway.

6 1/2" wide x 6'-8" long full depth spall adj. to median granite curb, span 20, eastbound

roadway.

Typical condition of steel grating away from deck joints and curb lines wi surface rust to grating

and paint remaining on SIP forms.

Underside of filled steel grating, span 11, between beams 10 & 11 near pier L with 100% loss

to SIP forms and some salt efflorescence.

Upward bow in filled steel grating at west end of span 12 with up to 1 3/4" gap between

underside of deck and beam 3.

Scattered loose fragments of concrete noted along top flange of exterior girders (south girder,

span 5, shown above).

9/16" gap between concrete deck and top flange of south exterior girder, span 11, at pier L.

Delaminated concrete along north fascia, span 9, near pier J

Section of granite curb on west approach, westbound roadway, is shifted 1" into roadway at

west abutment.

9' long x 2" deep spalling along east approach median, at east abutment.

Water ponding on north sidewalk over a 15' length in span 14 at pier N.

South elevation at span 3 (turnaround roadway). Note recent fabric wrapping of bridge fascia

over roadway areas.

1 1/2" horizontal misalignment of south parapet at pier U expansion joint.

General view of north sidewalk looking west from pier E. Note tree branches extending

through railing at this location.

Plugged scupper, eastbound roadway, adjacent to median curb, span 2, near pier A.

Active leakage from drainpipe along the west face of pier C.

Disconnected drainpipe hanger below median, span 10, at pier J.

1/32" to 3/16" vertical cracks in lower 3' of median light standard, span 1, with exposed

reinforcement from cracks, delamination.

Northeast anchor bolt missing at base plate for median light standard, span 10.

Light fixture attached to beam 8, in span 7, with fixture loose due to broken clip replaced with

tie wire.

1" diameter lighting conduit is sagging down 12", east half of span 9, due to 10 consecutive

broken clips to beam 8.

Open electrical junction box at base of pier C with exposed wires.

Expansion Joint at Pier U, Westbound Roadway- Typical sand covering joint seal wi section of

joint seal missing.

Expansion Joint at Pier P, Westbound Roadway- Vertical section of joint seal is torn &

displaced along median curb.

Expansion Joint at Pier L, Eastbound Roadway- Crack in joint armor in the left lane and joint

armor rotated inward to south of crack.

North Sidewalk Expansion Joint at Pier T- Elastomeric concrete headers heaved up to 2 1/4"

above sidewalk surface.

North Median Stringer, Span 10, near Pier K- Heavy rust delamination and section loss.

General underside view at median, looking east in span 19. Note typical replacement of south

median stringers & support brackets.

South Sidewalk Stringer, Span 7, at Pier F- Heavy section loss to web with 2 1/2" diameter rust

hole in upper web.

Beam 2, Span 6, at Pier E- Rust delamination with minor section loss to web over the bearing

area.

PAGE

CITYffOWN

B.I.N.

BR. DEPT. NO.

8.-STRUCTURE NO.

BOSTON

4EX

B-16-367

B16367 -4EX-OOT -NBI

18

OF

70

INSPECTION DATE

JAN 29, 2010

REMARKS

Photo 35 :

Photo 36:

Photo 37 :

Photo 38:

Photo 39 :

Photo 40 :

Photo 41:

Photo 42:

Photo 43:

Photo 44 :

Photo 45:

Photo 46 :

Photo 47:

Photo 48:

Photo 49 :

Photo 50 :

Photo 51:

Photo 52:

Photo 53:

Photo 54 :

Photo 55 :

Photo 56:

Photo 57:

Photo 58:

Photo 59:

Photo 60 :

Photo 61:

Photo 62 :

REM.(2)7·S6

Beam 2, Span 8, at Pier G- Salt staining and minor section loss to web over the bearing area.

Beam 7, Span 16, near Midspan- Heavy rust delamination to lower web and north half of

bottom flange (side facing median joint).

Beam 2, Span 5, Midspan Region- Close-up view of section loss to top flange.

Beam 13, Span 11, @ Cov. PI. Cut-off - Hvy rusting and minor section loss to inside surface of

flanges due to deck leakage near curbline.

South Exterior Girder, Span 5- Several local bends (typically 3/8" bend over 5" to 6" length)

along inside edge of bottom flange.

South Exterior Girder, Span 5- Typical rust delamination on top surface of bottom cover plate

with minor section loss.

Beam 6 Rocker Bearing, Span 17, at Pier R- Rust packing between curved rocker and

masonry plate and lifting bearing.

Beam 4 Bearing, Span 13, at Pier M- Up to 3/8" uplift of bearing evident at north side. Pack

rust surrou nds south pintle.

Beam 5 Bearing, Span 16, at Pier R- Upper section of bearing assembly is laterally misaligned

1 1/4" with lower section.

Beam 7 Bearing, Span 11, at Pier L- Rocker bearing exhibits excessive tilt to the west (mov't

expected in opp. dir. @ 28 deg rees).

End Diaphragms, between Beams 1 & 2, at Pier D- Complete loss of section to lower 5" of web

for full length of diaphragms.

End Diaphragm Bracket at Beam 8, Span 2, at Pier B- Ineffective due to major web loss;

member vibrates when struck with hammer.

Diaphragm Bracket for North Median Stringer, Span 10, 4th from East- Rust holes in upper &

lower web.

Diaphragm Bracket for N. Median Stringer, Span 12, 3rd Bracket from East- Bracket ineffect.

wlcomplete loss of bot. f1ng. & web holes.