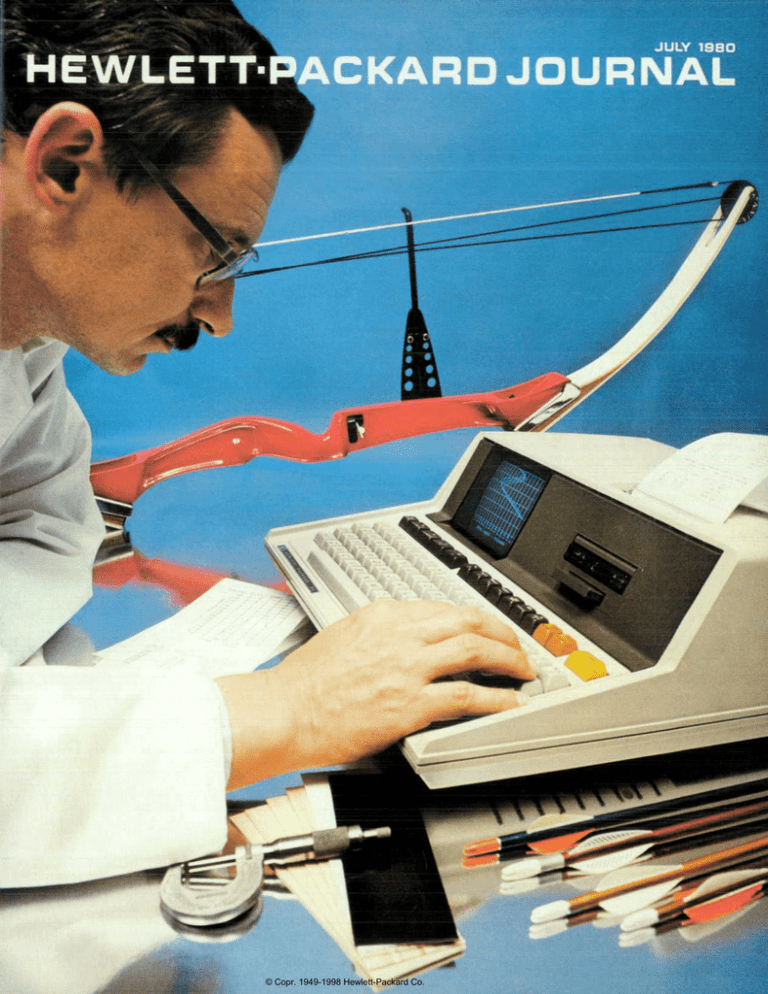

H E W L E T T - P A... J U L Y 1 9 8 0

advertisement