Selection of Vibratory Motors for Vibrating Feeder by Analytical Approach for

advertisement

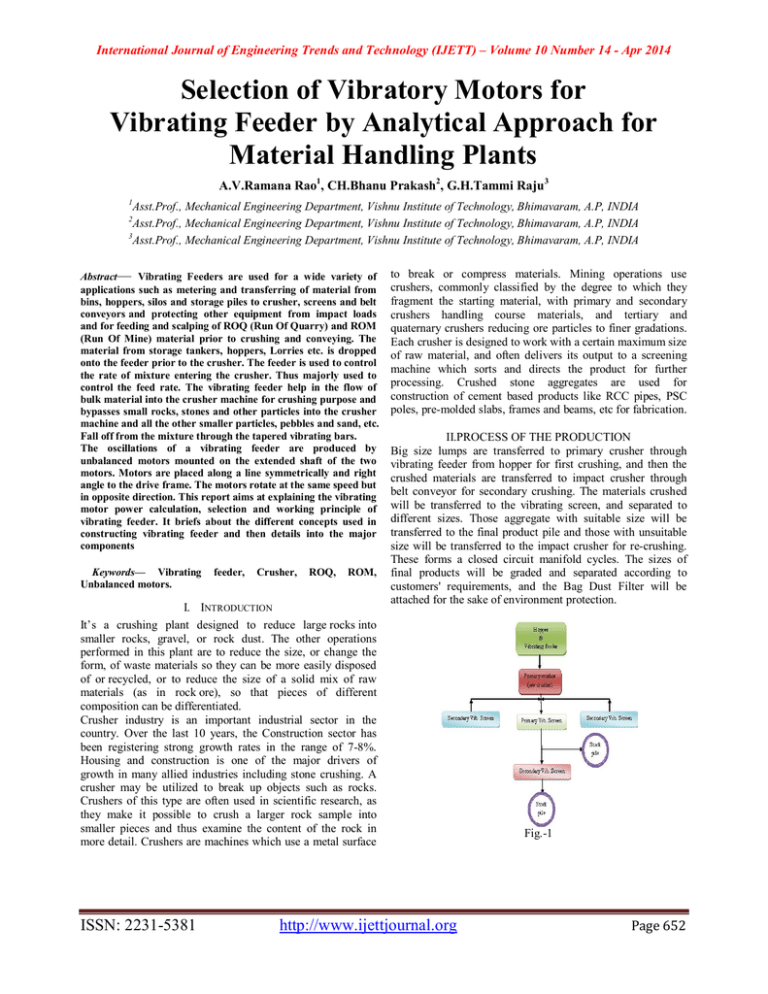

International Journal of Engineering Trends and Technology (IJETT) – Volume 10 Number 14 - Apr 2014 Selection of Vibratory Motors for Vibrating Feeder by Analytical Approach for Material Handling Plants A.V.Ramana Rao1, CH.Bhanu Prakash2, G.H.Tammi Raju3 1 Asst.Prof., Mechanical Engineering Department, Vishnu Institute of Technology, Bhimavaram, A.P, INDIA Asst.Prof., Mechanical Engineering Department, Vishnu Institute of Technology, Bhimavaram, A.P, INDIA 3 Asst.Prof., Mechanical Engineering Department, Vishnu Institute of Technology, Bhimavaram, A.P, INDIA 2 Abstract— Vibrating Feeders are used for a wide variety of applications such as metering and transferring of material from bins, hoppers, silos and storage piles to crusher, screens and belt conveyors and protecting other equipment from impact loads and for feeding and scalping of ROQ (Run Of Quarry) and ROM (Run Of Mine) material prior to crushing and conveying. The material from storage tankers, hoppers, Lorries etc. is dropped onto the feeder prior to the crusher. The feeder is used to control the rate of mixture entering the crusher. Thus majorly used to control the feed rate. The vibrating feeder help in the flow of bulk material into the crusher machine for crushing purpose and bypasses small rocks, stones and other particles into the crusher machine and all the other smaller particles, pebbles and sand, etc. Fall off from the mixture through the tapered vibrating bars. The oscillations of a vibrating feeder are produced by unbalanced motors mounted on the extended shaft of the two motors. Motors are placed along a line symmetrically and right angle to the drive frame. The motors rotate at the same speed but in opposite direction. This report aims at explaining the vibrating motor power calculation, selection and working principle of vibrating feeder. It briefs about the different concepts used in constructing vibrating feeder and then details into the major components Keywords— Vibrating Unbalanced motors. feeder, Crusher, ROQ, ROM, I. INTRODUCTION It’s a crushing plant designed to reduce large rocks into smaller rocks, gravel, or rock dust. The other operations performed in this plant are to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated. Crusher industry is an important industrial sector in the country. Over the last 10 years, the Construction sector has been registering strong growth rates in the range of 7-8%. Housing and construction is one of the major drivers of growth in many allied industries including stone crushing. A crusher may be utilized to break up objects such as rocks. Crushers of this type are often used in scientific research, as they make it possible to crush a larger rock sample into smaller pieces and thus examine the content of the rock in more detail. Crushers are machines which use a metal surface ISSN: 2231-5381 to break or compress materials. Mining operations use crushers, commonly classified by the degree to which they fragment the starting material, with primary and secondary crushers handling course materials, and tertiary and quaternary crushers reducing ore particles to finer gradations. Each crusher is designed to work with a certain maximum size of raw material, and often delivers its output to a screening machine which sorts and directs the product for further processing. Crushed stone aggregates are used for construction of cement based products like RCC pipes, PSC poles, pre-molded slabs, frames and beams, etc for fabrication. II.PROCESS OF THE PRODUCTION Big size lumps are transferred to primary crusher through vibrating feeder from hopper for first crushing, and then the crushed materials are transferred to impact crusher through belt conveyor for secondary crushing. The materials crushed will be transferred to the vibrating screen, and separated to different sizes. Those aggregate with suitable size will be transferred to the final product pile and those with unsuitable size will be transferred to the impact crusher for re-crushing. These forms a closed circuit manifold cycles. The sizes of final products will be graded and separated according to customers' requirements, and the Bag Dust Filter will be attached for the sake of environment protection. http://www.ijettjournal.org Fig.-1 Page 652 International Journal of Engineering Trends and Technology (IJETT) – Volume 10 Number 14 - Apr 2014 Thus from the flow chart of the process flow of the stone crushing, the production line mainly consists of 1. Hopper 2. Vibrating Feeder 3. Conveyor Belt 4. Crushers 5. Vibrating Screens. III.COMPONENTS OF CRUSHING PLANT Hopper: A storage container used in industries and is provided with additional width and depth for temporary storage of raw materials, for dust collection, etc. Vibrating feeder: Vibrating Feeders provide the most efficient and economical method of conveying bulk materials and, most importantly it’s the simplest and easiest means of controlling the rate of flow or feed. Belt conveyor: A belt conveyor (or conveyor belt) consists of two or more pulleys, with a continuous loop of material - the conveyor belt - that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. Vibrating screen: Vibrating screen is a kind of sieving equipment used to separate materials into multiple grades by particle sizes as end product and for further processing. Crusher: Crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated. Types of crushers: 1. Jaw crusher 2. Gyratory crusher 3. Cone crusher 4. Impact crusher 5. Horizontal shaft impact crusher 6. Vertical shaft impact crusher IV.METHODS OF VIBRATION The vibration of a vibrating feeder is produced by unbalanced motors are 3 types: 1. Rotational vibration 2. Elliptical vibration 3. Linear vibration Working principle: The oscillations of a vibrating feeder are produced by unbalanced motors mounted on the extended shaft of the two motors. Motors are placed along a line symmetrically and right angle to the frame. The resultant forces of the two ISSN: 2231-5381 motors are along the line. Hence the line is called as drive line. The motors rotate at the same speed but in opposite direction. At any instant of 360° rotation, there are forces generated individually on the motors along the drive line and right angle to it. The forces at right angle cancel out each other and the resultant force is along the drive line. The two unbalanced motors which are placed along the main body and which drives the feeder is called an unbalance drive. The unbalanced drive is used to: (a) Create linear oscillations to the vibrating feeder, (b) The amplitude of the oscillations can be altered by displacing, adding or removing the additional weights. Fig.-2 V. CAPACITY CALCULATIONS Capacity requirements determine the feeder-pan dimensions and slope. The volumetric capacity of a feeder may be determined by the formula: AxV=Q Q = Cu. Fpm A = Projected horizontal area V = Average velocity of material through opening. The projected horizontal area is a function of the projected horizontal opening and feeder-pan width. The average material velocity will vary with material flow characteristics, coefficient of friction, feeder pan slope, length, and vibration intensity. Material velocities will range from 30 to 60 fpm with pan slopes from 0 to 20 deg. Feeder-pan trough length is determined by material angle of repose and pan slope. The feeder pan must be of sufficient length to assure complete material shutoff when the feeder is at rest. A line drawn from the maximum opening at the material angle of repose should intersect the pan trough, leaving a margin of cutoff length to allow for variations in material characteristics. Feeder Size Selection: Selection capacities shown in the table are guides for selecting the feeder size. Feed rates may vary widely with material characteristics such as density, particle size distribution, moisture content and angle of repose. Maximum feed rates are http://www.ijettjournal.org Page 653 International Journal of Engineering Trends and Technology (IJETT) – Volume 10 Number 14 - Apr 2014 obtained by declining feeder pan consistent with hopper opening and feeder length. Minimum length of feeder may be determined by hopper opening, feeder slope and angle of repose. Select feeder with adequate length to prevent flushing. Hopper opening required to minimize hopper bridging effect may determine width and length of feeder. In some cases, headroom or minimum tunnel depth consideration justify a size selection larger than required for volumetric flow. Fig.-3 VI.PARTS OF VIBRATING FEEDER The parts of vibrating feeder parts can be majorly divided as: (a) Main Body (b) Drive Frame Assembly (c) Vibrating Deck and Bar Assembly (d) Bottom Deck Assembly (e) Wire-mesh Assembly (f) Liners (g) Springs (h) Spring Holder Body: Body is a construction with many plates of different lengths, widths and different structures. The construction is to support different major assemblies of the feeder, for holding the structure. Drive Frame: Drive Frame is constructed with plates and the construction is made to hold the Vibratory motors. Vibratory motors are held onto the frame through bolts and nuts. ISSN: 2231-5381 Deck and Bar Assembly: Vibrating bars are tapered and are positioned in rows on the deck with some specific distance in between them. Underneath the vibrating deck and bar arrangement lays the bottom deck which consists of wire mesh assembly. The vibrating deck bar arrangement, bottom deck assembly are positioned in between the 2 main body plates. Wire - Mesh Assembly: The construction of wire-mesh assembly resembles a long cloth made of wires with holes (meshes) diameter as per the requirement of granular separation. Wire-mesh assembly also consists of components like rubber, bolts, etc. Liners: Liners are rectangular plates of a particular thickness which are shielded onto the body plates of the main body with the help of nuts and bolts. Liners are used to avoid any kind of damage to the vibrating feeder and the body plates due to the fall of bulk material from the hopper. Springs: Springs are used to remove any sudden shocks that are created due to the free fall of the bulk material onto the feeder. Thus the springs are used to reduce the effect of sudden shocks created and hence reducing the damage of the structure onto which the feeder is mounted Holder: Holders are used to hold the springs. They are given with the provision for holding onto the springs and are placed outside the main body. Vibrator: A device which creates mechanical vibrations for uses such as signaling enunciators, doorbells, or industrial uses such as compacting gravel, transporting materials, cleaning, etc. VII.VIBRATION THEORY Vibration refers to mechanical oscillations about an equilibrium point. The oscillations may be periodic such as the motion of a pendulum or random such as the movement of a tire on a gravel road. Types of vibration: (a) Free Vibration (b) Forced Vibration Methods of vibration: Different kinds of vibration is possible by using a different combination of electric vibrator, eccentric shaft, gear box, etc. as per the requirement. Few examples for methods of vibration are as follows: (a) Rotational type (b) Elliptical type (c) Linear type The parameters which characterize a vibrator are as follows: (a) Speed (rpm) (b) Static Moment (kg*mm) (c) Electric Power (kW) The parameters which characterize a vibrating machine are as follows: (a) Process (b) Speed (rpm) http://www.ijettjournal.org Page 654 International Journal of Engineering Trends and Technology (IJETT) – Volume 10 Number 14 - Apr 2014 (c) Stroke (mm) (d) Acceleration (Nr of “G” Force) (e) Angle of Line of force (f) Isolation system In the process of making a vibrating machine, few considerations have to be made. They are as follows: Type of vibration, speed, amplitude/acceleration, angle of force of vibrating machines depends on. (a) Type of process (b) Type of products (c) Capacity required Isolation system of vibrating machines depends on: (a) Type of vibration and speed (b) Installation of vibrating machine (c) Total weight of the vibrating machine (vibrating structure + vibrator) (d) Weight of product (depending on method of material loading) (e) Dimensions of vibrating machine (f) Characteristics of supporting structure VIII.BASIC INDICATIONS FOR LINEAR MOTION VIBRATING MACHINES PROCESS SPEED (RPM) 50 60 HZ HZ IX. CATALOGUE OF VIBRATING MOTORS Type Static moment (kg-mm) Centrifugal force (kg) Weig ht (kg) Pow er (W) 50 Hz 10/40-S02 30.1 35.0 9.70 120 10/100S02 84.2 94.3 12.5 120 10/200S02 163 183 19 185 10/310S02 286 321 23.5 350 10/550S90 457 512 36.5 350 STROK E (MM) (G) ANGL E (°) 10/810S90 723 809 54.0 680 CONVEYING 75010001500 90012001800 4.5-7 5-8 25-30 10/1110S90 1012 1132 64.0 750 PRIMARY SCREENING 7501000 900-1200 4.5-7 4-7 30-45 10/1400S90 1274 1424 78.0 950 FINE SCREENING 15003000 18003600 4.5-7 4-7 30-45 10/1610S02 1464 1638 93.0 1100 EXTRACTIN G 10001500 12001800 4-6 4-5 25-30 10/2100S02 1927 2154 105 1500 PRIMARY FEEDING 7501000 900-1200 6-11 4-6 25-35 10/2610S02 2326 2601 130 1960 FEEDING 10001500 12001800 6-11 5-6 25-35 10/3000S02 2690 3007 145 2200 SEPARATING 7501000 900-1200 5-8 34.5 30-45 10/3810S02 3422 3826 188 2500 FLUIDIZING 7501000 750-1000 7501000 5-8 50-80 10/4700S02 4206 4701 204 3200 10/5200S02 4658 5208 238 3800 ISSN: 2231-5381 http://www.ijettjournal.org Page 655 International Journal of Engineering Trends and Technology (IJETT) – Volume 10 Number 14 - Apr 2014 10/6500S02 5832 6527 268 4300 10/6600S02 6083 6799 285 5000 10/8000S90 7197 8046 315 7000 10/9000S90 7752 8666 326 7500 10/10000S02 8673 9695 381 7600 10/12000S90 10996 12294 500 9000 10/13000S02 11510 12867 420 9600 10/15000S90 12662 14155 643 1060 0 10/17500S90 15500 17327 705 1300 0 10/19500S90 17947 20062 711 1400 0 10/22000S90 20025 22386 926 1900 0 10/25000S90 22364 25000 960 1900 0 X. CALCULATION OF VIBRATING MOTOR: Known information: (a) Type of vibration = linear (2 Vibrators) (b) Weight of Vibrating structure = 4847. 5 kgs = 5000 kgs (approx.) (c) Stroke = 8 mm (d) Speed = 1000 rpm Selection of Vibrator: (i) e = S / 2 => e = 8.0 / 2 = 4.0 mm Therefore, eccentricity equals 4 mm. (b) Mt = Wt x e => Mt = 5000 x 4.0 = 20000 kg*mm Therefore, static moment equals 26000 kg*mm. (c) Mv = Mt/ Nr of Vib Number of vibrators = 2 (As type of vibration is linear) => Mv = 20000 / 2 = 10000 kg*mm ISSN: 2231-5381 Hence static moment of vibrator (Mv) ≥ 10000 kg*mm From the catalogue to 6 pole.-1000/1200, we find to the static moment column that the closest model is the 10/12000s90, which has a static moment of 10996 kg-mm and weight of 500 kg. Check the selection of Vibratory Motor: Trail-I Known information: (a) Type of vibration = linear (2 Vibrators) (b) Weight of Vibrating structure = 4847. 5 kgs = 5000 kgs (approx.) (c) Static moment of vibrator (Mv) = 10996 kg-mm (d) Total weight of machine (Wt) = 5000 kg Selection of Vibrator: (a) Mt = Mv x 2 => Mt = 10996 x 2.0 = 21992 kg*mm (b) Wt = Ws + Wv => Wt = 5000 + (500x2) = 6000 kg (c) e = Mt / Wt e = 21992 / 6000 = 3.67 mm In this case we need a bigger unit to get the stroke required; the next model from the catalogue is the 10/13000s02 which has a static moment of 11510 kg-mm and a weight of 420 kg. Trail-II Known information: (a) Type of vibration = linear (2 Vibrators) (b) Weight of Vibrating structure = 4847. 5 kgs = 5000 kgs (approx.) (c) Static moment of vibrator (Mv) = 11510 kg-mm (d) Total weight of machine (Wt) = 5000 kg Selection of Vibrator: (a) Mt = Mv x 2 => Mt = 11510 x 2.0 = 23020 kg*mm (b) Wt = Ws + Wv => Wt = 5000 + (420x2) = 5840 kg (c) e = Mt / Wt e = 23020 /5840 = 3.9 mm In this case we need a bigger unit to get the stroke required; the next model from the catalogue is the 10/15000s90 which has a static moment of 12662 kg-mm and a weight of 643 kg. Trail-III Known information: (a) Type of vibration = linear (2 Vibrators) (b) Weight of Vibrating structure = 4847. 5 kgs = 5000 kgs (approx.) (c) Static moment of vibrator (Mv) = 12662 kg-mm (d) Total weight of machine (Wt) = 5000 kg Selection of Vibrator: (a) Mt = Mv x 2 => Mt = 12662 x 2.0 = 25324 kg*mm (b) Wt = Ws + Wv => Wt = 5000 + (643x2) = 6286 kg (c) e = Mt / Wt e = 25324 /6286 = 4.02 mm In this case the vibrator must be set at 99.28%, a bigger unit is recommended to have a higher stroke available. http://www.ijettjournal.org Page 656 International Journal of Engineering Trends and Technology (IJETT) – Volume 10 Number 14 - Apr 2014 Thus the vibratory motor is selected in trail-III i.e 10/15000S90, which has a static moment of 12662 kg-mm, 10.6 KW power and a weight of 643 kg. XI CHECKING THE ACCELERATION OF THE MACHINE Known information: a = Acceleration (Nr of G’s) Mt = Total Static Moment (Static Moment of Vibrator x Nr of vibrator) (kg*mm) Fv = Centrifugal Force of Vibrator = 14155 kg Wt = Ws + Wv = 5000 + (643x2) = 6286 kg Ft = Fvx2 = 15155 x 2 = 28310 kg-mm a = Ft / Wt = 28310 / 6286 = 4.50 =4.50 x 99.28 % = 4.4 G Therefore the acceleration of the total machine is 4.4. REFERENCES: [1] www.google.com [2] www.wikipedia.com [3] www.wisegeek.com/what-is-a-crusher.html [4] www.crusherplants.com/plants/types-ofcrushers.html [5] www.articlesbase.com/training-articles/vibratingfeederselection-and-sizing-5847091.html [6] http://pdf.directindustry.com/pdf/eriez/heavy-dutyvibratoryfeeders/19120-124854-_12.html [7] http://www.vibratingfeeders.com/reclaimarticle.cfm ISSN: 2231-5381 http://www.ijettjournal.org Page 657