Application of High Throughput technologies to Drug Substance and Drug Product Development

advertisement

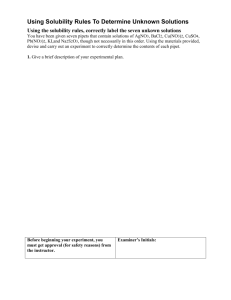

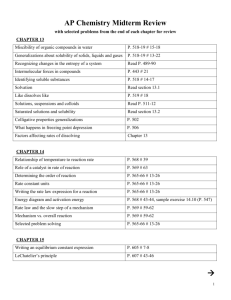

Application of High Throughput technologies to Drug Substance and Drug Product Development Colin R. Gardner TransForm Pharmaceuticals Inc. Lexington, MA 02421 www.transformpharma.com FOCAPO, 12 Jan 2002 1 Drug Discovery / Development Discovery Targets Hits Leads Candidate 2-5 yrs Market Development Preclinical Development 0.5 - 2 yrs $2-4 MM Phase 1 Phase 2a/b 1 - 2 yrs 1.5 - 3.5 yrs $1-3 MM $5-25 MM Phase 3 Submission& Approval 2.5 - 4 yrs 0.5-2 yrs $50-250 MM $5-20 MM Lifecycle Management 10-20 yrs R&D takes 6.5 - 13.5 years $60- 300 million Source: PRTM Historic NCE Pipeline Success NCE Probability of Success by Phase: 1990s Estimates 10 NCE’s Approved 100 Preclinical Candidates Preclinical Phase 1 Phase 2 Phase 3 Registration to Approval 15 – 35% 7 – 20% 6 – 18% 5 – 16% 60 – 70% 50 – 60% 80 – 90% 90 – 95% Cumulative Success 25 – 50% Probability of Success by Phase 25 – 50% Source: SDG, London; GW Journal of Innovation, Vol 1, Issue 3, 1995; PRTM estimates Why Product Candidates Fail 45 40 35 30 25 20 15 10 5 0 Tox Efficacy Biopharm Business Global view: Pre-clinical R & D Process Early Discovery Genomics Libraries HTS Target Hits to Leads Discovery Development Synthetic chemistry Scale up 100-500mg Lead optimization Sample collection in vitro selectivity Animal model Probe Tox, PK, met in vitro metabolism Animal model efficacy in vitro Tox Lead optimization 2-4 cmpds F&F GLP Tox Ph I Process chemistry Pharm. Sci. Form & Formulation Active compound Optimized form FORM Small molecule drugs: •Solubility •Dissolution Rate •Bioavailability •Release profile •Stability Effective formulation FORMULATION Biologics/Vaccines: •Stability •Solubility •Activity, yield •Efficacy •Delivery profile Maximize Product Value Form & Formulation: Traditional Drug Discovery Preclinical development Clinical development Regulatory Manufacture Marketing/ Sales •Mostly manual experimentation •Low throughput New R&D Challenges Resource constraints Discovery revolution Pharmaceutical Development Drug Discovery Preclinical development Clinical development Time constraints Bringing High Throughput to the Process Drug Discovery • Solubility • Lead selection Preclinical development • Bioavailability • Stability • “Bricks” Clinical development • Dosage form • Regimen Regulatory Manufacture • COGS • Rational process design • Risk reduction •Automated, high throughput experimentation •Microscale •Informatics driven Marketing/ Sales • Product enhancements • IP Optimal Integrated Technology Platforms Active pharmaceutical ingredient CrystalMaxTM INFORM FASTTM/SFinXTM Solid forms Informatics Formulations Exploration of Solid Forms and Methods TransForm (CrystalMaxTM) Traditional salt former API process impurity O activity H / salt ratio or 2degradate process impurity or degradate 3 1 2 2 process (t,T) solvent 14 solvent solvent solvent 3 5 23 4 1 process (t,T) pH temperature Salts Hydrates Polymorphs CrystalMax™ •Best solid form •Efficient • micro-scale (sub-mg) • massively parallel (20,000) •Comprehensive exploration of ‘space’ •Automatic data capture Why Use Tubes Rather Than Plates? Volume remaining (%) 100 µL evaporation study 100 90 80 70 60 50 MeOH /w e ll Pentane/w ell MeOH /tube Pentane/tube 40 30 0 5 10 15 20 T im e ( m in ) 25 30 Acquisition time (seconds) 2000 micro XRD, acetam inophen Raman, acetam inop hen Raman, alendro nate sodiu m 1500 1000 500 0 0.01 0.1 1 10 Sample size (mg) 1 10 2 Innovative Approach to Primary Analysis 5500 5000 4500 4000 3500 3000 2500 2000 1500 1000 500 -0 2000 1000 Acetaminophen: Iteration to Find Form III Step 1 Step 2 Step 3 Micro-XRD structure solution of form III I/II 95/5 II/I 50/50 II/III 90/10 • Three polymorphs of acetaminophen identified and characterized using informatics-driven, iterative experimentation • Different process modes: thermal, evaporative and melt • Over 10K experiments to explore HT polymorph diversity in < 6 weeks High Throughput Formulation Discovery TransForm HT Platforms (FASTTM & SFinXTM) Traditional Stability Stability Stability • Limited experiments • No informatics • “Good enough” formulation Solubility Solubility Solubility Dissolution rate Informatics-Enhanced Experimental Design Dissolution rate • Many experiments • Comprehensive data capture • New knowledge Dissolution rate • “Smarter” experiments • Data capture & mining • New knowledge • Optimized formulations FAST TM Best formulation for specific application • solubility, stability, device compatibity Efficient • micro-scale (ug range) • massively parallel (>5,000) Comprehensive exploration of ‘space’ Automated data capture End-to-end automation •Small molecules •Biologicals •Vaccines InformTM: Informatics Desktop design Relational database Process control Analysis and Predictive Modeling Software Integrated data capture, storage and analysis Knowledge-driven discovery Designed for U.S. regulatory compliance (CFR 21.part 11) Proprietary design Discovery Applications Building in “Developability” Lead (active molecule) Potency Physical properties Metabolism Potency Metabolism Selectivity Selectivity LO (optimized molecule) Physical / chemical properties Biopharmaceutics Best leads Animal Studies: Bioavailability Oral Formulations Intravenous Formulations TPI Formulations Standard Formulation Plasma Concentration (ng/mL) 10000 Compound 680463 (0.2 mg/kg) (90%water, 6.9%Polyoxyl 35 Caster oil, 3.1%Propylene Glycol) Compound 647271 (0.5 mg/kg) (60%water, 12.5%of 50%HPBCD, 27.5%Polyoxyl 35 Caster oil) 1000 TPI Formulations 100 10 1 0 6 12 18 24 Time (hours) Improved oral bioavailability demonstrated with TPI formulations IV dosing enabled by TPI formulations Applications in Pre-Clinical and Clinical Development Development Risk: Norvir PR Newswire July 27, 1998 TransForm Solution: Norvir Within 4 weeks: Both known forms identified/characterized Three new forms discovered Novel, robust methods identified to make each form MPT 122 °C MPT 125 °C MPT 80 °C Form I Form II Form III MPT 97 °C Form IV TPI’s analysis required < 2 g of material MPT 116 °C Form V TPI 211: Identification of improved formulations TPI 211: Challenge Marketed intravenous anti-cancer drug Excipient-related adverse effects 100 • Eliminate toxicity 80 • Maintain 60 • solubility • physical stability 40 • chemical stability 20 TransForm Solution •4 lead formulations identified from 96,000 experiments •Scale-up •>24 weeks stability •Better animal tolerance Applications in Life Cycle Management / Line Extensions Oral delivery High-throughput salt screening Experimental variables: Salt-forming reagents pharma acceptable > 40 acids (basic compounds) > 20 bases (acidic compounds) API/salt former ratio pH ionic strength solvent composition Complex system TPI 745: New Form for Faster Onset and New Delivery Systems Problem: Potential new indications complicated by slow onset and side effects at high dosage levels May require new controlled release delivery system Solubility TransForm Solution New form with superior solubility • Within 2 weeks • 100X more soluble than parent drug • New IP Potential to reformulate with controlled release New TPI-745 Form Has Faster Onset & Better Bioavailability Plasma concentrations ng/ml 2 10 30 mpk P.O. 4 1.5 10 4 1 10 4 TPI-745A TPI-745B TPI-745 Cmax Tmax Salt form with “solubility modifier” AUC TPI-A 23.2±6.2 1.3±1.0* 139±26 TPI-B 19.6±4.6 2.1±1.1 135±24 T-745 21.4±4.0 2.8±1.6 150±43 5000 0 0 2 4 time, hours 6 8 Transdermal delivery • Standard Diffusion Cell Low throughput Slow Skin • HT Diffusion Cell Array High throughput Fast Transdermal patch Skin Receptor compartment Skin permeation from HT system Comparison of Fluxes Comparison of 4 formulations Cumulative Amount Transported (ug/cm2) 30.0 25.0 20.0 15.0 10.0 5.0 0.0 0 2 4 Time (hr) 6 8 10 Conclusions • “Developability” is a key factor in finding new drugs • Potent active compounds are not necessarily drugs – other properties are critical • HT form and formulation techniques are important • Discovery: helps medicinal chemists with SAR •Pre-clinical: optimizes products • Marketed products: improves product performance and provides new IP • High throughput technologies do not replace good science and engineering – they provide more data and enable better decisions 35