Substation Phase Controller Deepa Chavan , Ms. Mahejabeen Ilkal

advertisement

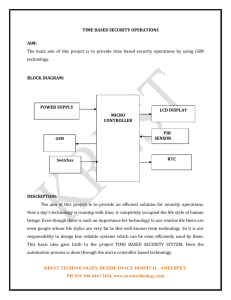

International Journal of Engineering Trends and Technology (IJETT) – Volume 10 Number 4 - Apr 2014 Substation Phase Controller Deepa Chavan#1, Ms. Mahejabeen Ilkal*2 # Assistant Professor, M.Tech (Digital Communication) Department of ECE, SIET, Bijapur, India * Student, B.E (ECE), Department of ECE, SIET, Bijapur, India. ABSTRACT Now a day’s the human life is fully depend on the electricity. Without this they can’t survive the life. Electricity is very need full in Domestic, Industries and Agriculture fields. So our power generation stations are not able to produce that much of power to supply as per the human requirements. So for avoiding this problem, they will supply power in shift wise. That one they called as load shedding. For example in agriculture field, all the water lifting pumps are work on three phase power, but our electricity board is not capable to supply the three phase power in all the 24 hours. So they will supply this power in shift wise to the all village. Through this system they will share the power. But this one thy will maintain manually. But some time man power is not sufficient to maintain it. So for avoiding this problem in substation, we have done one project that is “SUB STATION PHASE CONTROLLER”. INDEXTERM: III. SYSTEM WORKING PRINCIPLE AND IMPLEMENTATION This project consists, GSM and LCD display. Which are interfaced with microcontroller 8051.The process of changing the phase of electricity starts with selecting the mode of operation, we can select either automatic timing mode or normal mode, and if auto mode is selected then we must specify time for which particular phase electricity should be supplied. These modes are select by the virtual key pad. And also selected modes are displayed in the LCD display unit, these all changes are transmitted to the particular mobile phone as a SMS alerts, through the GSM module. For the indication of single and three phase electricity we use bulbs and these bulbs are switch ON and OFF through the relay and these relays are operated by the relay driver circuit. IV.BLOCK DIAGRAM DESCRIPTION: SUBSTATION, MICROCONTROLLER , GSM. I. INTRODUCTION The main aim of the project is to change the phase of electricity supplied from substation to different villages i.e. from single phase to three phase and vice versa and also to provide antitheft mechanism using GSM alert system. Substations are the stations under which several villages are combined and electricity is controlled from this station. In villages there is no need of continues supply of 3 phase electricity because there no much industrial area but they also required 3phase for irrigation purpose i.e for water supply through motor pumps hence substation gives for small amount of time 3phase as per the timing and most of time single phase is given. For this changing the phases for different villages in the substation there is junior engineer. By making use of this project we can change phase by automatically or manually and also we can catch corrupted officers who are working in the substation. II. BLOCK DIAGRAM GSM Module Max 232 Power Supply driver circuit Relay Load Micro Controller 89C51 driver circuit Relay Load A. COMPONENTS Microcontroller LCD display Solid state relay MAX 232 IC GSM Module Driver circuit Relays MICRO CONTROLLER UNIT: Microcontroller is the brain of the project, it will run according to the program has to be written, here we have used as an 89C51RD2BN microcontroller. LCD DISPLAY: In this project we are using 16*2 LCD display which shows the selection for automatic mode or manual mode operations and also which phase we have to choose and if we chosen the automatic mode it will display that for what time duration we want that particular phase which is given by keypad. SOLID STATE RELAY : In this relay there is no coil, spring, or mechanical contact switch, the entire relay is made up of semiconductor material because no mechanical parts are involved in solid state relays, their switching response time is much faster than that of electromagnetic relay. So we can use this solid state relay to trip on and trip off the electricity. Key Pad LCD Display driver circuit Fig1: Block Diagram of the system ISSN: 2231-5381 Relay Load MAX 232 IC: MAX 232 IC, which is used to communicate between microcontroller and the GSM modem. It transfers the data http://www.ijettjournal.org Page 202 International Journal of Engineering Trends and Technology (IJETT) – Volume 10 Number 4 - Apr 2014 to GSM & from the µ-controller unit. This unit converts microcontrollers TTL signals into RS232 signal type as the GSM modem needs RS232 signals. GSM MODULES: GSM, which stands for Global System for Mobile communications, reigns as the world’s most widely used cell phone technology. Cell phones use a cell phone service carrier’s GSM network by searching for cell phone towers in the nearby area. GSM circuit receives message and give it to the microcontroller, then microcontroller sends the appropriate message to HESCOM using GSM module. B. TECHNICAL SPECIFICATIONS: Operating voltage of embedded circuitry is 5vdc. Current consumption of device in active mode 200mill amp. Operating frequency of device is 11.0592MHZ. V. MICROCONTROLLER CPU, RAM, ROM, I/O and timer are all on a single chip fix amount of on-chip ROM, RAM, I/O ports for applications in which cost, power and space are critical single-purpose A. FEATURES: Compatible with MCS-51tm Products. 8K byte of in system re-programmable flash memory. Endurance: 1000 write / Erase cycle. Fully static operation. 3 Level program memorial clocks. 256 X 8 bit internal RAM. 32 programmable I/O Line. 3-16 bit timer/Counter. 8-Interupt Source. Programmable serial channel. Low power, Ideal and Power down modes. Four register Banks each containing 8 registers VI. GSM MODEM HARDWARE features GPRS multi-slot class 10/ class 8 (optional) and supports the GPRS coding schemes CS-1, CS-2, CS-3 and CS-4. You can use AT Command to get information in SIM card. The SIM interface supports the functionality of the GSM Phase 1 specification and also supports the functionality of the new GSM Phase 2+ specification for FAST 64 kbps SIM (intended for use with a SIM application Tool-kit).Both 1.8V and 3.0V SIM Cards are Supported. The SIM interface is powered from an internal regulator in the module having nominal voltage 2.8V. All pins reset as outputs driving low. Logic levels are as described in table Network status indication LED lamp State SIM300 function Off - SIM300 is not running 64ms On/ 0.8 sec Off - SIM300 does not find the network 64ms On/ 3 Sec Off - SIM300 find the network 64ms On/ 0.3 sec Off - GPRS communication VII. SOFTWARE IMPLEMENTATION A. SYSTEM ALGORITHM Start Serial port initialization GSM initialization Select mode of operation If manual mode wait for keys. Change the phase manually Send respective SMS If auto mode Specify the time duration Change phase automatically Send respective SMS Reset This document describes the hardware interface of the SIMCOM SIM300 module that connects to the specific application and the air interface. As SIM300 can be integrated with a wide range of applications, all functional components of SIM300 are described in great detail. A. PRODUCT CONCEPT Designed for global market, SIM300 is a Tri-band GSM/GPRS engine that works on frequencies EGSM 900 MHz, DCS 1800 MHz and PCS 1900 MHz. SIM300 ISSN: 2231-5381 http://www.ijettjournal.org Page 203 International Journal of Engineering Trends and Technology (IJETT) – Volume 10 Number 4 - Apr 2014 VIII. ADVANTAGES AND APPLICATION A. ADVANTAGES It saves time. No need to operate manually. Compact and low cost. Theft of electricity can b controlled. B. Application It can be used in industries. It can be used apartments. IX. CONCLUSION By implementing this project in substation we can easily control and change phase of electricity from single phase to three phase and vice versa by selecting auto mode or manual mode. And also by making use of automatic change of phase of electricity we can reduce man power. Since alerts of changing the phase of electricity is sent to head office through GSM module by which head officer will come to know changes in phases of electricity in the respective substation and hence theft of electricity and corrupt officers in respective substation can be known easily. REFERENCES Fi g : 2 . F l o w c ha r t of t h e s y st e m ISSN: 2231-5381 [1] Amit Sachan"Microcontroller Based Substation Monitoring and Control System with Gsm Modem"IOSR Journal of Electrical and Electronics Engineering (IOSRJEEE)ISSN: 2278-1676 Volume 1, Issue 6 (July-Aug. 2012), PP 13-21cien [2] V. Thiyagarajan &T.G. Palanivel "An Efficient Monitoring Of Substations Using Microcontroller Based Monitoring System.IJRRAS 4 [3] Jyotishman Pathak, Yuan Li, Vasant Honavar and James D. McCalley, “A Service-Oriented Architecture for Electric Power Transmission System Asset Management", In ICSOC Workshops, pp: 2637, 2006. [4] B. A. Carreras, V. E. Lynch, D. E. Newman and I. Dobson, "Blackout Mitigation Assessment in Power Transmission Systems", Hawaii International Conference on System Science, January 2003. [5]. Xiamen Li and Ganesh K. Venayagamoorthy, "A Neural Network Based Wide Area Monitor for a Power System", IEEE Power Engineering Society General Meeting, Vol. 2, pp: 1455-1460, 2005. [6]. Argonne National Laboratory, "Assessment of the Potential Costs and Energy Impacts of Spill Prevention, Control, and Countermeasure equirements for Electric Utility Substations", Draft Energy Impact Issue Paper, 2006. [7]. R.R. Negenborn, A.G. Beccuti, T. Demiray, S. Leirens, G. Damm, B. De Schutter and M. Morari, "Supervisory hybrid model predictive control for voltage stability of power networks", Proceedings of the 2007 American Control Conference, New York, New York, pp: 54445449, July 2007. [8]. Daponte, M. Di Penta and G.Mercurio, "TRANSIENTMETER: A Distributed Measurement System for Power Quality Monitoring", IEEE Transactions on Power Delivery, Vol. 19, Issue. 2, pp: 456-463, 2004. http://www.ijettjournal.org Page 204