Document 12918097

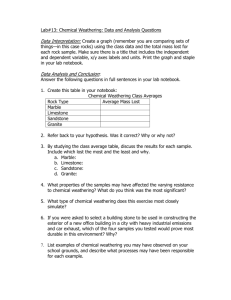

advertisement