Document 12914472

advertisement

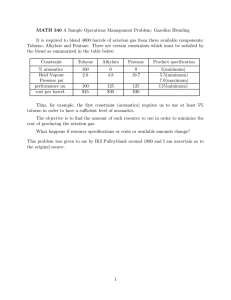

International Journal of Engineering Trends and Technology (IJETT) – Volume 29 Number 6 - November 2015 Ignition Mechanism Analysed through Transient Species Measurements and its Correlation with 0-D and 3-D Simulations for PRF and Toluene/ n-heptane Mixture Mohd Adnin Bin Hamidi#1#2 Muhammad Faizzuddeen Bin Yunadi#1 Atsumu Tezaki#1 #1 University of Toyama, 3190 Gofuku, Toyama 930-8555, JAPAN #2 University Malaysia Pahang, MALAYSIA 1 adninaddin@gmail.com 2 kembar.albiruni@gmail.com 3 tezaki@eng.u-toyamna.ac.jp Abstract— FT-IR was used to detect intermediate species which formed throughout the exhaust gas in a test engine at cool ignition condition. PRF (isooctane/n-heptane) and NTF (toluene/n-heptane) were used as fuel mixtures. Fuel consumption decreases with increasing iso-octane content in PRF and toluene content in NTF. These tendencies correspond to the difference in detail reaction mechanism for PRF and NTF oxidation. The essential mechanism affecting the ignition property of n-heptane is discussed by simplified model supported by simulation by Chemkin Pro reproducing the experimental results. FORTE was used to analyze temperature and fuel concentration change inside combustion chamber through multidimensional simulation. Keywords— Homogenous Charge Compression Ignition / PRF, NTF, Low Temperature Oxidation, FT-IR, Chemical Kinetics. I. INTRODUCTION A typical process of compression ignition is composed of low and high temperature oxidation stages. Ignition timing of the high temperature oxidation is influenced by heat release and composition change in the low temperature oxidation (LTO). While high temperature oxidation mechanism is common to most hydrocarbons, LTO property depends strongly on molecular structure of hydrocarbons. Our group has conducted experimental methodologies which is originated from a study of Leppard et al. [2], can detect variety of species present after LTO. In this study, we applied the methodologies to NTF (n-heptane and toluene mixture). Toluene and iso-octane are typical high octane number fuels that reduce ignition activity of n-heptane when mixed, but some different behaviors between these fuels on the ignition control were reported by Shibata et al. [3]. In the following chapters, we present data of chemical composition in the course of compression ignition of NTF. Relevant chemical kinetic mechanisms are discussed with a simplified model constructed with a consideration of the property of chain reaction. Finally the ignition behaviour ISSN: 2231-5381 changing with the fuel mixing ratio is reproduced by non-dimensional and 3-dimensional numerical simulations by using CHEMKIN PRO and FORTE, respectively. II. EXPERIMENTAL SETUP As shown in fig. 1, the experimental engine is a single cylinder, 4-stroke overhead valve engine (displacement 541 cm3, compression ratio 8.0). It is motored with the standard speed of 600 rpm. Liquid fuel is injected into the intake port, evaporated and mixed with preheated air to form combustible mixture gas. Crank angle resolved cylinder pressure is measured by a mounted pressure gauge. For Exhaust Gas Analysis, a part of exhaust gas is introduced in an optical cell of 3 m path length at the pressure of 10 kPa, and the chemical composition is analyzed by a Fourier transform Infrared spectrometer (FT-IR, Shimadzu IR Prestige-21). Fuel mixtures are prepared prior to experiments. The mixing composition is defined by liquid volume ratio and indicated by the percentage of toluene for NTF; for example, NTF10 is 10% toluene + 90% nheptane mixture. Non dimensional and 3-dimensional numerical simulation of compression ignition was carried out on CHEMKIN PRO and FORTE platform with existing detailed oxidation reaction models of M. Mehl for PRF and NTF [4], [5]. (Size 10 & Normal)An easy way to comply with the conference paper formatting requirements is to use this document as a template and simply type your text into it. III. RESULTS AND DISCUSSIONS A. Composition Change in Cool Ignition Stage Figure 2 shows species composition after low temperature ignition stage depending on toluene content in NTF. This is a result of model calculation described in the next section, and is in good agreement with experimental observation. Overall trend is that the fuel consumption and formaldehyde production decrease with increasing toluene content; however, the decreasing rate is slow at lower toluene content up to 60% and turns fast until they at over http://www.ijettjournal.org Page 281 International Journal of Engineering Trends and Technology (IJETT) – Volume 29 Number 6 - November 2015 60% until the consumption and production fall to zero at around 80% of toluene. Where ki is the rate constant of species i with OH, and the subscript a denotes aldehyde. Above equations can be translated into a form in which the independent variable is percentage consumption of base fuel x as: (7) (8) (9) B. Simplified Model The low temperature oxidation mechanism of hydrocarbons consists of complicated reactions such as H-abstraction, O2-addition, isomerization, second O2-addition, decomposition and branching passes. Here, the oxidation mechanism of a mixture of nheptane (base fuel) and toluene (second fuel) is expressed in a summarized manner as: nC7H16 + OH bOH + bHCHO + other products (1) C6H5CH3 + OH sOH + sHCHO + other products (2) where αi is the reproduction index of OH from species i, and βi is the production yield of chain terminating intermediate represented by HCHO from species i. There are products that absorb OH other than HCHO, but they are included in the group of “HCHO”. Other products are regarded as unreactive during the course of low temperature reaction. Differential equations governing time evolution of relevant species are described as: = , (3) = , (4) production or consumption Fig.1 Experimental apparatus for exhaust gas analysis. where ys is the remaining amount of second fuel (relative to initial amount of base fuel, and so forth), ya is the accumulated amount of aldehyde, yOH is the amount of OH, g1 = ks/kb and g2 = ka/kb. αb of low ON fuel is necessarily exceeding unity, but αs may differ. When initial overall of OH reproduction index is over unity, the OH concentration increases with repetition of the reaction chain. According to decrease in fuel and increase in the OH consuming aldehyde, the slope OH increase gradually reduces, turns into decrease, and finally the chain system is terminated. The point of termination is represented by the overall OH reproduction index = 1.The parameters used for NTF are kb/ks = 5, αb= 2, αs= 0, β b = 1.6, βs= 0, a part of which was assumed by overlooking the toluene oxidation mechanism [6]. The composition at the point of termination is summarized in Figs. 2. These calculations successfully reproduce the experimentally observed tendency, i.e., toluene consumption is less than those of n-heptane, the effect of reducing n-heptane consumption is less in toluene, and aldehyde production reduces with increasing toluene content. 1 n-heptane Toluene [HCHO]/[Fuel] 0 0.8 0.6 0.4 0.2 0 0 20 40 60 80 toluene content [%] Fig.2 Model results of fuel consumption and formaldehyde production at the end of lowtemperature chain reaction in NTF compression as a function of toluene content. = (5) = (6) ISSN: 2231-5381 C. Simulation of Ignition Processes Figure 3 shows comparison of temperature profiles between CHEMKIN and FORTE, in which average in the cylinder is taken for FORTE. Fuel is n-heptane with 0.5 equivalence ratio. For FORTE calculation, 403.5K was used as intake temperature http://www.ijettjournal.org Page 283 International Journal of Engineering Trends and Technology (IJETT) – Volume 29 Number 6 - November 2015 to simulate the real experimental work with our engine. The CHEMKIN calculation result of 403.5K intake shows distinctive difference from FORTE calculation, and the best matching was obtained at 550K intake temperature of CHEMKIN. There may be a number of reasons for this difference, such as dimensionality of the calculation, heat transfer from intake port and cylinder wall included only in FORTE, and the difference in intake valve closing in FORTE and starting crank angle in CHEMKIN. We conclude the last reason is most important and the other ones are minor. Figure 4 shows cool stage and final ignition timing as a function of toluene content in NTF, obtained by FORTE. Low temperature heat release (LTHR) of cool ignition stage arrives in the lower range of toluene content. Since LTHR advances the final hot ignition, there is a large difference in ignition timing between the ranges of LTHR and no LTHR. The trend is consistent with the experimental and modeling observation of composition change during the low temperature oxidation. Fuel consumption decreases with increasing toluene/n-heptane ratio although it’s weak. It is because toluene has lower rate constant with OH, so that toluene barely interrupts the OH reproducing chain reaction of n-heptane. Comparison between CHEMKIN and FORTE calculation shows distinctive difference due to the difference in dimensionality of the calculation, heat transfer from intake port and cylinder wall included only in FORTE, and the difference in intake valve closing in FORTE and starting crank angle in CHEMKIN. The trend in ignition timing in FORTE calculation is consistent with the experimental and modeling observation of composition change during the low temperature oxidation. Last but not least, further recalibration in simulation work are needed to get more reliable in comparing variable parameters. ACKNOWLEDGMENT This work was supported by JSPS KAKENHI Grant Number 24560226. Mohd Adnin expresses special thanks to University Malaysia Pahang, UMP as the sponsor for his studies in University of Toyama. REFERENCES [1] [2] [3] Fig. 3 Temperature Profiles in Simulation Platforms. [4] [5] [6] A. Tezaki, T. Miyashita and H. Murasawa, Transient Chemical Composition Analysis in HCCI of n-Heptane Fuel, Proc. 7th COMODIA, Sapporo, Japan (2008), 329334. W. R. Leppard, A Comparison of Olefin and Paraffin Autoignition Chemistries: A Motored-Engine Study, SAE 892081. G. Shibata and T. Urushihara, Dual Phase High Temperature Heat Release Combustion, SAE 2008-010007. M. Mehl, H. J. Curran, W. J. Pitz and C. K. Westbrook, Chemical kinetic modeling of component mixtures relevant to gasoline, European Combustion Meeting, Vienna, Austria, 2009. Mehl M., W.J. Pitz, C.K. Westbrook, H.J. Curran, Kinetic Modeling of Gasoline Surrogate Components and Mixtures Under Engine Conditions, Proceedings of the Combustion Institute 33:193-200 (2011). H. Ando, Y. Sakai and K. Kuwahara, Universal Rule of Hydrocarbon oxidation, SAE paper-2009-01-0948 (2009). (Size 8) S. M. Metev and V. P. Veiko, Laser Assisted Microtechnology, 2nd ed., R. M. Osgood, Jr., Ed. Berlin, Germany: Springer-Verlag, 1998. Fig.4 Ignition Timing vs. Toluene Percentage in NTF, obtained by FORTE. IV. CONCLUSIONS Production yield of HCHO decreases with increasing toluene/n-heptane ratio. HCHO is a product of ketoalkylperoxide that makes benzyl radical from toluene does not proceed such way because of the firmness of its aromatic ring. ISSN: 2231-5381 http://www.ijettjournal.org Page 283