Introduction

advertisement

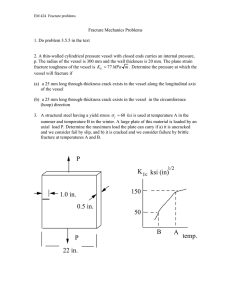

Introduction Thank you for participating in the Sandia Fracture Challenge. The purpose of this exercise is to: (a) compare methodologies for predicting fracture behavior of metallic alloys, and (b) identify methodologies that appear to be most predictive. Sandia National Labs and Naval Surface Warfare Center (NSWC) hope to use this exercise to foster future relationships and develop strategy in fracture prediction. In this exercise, participants are asked to predict the forces and displacements required to initiate and propagate a crack from a relatively simple geometry, and predict the path of crack propagation. Participants are allowed to bound their predictions as they see fit. Participants are also asked to submit their best estimate for the observed force-displacement response of the test geometry. Details are provided regarding the challenge geometry and material (see subsequent slides). Experiments will be performed by two independent test labs to confirm the experimentally observed behavior. The following deadlines are in effect: (1) Any concerns regarding the challenge or sufficiency of the supplied data should be communicated to Brad Boyce blboyce@sandia.gov by May 23rd. (2) Predictions must be e-mailed to blboyce@sandia.gov by midnight, September 15, 2012 (4 months after challenge was issued). (3) Experimental results will be e-mailed to all participants by October 15th, 2012 using the form provided. (4) For those participants who agreed to participate prior to the May 15th start date, you have been reserved a slot to present your findings in Symposium 9-13: “Symposium on Simulation and Experiment of Ductile Tearing” at the ASME International Mechanical Engineering Congress and Exposition, November 9-15. knife edge points for COD measurements The Sandia Fracture Challenge Holes for loading pins D C A B E The alloy. Precipitation hardened stainless steel, alloy 15-5 PH, purchased from AK-Steel and heat treated at 1100 ºF for 4 hours. Resulting tensile data (included in subsequent slides) indicates properties that are consistent with the H1075 or H1100 condition. The geometry. A sheet of nominally 0.125 inch thick (actual 0.124 inch thick) 15-5 PH was machined into the challenge geometry as well as tensile bars, fracture toughness samples, and metallurgical coupons. The challenge geometry, shown on the left, includes detailed engineering drawings in the subsequent slides. The challenge. When loaded at room temperature at a loading rate of 0.0005 inches/sec, (Q1) What is the force and COD displacement1 at which a crack first initiates2? (Q2) The starter notch, A, holes B-D, and the backside edge, E are labeled in the drawing. What is the path of crack propagation? i.e. a crack that initiated on the backside and propagated to hole D and then to notch A would be labeled “E-D-A”. (Q3) If the crack does propagate to either holes B,C, or D, at what force and COD displacement does the crack re-initiate out of the first hole? 1COD: A Crack opening displacement (COD) gage will be used to monitor load-line displacement at the point of the ‘knife-edge’ features, akin to fracture toughness testing. Only COD will be measured (the test will begin with COD=0 inches). 2For the purposes of this challenge, crack initiation will be defined as a crack 100m on the sidewall surface of the sample, so as to be witnessed by in-situ microscope. The Sandia Fracture Challenge Reporting Form Please report predictions to Brad Boyce, blboyce@sandia.gov, by September 15, 2012 using the following form: Q1 force (lbs) Q1 displacement (inches) Q2 path (i.e. AB-C-D-E) Q3 force (lbs) Upper Bound Ex: 100 lbs Expected Outcome Ex: 98 lbs Lower Bound Ex: 90 lbs Filename for Force-COD data Ex: Groupname-force-COD-data.txt Participants reporting these results: Ex: John Doe, Joe Public, Annie Result, University of Awesome Q3 displacement (inches) Ex: A-B-C-D-E In addition to the scalar quantities reported in this table, please supply a single datafile representing your best estimate for the force vs COD displacement. Data file should be 2 columns of ASCII text: first column- force in lbs, second column- COD displacement in inches (change in displacement between knife edges). The Sandia Fracture Challenge Ethics Detailed material property data has been included in the challenge, including heat treatment schedule, chemistry certifications, hardness measurements, tensile behavior, and sharp crack behavior. Any participant can request a sample coupon of material for the sole purpose of metallurgical examination. By participating in the Sandia Fracture Challenge, all participants agree to not perform any mechanical experiments for the purpose of calibrating or validating their models. The intent of this exercise is to be a computational exercise based solely on data provided. Challenge Geometry – dimensions in inches Challenge Geometry – dimensions in millimeters Original Material Cert. Nominal Material Properties for AK Steel 15-5 PH H1075 Nominal Material Properties 0.2% Yield Strength Condition A H 900 H 925 H 1025 H 1075 H 1100 H 1150 H 1150M Ultimate Tensile Strength ksi MPa ksi MPa -185** 175 165 150 135 125 85 -1276 1207 1138 1035 931 862 584 -200 190 170 165 150 145 125 -1378 1309 1173 1138 1035 1000 882 Condition H 900 H 925 H 1025 H 1075 H 1100 H 1150 H 1150M % Rockwell Elongation Reduction C in 2" of Area Hardness % -14 14 15 16 17 19 22 -50 54 56 58 58 60 68 Ultimate Tensile Strength 0.2% Yield Strength ksi MPa ksi MPa 185 175 165 150 135 125 85 1276 1207 1138 1035 931 862 584 200 190 170 165 150 145 125 1378 1309 1173 1138 1035 1000 862 35 44 42 38 36 34 33 27 Charpy V-Notch Impact Strength Modulus of Elasticity (E)* ft-lb J ksi MPa -15 25 35 40 45 50 100 -20 34 48 54 61 68 138 -28.5 ------- -195 ------- % Elongation in 2" % Reduction of Area Rockwell C Hardness 10 11 12 13 14 15 18 30 35 42 43 44 45 50 44 42 38 36 34 33 27 Modulus of Rigidity (G) ksi x 10³ MPa x 10³ -11.2 -11.0 10.0 -10.0 -- -77.3 -75.9 69.0 -69.0 -- Charpy V-Notch Impact Strength ft-lb J 7 17 27 30 30 50 100 10 23 37 41 41 63 136 Heat Treatment Performed at Sandia H1100 – 4 hrs. at 1100˚F All samples and coupons were fabricated from a single 12”x12” plate of 15-5 PH SS. DAQSTANDARD Data Viewer Microsoft R8.22.01 R8.22.01 Microsoft Device Type Serial No. File Message Time Correction Starting Condition Dividing Condition Meas Ch. Math Ch. Ext Ch. Data Count Sampling Interval Start Time Stop Time Trigger Time Trigger No. Damage Check Started by Stopped by DX2000 U1J802972 None Restart after Black Out Auto 10 0 0 900 4 sec Note added RNS 02.20.12 Part A-C only. Parts D-G are 60 seconds. 3/19/2012 14:10:36 0 3/19/2012 15:10:32 0 3/19/2012 15:10:32 0 899 Not Damaged [ Key In ] [ Running ] Num. Of Converted Data Num. Of Converted Ch. Converted Group (double click on the embedded worksheet to access all heat treat data) Date Time 3/19/2012 14:10:36 3/19/2012 14:10:40 3/19/2012 14:10:44 3/19/2012 14:10:48 3/19/2012 14:10:52 3/19/2012 14:10:56 3/19/2012 14:11:00 3/19/2012 14:11:04 3/19/2012 14:11:08 3/19/2012 14:11:12 3/19/2012 14:11:16 3/19/2012 14:11:20 3/19/2012 14:11:24 3/19/2012 14:11:28 3/19/2012 14:11:32 3/19/2012 14:11:36 3/19/2012 14:11:40 3/19/2012 14:11:44 3/19/2012 14:11:48 3/19/2012 14:11:52 3/19/2012 14:11:56 3/19/2012 14:12:00 3/19/2012 14:12:04 3/19/2012 14:12:08 3/19/2012 14:12:12 3/19/2012 14:12:16 3/19/2012 14:12:20 3/19/2012 14:12:24 848-98024-**** 900 4 1 - 1 MAX TEMPS: 598.4 Ch. CH001 Tag CONTROL Tag No. Unit °C sec MIN MAX 0 28.3 28.3 0 28.3 28.4 0 28.3 28.4 0 28.3 28.4 0 28.3 28.4 0 28.4 28.4 0 28.4 28.4 0 28.4 28.4 0 28.4 28.4 0 28.4 28.4 0 28.4 28.4 0 28.4 28.4 0 28.4 28.4 0 28.4 28.4 0 28.4 28.4 0 28.3 28.4 0 28.3 28.4 0 28.3 28.4 0 28.3 28.3 0 28.3 28.4 0 28.3 28.3 0 28.2 28.3 0 28.2 28.3 0 28.2 28.3 0 28.2 28.2 0 28.2 28.2 0 28.1 28.2 0 28.1 28.1 587.6 22 CH002 OVERTEMP CH003 WORK 1 °C MIN °C MIN MAX 29.1 29.1 29.1 29.2 29.2 29.2 29.2 29.2 29.1 29.1 29.1 29.1 29 29 29 29 29 28.9 29 28.9 28.9 28.8 28.8 28.7 28.7 28.6 28.4 28.4 29.1 29.1 29.2 29.2 29.2 29.2 29.2 29.2 29.2 29.1 29.1 29.1 29.1 29.1 29 29 29 29 29 29 28.9 28.9 28.8 28.8 28.7 28.7 28.6 28.4 °C MIN MAX 20.9 20.9 20.9 20.9 20.9 20.9 21 21 20.9 20.9 21 21 21 21 21 21 21 21 20.9 20.9 20.9 20.9 20.9 20.9 20.9 20.9 20.8 20.8 616.7 CH004 WORK 2 20.9 20.9 20.9 20.9 20.9 21 21 21 21 21 21 21 21 21 21 21 21 21 21 21 20.9 20.9 20.9 20.9 20.9 20.9 20.9 20.8 MAX 27.8 27.8 27.8 27.7 27.4 27.2 26.8 26.5 26.2 26 25.9 25.9 26 26 26.1 26.2 26.2 26.3 26.3 26.2 26 25.8 25.7 25.3 25 25 24.8 24.8 27.8 PART A 27.8 27.8 27.8 27.7 27.4 27.2 26.8 26.5 26.2 26 26 26.1 26.1 26.2 26.2 26.3 26.3 26.4 26.3 26.2 26 25.8 25.7 25.3 25 25 24.8 Sample Extraction from a single 15-5 PH SS plate (12”x 12”x 0.123”) Metallurgy Witness Samples for Participants 5 Fracture Toughness Samples 3 Long. Tensiles Tensile Sample Drawing Tensile Test Setup 20 kip MTS system cell (ser. # 4678) Universal joint 20 kip wedge loaded grips 1” 50% MTS Extensometer (ser. # 10192232C) 20 kip actuator, MTS test frame (ser. #1327) Summary of Tensile Test Results UTS (ksi) YS (ksi) Strain (%) RA (%) • Longitudinal 1 162.9 159.8 16.3 54.0 27.2 • Longitudinal 2 162.4 160.1 16.7 53.6 28.7 • Transverse 1 160.9 157.7 15.8 46.6 28.9 • Transverse 2 160.3 155.5 15.9 50.1 27.6 Modulus (mpsi) Tensile Data Files with 180000.0 Trans2, Wo=0.248", Thicko=0.123" psi Stress/Strain Conversions and YS Determinations (double click on the embedded graphs to access all data) 668.1 1097.8 1594.7 2148.4 2652.4 3109.0 3669.1 4227.3 4679.2 5181.6 5731.8 6203.0 6689.0 7203.6 7634.5 8174.0 8552.8 9046.2 9474.8 9983.9 10409.2 10801.1 11181.8 11701.5 12048.9 12500.5 12899.6 13240.2 13655.4 14152.7 14455.3 14833.6 15107.8 15548.0 16014.8 16357.7 16846.6 17064.4 17442.2 17917.1 18226.5 18642.3 18950.5 19488.2 19798.2 20235.9 20543.8 20955.6 21390.0 21681.0 22191.3 22577.0 22886.1 23283.6 23727.1 160000.0 140000.0 120000.0 100000.0 Long 1 Long 2 Trans 1 80000.0 Trans 2 60000.0 40000.0 20000.0 -2.00E-02 0.0 0.00E+00 2.00E-02 4.00E-02 6.00E-02 8.00E-02 1.00E-01 1.20E-01 1.40E-01 1.60E-01 180000 1.80E-01 Trans 1 160000.0 160000 140000.0 140000 y = 28,897,374x + 30,733 120000.0 100000.0 120000 Trans 1 80000.0 100000 80000 0.2% Offset 60000.0 Trans 1 40000.0 Linear (Trans 20000.0 60000 0.0 0.00E+00 1.00E-03 2.00E-03 3.00E-03 4.00E-03 40000 20000 0.00232 0.00682 0 -0.005 0 0.005 0.01 0.015 0.02 0.025 40000 170000 Stress/Strain Plots UTS Long 1 = 162.9 ksi Long 2 = 162.4 ksi Trans 1 = 160.9 ksi Trans 2 = 160.3 ksi 180000.0 160000.0 140000.0 Engineering Stress (psi) 120000.0 YS Long 1 = 159.8 ksi Long 2 = 160.1 ksi Trans 1 = 157.7 ksi Trans 2 = 155.5 ksi Total Strain Long 1 = 16.3 % Long 2 = 16.7 % Trans 1 = 15.8 % Trans 2 = 15.9 % 100000.0 80000.0 Long 1 Long 2 Trans 1 Trans 2 60000.0 RA Long 1 = 54.0 % Long 2 = 53.6 % Trans 1 = 46.6 % Trans 2 = 50.1 % 40000.0 20000.0 0.0 0.00E+00 2.00E-02 4.00E-02 6.00E-02 8.00E-02 1.00E-01 1.20E-01 1.40E-01 Engineering strain measured using a 1-inch extensometer (inch/inch) 1.60E-01 1.80E-01 Raw Tensile Data Files (double click on the file icons to open data files) Data files are ASCII text files with space-separated columns Fracture Cross-Sections Longitudinal 1 - 54.0% RA Longitudinal 1 – 53.6% RA Transverse 1 – 46.6% RA Transverse 2 – 50.1% RA Side view of fracture profile Longitudinal 1 - 54.0% RA Transverse 1 – 46.6% RA Longitudinal 1 – 53.6% RA Transverse 2 – 50.1% RA Average Rockwell Hardness Values Mean: 34.9 HRC Std. Dev. 0.31 Hardness values were taken from the “skeletons” left from the tensile samples Mean: 36.1 HRC Std. Dev. 0.55 Fracture Toughness Sample Drawing Fracture Toughness Test Setup 0.5 kip Interface cell (ser.# 62003) – precracking 5 kip Interface cell (ser.# 10541) - testing Universal joint MTS COD gage (ser. # 213) 0.0” – 0.200” 20 kip actuator, MTS test frame (ser. #1327) Fatigue Precracking Load Shedding Schedule to prepare samples for Fracture Toughness Tests a/w 0.5 0.55 0.6 delta P Pmax Pmin delta K 240 266.6667 26.66667 19 120 133.3333 13.33333 12 50 55.55556 5.555556 6 Fracture Toughness Test Results 1200 KQ values are offered as an indication only as the sample thickness was insufficient for a valid K1c and the Pmax/PQ ratio was invalid KQ = 60.5 ksi √in 1000 KQ = 66.0 ksi √in KQ = 74.4 ksi √in Force (lbs) 800 15-5 H1100 K1c Test 1 600 15-5 H1100 K1c Test 2 15-5 H1100 K1c Test 3 400 200 F(a/W) = 12.84 F(a/W) = 13.82 F(a/W) = 15.01 Initial a/W after fatigue precracking = 0.584 Initial a/W after fatigue precracking = 0.603 Initial a/W after fatigue precracking = 0.623 0 0.00E+00 5.00E-02 1.00E-01 1.50E-01 COD Displacement (inch) 2.00E-01 2.50E-01 Raw Fracture Toughness Data Files (double click on the file icons to open data files)