Comparison of Flow Analysis through Sudden Contraction

advertisement

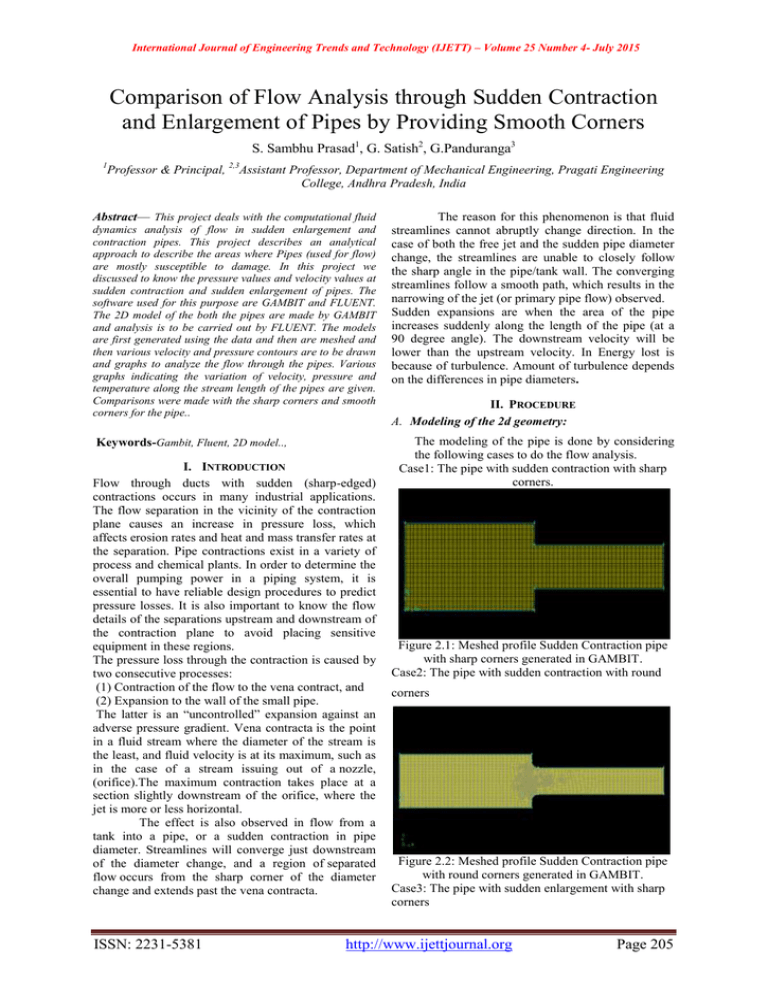

International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 4- July 2015 Comparison of Flow Analysis through Sudden Contraction and Enlargement of Pipes by Providing Smooth Corners S. Sambhu Prasad1, G. Satish2, G.Panduranga3 1 Professor & Principal, 2,3Assistant Professor, Department of Mechanical Engineering, Pragati Engineering College, Andhra Pradesh, India Abstract— This project deals with the computational fluid dynamics analysis of flow in sudden enlargement and contraction pipes. This project describes an analytical approach to describe the areas where Pipes (used for flow) are mostly susceptible to damage. In this project we discussed to know the pressure values and velocity values at sudden contraction and sudden enlargement of pipes. The software used for this purpose are GAMBIT and FLUENT. The 2D model of the both the pipes are made by GAMBIT and analysis is to be carried out by FLUENT. The models are first generated using the data and then are meshed and then various velocity and pressure contours are to be drawn and graphs to analyze the flow through the pipes. Various graphs indicating the variation of velocity, pressure and temperature along the stream length of the pipes are given. Comparisons were made with the sharp corners and smooth corners for the pipe.. Keywords-Gambit, Fluent, 2D model.., I. INTRODUCTION Flow through ducts with sudden (sharp-edged) contractions occurs in many industrial applications. The flow separation in the vicinity of the contraction plane causes an increase in pressure loss, which affects erosion rates and heat and mass transfer rates at the separation. Pipe contractions exist in a variety of process and chemical plants. In order to determine the overall pumping power in a piping system, it is essential to have reliable design procedures to predict pressure losses. It is also important to know the flow details of the separations upstream and downstream of the contraction plane to avoid placing sensitive equipment in these regions. The pressure loss through the contraction is caused by two consecutive processes: (1) Contraction of the flow to the vena contract, and (2) Expansion to the wall of the small pipe. The latter is an ―uncontrolled‖ expansion against an adverse pressure gradient. Vena contracta is the point in a fluid stream where the diameter of the stream is the least, and fluid velocity is at its maximum, such as in the case of a stream issuing out of a nozzle, (orifice).The maximum contraction takes place at a section slightly downstream of the orifice, where the jet is more or less horizontal. The effect is also observed in flow from a tank into a pipe, or a sudden contraction in pipe diameter. Streamlines will converge just downstream of the diameter change, and a region of separated flow occurs from the sharp corner of the diameter change and extends past the vena contracta. ISSN: 2231-5381 The reason for this phenomenon is that fluid streamlines cannot abruptly change direction. In the case of both the free jet and the sudden pipe diameter change, the streamlines are unable to closely follow the sharp angle in the pipe/tank wall. The converging streamlines follow a smooth path, which results in the narrowing of the jet (or primary pipe flow) observed. Sudden expansions are when the area of the pipe increases suddenly along the length of the pipe (at a 90 degree angle). The downstream velocity will be lower than the upstream velocity. In Energy lost is because of turbulence. Amount of turbulence depends on the differences in pipe diameters. II. PROCEDURE A. Modeling of the 2d geometry: The modeling of the pipe is done by considering the following cases to do the flow analysis. Case1: The pipe with sudden contraction with sharp corners. Figure 2.1: Meshed profile Sudden Contraction pipe with sharp corners generated in GAMBIT. Case2: The pipe with sudden contraction with round corners Figure 2.2: Meshed profile Sudden Contraction pipe with round corners generated in GAMBIT. Case3: The pipe with sudden enlargement with sharp corners http://www.ijettjournal.org Page 205 International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 4- July 2015 C. Solver, Material Selection & Operating Condition Defining in Fluent: Figure 2.3: Meshed profile Sudden Enlargement pipe with sharp corners generated in GAMBIT. Case4: The pipe with sudden enlargement with round corners The solver is defined first. Solver is taken as pressure based and formulation as implicit, space as 2D and time as unsteady. Velocity formulation as absolute and gradient options as Green-Gauss Cell based are taken. Energy equation is taken into consideration. The viscous medium is also taken. First the analysis is carried using laminar flow and then the k-epsilon is considered. 2 results are to be found out. The selection of material is done. Material selected is water-liquid. The properties of Water -liquid is taken as followsi. Density = 998.2 kg/m3 ii. Cp (specific heat capacity) = 4182 J/kg K iii. Thermal conductivity = 0.6W/m K iv. Viscosity =0.001003 kg/m s The analysis is carried out under operating conditions of 101325 Pascal. Gravity (981 mm/sec 2) is taken into consideration. D. Boundary Conditions: 1. Figure 2.4: Meshed profile Sudden Enlargement pipe with round corners generated in GAMBIT. B. Fluent Analyses. FLUENT is the software used for modeling fluid flow and heat transfer in complex geometries. It provides complete mesh flexibility, including the ability to solve your flow problems using unstructured meshes that can be generated about complex geometries with relative ease. It is written in the C computer language and makes full use of the flexibility and power offered by the language. Consequently, true dynamic memory allocation, efficient data structures, and flexible solver control are all possible. All functions required to compute a solution and display the results are accessible in FLUENT through an interactive, menu-driven interface. The basic procedural steps for solving a problem in FLUENT include: 1) Define the modeling goals. 2) Create the model geometry and grid. 3) Set up the solver and physical models. 4) Compute and monitor the solution. 5) Examine and save the results 6) Consider revisions to the numerical or physical model parameters, if necessary ISSN: 2231-5381 Fluid Fluid is taken as water-liquid. 2. Inlet Velocity inlet was taken for the nozzle inlet and the value of velocity inlet was taken as 2m/sec. Initial gauge pressure was taken as 101325 Pascal. Temperature was taken as 500K. 3. Outlet The diffuser was set as outflow and the flow rate as 1. 4. Wall In wall, the motion of wall is selected as stationary wall. 5. Controls Set Up The solution is set as listed below. The under relaxation factor was set as givenPressure-0.3 Density-1 Body forces-1 Momentum-0.7 Pressure Velocity Coupling was taken as SIMPLE Discretization Equation are selected as givenPressure- Standard Momentum- First Order Upwind Energy- First Order Upwind (For turbulent flow Power Law was taken into Consideration) 6. Initialization Solution initialization is done. Initial values of velocity are taken as 2m/sec along all zones of direction. Temperature is taken as 500K. Residual Miniaturization is done and convergence criteria are set up. The convergence Criteria of various parameters are listed below. Continuity- 0.001 X-Velocity- 0.001 Y-Velocity- 0.001 http://www.ijettjournal.org Page 206 International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 4- July 2015 Z-Velocity- 0.001 Energy- 1e-06 The number of iterations is then set up and iterations starts. The iteration continues till convergence is reached. III RESULTS A. Flow Analysis in Sudden Contraction: (With Sharp corners): Figure 3.4: Sudden Contraction (Pressure Behaviour) Figure 3.1: Sudden Contraction (Velocity Figure 3.5: Sudden Contraction (Pressure Behaviour). Behaviour) Figure 3.6: Sudden Contraction (Turbulent Behaviour) Figure 3.2: Sudden Contraction (Velocity Behaviour) Figure 3.7: Sudden Contraction (Turbulent Behaviour). Table 3.1: Parameters. Figure 3.3: Vena Contracta. S.No. 1 2 3 ISSN: 2231-5381 Parameter Pressure (pascal) Velocity (m/s) Turbulent K.E (k) http://www.ijettjournal.org Min. Max. 92151.74 112316.3 0 5.021684 0.003131546 1 Page 207 International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 4- July 2015 Table 3.2: Mass Flow Rate. MASS FLOW RATE Default-Interior Inlet Outlet Wall Net B. (Kg/s) 79557.105 79856.001 -79854.269 0 1.7317627 Flow Analysis in Sudden Contraction: (With round corners of radius 5mm): Figure 3.12: Sudden Contraction (Turbulent Behaviour) Figure 3.8: Sudden Contraction (Velocity Behaviour) Figure 3.13: Sudden Contraction (Turbulent Behaviour). Table 3.3: Parameters. S.No. Figure 3.9: Sudden Contraction (Velocity Behaviour) Parameter Pressure (pascal) Velocity (m/s) Turbulent K.E (k) 1 2 3 Min. Max. 96756.22 110142.2 0 4.407094 0.004398072 1 Table 3.4: Mass Flow Rate. MASS FLOW RATE Default-Interior Inlet Outlet Wall Net C. Figure 3.10: Sudden Contraction (Pressure Behaviour) Figure 3.11: Sudden Contraction (Pressure Behaviour). ISSN: 2231-5381 (Kg/s) 104506.82 79856.001 -79855.961 0 0.039694196 Flow Behaviour in Sudden Enlargement (With Sharp corners): Figure 3.14: Sudden Enlargement (Velocity Behaviour) http://www.ijettjournal.org Page 208 International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 4- July 2015 Figure 3.19: Sudden Enlargement (Turbulent Figure 3.15: Sudden Enlargement (Velocity Behaviour) Behaviour). Table 3.5: Parameters. S.No. 1 2 3 Parameter Pressure (pascal) Velocity (m/s) Turbulent K.E (k) Min. Max. 100426.9 101375.1 0 2.109524 0.002080848 1 Table 3.6: Mass Flow Rate. MASS FLOW RATE Default-Interior Inlet Outlet Wall Net Figure 3.16: Sudden Enlargement (Pressure Behaviour) D. (Kg/s) 199345.33 39928 -39928.963 0 -0.96245855 Flow Analysis in Sudden Enlargement: (With round corners of radius 5mm): Figure 3.17: Sudden Enlargement (Pressure Figure 3.20: Sudden Enlargement (Velocity Behaviour) Behaviour). Figure 3.18: Sudden Enlargement (Turbulent Figure 3.21: Sudden Enlargement (Velocity Behaviour) Behaviour) ISSN: 2231-5381 http://www.ijettjournal.org Page 209 International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 4- July 2015 Table 3.8: Mass Flow Rate. MASS FLOW RATE Default-Interior Inlet Outlet Wall Net E. (Kg/s) -398294.2 39928 -39928.772 0 -0.77170309 Comparison Of Velocity’s For Different Geometry’s: Figure 3.22: Sudden Enlargement (Pressure Behaviour) Figure 7.5.1: Comparison Figure 3.23: Sudden Enlargement (Pressure Behaviour). A Sudden Contraction with sharp corners. B C D Sudden Contraction with round corners. Sudden Enlargement with sharp corners. Sudden Enlargement with round corners. IV THEORITICAL CALCULATIONS (Sudden Contraction Pipes): Let, D1 be the diameter of cross-section area 1 = 0.04m Figure 3.24: Sudden Enlargement (Turbulent D2 be the diameter of cross-section area 2 = 0.02m Behaviour) The inlet velocity V1 =2m/sec Area A1=1.257*10-3m Area A2 =0.314*10-3m Outlet velocity V2=? By applying Continuity equation A1V1=A2V2 V2= A1V1/ A2 V2 =8.0063 m/sec Figure 3.25: Sudden Enlargement (Turbulent Behaviour). Head loss = 0.5 Table 3.7: Parameters. S.No. 1 2 3 Parameter Pressure (pascal) Velocity (m/s) Turbulent K.E (k) ISSN: 2231-5381 = Min. Max. 99371.92 101325.8 0 2.115486 0.002659606 1 = m of water. Experimental Calculations: By using FLUENT software, Velocity outlet = 4.58 m/sec. http://www.ijettjournal.org Page 210 International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 4- July 2015 Velocity inlet = [6] Colebrook C.F.,―Turbulent Flow in Pipes with Particular 2 m/sec. reference to the Transition Region between the Smooth and Rough Head loss = Pipe Laws‖, J. Inst. of Civil Engrs.N° 11,(1939), pp.133-156. [7] Bhave, P.R.,―Analysis of flow in water distribution networks‖, pp.25-68 Technomic = 0.5 Pub. Co., Inc., USA, (1991). = 0.53 m of water. [8] Rouse H., ―Evaluation of Boundary Rough Proc.2nd Hydraulic. Conf., Bulletin N° 27, Univ. of Lowa, Lowa City, (1943). After making Round Corners Velocity inlet = 2 m/sec. Velocity outlet = 4.33 m/sec [9] Moody L.F., ―Friction Factors for Pipe Flow‖, Trans. American Society of Mechanical. Engineers. No. 66, (1944), pp. 671-684. [10] Head loss = Hazen-Williams Formula http://www.pipeflow.com/pipe- pressure-drop-calculations/ pipe-friction-loss (12/15/2011) [11] Ansys, Inc. http://http://www.idac.co.uk/products/downloads/ Meshing.pdf =0.5 [12] Tobias Zitzmann1, Malcolm Cook2, Peter Pfrommer1, Simon = 0.47 m of Rees2, Ljiljana Marjanovic2, ―Simulation Of Steady-State Natural Convection Using CFD‖ Ninth International IBPSA Conference water. Montréal, Canada [13] V. CONCLUSION: From the above analysis, it is observed that the flow is severely disrupted if there are contour changes occurring in the downstream flow in the pipe. Sudden enlargement creates more severe formation of flow eddies than sudden contraction. Also, the losses are more at the point where the enlargement in the pipe begins. In the sudden contraction, vena contracta’s are formed at the point of contraction and this point is the most susceptible point for pipe damage. So, to increase the life of the pipe in cases of sudden contraction the pipes must be designed in view of the above observations making the corners more rounds so as to minimize the losses in the pipes To conclude, this examination results indicate that FLUENT can be used with high degree of accuracy to visualize the minor or singular head losses due to minor appurtenances and accessories present in a pipe network. JONAS BREDBERG http://www.tfd.chalmers.se/~lada/postscript_files/ jonas_report_lowre.pdf REFERENCES: [1] Lahiouel Y., Haddad A., Khezzar L., Chaoui K., Kondratas A.,―Development of method of routing fluid distribution networks‖, J. Mechanica, Vol. 43, N° 4, (2003), pp. 27-34. [2] Lahiouel Y., Haddad A., Chaoui K., ―Evaluation of head losses in fluid Transportation networks Sciences & Technologies B – N°23, juin (2005), pp. 89-94 [3] Weisbach J. ―Die Experimental Hydraulik‖, Freiberg, Germany: Engelhardt, (1855). [4] Darcy Weisbach Formula http://www.pipeflow.com/pipepressure-drop-calculations/ pipe-friction-loss (12/15/2011) [5] Nikuradse J., 1933, ―Strmungsgesetze in Rauben Rohren‖, pp 361, Verein Deutsher Ingenieure, Forschungsheft, (1933). ISSN: 2231-5381 http://www.ijettjournal.org Page 211