Enhancement of Machine Utilization by Using Digital Manufacturing

advertisement

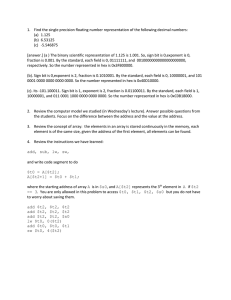

International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 5- June 2015 Enhancement of Machine Utilization by Using Digital Manufacturing Putta Priyanka¹ Dr. G. Amarendar Rao² Department of Mechanical Engineering VBIT, Hyderabad, Telangana, INDIA ABSTRACT Digital manufacturing or virtual machining Tool Kit will be a one stop solution right from operation creation, post process to NC validation with real time Machine simulation. Digital manufacturing is an off-line tool for detailed analysis and optimization of NC programs. Depending on the batch size (job-shop or large-volume), reduction of setup times or shortening of cycle times are two major benefits. Digital manufacturing enables the user to identify and realize potential savings in machining processes at an early stage. In Digital manufacturing any NC program can be validated and optimized according to the requirement. This optimization results in reduction of setup time, manufacturing cost, collision detection and finally increases machine utilization. In this project to validate virtual machine, steering knuckle is taken as case study. In automotive suspension, a steering knuckle is that part which contains the wheel hub or spindle, and attaches to the suspension components. In manufacturing environment before development of digital manufacturing operators used to generate NC program manually or by using postprocessors, this generated NC program is fed to machine directly or through DNC (direct numerical control) lines for CNC machines. The generated NC program using postprocessor or by manually result in dimensional error of component, collision of part and spindle, tool and work table or spindle and worktable. Collisions leads to breakage of component or tool sometimes results badly as damage to machine. The generated NC program will be edited manually to obtain component as customer required and trails are also done for modified NC program to find whether this modified NC program will produce the component as customer requirement. There are some collisions due to error in NC program or by considering wrong tools. Below images shows spindle-part collision due to length of the tool and tool-part collision. Tool breaks the part and damages due to error in NC program. Aim of the project is to develop virtual machine of DMG 5-axis using NX software and validate machine by taking steering knuckle component as case study. Keywords: Digital Manufacturing, 5-axis milling machine, steering knuckle, Machine tool builder, UNIGRAPHICS. I. Fig1. collision of spindle and part INTRODUCTION Manufacturing Process before Development of Digital Manufacturing: Fig 2. Breakage of work piece ISSN: 2231-5381 http://www.ijettjournal.org Page 237 International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 5- June 2015 To avoid this collisions digital manufacturing process is developed to check the generated NC program before fed to machine. The complete manufacturing process is examined in digital manufacturing process and collisions are detected and modifications in NC program are done. Finally modified NC program is given to machine these results in reduction of manufacturing errors. Fig.3 Final Assembly of DMG 5 axis CNC milling machine II. METHODOLOGY Virtual Machine Tool Kit will be a one stop solution right from operation creation, post process to NC validation with real time Machine simulation. VIRTUAL KIT is an off-line tool for detailed analysis and optimization of NC programs. Depending on the batch size (jobshop or large-volume), reduction of setup times or shortening of cycle times are two major benefits. VIRTUAL KIT enables the user to identify and realize potential savings in machining processes at an early stage. PROCESS TO SET UP AN ISV SCENARIO RUNNING TOGETHER WITH DMG_MILL_5AX Building a directory for the machine tool resources NX has 2 places (directories) for storing the machine tool data: One for the resources (geometries, Post Processor files etc.) and another one for the ready-to-use machines including kinematics structure and other settings. We will build the machine model in the resources and will copy it later into the other directory. By default the resource directory is located in the installation directory of UG NX, such as …..\NX 7.5\MACH\resource\library\machine\instal led_machines Create a new folder in the installed_machines library and name it DMG_mill_ 5ax Create a subdirectory called graphics and another subdirectory named postprocessor so that the structure looks like this: 3D MODELING OF VIRTUAL KIT Fig4. List of all geometry part file of the DMG_mill_ 5ax My project deals with the virtual machining of 5-axis DMG milling machine The related cse_driver folder needs to be copied from one of the existing installed machine tools. Copy all geometry part files into the \graphics subdirectory ISSN: 2231-5381 http://www.ijettjournal.org Page 238 International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 5- June 2015 The location of the geometry files is assigned in the machine database later on. We will define a directory name which clearly identifies the machine tool (DMG_mill_ 5ax). Kinematics to the Geometric Model Now that we have built up the geometric structure of the model we have to define in which way the different components of the machine will move later on when we are going to simulate the machining process. Basically the kinematics definition procedure can be split in 4 areas: Definition of kinematics components (k-components) which are placeholders for further kinematics information. K-components are nodes in the kinematics tree Definition of junctions for the kcomponent. A junction or coordinate system defines the location and orientation of all components referring to that coordinate system. By way of example the junction of the fixture defines how the cam part is mounted. Selection of axes for determining the moving direction of the k-component. Axes can be regarded as one of the properties of k-components. Axes are selected according to the respective junctions. Classification of k-components. By assigning classes for the components a proper handling of the collision calculation and other information will be achieved later. Let’s build the kinematics for the current example: Select menu Start → All Applications → Machine Tool Builder Open the Machine Tool Navigator, click twice on the item NONAME and change the name to "DMG_mill_ 5ax" Highlight this name and open the context menu by clicking with the right mouse button. ISSN: 2231-5381 Select Insert → Machine Base Component In the Create K-component Dialog, press Add to add the geometry. Select the geometry of the machine (BED) directly in the graphics window. Use the Class selection dialog to apply the classification “MACHINE_BASE" Below image shows getting in to machine tool builder Fig.5. Getting in to machine tool builder Next step is to add a junction with a specified name. This will be the basic junction for further handling of components in the machine model. Select the item MACHINE_BASE, click the right mouse button and select →Junctions →Add. Enter the designation “MACHINE_ZERO” as name. Leave the dialog open and define a coordinate system. In the current case the zero coordinate system is located at the intersection of the vertical axis of the B_rotary table and the horizontal axis of the fixture (part holder). For the orientation it is a rule that the Z-axis is always pointing towards the tool. In principle the orientation of the X and Y axis are arbitrary but you should always contact the machine tool documentation for the exact definition for orientation and position of the machine zero. Change the selection scope to “Entire Assembly” if not already done. This makes sure that you can select all components inside the graphics. http://www.ijettjournal.org Page 239 International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 5- June 2015 Measure the distance between the centre of the B_ROTARY component and the centre of the C-axis_Rotary (refer to the assembly navigator). Activate the information window when the measurement is done. (Results Display→Show Information) Read the Delta in Z-direction which is 85 mm. Place the coordinate system at the centre of the fixture, then make an adjustment of 85 mm in z-direction. Be sure that Z is pointing towards the tool (away from the fixture) Select OK to complete the junction definition. Below image shows creating junction to machine base component Fig. 6. creating junction to machine base component Below image shows display of the machine zero junction and classification of the machine zero junction “Classify”. Select “Machine Zero” as classification. The next task is the definition of further k-components for building the kinematics chain. Be sure to keep in mind the two major rules for kinematics definition: Every component or assembly that can move has to be a separate kinematics component If the component or assembly which you are defining is itself mounted on another moveable component / assembly then the latter one has to precede the first one in the kinematics chain. If you click on the respective components in the assembly navigator you can identify the machine components. MACHINE CONFIGURATION MOVEMENT AXIS LIMITS 1. X SPINDLE X = 880 to -220 2. Y SPINDLE Y = 630 to 0 3. Z TABLE Z = 0 to -630 4. B SPINDLE B = +30 to -120 5. C TABLE C = 360deg FINAL KINEMATIC MACHINE MODEL: This is the required CNC machine model with kinematics given to x-slide ,y-slide, table rotary and spindle. Fig7. Display of the machine zero junction and Classification of the machine zero junction With the Junction definition dialog still open highlight the item MACHINE_ZERO and click ISSN: 2231-5381 Fig.8. Final Kinematic Machine Model Adding the Machine To Machine Database: Machine data base file is located in …\ProgramFiles\UGS\NX7.5\MACH\ http://www.ijettjournal.org Page 240 International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 5- June 2015 resource\library\machine\ascii\ machine_database.dat Fig.11. postprocessor input window Fig.9. machine data base file III. POST PROCESSOR: For every CNC machine there will be a specified post processor to generate NC program. Postprocessor is created using post builder application. Process to open post builder Start all programs UGS NX7.5 manufacturing tools post builder File new postprocessor specify name of the processor going to create and specify all required data. Fig.10. creating new postprocessor The below image shows generated Post processor of DMG_mill_5ax. Specify all required machine specifications to generated postprocessor for virtual kit DMG_mill_5ax. 3 Post processor files will be generated as def, tcl, pui DMG_mill_5ax.PUI: Post User Interface file (.pui) used by post builder to edit the event handler (.tcl) and definition files (.def).This file contains static information on how to write out the .tcl file. DMG_mill_5ax.TCL: Tool Command Language or Event handler (.tcl) contains a set of instructions dictating how each event type is to be processed. Post also uses this file at run time to generate NC code. DMG_mill_5ax.DEF: Definition file (.def) This file defines all the static information for the postprocessor. This includes formats, address and NC blocks. This file is used by Post to postprocess the tool path and generate NC code. DMG_mill_5ax.CDL: User defined events and machine control events are how NX sends messages to the postprocessor that are outside of the normal tool path messages. this would be a message to turn on high pressure coolant or unclamp a rotary axis. These events are added to a program using the User Defined Events. The below image shows Post processor files of DMG_mill_5ax. Fig.12. Post processor files of DMG_mill_5ax ISSN: 2231-5381 http://www.ijettjournal.org Page 241 International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 5- June 2015 This generated file should be pasted in DMG_mill_5ax postprocessor which is located in C folder installed machines. Along these 3files another .cdl file is generated, paste .cdl file in user_def_event. 3d Model of Steering Knuckle The below image shows installed machine folder. Fig.15 final 3D model of Steering Knuckle COMPUTER AIDED MANUFACTURING (CAM) Fig.13. installed machine folder The below image shows user_def_event folder. Along these 3files another .cdl file is generated, paste .cdl file in user_def_event. The generation of tool path on 3D model of Steering knuckle will be done using NXCAM software. By generating tool path NC program will be generated. This NC program is given input to the CNC machine to run operations. The main objective of the project is to obtain to reduce machining errors and collision of tools and rotary table by developing virtual kit. Methodology knuckle Fig.14. user_def_event folder This post process files helps virtual machine to run according to generated NC program and shows exact simulation of machine. Errors and collisions can be detected while simulation of virtual machine is going on, NC program will be edited to remove collisions and errors according to the simulation of tools and part. of manufacturing Steering Identify suitable machine. Selecting suitable tools for manufacturing Steering knuckle component. Selection of fixture. Listing down the Sequence of operation performed on Steering knuckle component. Generating tool path at specified cutting speed. Retrieving virtual machine in NXCAM and simulating machine. Verification of machining process in virtual machine simulation. Generating NC program using NX-CAM software. ISSN: 2231-5381 http://www.ijettjournal.org Page 242 International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 5- June 2015 SEQUENCE OF OPERATIONS PERFORMED ON STEERING KNUKCLE DRILLING_ Drilling TOOL Tool DRILLING_ Drilling TOOL_D Tool DRILLING_ Drilling 7.5000 118.0 35.00 000 00 Setup_1 Face milling 3.0000 118.0 35.00 000 00 Planar milling Fixed contour TOOL_D3.58 Tool 3.5800 118.0 35.00 000 00 Spot drilling Drilling DRILLING_ Drilling TOOL_D2 Tool DRILLING_ Drilling TOOL_D2.1 Tool DRILLING_ Drilling 2.0000 118.0 35.00 000 00 Setup_2 Face milling 2.1200 118.0 35.00 000 00 Planar milling Spot drilling TOOL_D1.22 Tool 1.2200 118.0 35.00 000 00 Drilling DRILLING_ Drilling TOOL_D3 Tool DRILLING_ Drilling TOOL_1 Tool DRILLING_ Drilling TOOL_2 Tool 3.0000 7.5000 3.0000 118.0 35.00 000 00 118.0 35.00 000 00 118.0 35.00 000 00 MILLING TOOLS Fig.16 Final cam part TOOL NAME DESCRIP TION DIAMETER COR FLUTE RAD LEN TOOLING LIST MILL DRILLING TOOLS TOOL DESCRIPT DIAME TIP NAME ION SPOTDRILLI Drilling NG_TOOL Tool ISSN: 2231-5381 TER 2.0000 ANG FLUT MILL_1 E Tool Milling Tool 20.0000 0.0000 50.0000 20.0000 0.0000 50.0000 3.6000 0.0000 50.0000 LEN 120.0 35.00 000 Milling MILL_2 Milling Tool 00 http://www.ijettjournal.org Page 243 International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 5- June 2015 BALL_ MILL MILL_3 MILL_4 MILL_5 MILL_6 MILL_7 MILL_8 MILL_9 MILL_10 MILL_11 MILL_12 MILL_D4 MILL_13 MILL_14 Milling Tool Tool-Ball 3.4000 1.7000 50.0000 Mill Milling Tool Milling Tool Milling Tool Milling Tool Milling Tool Milling Tool Milling Tool Milling Tool Milling Tool Milling Tool Milling Tool Milling Tool Milling MILL_15 4.0000 0.0000 50.0000 MILL_16 3.0000 0.0000 50.0000 MILL_17 12.0000 0.0000 50.0000 10.0000 0.0000 50.0000 3.0000 0.0000 50.0000 8.0000 0.0000 50.0000 5.0000 0.0000 50.0000 2.4000 0.0000 50.0000 4.0000 0.0000 50.0000 Milling Tool Milling Tool Milling Tool 3.0000 0.0000 50.0000 2.4000 0.0000 50.0000 4.0000 0.0000 50.0000 Integrated Simulation Verification process Fig 17. Dialog to load objects like machine tool, tool or devices from the library 6.0000 0.0000 50.0000 4.0000 0.0000 50.0000 10.0000 0.0000 50.0000 2.0000 0.0000 50.0000 ISSN: 2231-5381 Creating the machining scenario For building a complete simulation scenario where the machine is simulated it is expected that a CAM part which already has some operations defined so that the tool path can be generated. Furthermore this method requires that the machine is a member of the machine tool library, this is true for our sample. Open the CAM sample part in NX. It is called cam_sample.prt and has some common parts in a subdirectory. http://www.ijettjournal.org Page 244 International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 5- June 2015 Time taken to manufacture steering knuckle Below image shows only machining time of steering knuckle with defined speed and feed ISSN: 2231-5381 http://www.ijettjournal.org Page 245 International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 5- June 2015 Tool used before collision Simulation verification Tool used after collision detection Fig. 18 Simulation verification to check the errors developed while machining the component Collision of spindle and fixture when spindle is tilted to 90 deg for milling operation Fig.19 Simulation verification Again the same operation is verified to check whether collision is occurs with new tool. Remedy for collision is to increase tool length. Flute length and total length of the tool is increased to overcome collision of spindle and fixture Fig.20. No collision observed with new tool ISSN: 2231-5381 http://www.ijettjournal.org Page 246 International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 5- June 2015 Collision occurred between spindle house and rotating work table while doing fixed contour operation. Below image shows the fixture used after collision detection to avoid the collision between spindle house and work table Fig.21 Collision occurred between spindle house and rotating work table Remedy to overcome from this collision is to increase the fixture height. Below image shows the fixture used before collision Fig.23. 2D input and 3D model of new fixture Fig.24. Remedy to overcome from this collision is to increase the fixture height Machine vice is fixed on the work table along with fixture and raw material of steering knuckle to increase the height of fixture. Fig.22. 2D input and 3D model of fixture ISSN: 2231-5381 http://www.ijettjournal.org Page 247 International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 5- June 2015 Manufacturing time of steering knuckle after virtual simulation verification ISSN: 2231-5381 http://www.ijettjournal.org Page 248 International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 5- June 2015 SET UP Product cost reduction, Reduction of setup times Milling&drill ing operations TIME REQUIR ED IN MINS. Manufacturing component on CNC machine without virtual simulation Milling 279 RS.1000/HR RS.4650 Drilling 3 RS.800/HR RS.40 TOTAL 282 IV. RESULTS The component directly machined on the CNC machine with trial and error and after each operation machine will be stopped and inspection will be done this increases manufacturing time of the part and as well as increases cost and reduces machine utilization. Time and cost calculation for manufacturing steering knuckle as shown below including setup time and manual modification of NC program on CNC machine. Manufacturing time taken component= 4hrs 42min by single Machining cost per operations = 1000rs hour for milling Machining cost per operations = 800rs hour for drilling Machining cost per piece for milling operations (machining cost per min x machining time in min) = 1000/60*279 min= 4650 rs Machining cost per piece for drilling operations (machining cost per min x machining time in min) = 800/60*3 min= 40 rs Total machining cost per piece= milling + drilling= 4650 + 40 = 4690 rs Table 1: time and machining cost of MACHINING COST MACHINING COST/PIECE PER HOUR RS.4690 Manufacturing component on machine with virtual simulation CNC There is no time waste for trial and error operations on machine and time consumption will be less because every operation is virtually verified and modification will be done in software itself. Speed and feed is increased along depth of cut to reduce machining time. Increased parameters are verified using virtual simulation. This reduces setup time and product cost. Manufacturing time taken by single component= 3hrs 9min Machining cost per operations = 1000rs hour for milling Machining cost per operations = 800rs hour for drilling Machining cost per piece for milling operations (machining cost per min x machining time in min) = 1000/60* 186min= 3100 rs Machining cost per piece for drilling operations (machining cost per min x machining time in min) = 800/60* 3min= 40 rs Total machining cost per piece= milling + drilling= 3100+40 = 3140 rs operation without VMS ISSN: 2231-5381 http://www.ijettjournal.org Page 249 International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 5- June 2015 Table 2: time and machining cost of operation with VMS SET UP Milling&dri lling operations Milling TIME REQUI RED IN MINS. MACHIN ING COST MACHIN ING COST/PI ECE 186 RS.1000/ HR RS.3100 RS.800/H R RS.40 Drilling 3 TOTAL 189 5000 4000 3000 2000 1000 0 which reduces machine idle time and increases machine utilization. Table 3: cycle time with and without VMS NO.OF PARTS cycle time(hrs) without VMS cycle time(hrs) with VMS 50 235 157.5 100 470 315 150 705 472.5 200 940 630 250 1175 787.5 300 1410 945 350 1645 1102.5 400 1880 1260 RS. 3140 4690 3140 282 189 without virtual simulation TIME (min) with virtual simulation VMS = virtual machining simulation COST (rs) Optimization of cycle times GRAPH 2000 Manufacturing time taken by single part in mins = 282mins Cycle time (hrs) with VMS= no.of parts x manufacturing time taken by single part in hrs. Manufacturing time taken by single part in mins = 189mins 1800 1600 cycle time in hrs Optimization of cycle times Cycle time (hrs) without VMS= no.of parts x manufacturing time taken by single part in hrs. 1400 1200 1000 cycle time(hrs) with out VMS 800 cycle time(hrs) with VMS 600 400 200 0 50 150 250 350 no.of parts Cycle time is optimized by using virtual simulation. In virtual simulation complete manufacturing process can be checked and verified in offline if any modification in NC program will be edited in software itself ISSN: 2231-5381 http://www.ijettjournal.org Page 250 International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 5- June 2015 Increase in machine utilization The values are directly taken when component is manufacturing on the machine without virtual simulation. First component on CNC machine is run in block mode, means component is inspected after every operation by stopping machine. At that time machine is idle which decreases machine utilization. Table 4: machine utilization with and without VMS Single part Machine Machine manufacturing utilization utilization with time without VMS VMS (min) (min) Total time Machine cutting 4hrs 42min 3hrs 9min 3hrs 28min 2hrs 48min 1hr 14min 21min time Machine idle time Total manufacturing time is reduced by 33% Machine idle time and machine utilization time are inversely proportional. When idle time is reduces then machine utilization time will increases. Machine utilization is increased by 71% V. CONCLUSION By developing virtual machine, spindle house and work table collision is detected, spindle and fixture collision is detected. Remedy for this collisions is done in software itself by increasing tool length and changing fixture. Manufacturing time taken for steering knuckle without virtual simulation verification and with virtual simulation verification is shown in results by plotting graphs as well as optimization of cycle time and machine utilization also shown in results. Finally concluding using virtual simulation process will benefits small scale and large scale ISSN: 2231-5381 industries investment for this process is very less and results in more profits for industries. REFERENCES 1. Development of Virtual Machine Tool for Simulation and Evaluation Volume 8 Number 6 Pages 849-858, DOI: 10.3722/cadaps.2011.849-858. 2. Research of Virtual Machine Based on UG and VERICUT, Applied Mechanics & Materials;2014, Issue 644-650, p782 3. Fredin J., Wall J., Jönsson A. & Broman G., A robust motor and servo drive model for real-time machine tool simulation, in: Proceedings of the 19th European Modeling and Simulation Symposium (EMSS 2007),Bergeggi, 4-6 October, 2007 4. Damien Chablat, Peer-Oliver Woelk VIRTUAL MANUFACTURING Tools for improving Design and Production. 5. P. Depinc ´ e, E. Noel, P.O. Woelk 2004 THE VIRTUAL MANUFACTURING CONCEPT: SCOPE, SOCIO-ECONOMIC ASPECTS AND FUTURE TRENDS. ASME 2004 Design Engineering Technical Conferences and Computers and Information in Engineering Conference September 28-October 2, 2004, Salt Lake City, Utah, USA. 6. E. Raj Kumar, K.Annamalai AN OVERVIEW OF VIRTUAL MANUFACTURING WITH CASE STUDIES International Journal of Engineering Science and Technology Vol. 3 Apr 2011. 7. Marinov V., What Virtual Manufacturing is? Part I: Definition, 13 October 2000, <bosphorus.eng.emu.edu.tr/vmarinov/VM/VMdef.ht m> 8. Marinov V., What Virtual Manufacturing is? Part II: The Space of Virtual Manufacturing: October 2000, <bosphorus.eng.emu.edu.tr/vmarinov/VM/VMspace .htm> 9. Iwata K., Onosato M., Teramoto K., Osaki S. A., Modeling and Simulation Architecture for Virtual Manufacturing System, Annals CIRP, 44, 1995, pp. 399-402 10. Lee D.E., Hahn H.T., Generic Modular Operations for Virtual Manufacturing Process, Proceedings of DETC’97, ASME Design EngineeringTechnical Conferences, 1997. 11. BowyerA., Bayliss G., Taylor R., Willis P., A virtual factory, International Journal of Shape Modeling, 2, N°4, 1996, pp215-226. 12. Lin E., Minis I., Nau D.S., Regli W.C., The institute for System Research, CIM Lab, 25 March 1997, www.isr.umd.edu/Labs/CIM/vm/ vmproject.html http://www.ijettjournal.org Page 251