Document 12913230

advertisement

International Journal of Engineering Trends and Technology (IJETT) – Volume 27 Number 5 - September 2015

PV Based Resonant Two Inductor Boost Converter for

Induction Machine Drive Application

1

Praveen Sebastian, 2Jomole Joseph

Mar Baselios College of Engineering, Electrical and Electronics Engineering

2

Assisstant Professor, Electrical and Electronics Engineering, Mar Baselios College of Engineering

Kerala university

1

Abstract— A new converter is designed to drive an

induction motor directly from PV energy. The

developed system is based on a current-fed multi

resonant converter for achieve zero current

switching. It is also known as resonant two-inductor

boost converter (TIBC) and a three-phase voltage

source inverter. The classic topology of the TIBC has

features like high voltage gain and low input current

ripple. The topology is further improved with the use

of a non isolated recovery snubber. The converter

output is fed to a three phase ac motor via a three

phase inverter.

condition for the input switches and output rectifying

diodes and this enables the converter to operate at

high frequency with greater efficiency.

This paper introduce a new DC-DC converter for

photovoltaic water pumping systems. The

arrangement will be in the form section II gives

detailed description about solar system III gives

detailed description about proposed system, detailed

working of converter is presented in section IV

control part in section V; simulation results in section

VI

II.SOLAR SYSTEM

Keywords— photovoltaic

converter, AC motor drives

I.

power

system,

tibc

INTRODUCTION

In conventional PV based drive systems boost

converter and low voltage DC machine is used. Input

current ripple in the boost converter fed drive system

is higher and DC motor have lower efficiency and

higher maintenance cost compared with Induction

machine. To avoid these problems two inductor boost

converter fed induction machine drive system was

introduced. Input current ripple is less but power

regulation range is reduced[2]. The two inductor

boost converter exhibits benefits in high power

applications and high input current is split between

two inductors, thus reducing power loss in both

copper windings and primary switches. Maintain

power regulation range in the TIBC converter fed

induction machine drive system an auxiliary

transformer is introduced. But they still have

problems with high voltage spikes created due to

leakage inductance of the transformer and high

voltage stress on the rectifying diodes[1]. The

solution to the current fed PWM converter is use of

resonant topologies able to utilize the component

parasitic characteristics such as the leakage

inductance and winding capacitance of transformers

in a productive way to achieve the zero current

switching(ZCS) or zero voltage switching(CVS)

condition. Modified resonant two inductor boost

converter is introduced for PV based drive system

due to its very small no of components, simplicity,

high efficiency, easy transformer flux balance and

common ground gating driving for both switches[3].

Input current is distributed through the two boost

inductors having its current ripple amplitude halved

at twice the PWM frequency. TIBC can be modified

to multiresonant converter to achieve zero current

ISSN: 2231-5381

A solar cell is the building block of a solar

panel. A photovoltaic module is formed by

connecting many solar cells in series and parallel.

Considering only a single solar cell; it can be

modeled by utilizing a current source, a diode and

two resistors[4]. This model is known as single diode

model of solar cell. Two diode models are also

available but only single diode model is considered

here

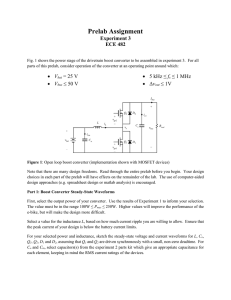

Fig 1: Single diode model of a solar cell

The characteristic equation for a photovoltaic cell is

given by

Iph= Iscr+ Ki (T-298)*ƛ ⁄1000

Where,

Irs=Iscr⁄([exp(qVoc/(Ns kAT))-1])

Io

I rs [

T 3

Ego

1

] exp[ q *

]{

Tr

Bk

Tr

Ipv=Np*Ipv-Np*Io[exp〖{(q*(Vpv+IpvRs

1

}]

T

))/(Ns

AkT)}-1]〗

I & V : Cell output voltage and current

Ios : Cell reverse saturation current

T : Cell temperature in celsius

-19

k : Boltzmann's constant, 1.38 * 10

http://www.ijettjournal.org

J/K;

Page 254

International Journal of Engineering Trends and Technology (IJETT) – Volume 27 Number 5 - September 2015

-23

q : Electron charge, 1.6*10 C;

Ki : Short circuit current temperature coefficient at

Iscr;

Iscr : Short circuit current at 25 degree Celsius;

Ilg : Light-generated current;

Ego : Band gap for silicon;

A : Ideality factor;

Tr :Reference temperature;

Ior : Cell saturation current Tr;

Rsh : Shunt resistance;

Rs : Series resistance;

The characteristic equation of a solar module is

dependent on the number of cells in parallel and

number of cells in series[4]. It is observed from

experimental results that the current variation is less

dependent on the shunt resistance and is more

dependent on the series resistance.

PV module models are implemented as

masked subsystems in Simulink. Inputs are PV

current and insolation and outputs are PV voltage and

PV power. Matlab M-file program written inside

matlab function to obtain PV current as output with

voltage, irradiation and temperature as inputs.

Filter capacitors are electrolytic so it will affects the

life time of the converter

Current fed converters have some

advantages they are it have high step-up voltage ratio

and reduces transformer turns ratio but its

disadvantages are high voltage stress due to leakage

inductance of transformers and high high voltage

stress on rectifying diodes. This disadvantages can be

overcome by the use of resonant topology. There for

the converter will modified as resonant converter.

The component parasitic parameter like the leakage

inductance and winding capacitance of transformer in

a fruit full way to achieve zero current

switching(ZCS) or zero voltage switching(ZVS)[6].

Table 1.Electrical characteristics data of solar 1.3 KW PV

module

Rated Power

1.3KW

Voltage at maximum power

87V

Current at maximum power

15.04A

Open circuit voltage

88.2V

Short circuit current

29.95 A

Total no of cells in series

10

Total no cells in parallel

8

Cell voltage(series)

8.82V

Cell voltage(parallel)

3.74V

Fig:2 simplified block diagram of water pumping system

III. PROPOSED CONVERTER

Proposed converter is designed for higher

efficiency application. Its advantages are high life

time, low cost and easy accessibility. This converter

design focused on single stage PV module. Fig.2

shows the basic block diagram of the system.

The energy from PV panel fed to induction

motor by two simple power stages. The TIBC

converter used here for boost the voltage from the PV

panel and Three phase inverter convert the DC

voltage from the converter to 3phase AC voltage.

The two inductor boost converter requires

large voltage conversion ratio because of low input

current ripple and low voltage nature of photovoltaic

panels. The commonly use voltage fed converter have

high input current ripple so filter capacitor needed[5].

ISSN: 2231-5381

Fig.3 shows the modified tibc topology. The main

parts are

resonant tank circuit, voltage doubler

rectifier and snubber circuit. Resonant tank circuit is

for achieving zero current switching or zero voltage

switching. By employing a voltage double rectifier at

the secondary terminal of the transformer as in

fig.3(b), it is possible to reduce voltage stress on the

MOSFETs to half of the orginal ones, transformer

turns ratio as well as necessary ferrite core can be

reduced. Finally as a result the transformers and

MOSFETs can be made cheaper and the no of diodes

in the secondary sides can be halved. Classically, the

TIBC have a minimum operation load to maintain an

established output voltage. Below a certain load level,

the energy transferred to the output capacitor is not

completely transferred to the load and causes an

increase in the output voltage[9]. This happens

because the inductors are charged even if there is no

output current. As a result, this converter has a

drawback when used in motor drive systems. Since

the motor is a variable load and it has large time

constants, it will demand low power at some

operation points. As a solution non dissipative

regenerative snubber circuit is presented shown in fig

3(c)..

http://www.ijettjournal.org

Page 255

International Journal of Engineering Trends and Technology (IJETT) – Volume 27 Number 5 - September 2015

Fig.3 Modified TIBC topology: (a) resonant tank (b)

voltage doubler rectifier (c) snubber

IV. OPERATION PRINCIPLE

Two Inductor boost converter have six operating

modes. The theoretical wave forms of these operating

modes are illustrated in fig.4. At time t1, the

rectifying diode Do1 is already conducting, and the

voltage on resonant capacitor Cr is clamped at +Vout/2.

At this instant, the switch Q1 is activated by VgQ1.

As the switch is turned ON, its voltage drops to zero,

and the snubber diode Ds1 is forced to stop

conducting. From t1 to t2, Cr transfers its energy to

the leakage inductance Lr, beginning the primary

switch’s resonant process and forcing the current IQ2

on the switch Q2 to decrease.

decrease until it reverses its polarity. When IQ2 is

negative, the switch can be turned off. This happens

at instant t3 when VgQ2 is forced to zero. At the time

t3, the voltage VdsQ2 starts to increase, Q2 is

completely blocked, and the snubber diode Ds2

begins to conduct, transferring energy directly to the

snubber capacitor Cs. Between t3 and t4, Cr and Lm

continue to resonate, decreasing the voltage on the

doubler rectifier’s input and on VCr. At instant t4, the

voltage across Cr reaches −Vout/2, and the rectifying

diode Do2 starts to conduct, clamping VCr in

−Vout/2. From t4 to t5, the capacitor Co1 is

charged, and the current Of Do2 starts to decrease.

At the instant t5, Q2 is turned on, initiating the

resonant process on Q1. As Q2 is activated, Ds2 is

forced to stop conduction. At the instant t6, the

current in Do2 reaches zero, and Do2 stops

conducting, reinitiating the resonance between Cr and

Lm. From this moment, until the end of the switching

period, the process repeats symmetrically as

explained for the other input switch. A simplified

methodology based on the effect of each resonant

process, the resonant frequencies, and the switching

frequency is applied. Matlab simulations and a

prototype is used to show that, despite the simplicity

of the design methodology, the correct operation of

the converter is guaranteed, particularly the soft

switching of the primary switches for the whole

operating load range. Although the resonant process

affects the output voltage, depending on the resonant

tank component values and the load, this can be

neglected because of its small influence and complex

effect.

Although the resonant process affects the

output voltage, depending on the resonant tank

component values and the load, this can be neglected

because of its small influence and complex effect.

Thus, neglecting the resonant effect over the output

voltage, including the voltage doubler rectifier and

the snubber connecting the primary and the secondary

side of the converter[1].

V.SYSTEM DESIGN

The static voltage gain (Kv) of the converter

is defined as

Vout

Vin

Fig.4 key wave forms of the tibc during switching

period

From t2 to t3, the primary switch’s

resonance (Q2) continues to force its current to

ISSN: 2231-5381

Kv

1

1

D

(2

Ns

Np

1)

where D represents the duty cycle of each

switch and must be higher than 50% to guarantee the

necessary overlapping for the correct operation.

Ns/Np represents the transformer turns ratio. To

minimize the influence of the load on the resonant

process on the primary current commutation interval,

the switching frequency (Fsw) should be higher than

http://www.ijettjournal.org

Page 256

International Journal of Engineering Trends and Technology (IJETT) – Volume 27 Number 5 - September 2015

the resonant frequency (Frs) of Lm and Cr by a value

of at least 1.1. Thus,

Frs

1

LmCr

2

RESONANT TANK CIRCUIT DESIGN

Fsw

1.1

1

Lm Lr

Cr

Lm Lr

(D

2

2

Lm 5.8 10

Fsw 1.1

80 103 /1.1

1

Lm

Frp

2

72727.27

9

456958.9314

9

1

5.8 10 9 Lm

0.5)

2.08811465

Fsw

2

8.25 10

1

Lr Cr

4

9

0.000825

Fsw

(2 D 1)

Lr 5.8 10

1

Lr 5.8 10 9

9

Lr 5.8 10

40 103

40 103

251327.4123

1

2

TON

10

1211.106497

1

The whole resonant process of the primary

switches has the duration of half a resonant cycle, as

shown in Fig. 4. To guarantee the ZCS condition for

the entire load range, the following conditions must

be satisfied:

9

40 103

1

6.31 1010

9

(5.8 10 Lr )

1

360.359

Lr

r

Frp

LmCr

1

LmCr

1

Lm

The duration of the commutation interval is

equal to the overlapping time (Tov) of the pulse

driving signals and can be calculated as

TON

2

5.8 10

1

Lr Cr

2

Lm Cr

1

Considering that Lm represents the

magnetizing inductance and Lr

represents the

leakage inductance, then Lm is much larger than Lr;

thus, can be simplified to

Frp

2

1

During the primary current commutation

interval, when both switches Q1 and Q2 are turned

on, inductor Lr participates on the resonance in

parallel with Lm and Cr; thus, the resonant frequency

for this interval is defined as

Frp

1

Frs

FSW

2D 1

Another important constraint is the energy

accumulated in Cr at the beginning of the primary

switching resonant process. This energy needs to be

completely transferred to the leakage inductance Lr

during this process. From this condition, the

following equation is derived:

Lr

2.729 10

3

2

Lr

V0

2

VO

Cr

2 I 2 in

ISSN: 2231-5381

http://www.ijettjournal.org

Page 257

International Journal of Engineering Trends and Technology (IJETT) – Volume 27 Number 5 - September 2015

The bus voltage which is defined using the

minimum necessary voltage for the inverter topology

and PWM strategy. Two inductor boost converter

switching frequency must be compromised between

the switching losses and the inductor as well as

transformer size. Switching frequency is usually

designed to be 80 KHZ, which is used in simulation.

During fixed duty cycle control in order to guarantee

overlapping conduction of MOSFETs, D is chosen to

be 53% based on the

minimum required overlapping and commutation

times of the MOSFT and the drivers selected

VI.SIMULATION RESULTS

The simulink model of PV based two

inductor boost converter connected to induction

motor is shown below

Fig 5. Simulink model of PV based TIBC connected

to induction motor

Fig 6 shows the gate voltages of two

switches. During fixed duty cycle control in order to

guarantee the overlapping conduction of MOSFETs,

D is chosen to be 53% based on the minimum

required overlapping and commutation times of the

MOSFET and the drivers selected.

Fig.6 Gate voltage waveforms

ISSN: 2231-5381

Table.2 Converter parameters

Parameters

Values

Inductance Li1,Li2,Li3

100µH

Capacitance C01,C02,C03

1.5µF

Cr

5.8nF

Lr

2.729mH

Lm

0.825mH

Switching frequency

80kHZ

The output of two inductor boost converter

settles at 415V. The simulation result of output of the

converter is shown below. Simulation result of input

of the DC to DC converter.

Fig 7 shows the output voltage of the DCDC converter.

Fig.7 output of the DC to DC converter

Fig 8 shows the simulation result of zero

current switching. From the simulation result it is

clear that both turn on and turn off occurs at zero

current switching.

Fig.8 Verification of zero current condition on the input

switch Q2

http://www.ijettjournal.org

Page 258

International Journal of Engineering Trends and Technology (IJETT) – Volume 27 Number 5 - September 2015

As can be seen, for an input DC voltage of

415V, the circuit produces 3phase ac voltage output

(fig .9).The output voltages of three phases are 120

degree apart from one another. Thus inverter action

was obtained. The filtered output voltage waveforms

of inverter are shown below in fig 10.

Fig 9 Output line voltage waveforms for 3 phase PWM

inverter with machine load

Fig.10 Filtered output voltage of inverter

Table.3 Machine parameters

PARAMETERS

VALUES

Rr

3.805

Rs

4.85

Lls

0.0062

Llr

0.0062

Lm

0.25

fb

50

p

4

J

0.03

Lr

Llr+Lm

Tr

Lr/Rr

wb

2*pi*fb

Xls

wb*Lls

Xlr

wb*Llr

Xm

wb*Lm

Xmstar

1/(1/Xls+1/Xm+1/Xlr).

Fig.12 shows three phase current,torque and speed of

the machine. The machine accelerates and come to

steady state at 0.5 sec with a small slip because of

inertia load. The machine is simulated by applying

415V three phase ac voltage at 50 Hz

With just inertia (TL=0).

Fig.11 complete dq model of induction

machine

The inputs of a Induction machine are the

three-phase voltages, their fundamental frequency

and the load torque. On the other hand the outputs are

the three-phase currents, the electrical torque and the

rotor speed. The machine parameters of 2Hp

induction machine is used for simulation.

ISSN: 2231-5381

Fig.12 Three phase currents ,torque and speed of induction

machine

When TL= 10 Nm, at steady state Te approaches TL,

rotor speed reduces due to loading with ὡe =313

rad/sec and ὡr = 299rad/sec shown in Fig.13

http://www.ijettjournal.org

Page 259

International Journal of Engineering Trends and Technology (IJETT) – Volume 27 Number 5 - September 2015

Fig.13 The stator current of the induction motor at rated

speed

VII.CONCLUSION

Software model of PV based two inductor boost

converter fed induction machine drive is done and

concluded that the DC output obtained was very high

in PV based TIBC fed induction machine drive

compare with conventional topology. Switching

losses are eliminated by achieving zero current

switching(ZCC).

[13] R.-Y. Chen, T.-J.Liang, J.-F.Chen, R.-L.Lin, and K.-C. Tseng,

―Study and implementation of a current-fed full-bridge boost dc-dc

converter

withzero-current

switching

for

high-voltage

applications,‖ IEEE Trans. Ind.Appl., vol. 44, no. 4, pp. 1218–

1226, Jul./Aug. 2008.

[14J. Kim, H.-S.Song, and K. Nam, ―Asymmetric duty control of a

dualhalf- bridge dc/dc converter for sing] le-phase distributed

generators,‖ IEEETrans. Power Electron., vol. 26, no. 3, pp. 973–

982, Mar. 2011.

[15] B. Liu, C. Liang, and S. Duan, ―Design considerations and

topology selection for dc-module-based building integrated

photovoltaic system,‖ in Proc. 3rd IEEE Conf. ICIEA, Jun. 3–5,

2008, pp. 1066–1070.

[16] J. Biela and J. W. Kolar, ―Using transformer parasitics for

resonant converters—A review of the calculation of the stray

capacitance of transformers,‖ in Conf. Rec. 40th IEEE IAS Annu.

Meeting, 2005, pp. 1868–1875.

[17] L. Yan and B. Lehman, ―Isolated two-inductor boost converter

with one magnetic core,‖ in Proc. IEEE Appl. Power Electron.

Conf. Expo., 2003,pp. 879–885.

[18] Y. Jang, ―Two-boost converter,‖ U.S. Patent 6 239 584, May

29, 2001.

[19] Q. Li and P. Wolfs, ―The power loss optimization of a current

fed ZVS two-inductor boost converter with a resonant transition

gate drive,‖ IEEETrans. Power Electronics, vol. 21, pp. 1253–

1263, Sep. 2006.

[20] B. Ozpineci and L. Tolbert, ―Simulink implementation of

Induction machine model,‖ IEEETrans. Power Electronics,vol.14,

pp. 623-632, feb.2013

REFERENCES

[1]J. victor, G. Farias, L.Teizeira, L. Ribeiro, ―Implementation of

high efficiency, High-life time, and low cost converter For an

autonomous photovoltaic water pumping system,” IEEE Trans.

Ind. Applications, vol. 50, no.1,pp. 631-637,feb. 2014

[2] United state patents –Jang et. Al. patent no US 6,239,584B1

[3] D. Tschanz, H. Lovatt, A. Vezzini, and V. Perrenoud, ―Single

phase three level boost power factor correction converter,‖ in Proc.

IEEEAPEC, Proc, pp. 434–439,1995

[4] N. Pandirajan, R. RanganathMuthu ―Mathematical modelling

of photovoltaic module with simulink,‖ICEES,pp.3-5,jan 2011

[5] M. A. Vitorino, M. B. R. Correa, C. B. Jacobina, and A. M. N.

Lima, ―An effective induction motor control for photovoltaic

pumping,‖ IEEE Trans.Ind. Electron., vol. 58, no. 4, pp. 1162–

1170, Apr. 2011.

[6] S. R. Bowes and A. Midoun, ―Suboptimal switching strategies

for microprocessor controlled PWM inverter drives,‖ Proc. Inst.

Elect. Eng.—Elect.Power Appl., vol. 132, no. 3, pp. 133–148, May

1985.

[7] M. Cacciato, A. Consoli, and V. Crisafulli, ―A high voltage

gain dc/dc converter for energy harvesting in single module

photovoltaic applications,‖ in Proc. IEEE ISIE, 2010, pp. 550–555.

[8] P. J. Wolfs, ―A current-sourced dc-dc converter derived via the

duality principle from the half-bridge converter,‖ IEEE Trans. Ind.

Electron., vol. 40, no. 1, pp. 139–144, Feb. 1993.

[9] P. Wolfs and Q. Li, ―An analysis of a resonant half bridge dual

converter operating in continuous and discontinuous modes,‖ in

Proc. IEEE PowerElectron. Spec. Conf., 2002, pp. 1313–1318.

[10] W. Li, L. Fan, Y. Zhao, X. He, D. Xu, and B. Wu, ―High stepup and high efficiency fuel cell power generation system with

active clamp flybackforward converter,‖ IEEE Trans. Ind.

Electron., vol. 59, no. 1, pp. 599–610, Jan. 2012.

[11] T.-J. Liang, R.-Y.Chen, J.-F.Chen, and W.-J. Tzeng, ―Bucktype currentfed push-pull converter with ZCS for high voltage

applications,‖ in Proc.IEEE Region 10 Conf., 2007, pp. 1–4.

[12] P. M. Barbosa and I. Barbi, ―A new current-fed, isolated

PWM dc-dc converter,‖ IEEE Trans. Power Electron., vol. 11, no.

3, pp. 431–438, May 1996.

ISSN: 2231-5381

http://www.ijettjournal.org

Page 260