Spatial Kinematic Linkage for Dough Kneading Mechanism .

advertisement

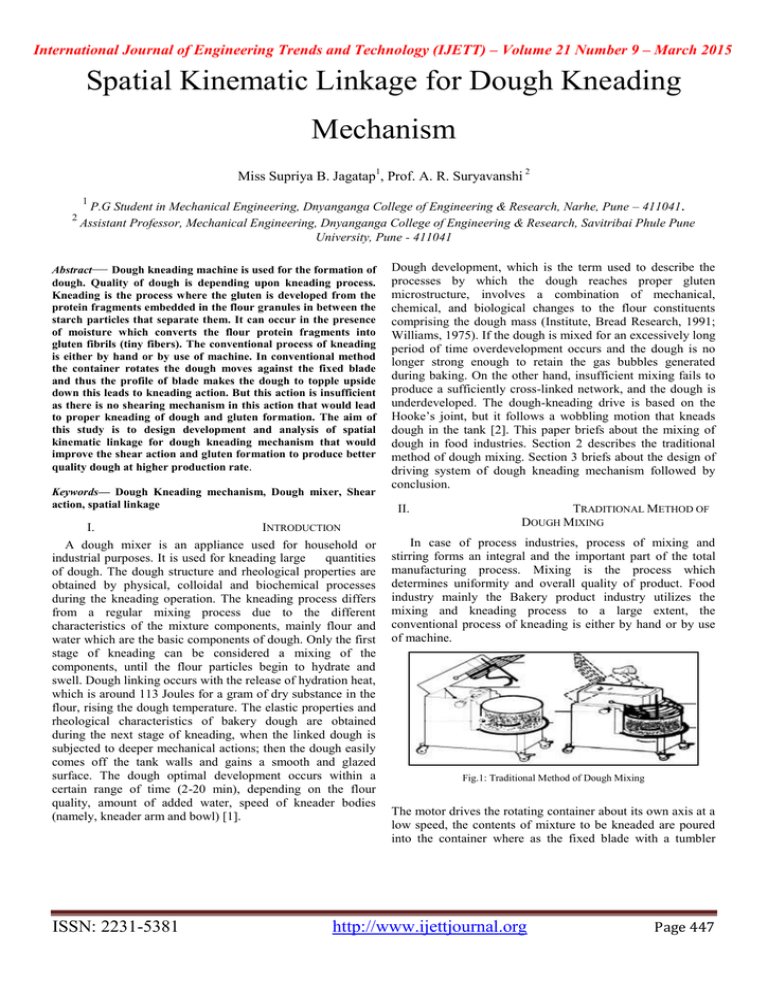

International Journal of Engineering Trends and Technology (IJETT) – Volume 21 Number 9 – March 2015 Spatial Kinematic Linkage for Dough Kneading Mechanism Miss Supriya B. Jagatap1, Prof. A. R. Suryavanshi 2 1 2 P.G Student in Mechanical Engineering, Dnyanganga College of Engineering & Research, Narhe, Pune – 411041. Assistant Professor, Mechanical Engineering, Dnyanganga College of Engineering & Research, Savitribai Phule Pune University, Pune - 411041 Abstract— Dough kneading machine is used for the formation of dough. Quality of dough is depending upon kneading process. Kneading is the process where the gluten is developed from the protein fragments embedded in the flour granules in between the starch particles that separate them. It can occur in the presence of moisture which converts the flour protein fragments into gluten fibrils (tiny fibers). The conventional process of kneading is either by hand or by use of machine. In conventional method the container rotates the dough moves against the fixed blade and thus the profile of blade makes the dough to topple upside down this leads to kneading action. But this action is insufficient as there is no shearing mechanism in this action that would lead to proper kneading of dough and gluten formation. The aim of this study is to design development and analysis of spatial kinematic linkage for dough kneading mechanism that would improve the shear action and gluten formation to produce better quality dough at higher production rate. Keywords— Dough Kneading mechanism, Dough mixer, Shear action, spatial linkage I. INTRODUCTION A dough mixer is an appliance used for household or industrial purposes. It is used for kneading large quantities of dough. The dough structure and rheological properties are obtained by physical, colloidal and biochemical processes during the kneading operation. The kneading process differs from a regular mixing process due to the different characteristics of the mixture components, mainly flour and water which are the basic components of dough. Only the first stage of kneading can be considered a mixing of the components, until the flour particles begin to hydrate and swell. Dough linking occurs with the release of hydration heat, which is around 113 Joules for a gram of dry substance in the flour, rising the dough temperature. The elastic properties and rheological characteristics of bakery dough are obtained during the next stage of kneading, when the linked dough is subjected to deeper mechanical actions; then the dough easily comes off the tank walls and gains a smooth and glazed surface. The dough optimal development occurs within a certain range of time (2-20 min), depending on the flour quality, amount of added water, speed of kneader bodies (namely, kneader arm and bowl) [1]. ISSN: 2231-5381 Dough development, which is the term used to describe the processes by which the dough reaches proper gluten microstructure, involves a combination of mechanical, chemical, and biological changes to the flour constituents comprising the dough mass (Institute, Bread Research, 1991; Williams, 1975). If the dough is mixed for an excessively long period of time overdevelopment occurs and the dough is no longer strong enough to retain the gas bubbles generated during baking. On the other hand, insufficient mixing fails to produce a sufficiently cross-linked network, and the dough is underdeveloped. The dough-kneading drive is based on the Hooke’s joint, but it follows a wobbling motion that kneads dough in the tank [2]. This paper briefs about the mixing of dough in food industries. Section 2 describes the traditional method of dough mixing. Section 3 briefs about the design of driving system of dough kneading mechanism followed by conclusion. II. TRADITIONAL METHOD OF DOUGH MIXING In case of process industries, process of mixing and stirring forms an integral and the important part of the total manufacturing process. Mixing is the process which determines uniformity and overall quality of product. Food industry mainly the Bakery product industry utilizes the mixing and kneading process to a large extent, the conventional process of kneading is either by hand or by use of machine. Fig.1: Traditional Method of Dough Mixing The motor drives the rotating container about its own axis at a low speed, the contents of mixture to be kneaded are poured into the container where as the fixed blade with a tumbler http://www.ijettjournal.org Page 447 International Journal of Engineering Trends and Technology (IJETT) – Volume 21 Number 9 – March 2015 profile is introduced into the container from the top as shown in fig. 1. As the container rotates the dough moves against the fixed blade and thus the profile of blade makes the dough to topple upside down this leads to kneading action. But this action is insufficient as there is no shearing mechanism that would lead to proper kneading of dough and gluten formation thus there is need of a special mechanism that would expedite the shear action and gluten formation to produce better quality dough at higher production rate. A. Kinematic Link Each part of a machine which moves relative to some other parts is known as kinematic link. A link need not to be a rigid body, but it be a resistant body. The linkages are two types, (1) Planner motion, (2) Spatial motion. A body is in planar motion if all its particles move in parallel planes, i.e. when the true paths of all its particles can be represented on a single plane parallel to the planes of the moving particles. A mechanism whose links have planar motions all parallel to the same plane is called a planar mechanism, for examples The four-bar linkages, the slider crank mechanism, gear on parallel shafts, the disk cam with reciprocating follower, etc. A body is in spatial motion if all its particles do not move in parallel planes. A Mechanism whose one link having spatial motion or it may have a number of links whose planar motion are not parallel to a common plane. The Hook universal joint is familiar spatial linkage it is also a representative of the spatial case of spherical mechanism [3]. B. Kneading Mechanism This is the process of forming dough to develop the elasticity of the gluten. This can be done by hand, the traditional method, or with an electric mixer equipped with a dough hook. The way ingredients are mixed affects the final product. The dough must be well mixed to combine the ingredients uniformly, with a uniform texture, as well as effectively developing the gluten and distributing the yeast throughout. If this is not done, the texture and shape of the final product will suffer. The dough should be kneaded until it is smooth and moderately elastic. The presence of one or two bubbles beneath the surface of the dough is a sign that the dough is sufficiently well kneaded. Fat and sugar have a tendency to slow the development of gluten, so rich breads may require longer kneading. Over-kneading may result in sticky dough but this is rarely a problem except with powerful commercial mixers. C. Applications of dough kneading Mechanism The dough kneading machine with 4-R spatial kinematic linkage, 1. Production of dough used in Indian food industry. 2. Production of pharmaceutical & medicinal products. 3. Production of food product 4. Bakery industry. ISSN: 2231-5381 III. DOUGH KNEADING MECHANISM Dough kneading mechanism has been successfully used to solve various dough mixing problems. Spatial kinematic linkage for dough kneading mixer is the standard mixing device which is widely used in food industry. Gheorghe Voicu, Gheorghe Constantin, E.M. Stefan, George Ipate, [1] conducted experimental study on the rheological characteristics of the doughs obtained from FA480 wheat flour and ryeflour mixtures in different ratios (0, 10, 20, 30 and 40%), purchased from regular stores. The measurements were made using an electronic Brabender farinograph and a kneader with a planetary spiral arm equipped with a torque transducer and a proper strain gauge. The data acquisition and plotting of torque variation at the resistant shaft of the kneader was performed on the computer, using a special data acquisition system. The farinograph parameters given by the obtained curves were then analyzed for the five types of dough, as well as the shape of the curves and the parameters for the torque variation at the shaft. Kneading curves may vary depending on the amount of added water, flour quality, auxiliary added materials and the kneading equipment. Hadi Peighambardoust,[4] studied the different parameters of dough. He concentrated on mixing behavior of a zero-developed dough compared to a flour water mixture, study simple shear processing of wheat gluten-starch mixtures, effect of simple shear on the physical properties of glutenin macro-polymer (GMP), microstructure formation and rheological behavior of dough under simple shear flow, dough processing in a Couette-type device with varying eccentricity, effect on glutenin macro-polymer properties and dough microstructure. Wen-TzongLee,[5] presents a new method for synthesizing adjustable spherical four and five-bar motion, path and function generators using planar motion, path and function generation methods respectively. The twice benefits of this method are, one benefit is that the user can design spherical mechanisms to approximate multiple phases of prescribed rigid-body path points. Another benefit is that the user can design spherical path generators using synthesis methods for planar path generators. By projecting the coordinates of a given spherical mechanism on a plane or the coordinates of a given planar mechanism on a sphere using the method introduced in this work, the user can design both planar and spherical mechanisms respectively. This research introduces sphere-to-plane and plane-to-sphere projection methods with optimization methods to minimize the structural error between the prescribed performance of the adjustable spherical mechanism and the performance achieved by the synthesized adjustable spherical mechanism. This research considers two-phase moving pivot adjustment problems with constant crank and follower lengths for the spherical mechanism. The spherical mechanisms considered in this research are four-bar motion, path and function generators as well as five-bar motion and path generators. Codified models http://www.ijettjournal.org Page 448 International Journal of Engineering Trends and Technology (IJETT) – Volume 21 Number 9 – March 2015 of the projection and optimization methodologies introduced are also included. R. Kieffer and N. Stein,[6] investigated reshaping of relaxed wheat doughs leads to an increase in firmness that significantly changes the results of rheological measurements involving large uniaxial deformations of the dough, whereas the gluten properties remain unaffected. Microscopic investigations reveal that directly after kneading, starch and gluten are thoroughly mixed. However, the shaping procedure of a relaxed dough or shear-flow during rheological measurements cause a separation of gluten and starch. The dilatants behavior of the starch granules and the capacity of gluten to aggregate account for the observed dough-hardening. Muchova Z., Zitny B. and Czech J.[7] studied the importance of the dough mixing, knowledge of the requirements of individual types of flour in the mixing, and achieving the proper quality with respect to the final dough properties are still actual problems. This study describes the changes in consistency, extensor graphic energy, and temperature progress in connection with the mechanical energy flow into the dough during mixing on Diosna SP12 kneader. The results of the mixing tests on the first gear indicate that different energy inputs caused different changes in consistency, the development time, and temperature increase of mixed dough. By the alteration of the mixing energy is it probably possible to utilize this energy achieving, dough with a better quality, despite the fact that this was not proved statistically. However, it was proved that energy consumption was more effective in the experimental regimes in comparison to the standard regime. The experimental regimes required a lower energy input, while the achieved consistency level was similar and durability of the positive consistency changes was higher. The temperature increase was significantly higher when the standard regime was used. Dr.ssa Federica Balestra[8] recognized that research rheological assessment of doughs and breads was performed by using empirical and fundamental methods at both small and large deformation, in order to characterize different types of doughs and final products such as bread. In order to study the structural aspects of food products, image analysis techniques was used for the integration of the information coming from empirical and fundamental rheological measurements. He was carried out evaluation of dough properties was carried out by texture profile analysis (TPA), dough stickiness (Chen and Hoseney cell) and uniaxial extensibility determination (Kieffer test) by using a Texture Analyzer, small deformation rheological measurements, were performed on a controlled stress–strain rheometer, moreover the structure of different dough’s was observed by using the image analysis; while bread characteristics were studied by using texture profile analysis (TPA) and image analysis. literature survey reveals that the traditional methods, rheological properties of dough, shear flow of gluten formation. Researcher not concentrated on kneader profile, so we have studied spatial kinematic linkage for dough kneading mechanism. REFERENCES [1] [2] [3] [4] [5] [6] [7] [8] Gheorghe Voicu, Gheorghe Constantin, E.M. Stefan, George Ipate, (2012) Variation of Farinographic Parameters of Doughs Obtained From Wheat And Rye Flour Mixtures During Kneading,U.P.B. Sci. Bull, Series D Vol. 74, Iss 2. Neil Sclaterand Nicholas P. Chironis, (2001), Mechanisms & mechanical devices sourcebook, 3rd ed., McGraw-Hill, , pp 174-177 Richard S. Hartenberg, and Jacques denavit, (1994), Kinematic synthesis of Linkages, McGraw-Hill Series in Mechanical Engineering, pp.343-366 Hadi Peighambardoust, (2006), Development of Dough under Shear Flow. Ph.D., Food and Bioprocess Engineering Group, Agro technology and Food Sciences Department, Wageningen University, Netherlands. Wen-Tzong Lee, (2004), The Design of Adjustable Spherical Mechanisms Using Plane-To-Sphere And Sphere-To-Plane Projections, Ph.D. Thesis, New Jersey Institute of Technology. R. Kieffer and N. Stein, The Role of Gluten Elasticity In The Baking Quality of Wheat, Gluten Elasticity, pp 169 -178. Muchova Z., Zitny B.( 2010), New approach to the study of dough mixing processes,Czech J. food sci.,Vol 28, ,pp.94 -107. Dr.ssa Federica Balestra, (2009), Empirical and fundamental mechanical tests in the evaluation of dough and bread rheological properties, pp.1-186. IV. CONCLUSION Dough kneading mechanism with of spatial kinematic linkage will gives the good quality homogeneous dough. Kneading mechanism was based on wheat flour, addition of water, properties of dough, shape and movement of kneader. This ISSN: 2231-5381 http://www.ijettjournal.org Page 449