Impact Analysis of Front Bumper Prof.P.R.Kulkarni Mr. Nitin S. Motgi

advertisement

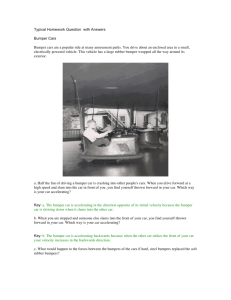

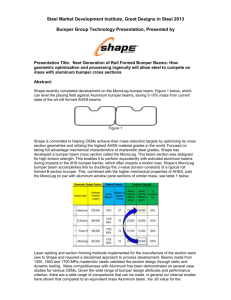

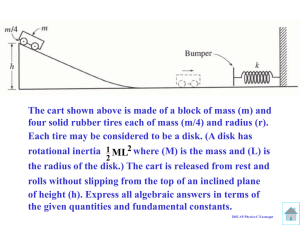

International Journal of Engineering Trends and Technology (IJETT) – Volume 6 Number 5- Dec 2013 Impact Analysis of Front Bumper Mr. Nitin S. Motgi Prof. S. B. Naik Prof.P.R.Kulkarni ME Design –II, Walchand Institute of Technology, Solapur (India) Associate Professor, Walchand Institute of Technology, Solapur (India) Associate Professor, Walchand Institute of Technology, Solapur (India) ABSTRACT the hood, trunk, grill, fuel, exhaust and cooling system as Automotive industry is a very huge ground and research is well as safety related equipment such as parking lights, still evolving. From this safety and comfortness of headlamps and taillights, etc [1]. A good design of car passenger car is very important. Hence the researchers bumper must provide safety for passengers and should have to be focused on safety and comfortness. In tune have low weight [2]. Different countries have different with this improvement in the design of a bumper is very performance important. This will increase the performance of the International safety regulations originally developed as bumper, improve absorbing capacity during impact load European standards and now adopted by most countries and increase the protection of the front car component. outside North America, a car's safety systems still This research aims towards improvement in the design of function normally after a straight-on pendulum or front bumper of passenger car and gives the economical moving-barrier impact of 4 km/h (2.5 mph) to the front solution for the front bumper material by emphasizing the and the rear, and to the front and rear corners of 2.5 km/h cost reducing aspect. The methodology employed (1.6 mph) at 45.5 cm (18 in) above the ground with the includes study of front bumper system, design and vehicle loaded or unloaded. In North America (FMSS: analysis of the improved front bumper using CAD/CAE Federal Motor Vehicle Safety Standards) and Canada softwares. (CMVSS: Canadian Motor Vehicle Safety Standards), it standards for bumpers. Under the should be meet 4KMPH pendulum and barrier impacts [3]. Keywords-Impact, bumper, CAD, FEA The function of automotive bumpers has changed considerably over the past 70 yrears. The later 1. INTRODUCTION performance is achieved by a combination of careful Car accidents are happening every day. Most drivers are design, material selection to obtain a particular balance of convinced that they can avoid such troublesome situations. stiffness, strength and energy absorption. Stiffness and However the statistics shows that ten thousand dead and Energy absorption are essential criterion. Stiffness is hundreds of thousands to million wounded each year. important because vehicle design consideration limits the Hence, improvement in the safety of automobiles is packaging space for the bumper design to deform under prerequisite to decrease the numbers of accidents. load and Energy absorption is important because bumper Automotive bumper system is one of the key systems in must limt the amount of the impact force transmited to passenger cars. Bumper systems are designed to prevent the surrounding rails and vehicle frame. Automotive or reduce physical damage to the front or rear ends of bumper plays a very important role in absorbing impact passenger motor vehicles in collision condition. It protects enegry (original purpose of safety) and styling stand ISSN: 2231-5381 http://www.ijettjournal.org Page 287 International Journal of Engineering Trends and Technology (IJETT) – Volume 6 Number 5- Dec 2013 point/aesthetic purpose. Now a days ,automotive industry 3. STANDARDS FOR BUMPER concentrates on optimisation of weight and safety. In most jurisdictions, bumpers are legally required on all 2. LITERATURE vehicles. The height and placement of bumpers may be Literatures related to impact are studies by many researchers. It was observed that, major injury due to impact velocity of around 20-30 kmph was affected to the legally specified as well, to ensure that when vehicles of different heights are in an accident, the smaller vehicle will not slide under the larger vehicle. knee ligament. Davoodi et al. [4] proposed conceptual 3.1 International standards design of fiber reinforced epoxy composite bumper Under the International safety regulations originally absorber as a pedestrian energy absorber. The energy developed as European standards and now adopted by absorption capacity was sufficient for pedestrian impact most countries outside North America, a car's safety and it could possible to use as substitute for the existing systems must still function normally after a straight-on materials such as EPP foam for low impact collision. pendulum or moving-barrier impact of 4 km/h (2.5 mph) Mohapatra S [5] discussed that automotive development to the front and the rear, and to the front and rear corners cycles are getting shorter by the day. With increasing of 2.5 km/h (1.6 mph) at 45.5 cm (18 in) above the ground competition in the marketplace, the OEM’s and suppliers with the vehicle loaded or unloaded. main challenge is to come up with time-efficient design 3.2 India [7] solutions. Researchers are trying to improve many of India is the 10th largest producer of automobiles in the existing designs using novel approaches. Many times world. there is conflicting performance and cost requirements. requirements has progressed significantly since the year This and 2000. More than 35 million vehicles are registered in Development units to come up with a number of India. In 1989, the Central Motor Vehicle Rules (CMVR) alternative design solutions in less time and cost became effective and the rules are greatly enforced today. compared to existing designs. These best solutions are Under Rule 126 of the CMVR, manufacturers of motor best achieved in a CAE environment using some of the vehicles must allow a separate agency to test prototypes of modern CAD and FEM tools. Such tools are capable of new vehicle designs for safety requirements. It is effecting quick changes in the design within virtual necessary for all vehicles in India to have basic safety environment. features, such as seat belts, rear-view mirrors and puts additional challenge for Research Andersson R et.al [6] emphasized that to increase crash performance in automotive vehicles it is necessary to use new techniques and materials. The components that are linked to crash safety should transmit or absorb energy. The energy absorbing capability of a specific component is a combination of geometry and material properties. The chosen material should have high yield strength and relatively high elongation to fracture. These demands lead to increase strength stainless steels. interest to use of high The country's attention to vehicle safety laminated safety glass for windshields. Also, all vehicles in use must pass a pollution test every six months. 4. MODELLING AND ANALYSIS From literature review it is clear that automotive bumper has evolved over the years. Although it is evolved ergonomically there is no systematic study which explains design and analysis of front bumpers in the presence of solid mechanics using advanced FEA tools. 4.1 Modelling This section discusses CAD modelling approach followed in the various parts/components and assembly of front bumper. Modelling of front bumper and its component is ISSN: 2231-5381 http://www.ijettjournal.org Page 288 International Journal of Engineering Trends and Technology (IJETT) – Volume 6 Number 5- Dec 2013 carried out using CAD software. Keeping objectives in reasonable time frame with reasonable effort. The FEM is mind, existing bumper systems of different passenger cars one such approximate solution technique. Fig.2 shows the have been studied. Moreover, evolution of bumper system CAD model of bumper system. is also studied. There is trade off between weight and performance. Initially, most of the cars used metallic bumper systems with or without energy absorbing materials like rubber, foam, etc. This kind of design increases weight and number of parts in assembly. Recently, there is emphasis on use of composite materials like G-epoxy. This has reduced weight further and it is observed that composite materials are also capable to absorb energy along with a simplified geometry. Hence, present research includes study of following configurations of fascia and presents different designs in terms of reducing weight and increasing the performance. Foam-absorber type bumper assembly Fig. 2 CAD model of bumper system Fig, 3 shows meshed model of bumper system. Meshing is nothing but converting a whole geometry into number of elements and these elements are connected by nodes. with Aluminum fascia. (configuration 1) Modified absorber type bumper assembly with composite fascia.(configuration 2) Fig. 3 Meshed model of bumper The number of nodes and elements that are used are 23033 and 7120 respectively. To carry out impact analysis Fig. 1 Foam-absorber type bumper assembly with of bumper system within framework of FEA, this is low speed impact(4kmph) and as per standards bumper should Aluminium fascia withstand it. Appropriate contacts have been defined at 4.2 Finite Element Method Many problems in engineering are governed by differential or integral equations. The solution to these appropriate locations between different parts. Fig. 4 shows loads and boundary conditions. equations would provide an exact, closed-form solution to these equations to the particular problem being studied. However, complexities in geometry & in boundary conditions that are seen in most real world problems usually means that an exact solution cannot be obtained or obtained in real time. But current product design cycle times imply that engineers must obtain design solutions in Fig. 4 Loads and boundary conditions a short amount of time. They are content to obtain approximate solutions that can be readily obtained in a ISSN: 2231-5381 http://www.ijettjournal.org Page 289 International Journal of Engineering Trends and Technology (IJETT) – Volume 6 Number 5- Dec 2013 The given configuration of bumper system is solved using LS DYNA solver with inputs as discussed. Post processing involves the review of various results such as stresses and deformations. Fig. 9 Internal energy of aluminium bumper fascia Fig. 5 Stresses in bumper system of aluminium material Fig. 10 Internal energy of composite bumper fascia 5. CONCLUSION Fig. 6 Stresses in bumper system of Composite material The stress pattern within bumper system has been studied. Depending on outcome, metallic and composite bumper facia are selected for impact strength assesment. Finally, it is found that composite facia is suitable from impact point of view and which is comman now. AKNOWLEGEMENT Fig.7 Deformation in aluminium bumper fascia I take this opportunity to express my gratitude to the people who have been instrumental in the successful completion of this work. At the outset I articulate my overwhelmed feelings towards my guide Prof. S. B. Naik for being my teacher and providing confidence to carry out my research work. I am grateful to Dr. S. A. Halkude, Principal, Dr. K. H. Jatkar, Head of Mechanical Engineering Fig. 8 Deformation in composite bumper fascia Fig. 9 and 10 shows internal energies for bumper fascia made of aluminium and composites. Internal energies are indicator of energy absorption characteristic of fascia. From energy characteristics it appears that aluminium fascia has poor energy absorption characteristics when compared with composite fascia. ISSN: 2231-5381 Department, for allowing me to pursue this research work. I express my deep sense of appreciation to Prof. P.R.Kulkarni for his unrelenting help and moral support throughout the research work. I thanks to my parents for giving me the innate abilities that I have. I wish to recognize the moral support, proof reading and lively cooperation of my friends. http://www.ijettjournal.org Page 290 International Journal of Engineering Trends and Technology (IJETT) – Volume 6 Number 5- Dec 2013 REFERENCES [1] Hosseinzadeh RM, Shokrieh M, and Lessard LB,“Parametric study od automotive composite bumper beams subjected to low-velocity impacts”, J. Composite Stuct., P P 419-427, 2005 [2] Marzbanrad J M, Alijanpour M, and Kiasat MS, “Design and analysis of automotive bumper beam in low speed frontal crashesh”, Thin Walled Struct., P P 902-911, 2009. [3] http://www.nhtsa.dot.gov/cars/testing/procedures/TP -581-01.pdf [4] M.M Davoodi, S.M Sapuan, R. Yunus.. “Conceptual design of a polymer composite automotive bumper energy absorber”. Elsevier Ltd 2007 [5] Mohapatra Automotive S, “Rapid Bumper Design Solutions Energy Absorbers for using Morphing Technique”, Altair CAE users Conference, Bangalore, India. 2005. [6] Andersson R, Schedin E, Magnusson C, Ocklund J, “The Applicability of Stainless Steel for Crash Absorbing Components”, SAE Technical Paper, 2002. [7] https://www.araiindia.com/ ISSN: 2231-5381 http://www.ijettjournal.org Page 291