Dual Mass Flywheel - A Better Driving Experience by Reducing Vibration P.N.Ulhe

advertisement

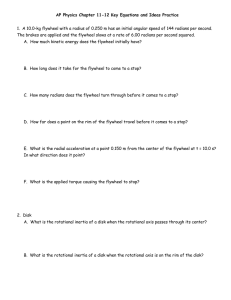

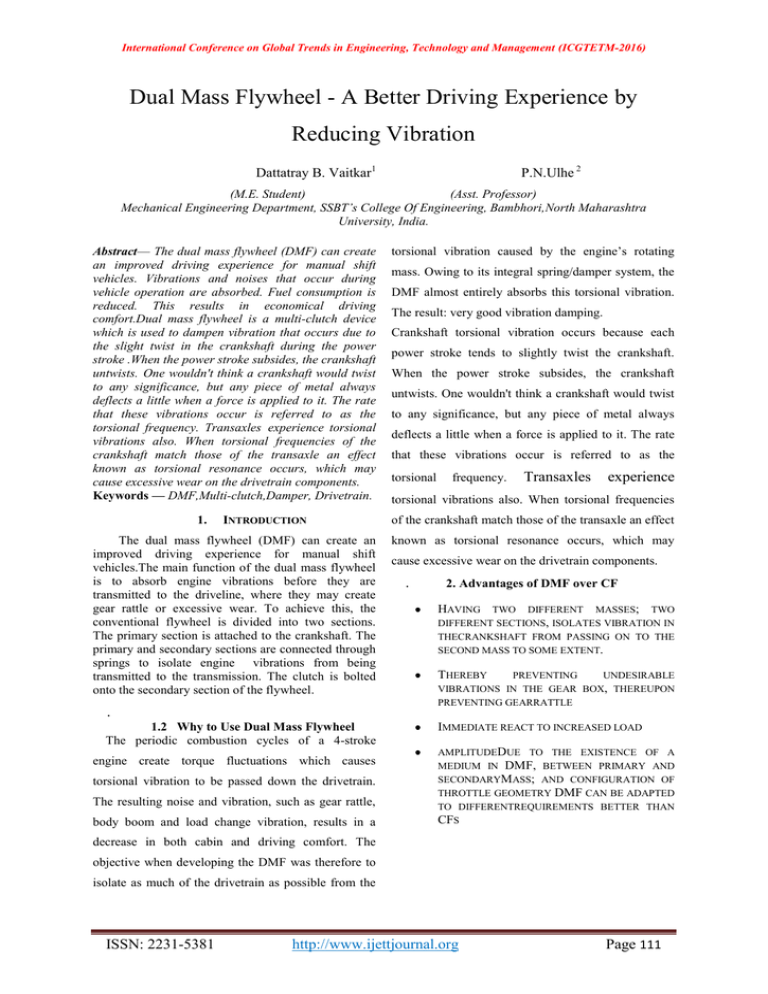

International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) Dual Mass Flywheel - A Better Driving Experience by Reducing Vibration Dattatray B. Vaitkar1 P.N.Ulhe 2 (M.E. Student) (Asst. Professor) Mechanical Engineering Department, SSBT’s College Of Engineering, Bambhori,North Maharashtra University, India. Abstract— The dual mass flywheel (DMF) can create an improved driving experience for manual shift vehicles. Vibrations and noises that occur during vehicle operation are absorbed. Fuel consumption is reduced. This results in economical driving comfort.Dual mass flywheel is a multi-clutch device which is used to dampen vibration that occurs due to the slight twist in the crankshaft during the power stroke .When the power stroke subsides, the crankshaft untwists. One wouldn't think a crankshaft would twist to any significance, but any piece of metal always deflects a little when a force is applied to it. The rate that these vibrations occur is referred to as the torsional frequency. Transaxles experience torsional vibrations also. When torsional frequencies of the crankshaft match those of the transaxle an effect known as torsional resonance occurs, which may cause excessive wear on the drivetrain components. Keywords — DMF,Multi-clutch,Damper, Drivetrain. 1. INTRODUCTION The dual mass flywheel (DMF) can create an improved driving experience for manual shift vehicles.The main function of the dual mass flywheel is to absorb engine vibrations before they are transmitted to the driveline, where they may create gear rattle or excessive wear. To achieve this, the conventional flywheel is divided into two sections. The primary section is attached to the crankshaft. The primary and secondary sections are connected through springs to isolate engine vibrations from being transmitted to the transmission. The clutch is bolted onto the secondary section of the flywheel. . 1.2 Why to Use Dual Mass Flywheel The periodic combustion cycles of a 4-stroke engine create torque fluctuations which causes torsional vibration to be passed down the drivetrain. The resulting noise and vibration, such as gear rattle, body boom and load change vibration, results in a torsional vibration caused by the engine’s rotating mass. Owing to its integral spring/damper system, the DMF almost entirely absorbs this torsional vibration. The result: very good vibration damping. Crankshaft torsional vibration occurs because each power stroke tends to slightly twist the crankshaft. When the power stroke subsides, the crankshaft untwists. One wouldn't think a crankshaft would twist to any significance, but any piece of metal always deflects a little when a force is applied to it. The rate that these vibrations occur is referred to as the torsional frequency. Transaxles experience torsional vibrations also. When torsional frequencies of the crankshaft match those of the transaxle an effect known as torsional resonance occurs, which may cause excessive wear on the drivetrain components. . 2. Advantages of DMF over CF HAVING TWO DIFFERENT MASSES; TWO DIFFERENT SECTIONS, ISOLATES VIBRATION IN THECRANKSHAFT FROM PASSING ON TO THE SECOND MASS TO SOME EXTENT. THEREBY PREVENTING UNDESIRABLE VIBRATIONS IN THE GEAR BOX, THEREUPON PREVENTING GEARRATTLE IMMEDIATE REACT TO INCREASED LOAD AMPLITUDEDUE TO THE EXISTENCE OF A MEDIUM IN DMF, BETWEEN PRIMARY AND SECONDARYMASS; AND CONFIGURATION OF THROTTLE GEOMETRY DMF CAN BE ADAPTED TO DIFFERENTREQUIREMENTS BETTER THAN CFS decrease in both cabin and driving comfort. The objective when developing the DMF was therefore to isolate as much of the drivetrain as possible from the ISSN: 2231-5381 http://www.ijettjournal.org Page 111 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) 3.1.3 Bearing Large and small ball bearing: The primary mass is fitted with a turned hub on which the large-size ball bearing is fitted. 3.1.4 Flange The task of the flange is to transfer torque from the primary mass via the arc springs to the secondary flywheel; in other words, from the engine to the clutch. . Fig.1 CF (SMF) VS DMF 3.1.5 Friction control disc During the start-up process, the DMF operates briefly 3. Dual Mass Flywheel (DMF) The Dual Mass Flywheel (DMF) is installed between the engine and the transmission along with in the resonant frequency range. 3.1.6 Arc springs The arc spring does the function of damper. The arc the clutch cover and clutch disc. 3.1Structure of Dual Mass Flywheel spring is also called as a heart of DMF.The material used for arc spring is60Si2MnAspringsteel Fig.2AStructure of Dual Mass Flywheel 3.1.1 Primary Mass The primary mass or flywheel is connected to the crankshaft of the engine. Fig.4 Arc Spring with Different Stiffness 3.1.2 Secondary Mass 3.2 Materials and Properties of Arc Sprin The engine torque is transferred from the primary mass to the secondary mass via the arc springs and the The material used in this investigation is 60Si2MnA spring steel; flange. T Table.1 Design Parameters of Arc Spring Fig. 3 Structure of Dual Mass Flywheel ISSN: 2231-5381 http://www.ijettjournal.org Page 112 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) higher comfort are fully met. Table.2 Material property of 60Si2MnA 4. Working Principle of Dual Mass Flywheel The functioning principle of a DMF is simple, yet efficient. Owing to the additional mass on the transmission input shaft, the vibration torque range, Fig.6 Transfer of Torsional Vibrations in DMF As shown in fig.6 the engine vibrations are reduced before they are transmitted to the driveline. which is normally between 1,200 rpm and 2,400 rpm with original torsion dampers, is moved to a lower resonance speed range. This ensures excellent damping of engine vibration even at idle speed. Fig.7 Working Principle of Dual Mass Flywheel 4.1 With and without Dual Mass Flywheel Fig 5. Working Principle of Dual Mass Flywheel 1 Engine 2 Clutch 3 Transmission 4 Torsion dampers 5 Primary mass 6 Secondary mass 7 Flywheel The spring/damper system of the DMF filters out the torsional vibrationsinduced by the engine as far as torsional vibration caused by the engine. This prevents possible from the rest of the drive train. A gearbox components knocking against each other – conventional system only satisfies this requirement at rattling does not occur and the driver’s demands for high engine speed, because the attainable torsion Fig.8 Dual Mass Flywheel Arrangement The goal of torsion damper development is to keep damper spring rates lead to naturalfrequencies which are always within the normal driving range.This unsatisfactory situation led to the development of a new torsiondamper concept - the dual mass flywheel (DMFW). This design shifts partof the flywheel inertia to the transmission input shaft and drastically lowersthe torsion damper spring rate by introducing ISSN: 2231-5381 http://www.ijettjournal.org Page 113 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) new spring designs (Figure5.5), thus reducing the Different compression pressures in various resonance speed to very low engine speeds. cylinders. 5. Advantages of Dual Mass Flywheel Extreme vibration due to worn drivetrain Elimination of gear rattle components Reduced drivetrain noise 6.1 Applications of Dual Mass Flywheel The DMF is used in luxury cars such as Ferrari 458, Reduced shifting frequency Less synchronizer wear Jaguar XJ, Audi A3 2.0TDI 140 etc. Lower engine operating speeds save fuel and reduced Conclusion emissions In this way the use of Dual Mass Flywheel with the Less drivetrain torque fluctuation Less axial vibrations utilization of Damping System we can say that the Long service life DMF gives the new way of driving experience by lowering the vibration and used in the most of the Smooth start/stop performance Outstanding vibration damping throughout the entire recent Cars. A vehicle with a DMFW offers increased fuel economy if the following conditions are met. rpm range The vehicle manufacturer reduces idle speed. 5.1Disadvantages of Dual Mass Flywheel The driver adopts economical driving habits by Hard to test driving in higher gears at lower engine speeds both of Impossible to machine these factors can be achieved without loss of driving Costly comfort. The compact DMFWs offer full dual-mass 5.2An Experimental Case-Study flywheel function and, therefore, improved noise An experimental case-study on Dual Mass flywheel gives the following results at different load condition. This is shown in tabulated form as follows; Sr.No. Load (gm) Speed Torque Power Efficienc y Acceler ation 1 1500 1315 0.47088 64.8516 31 32 2 2000 1275 0.62784 83.8386 40 40 3 2500 1245 0.78485 102.3324 49 50 4 3000 1205 0.94176 118.8535 57 63 5 3500 1185 1.09872 136.3616 66 80 6 4000 1155 1.25568 151.8958 74 100 7 4500 1020 1.41264 150.9090 77 125 control for the customer; with only minimal cost increases when compared to conventional systems. ACKNOWLEGEMENT I sincearly thanks to my guide Assi.Prof. P.N.Ulhe sir (SSBT’S College of Engg. Bambori Jalgaon.). Who encourage me continuously for this conference. At last I thanks to Michael Shell and other contributors for developing and maintaining the IJETT LaTeX style files which have been used in the preparation of this template. REFERENCES [1] [2] 6. Possible Causes of Failure of Dual Mass [3] Flywheel Frequent stalling of the engine / driving at [4] extremely low engine speeds. [5] ISSN: 2231-5381 A Textbook of Theory of Machines by R. S. Khurmi and J. K. Gupta – Torsional Vibrations (Page no. 972) A Textbook of Machine Design by R. S. Khurmi and J. K. Gupta – Flywheel (Page no. 776) Dr.-Ing. Albert Albers,: Advanced Development of Dual Mass Flywheel (DMFW) Design - Noise Control for Today's Automobiles ZF Services GmbH Obere Weiden 12 · 97424 Schweinfurt · Germany Borgwardstr. 16 · 28279 Bremen · Germany Govinda and Dr. Annamalai, K:VIT University, Chennai, India,: International Journal of Engineering & Technology Research Volume1, January February www.iaster.com, ISSN http://www.ijettjournal.org Page 114 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) [6] [7] [8] Online: 2347, 2014, pp. 3 54 1 , © IASTER 2014 4904: Design and Analysis of Arc Springs used in Dual Mass Flywheel Sameer More, Pravin Medankar, Prof.Mahesh Nagargoje: International Journal of Innovative Research in Science, Engineering and Technology Vol. 4, Issue 3, March 2015 Design and Development of Dual Mass Flywheel System Payam Bighal: High Efficiency Heavy Duty Truck Engine Advantages of DMF over CF Schaeffler Automotive Aftermarket GmbH & Co. KG September 2013 - Dual Mass Flywheel Technology ISSN: 2231-5381 http://www.ijettjournal.org Page 115