A Review on Cam Roller of Spark Ignition Petrol Engine

advertisement

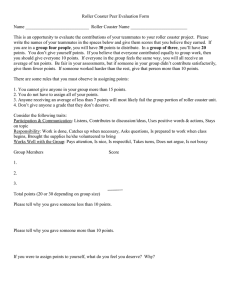

International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) A Review on Cam Roller of Spark Ignition Petrol Engine for Valve Mechanism Performance Enhancement Chetana S. Chopade1, Navneet K. Patil2 2 Student, ME Mechanical Engineering Associate Professor Department of Mechanical Engineering, SSBT College OF Engineering and Technology, Bambhori, Jalgaon 1 Abstract: Most of the Internal Combustion engines have roller cam and follower mechanisms, having a line contact between the cam and the roller follower. In effort to improve the mechanical efficiency of the mechanism the company requires us to change the line contact to a point contact. Hence it is required to change the flat roller follower to a curved profile. The existing cam & follower mechanisms used in Internal Combustion engines have a line contact between them causing frictional losses. These frictional losses in present line contact are being considered on the higher side. These frictional losses affect the total efficiency of an Internal Combustion engine. The mechanical efficiency of cam & follower mechanism is to be increase by minimizing the frictional losses. The roller of rocker arm of a Hero Honda passion bike is replaced by new one to check performance experimentally. Keywords: Cam; Follower; Line contact; Point Contact; Vibration Analysis; I. INTRODUCTION In the 21th century, with the advance technologies the various vehicles have been modified as per the requirement of a consumer. Sometimes there is modified ignition system, modified shape, different cylinder arrangements etc. Thus we have decided to change the shape of a roller. The roller of the cam follower mechanism is of flat type; which makes line contact with cam. This line contact of roller with cam will be changed to point contact by doing modification in the geometry of a roller. The modified geometry of a roller should satisfy conditions: 1. 2. 3. company. Fig: 1. Details of Rocker Arm, cam roller Table. 1 1 2 3 4 5 Material Young's modulus Poisson Ratio Density Yield Strength 100cr6 2.1e5MPas 0.3 7.850×10-6 Kg/mm3 410MPa The existing cam & follower mechanisms used in Internal Combustion engines have a line contact between them causing frictional losses. These frictional losses in present line contact are being considered on the higher side. These frictional losses affect the total efficiency of an Internal Combustion engine. It should make point contact with cam of cam-follower mechanism. The values of stresses of an original geometry and modified geometry should be within limit. The value of frequencies of an original geometry and modified geometry should be within range. Fig. 2. Existing Cam-Follower The dimensions required for roller is measured manually by using vernier caliper are the workshop of a college as shown in figure 1 below. Another data required for analysis of a roller is given by a ISSN: 2231-5381 http://www.ijettjournal.org Page 94 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) II. TEST CRITERIA 1. Roller dimensions of Old Line & New Point contact roller Total 4 tests are conducted on motorcycle engine (Hero Honda passion) with replaced Stainless tungsten chrome steel roller –(N8) which is case hardened & with old roller also. Measurement of vibration parameters with engine of hero Honda passion motorcycle to get a average reading. These tests are taken for old and new roller that is line and point contact type. These readings are stored in FFT analyser and later on analysed in mat lab to produce graphs. III. RESULT AND DISCUSSION 1. TIME DOMAIN ANALYSIS OF VIBRATION SIGNAL (with old line contact roller) old line contact roller. Measurement of Noise with old line contact roller. Measurement of vibration parameters with new modified point contact roller. Measurement of noise with new modified point contact roller. 2. Experimental set up of vibration parameters with old line contact and new modified contact roller Graph 1: Time domain Analysis of vibration signal Above Graph shows Maximum amplitude is 11mm shown in graph which is very high need to be reduced. Time span is taken 15 seconds for every reading. 2. TIME DOMAIN ANALYSI S OF VIBRATION SIGNAL (with new modified point contact roller) Fig 3: Measurement of vibration parameters with old line and new modified contact roller 3. Experimental set up of noise with old line and new modified point contact roller Graph 2: Time domain Analysis of vibration signal Above Graph shows maximum amplitude is 3mm shown in graph which is very low i.e. reduced. Time span is taken 15 seconds for every reading. In old roller it was 11 mm so high. Hence our optimization is successful. The amplitude level decreases considerably by new roller. Fig 4: Measurement of noise with old line and new modified point contact roller Above (Photo) shows that noise test is going on with the noise sensor probe held in hand at the approximately same distance for all four sides of I C ISSN: 2231-5381 http://www.ijettjournal.org Page 95 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) IV. TIME DOMAIN ANALYSIS OF ACOUSTIC (NOISE) signal old roller VI. RMS VALUE VIBRATION ACOUSTIC Graph 3: Ti me domain Analysis of acoustic (noise) signal Above Graph shows Maximum amplitude is 50000 DB shown in graph which is very high need to be reduced. Time span is taken 15 seconds for every reading. V TIME DOMAIN ANALYSIS OF ACOUSTIC (NOISE) signal New roller Graph 4: Time domain Analysis of acoustic (noise) signal Above Graph shows Maximum amplitude is 45000 New roller 0.9331 13404.7 Old roller 1.0233 14624.2 Modal & stress analysis of existing and modified follower is carried out. As per the conditions initially frequency range was fixed and then the Modal analysis is performed. Frequency range of modified roller follower shows a very good match with the frequency range of existing roller follower. The obtained frequency range of existing roller follower is 828.32 HZ to 3272.8 HZ and for modified roller is 953.60 HZ to 3162.7 Hz .As frequency range of modified roller follower is within the frequency range of existing roller follower. Thus, the modified design proves to be safe. From modal analysis it is observed that the maximum values of deformation for modified roller follower is 21.675 mm, while for existing roller follower is 23.41 mm for the obtained frequency& in case of static stress analysis value of deformation in both cases is very small or it negligible. This shows modified roller follower deforms comparatively less as compared existing roller follower in case model analysis. This indicates change of the flat face of roller follower to a curved face roller follower mechanism results in low frictional losses due to point contact which results in improved in mechanical efficiency of internal combustion engine. DB shown in graph which is reduced. Time span is taken 15 seconds for every reading. The amplitude level decrease s considerably by new optimized roller. Hence our optimization is successful. The amplitude level decreases considerably by new roller. Vibration spectral analysis Comparison of effect on amplitude & frequency by both rollers with old line contact roller. Shows the vibration spectrum of old roller at idling speed of motorcycle (pink line) and with new modified point contact roller (black line) Graph 5: Comparison of effect on amplitude & frequency by both rollers ISSN: 2231-5381 http://www.ijettjournal.org Chart 1. Result Analysis Page 96 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) VII. CONCLUSION The change of roller can significantly reduce the costs of maintenance. In this research, vibration and acoustic signals were used in an engine of motorcycle. It was shown that various types of signals can be detected successfully by both types of rollers by acoustic and vibration signals analysis. The acoustic analysis method has gained wide industrial acceptance for engine condition monitoring. In this dissertation work, experimentation is carried out to vibration & noise level difference through acoustic and vibration analysis and feasibility of practical application of new modified roller in engine of motorcycle is investigated. The acoustic and vibration spectrums obtained for different rollers are presented on which following conclusions can be drawn. 1. Using Frequency Domain Spectrums With new point contact roller & old line contact roller a comparison shown that it reflects the change in spectrum. It is observed from the amplitude of frequency has decreased considerably. 2. Using Time Domain Spectrums With comparison of time domain spectrum, it is observed that an RMS value was decreased by the use of new point contact roller in engine of motorcycle. REFERENCES [1] TusharKiran, S. K. Srivastava, “Analysis and Simulation of Cam Follower Mechanism Using Polynomial Cam Profile”, International Journal of Multidisciplinary and Current Research, Research Article ISSN: 2321- 3124, Int. Journal of Multidisciplinary and Current research, Nov/Dec 2013, pp211220. [2] Variable valve timing, Aug 2011 & Douglas M. Vidler ISSN: 2231-5381 “Automotive engine performance.” [3] Prof. H.D.Desai, Prof. V.K.Patel, “Computer Aided Kinematic and Dynamic Analysis of Cam and Follower, Proceedings of the World Congress on Engineering 2010 Vol II WCE 2010, June 30 July2, 2010, London, U.K. [4] E.E. Zayas, S. Cardona, L. Jordi, “Analysis and synthesis of the displacement function of the follower in constant-breadth cam mechanisms, Mechanism and Machine Theory, 44, (2009), 1938– 1949. [5] ArunavaBiswas, Michael Stevens, Gary L. Kinzel, “A comparison of approximate methods for the analytical determination of profiles for disk cams with roller followers”, Mechanism and machine Theory, 39, (2004), pp 645–65. [6] Philippe de Abreu Duque, Dr.Ing. Mauro Moraes de Souza Juliano Savoy Carlos Coelho, “Contact pressure between cams and roller followers through Finite Elements Method (FEM) in assembled camshafts”. [7] O.E. Simolowo, M.Phil. and O.A. Bamiro, Ph.D. Roller-Cam Systems Design: Development of Profile Analysis Software, the Pacific Journal of Science and Technology, Volume 10. Number 1. May 2009. [8] Yuan L. Lai, Jui P. Hung, and Jian H. Chen, Roller Guide Design and Manufacturing for Spatial Cylindrical Cams, World Academy of Science, Engineering and Technology, Vol:2 200802-29. [9] R. L. Norton and R. G. Mosier, “Cam Design and Manufacturing Handbook,” Industrial Press, Inc., New York, pp 98-112, 2002. [10] J. W. David, C. Y. Cheng, T. D. Choi, C.T. Kelley and J. Gablonsky, “Optimal Design of High Speed Mechanical Systems,” North Carolina State University, Raleigh, Tech.Rep. CRSC-TR97-18, pp 84-97, 1997. [11] Tounsi M., Chaari F., Walha L., Fakhfakh T., Haddar M, “Dynamic Behavior Of A Valve Train System In Presence Of Camshaft Errors,” Wseas Transactions On Applied And Theoretical Mechanics, Vol.No. 6, pp. 17-26, 2011. [12] A. Cardona, E. Lens and N. Nigro, “Optimal Design of Cams,” Multibody System Dynamics, Vol. 7, No. 3, pp. 285-305, 2002. [13] Faculty Of Mechanical Engineering,"Design Data Book Of Engineers", Kalaikathir Achchagam, pp 7.110-7.116, 2011. http://www.ijettjournal.org Page 97