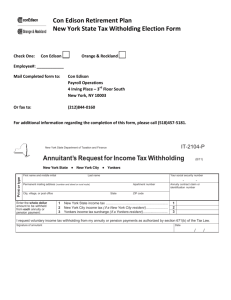

CASE STUDY CON EDISON C Co

advertisement

CON EDISON Con Edison: Estimating Power Loads wit h Progress® Object Store® CASE STUDY CHALLENGE As the fifth largest utility in the U.S., Con Edison must manage its distribution network to ensure that it has sufficient capacity to meet highly variable demands. SOLUTION Con Edison developed a Remote Monitoring Estimator (RME) application built on top of Progress® ObjectStore®. WHY PROGRESS® SOFTWARE ObjectStore helps ensure that the data to be used for load flow calculations is as accurate and up-to-date as possible. BENEFIT Con Edison now has a comprehensive, real-time understanding of how the network is performing; it has the ability to respond quickly to changing circumstances to ensure system integrity and maintain a high level of service reliability for its customers. Electricity is one of the things we have come to take for granted. But, when you are a public utility company and responsible for providing electricity, there is nothing you can take for granted. Demand for energy never ceases and a public utility is on call—24 hours a day, seven days a week—to ensure that power is available for its customers. Only with a power outage does our fundamental dependence on the availability of power become noteworthy. When Consolidated Edison of New York (Con Edison) needed to monitor the operation of its power distribution system to ensure it was meeting the demands of its customer base, it faced some real challenges. Electrical service delivery standards are important to Con Edison since its rate structure provides both incentives for good execution and penalties for poor performance. The fifth largest utility in the U.S. must manage its distribution network to ensure that it has sufficient capacity to meet highly variable demands. And for a key element in that operation Con Edison turned to Progress ObjectStore. THE ENVIRONMENT Con Edison services millions of customers in New York City’s five boroughs, as well as Westchester County—a territory that encompasses more than six hundred square miles and 8.7 million people. The Con Edison electrical grid includes approximately 27,000 km of primary distribution cables, supplying 24,000 network transformers in 63 secondary networks. Managing such an extensive operation requires a comprehensive, up-to-the-minute understanding of how the network is performing. It also requires the ability to respond quickly to changing circumstances in order to insure system integrity and maintain the high level of service reliability their customers have come to expect. Con Edison’s 63 secondary networks deliver power to specific geographies within its service territory. By some estimates Con Edison has half the electrical distribution networks in the world. Each network is supplied by high voltage “feeders” coming from local substations. Transformers connected to these feeders are dispersed throughout the networks to support the low voltage grid from which many of their customers draw their power. The performance of the power feeds, transformers, and cabling are critical operational factors in determining how the network is performing under all operating conditions and where problems may occur. Sensors installed on each of the 24,000 network transformers help Con Edison manage their complex secondary networks. These sensors provide important, up-to-date load and status information that is collected at the network level and downloaded to Con Edison regional headquarters for use in operating the network systems. This telemetry data feeds a variety of applications that help Con Edison manage their networks and provide customers with extremely reliable electric service. Remote Monitoring Estimation and Load Flow Calculation at Con Edison DYNAMIC ESTIMATION WITH OBJECTSTORE Key to leveraging the data gathered from these thousands of sensors is an estimating application powered by Progress. For a variety of reasons related to their underground locations, the transformer sensors can fail to issue a legitimate reading for a particular transformer, either failing to report or providing incorrect data. Accurate, timely readings are critical to Con Edison’s electric “load flow” application. Results of load flow calculations guide a utility in understanding how the network is currently operating and how the network will supply the future peak demand expected, given the variety of factors that influence both. Load flow calculations are dynamic, near real-time determinations and they require accurate, timely information. To ensure that Con Edison has the most accurate data available to support its load flow application engine, it developed a Remote Monitoring Estimator (RME) application that was built on top of ObjectStore. The ObjectStore solution reviews the telemetry data from the sensor units collected at each network collection point to determine if any readings are inaccurate or missing. The RME application replaces the missing or bad data with an estimate that it derives from calculations executed in ObjectStore. Thus, ObjectStore helps Con Edison ensure that the data to be used for load flow calculations is as accurate and up-to-date as possible. The result is an accurate picture of the network’s status under current and projected operating conditions. CON EDISON DELIVERS WITH THE HELP OF PROGRESS OBJECTSTORE Con Edison requires timely and accurate information. ObjectStore helps it deliver. > ObjectStore allows Con Edison to accommodate “dirty data.” Transformers operate in difficult operating conditions and sensor readings are subject to interference that can obstruct or distort the data readings. With ObjectStore, Con Edison can better accommodate the vagaries of these readings to deliver an accurate portrayal of what is happening in the network. > Transformer data is continuously picked up by specialized applications from each network collection point. This represents a constant refresh of the data that must be delivered to the load flow calculation application. With the ObjectStore-powered Remote Estimation Engine, the utility is able to quickly validate/correct the incoming data. In effect, ObjectStore acts as a front end processor that delivers the timely data needed for the load flow analysis. > The sensor data gathered and analyzed by ObjectStore is also used by Con Edison engineers to support reinforcement and maintenance decisions. Engineers can use historical transformer load data from the previous electrical peak season as a basis for their load flow analysis to predict how the system will perform during the next peak period and whether reinforcement will be required. ABOUT PROGRESS SOFTWARE Progress Software Corporation (Nasdaq: PRGS) provides application infrastructure software for the development, deployment, integration and management of business applications. Our goal is to maximize the benefits of information technology while minimizing its complexity and total cost of ownership. www.progress.com Worldwide Headquarters Progress Software Corporation, 14 Oak Park, Bedford, MA 01730 USA Tel: +1 781 280-4000 Fax: +1 781 280-4095 On the Web at: www.progress.com For regional international office locations and contact information, please refer to the Web page below: http://www.progress.com/worldwide © 2007 Progress Software Corporation. All rights reserved. Progress and ObjectStore are trademarks or registered trademarks of Progress Software Corporation or one of its affiliates or subsidiaries in the U.S. and other countries. Any other trademarks contained herein are the property of their respective owners. Specifications subject to change without notice.