INTEGRATED FARM ASSURANCE | INTRODUCTION ENGLISH VERSION 4.0 EDITION 4.0-2_MAR2013

advertisement

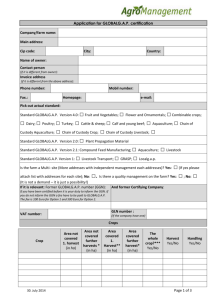

INTEGRATED FARM ASSURANCE | INTRODUCTION ENGLISH VERSION 4.0 EDITION 4.0-2_MAR2013 VALID FROM: MARCH 2013 OBLIGATORY FROM: JUNE 2013 TABLE OF CONTENTS 1. INTRODUCTION 2. GENERAL REGULATIONS 3. EXCEPTIONS AND ADDITIONS TO THE GLOBALG.A.P. GENERAL REGULATIONS SPECIFIC TO IFA 3.1 FRUIT AND VEGETABLES 3.2 FLOWERS AND ORNAMENTALS 3.3 CERTIFICATE INFORMATION DISCLAIMER 5. COPYRIGHT 130315_gg_ifa_intro_and_specific_rules_v4_0-2_update_Mar13_en 4. Code Ref: IFA V4.0_March11; Edition: 4.0-2_Update_Mar2013; English Version Introduction and specific rules Page: 2 of 15 1. INTRODUCTION a) The GLOBALG.A.P. Integrated Farm Assurance (IFA) Standard is a pre-farm gate or on-farm standard that covers the certification of the whole agricultural production process of the product from before the plant is in the ground (origin and propagation material control points) or from when the animal enters the production process to nonprocessed product (no processing, manufacturing or slaughtering is covered, except for the first level in Aquaculture). rd b) GLOBALG.A.P. provides the standard and framework for independent, recognized 3 party certification of farm production processes based on ISO/IEC Guide 65. (Certification of the production process – cropping, growing, rearing, or producing – of products ensures that only those that reach a certain level of compliance with established Good Agricultural Practice (G.A.P.) set out in the GLOBALG.A.P. normative documents are certified. 130315_gg_ifa_intro_and_specific_rules_v4_0-2_update_Mar13_en c) The IFA Standard offers several benefits to producers: (i) Reducing food safety risks in primary production by encouraging the development and adoption of national and regional farm assurance schemes and with a clear risk assessed HACCP based reference standard serving the consumer and food chain. It also serves as technical communication platform for continuous improvement and transparency through consultation across the entire food chain. (ii) Reducing the cost of compliance by avoiding multiple product audits on mixed farming enterprises by a single “one-stop-shop”, avoiding excess regulators burden by pro-active adoption by industry and by achieving global harmonization leading to a more level playing field. (iii) Increase in the integrity of farm assurance schemes worldwide by defining and enforcing a common level of auditor competence, verification status reporting and harmonizing interpretation of compliance criteria. d) The IFA Control Points and Compliance Criteria document is separated into different modules, each one covering different areas or levels of activity on a production site. These sections are grouped into: (i) “Scopes” – covering more generic production issues, classified more broadly. These are: All Farm Base (AF), Crops Base (CB), Livestock Base (LB) and Aquaculture Module (AB). (ii) “Modules” (or “sub-scopes”) – covering more specific production details, classified per product type. Code Ref: IFA V4.0_March11; Edition: 4.0-2_Update_Mar2013; English Version Introduction and specific rules Page: 3 of 15 130315_gg_ifa_intro_and_specific_rules_v4_0-2_update_Mar13_en The diagram below explains the structure of the IFA Standard and the interaction with other GLOBALG.A.P. Standards. Code Ref: IFA V4.0_March11; Edition: 4.0-2_Update_Mar2013; English Version Introduction and specific rules Page: 4 of 15 e) Legislation overrides GLOBALG.A.P. where relevant legislation is more demanding. Where there is no legislation (or legislation is not so strict), GLOBALG.A.P. provides a minimum acceptable level of compliance. Legal compliance of all applicable legislation per se is not a condition for certification. The audit carried out by the GLOBALG.A.P. Certification Body is not replacing the responsibilities of public compliance agencies to enforce legislation. f) Definitions of terminology used in the GLOBALG.A.P. General Regulations and Control Points and Compliance Criteria are available in the GLOBALG.A.P. GLOSSARY document on the website. g) Guidelines referred to by Compliance Criteria in the CPCC document are not normative documents, but only serve as guidance to the producers to comply with the requirements. h) Only products that are included in the GLOBALG.A.P. product list may be certified. Requests to add new products to the product list shall be send to the e-mail address: standard_support@globalgap.org with the following information: (i) Product (ii) Scientific name (iii) Any additional information e.g. cultivation, use, alternative names, pictures, etc. This can be supplied via a website link as well. 2. GENERAL REGULATIONS 130315_gg_ifa_intro_and_specific_rules_v4_0-2_update_Mar13_en a) The GLOBALG.A.P. General Regulations document describes the basic steps and considerations involved for the applicant to obtain and maintain GLOBALG.A.P. Certification, as well as the role and relationship of producers, GLOBALG.A.P. and the CBs. b) The GLOBALG.A.P. General Regulations documents relevant to the IFA Standard are: (i) PART I: GENERAL RULES- the base document, explains the certification options within GLOBALG.A.P., the registration, assessment and certification processes. (ii) PART II: RULES FOR OPTION 2 AND OPTION 1 MULTISITES WITH QMS (iii) PART III: CERTIFICATION BODY AND ACCREDITATION RULES c) Information on benchmarking and rules for benchmarked schemes are explained in the GLOBALG.A.P. benchmarking regulations. 3. EXCEPTIONS AND ADDITIONS TO THE GLOBALG.A.P. GENERAL REGULATIONS SPECIFIC TO IFA 3.1 FRUIT AND VEGETABLES 3.1.1 Normative Documents (i) GLOBALG.A.P. Checklist for unannounced surveillance inspections - The Fruit and Vegetables Sector Committee has approved a shortened checklist for the unannounced surveillance inspections of Option 1 producers. The producer must still comply with 95% of the Minor Musts of the original checklist. The results of the unannounced surveillance inspections replace the results of the corresponding control points of the announced inspection. Non-compliances against minor must control points that were detected during the announced inspections, which are not included in the unannounced surveillance inspection, shall be checked. Code Ref: IFA V4.0_March11; Edition: 4.0-2_Update_Mar2013; English Version Introduction and specific rules Page: 5 of 15 130315_gg_ifa_intro_and_specific_rules_v4_0-2_update_Mar13_en 3.1.2 Registration Process – Application and Certification Scope (i) Harvesting: a) Must be included in the certification scope, unless produce is sold before harvesting and the buyer will carry out handling. b) The CB is responsible for making the decision as to whether harvesting may be excluded or not, based on requirements set out in Part III. (ii) Post-harvest Produce Handling: a) When it does not take place under the ownership of the applicant, it must be declared during registration and indicated on the certificate. b) Is not applicable for a given product where the final packing or handling and the last human contact with the product has taken place in the field during harvest. In this case control points under FV 4.2 are applicable and consequently those under FV 5.0 are not applicable. However, when these products are stored in a walk-in faciity under ownership of the producer, relevant points under FV 5.0 are also applicable and product handling shall be included in the certificate. c) Cannot be included when harvesting is excluded (see (i) above). d) Must always be included as long as the product belongs to the producer during handling (by the producer or subcontractor), unless there is written evidence (contract, agreement, etc.) that the producer has no control over the packing/handling/storage and the product is not returned to the producer. e) Producers must register for “Parallel Production/Ownership” when they own (produce or buy) certified and non-certified products of the same product. f) When the product handling unit (PHU) already has a post-farm gate food safety certification recognized by GFSI (www.mygfsi.com), the GLOBALG.A.P. inspector must inspect segregation and traceability (that is AF.10, CB.1.1 and where applicable AF.12) as well as post-harvest treatments (FV.5.8.1-14) if applicable, unless there is a bilateral agreement between GLOBALG.A.P. and the GFSI recognized post-farm gate standard owner that these points are included in the scope of the post-farm gate certificate. If a producer does not perform product handling on farm, but at the facility of another producer that does have GLOBALG.A.P. Certification (including product handling), the CB may accept another CB’s certificate or the CB may decide to perform its own inspecton of the PHU. 3.1.3 Assessment Process (i) (ii) The Fruit and Vegetables Sector Committee has approved the use of a shortened checklist also for regular announced subsequent inspections as a reward to producers who have been certified for multiple years against Option 1 (possible for Option 3). Rules: 1. The reduced checklist can only be used once a producer has been certified for at least 2 years 2. The outcome of the last two inspection was 100% compliance with the major must and 95% with the minor must control points on the day of the inspection and there were no outstanding suspensions in the last two years. 3. The rules for inspection would be the same as for the unannounced surveillance inspection described above. 4. Whenever the rules for initial inspection as explained in the GLOBALG.A.P. General Regulations Part I holds true (e.g. changing from one CB to another, adding a new product) or when a new version is released, the CB must conduct an inspection against the original (full) checklist. Example 1: For a new Fruit and Vegetables producer seeking certification for the first time (in all years complying with the certification rules): 2011: Full checklist against IFA V4 2012: Full checklist against IFA V4 2013: Approved shortened checklist against IFA V4 2014: Approved shortened checklist against IFA V4 2015: Full checklist against IFA V5 Code Ref: IFA V4.0_March11; Edition: 4.0-2_Update_Mar2013; English Version Introduction and specific rules Page: 6 of 15 (iii) Example 2: For a producer who has been certified against IFA V3: 2011: Full checklist against IFA V3 or Full checklist against IFA V4 2012: Full checklist against IFA V4 or Approved shortened checklist against IFA V4 2013: Approved shortened checklist against IFA V4 This does not change the possibilty of receiving an unannounced surveillance inspection by the CB. 3.2 FLOWERS AND ORNAMENTALS 3.2.1 Conversion period for Flowers and Ornamentals Sometimes, flower and ornamental (FO) GLOBALG.A.P. producers buy material in their early stages of growth from non- certified sources and then complete the growth under certified environment and process until products can be marketed. One of the two options below has to be followed to allow these plants/flowers whose growth is completed under certified production (or controlled production in case of initial certification) to be sold as GLOBALG.A.P. certified. 130315_gg_ifa_intro_and_specific_rules_v4_0-2_update_Mar13_en Option A: 1. Crops shall be grown under the ownership of the FO certified/applicant producer at least 3 months before being sold as certified. 2. In case the growing cycle is shorter than 3 months, at least 2/3 of the growing cycle shall be done by the FO certified/applicant producer and in the case of flowers, growing under GLOBALG.A.P. Standard conditions shall also start before the flower has opened. 3. The beginning of the growing period counts from sowing or when the cuttings are planted. 4. The supplier of the non-certified material shall be an authorized supplier, e.g. propagation material license/authorization according to the national scheme shall be available. Option B: 5. Alternatively, producers can apply for a grace period. In such a case: 5.1. All their suppliers need to be registered for certification in the first year. 5.2. In second year of certification, 50% of suppliers must have obtained GLOBALG.A.P. FO Certification. Code Ref: IFA V4.0_March11; Edition: 4.0-2_Update_Mar2013; English Version Introduction and specific rules Page: 7 of 15 5.3. In third year, 100% of the suppliers must have obtained GLOBALG.A.P. FO Certification. Note: This situation is not considered as parallel production or ownership, therefore, producers do not need to register for it in the GLOBALG.A.P. Database. 3.3 CERTIFICATE INFORMATION The paper certificate issued by a CB must conform to the template as supplied by GLOBALG.A.P. See Template after 5. COPYRIGHT. 4. DISCLAIMER FoodPLUS GmbH and GLOBALG.A.P. approved Certification Bodies are not legally liable for the safety of the product certified under this standard and not liable for the data accuracy and completeness in the GLOBALG.A.P. Database entered by the GLOBALG.A.P. Certification Body. Under no circumstances shall FoodPLUS GmbH, its employees or agents be liable for any losses, damage, charges, costs or expenses of whatever nature (including consequential loss) which any producer may suffer or incur by reason of, or arising directly or indirectly from the administration by FoodPLUS GmbH, its employees or agents or the performance of their respective obligations in connection with the scheme save to the extent that such loss, damage, charges, costs and/or expenses arise as a result of the finally and judicially determined gross negligence or willful default of such person. 130315_gg_ifa_intro_and_specific_rules_v4_0-2_update_Mar13_en 5. COPYRIGHT © Copyright: GLOBALG.A.P. c/o FoodPLUS GmbH: Spichernstr. 55, 50672 Köln (Cologne); Germany, including all standard documents. Copying and distribution permitted only in unaltered form. Code Ref: IFA V4.0_March11; Edition: 4.0-2_Update_Mar2013; English Version Introduction and specific rules Page: 8 of 15 EDITION UPDATE REGISTER New document Replaced document Date of publication 120206_gg_ifa_intro_and_specific_rules_eng_v4_0-1 110411_gg_ifa_intro_eng_final_v4_and_ 6 February 2012 specific_rules Description of Modifications Modification GLOBALG.A.P to GLOBALG.A.P.; 2 b) (i) – modification of wording 120926_gg_ifa_intro_and_specific_rules_v4_0-2_en 120206_gg_ifa_intro_and_specific_rules 26 September 2012 Added new point 3.2 Flowers and Ornamentals incl. _eng_v4_0-1 3.2.1 Conversion period for Flowers and Ornamentals 130315_gg_ifa_intro_and_specifc_rules_v4_0-2_ update_Mar13_en 120926_gg_ifa_intro_and_specific_rules 15 March 2013 _v4_0-2_en 3.1.2 (ii) e) and 3.1.3 (ii) 2. – modification of wording If you want to receive more information on the modifications in this document, please contact the GLOBALG.A.P. Secretariat mailto:translation_support@globalgap.org. 130315_gg_ifa_intro_and_specific_rules_v4_0-2_update_Mar13_en When the changes do not affect the accreditation of the standard, the version will remain “4.0” and edition update shall be indicated with “4.0-x”. When the changes do affect the accreditation of the standard, the version name will change to “4.x”. Code Ref: IFA V4.0_March11; Edition: 4.0-2_Update_Mar2013; English Version Introduction and specific rules Page: 9 of 15 AB symbol accreditation mark2 CB Logo1 No. of Certification Body: xxx3 GGN: xxxxxxxxxxxxxxxxxxxx4 Registration number of producer / producer group (from CB) xxxxxxxxx5 Registration number from Benchmarked Schemes xxxxxxxxxxxx6 7 CERTIFICATE According to GLOBALG.A.P.® General Regulations Version8 Option X9 Issued to Producer group / Producer Company name, Address 10 Country of Production 11 The Annex contains details of the producers and production management units /product handling units included in the scope of this certificate.12 The Certification Body [Company Name] declares that the production of the products mentioned on this certificate has been found to be compliant in accordance with the standard: Scheme Logo (AMC) Standard Control Points and Compliance Criteria Version14 13 The [Standard Name] normative documents have achieved status of equivalence to GLOBALG.A.P. normative documents [Name and version] in accordance to the 15 GLOBALG.A.P. benchmarking procedure. 121108_gg_ifa_gr_paper_certificate_template_en Product 16 GLOBALG.A.P. Product Certificate 17 Number Further columns scope, sub-scope or product specific (description see 18 below) Date of Issuing (printing date of certificate): xx/xx/xxxx 23 Valid from: xx/xx/xxxx Valid to: xx/xx/xxxx24 Number of 19 producers Parallel 20 Production Parallel 21 Ownership 22 Authorized by25 ___________________ Date of Certification Decision: 26 xx/xx/xxxx The current status of this certificate is always displayed at: http://www.globalgap.org/search 27 CB contact data28 Company name, Address (incl. Email) Page: 10 of 15 ANNEX for GGN xxxxxxxxxxxxxxx29 Date of Issuing: xx/xx/xxxx 22 Producer Group Members (Option 2 or 4)30 Product(s) GGN 31 Company/Producer 32 name and address Product Handling/ Post Harvest 33 Activities Parallel 34 Production Parallel 34 Ownership Product Handling Units (PHUs) or Production Management Units (PMUs)35 GGN, GLN or Sub36 GLN Unit name and address 37 Parallel 34 Ownership 121108_gg_ifa_gr_paper_certificate_template_en Product(s) CB contact data28 Company name, Address (incl. Email) Page: 11 of 15 Notes 121108_gg_ifa_gr_paper_certificate_template_en The certificate shall be in English. A second language may be added in the certificate. 1 Certification Body (CB) Logo shall always appear on all certificates. 2 Accreditation Body (AB) symbol/accreditation mark is placed on all accredited certificates in conformity with AB's rules. Exception: When the CB is approved, but not yet accredited the following text must appear instead of the AB symbol: “Certificate issued by a GLOBALG.A.P. approved Certification Body [Company name], but not accredited to the GLOBALG.A.P Scope according to ISO 65/EN45011/ISO 17065 rules’’ or only ‘’Non-accredited certificate”. The AB logo can only be used when the scope of the accreditation of the CB shall correspond to the certified GLOBALG.A.P. Sub-Scope. 3 The number given by the Accreditation Body to the Certification Body shall be on all accredited certificates. 4 GLOBALG.A.P. Number (GGN) shall appear on all certificates. In case a certificate holder owns a Global Location Number (GLN), this number shall replace the GGN. The “GLN’’ or ‘’own GLN” may be used instead of “GGN”. 5 The registration number of a producer or producer group, which is assigned by the CB may appear on all certificates. It consists of the CB-Short and a number (with exactly one space character between, CB-Short xxxxxxxxxxx). 6 Registration number of benchmarked scheme may appear. 7 The logo of the scheme On accredited GLOBALG.A.P. Certificates: The GLOBALG.A.P. logo shall be added. Approved Modified Checklist (AMC): The GLOBALG.A.P. logo shall be added in addition to the AMC logo (13). Full Benchmarked and Equivalent Schemes: The GLOBALG.A.P. logo may be added in addition to benchmarked scheme’s logo. Note: Not-accredited provisionally approved CBs are not allowed to add the GLOBALG.A.P. logo. 8 Certification Scheme and Version For GLOBALG.A.P Certificates: Please enter, e.g. “GLOBALG.A.P General Regulations Version 4.x_date”. Always indicate the exact Version (e.g.: 4.0_Jan2011) For Approved Modified Checklist (AMC): Enter e.g. “GLOBALG.A.P General Regulations Version 4.x”. Please indicate the exact Version (e.g.: 4.0_Jan2011). For Full Benchmarked and Equivalent Schemes (Option 3 and 4): Enter the exact certification scheme version, e.g.: AMAGAP Produktionsbestimmungen Version January 2008. 9 Option must always appear on certificate as: ‘’Option 1 - individual producer’’, ‘’Option 1 - individual multisite producer’’, ‘’Option 1 - individual multisite producer with QMS’’, ‘’Option 2 - producer group’’, ‘’Option 3 - individual producer under full benchmarked or equivalent scheme’’, ‘’Option 4 - producer group under full benchmarked or equivalent scheme’’. CB contact data28 Company name, Address (incl. Email) Page: 12 of 15 Name of the certificate holder (legal entity) and the address shall be printed on the paper certificate. 11 Country of production shall appear on all certificates. 12 Applicable only if a) the certificate holder is a producer group (Option 2 or 4). All producer group members shall be listed in the Annex. b) product handling or packing is included in the scope of the certificate. All product packing and handling units shall be listed as a PHU in the Annex. c) the certificate refers to a multisite (Option 1 or 3) certificate. All sites of the multisite operation shall be listed as PMUs in the Annex. d) the certificate holder has registered for parallel production. All PMUs (production) or PHUs (packing and handling) with certified products shall be listed by product in the Annex. 13 In case of AMC, Full Benchmarked or Equivalent Scheme certificates: Logo of the scheme may appear. 14 Standard Control Points and Compliance Criteria (CPCC) Version, (e.g. “GLOBALG.A.P. Control Points and Compliance Criteria Integrated Farm Assurance Version 4.0_Jan2011” or “AMAG.A.P Version January 2008”). Indicate only the version of the All Farm Base Module. Indicate the version of the approved National Interpretation Guideline if published for the ‘Country of Production’ (according to note 11.). E.g.: “GLOBALG.A.P. Control Points and Compliance Criteria (CPCC) Version 4.0_Mar2011 - Interpretation Guideline The Netherlands (111122) ”. 15 Only applicable for Fully Benchmarked Equivalent Schemes and AMC 16 Certified product(s) shall always be listed according to the GLOBALG.A.P. product list. More detailed information may be included in brackets, e.g. stage of seedlings (species specific information: ova, smolt, fry, fingerling, larvae, alevin, spat, nauplii and post larvae, others) or variety (banana - cavendish). More detailed information shall be included in case of Parallel Production with different varieties. 17 The GLOBALG.A.P Product Certificate Number shall be printed on the paper certificate. It is a reference code to the certificate in the GLOBALG.A.P. Database per product and certificate cycle. The GLOBALG.A.P. product certificate number is generated automatically in the system and consists of 5 digits, 5 letters and a suffix (#####-ABCDE####). All changes to the certificate in a given certificate cycle are reflected in the suffix. 18 The columns and corresponding attributes linked to the products in the table are scope, sub-scope or product specific. Further Harvest Covered (ha) First Harvest Covered (ha) Further Harvest Non-Covered (ha) First Harvest Non-Covered (ha) Parallel Ownership Parallel Production Number of producers Product Handling included Harvest included GLOBALG.A.P. Product Certificate Number For Crops: Product 121108_gg_ifa_gr_paper_certificate_template_en 10 CB contact data28 Company name, Address (incl. Email) Page: 13 of 15 Notes: Harvest included: If produce handling is included, this data field (column) can be omitted. Note: If harvest is excluded, product handling is not applicable for the given product. Product handling (including field packing): Enter yes or no in the column. If product handling in a facility does exist, the PHU for handling or packing shall be listed in the Annex. In case packing is done in the field, the fields or sites may be listed. Quantity (voluntary): Area (in ha) may be included per product according to segregation in “First” and “Further” Harvest or without segregation. In case quantity (in ha) is displayed, “Non-Covered” and “Covered” shall be segregated. Quantity (in tons) Parallel Ownership Parallel Production Number of producers GLOBALG.A.P. Product Certificate Number Product For Livestock products: Quantity (voluntary): Tons (live weight) may be included in certificate. Quantity Seedlings (Estimated no. of organism) Quantity Broodstock (Estimated no. of organism) Farmed Fish (in tons) Parallel Ownership Parallel Production Number of producers Post harvest activity Seedlings purchased? Broodstock purchased? GLOBALG.A.P. Product Certificate Number Scientific name Product For Aquaculture products: 121108_gg_ifa_gr_paper_certificate_template_en Notes: Scientific name: The scientific name shall be listed according to the GLOBALG.A.P. product list. If broodstock is purchased: enter yes/no. If seedlings are purchased: enter yes/no into that column. Post harvest activity: Enter yes or no in the column. If post harvest activity does exist, the PHU (handling or packing) shall be listed in the Annex. Quantity of farmed fish, broodstock, seedlings (voluntary): Tons (live weight) may be included for farmed fish, estimated number of organism may be entered for broodstock and seedlings (in-house production). 19 Applicable for Option 2 or 4: Add number of producers, which are listed in the Annex. Column shall appear only in case of Option 2 or 4. CB contact data28 Company name, Address (incl. Email) Page: 14 of 15 121108_gg_ifa_gr_paper_certificate_template_en 20 Applicable in case of parallel production of non-certified and certified products (yes/no) All PHUs/PMUs for certified products shall be listed in the Annex. 21 Applicable in case of parallel ownership (buying the same, but not certified product, yes/no). 22 Date of Issuing is the printing date of the paper certificate. It shall be added to the first page of the certificate and to the Annex to connect each other. 23 The certificate “Valid from” date defines the beginning of a certification cycle. 24 The certificate “Valid to” date is the expiry date of the certificate. 25 The first and the last name of the person who has authorized the certificate, it shall be written in block letters. This person must sign the certificate. 26 “Date of Certification Decision” shall appear on all certificates. It is the date when the Certification Committee makes the certification decision. 27 This note shall be added to all paper certificates to point out that only a validation in the GLOBALG.A.P. Database proves the current status of the certificate. 28 CB contact data (company name, address, email) shall appear on all certificates. 29 The Annex (incl. the GGN of the certificate holder) shall be added, if applicable. 30 In case of Option 2 or 4, all members of the producer group shall be listed in a table per product. 31 All members of the producer groups (Option 2 and 4) are different legal entities and receive a GGN, which shall appear in the table. 32 Name and address of the producer group members shall be printed on the certificate. 33 Indicate which members have product handling (“Yes”) and which do not (“No”). 34 In case of parallel production or parallel ownership of non-certified and certified products this shall be indicated (yes/no). In this case, all PHUs and PMUs with certified products shall be listed. Column shall appear only if certificate holder /group member has registered for parallel production or for parallel ownership. 35 In case of product handling and packing (including storage) or post harvest activity: all PHUs for handling or packing shall be listed in a table per product. In case of multisite Option 1 or 3: all sites (PMUs) shall be listed in a table per product. In case of parallel production or parallel ownership: all PHUs (packing and handling) and PMUs (production) with certified products shall be listed in a table per product. 36 In case PHU or PMU has a, (own) GLN or Sub-GLN, it shall be listed. This is applicable independently from legal ownership of the units. In case PHU or PMU belongs to another legal entity and has no Sub-GLN, certificate holder’s GGN or GLN shall be noted. In all other cases (e.g.: subcontracted packaging company without agricultural production) this entry is optional. 37 Name and address of the PHU or the PMU shall be listed. It can be the same address as the legal entity. Units may have the same physical address. CB contact data28 Company name, Address (incl. Email) Page: 15 of 15