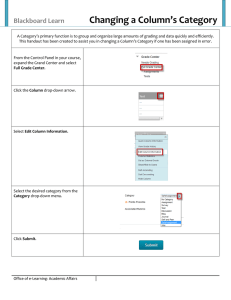

Pergamon

advertisement

J. Mech. Phys. Solids, Vol. 46, No. 7, pp. 1155 1181, 1998

(~) 1998 Elsevier Science Ltd. All rights reserved

Printed in Great Britain

0022-5096/98 $19.00 + 0.00

Pergamon

PII : S0022-5096(98)00004-0

THE POST-BUCKLING

RESPONSE OF A BI-LATERALLY

CONSTRAINED

COLUMN

HERZL CHAI*

Department of Solid Mechanics, Materials and Structures, Faculty of Engineering, Tel Aviv

University, R a m a t Aviv, Tel Aviv 69978, Israel

(Receit~ed 28 April 1997; in revised form 6 January 1998)

ABSTRACT

The post-buckling behavior of a linearly elastic column under a bi-lateral constraint is studied experimentally and analytically with an eye toward applications to corrugated sandwich structures. Under a

controlled axial displacement, a rather rich sequence of events unfolds, including the formation of discrete

or continuous contact zones between the column and the guiding walls and the instantaneous transition of

the buckling waveform to a new equilibrium configuration due to local instability. The specific details,

which depend on the system parameters as well as on the loading direction, are quantified based on the

linearized differential equation of the column and without recourse to imperfections or energy considerations. For a frictionless contact, the response of the column exhibits a degree of statistical variation, but

the range of this variation can be bounded. A companion elastica type analysis is also developed to account

for large rotations which occur at large end shortenings. Under this condition, the ever repeating mode

transition process which is predicted by the small deformation analysis ceases. Other interesting buckling

characteristics are found which should be useful for the understanding of more complex contact/stability

systems. ~ 1998 Elsevier Science Ltd. All rights reserved.

Keywords: A. buckling, B. beams and columns, contact mechanics, stability and bifurcation, elastic

materials.

1.

INTRODUCTION

This work was originally motivated by studies of buckling induced growth of subsurface interlaminar defects in layered composites. For certain disbond geometry and

boundary conditions, a wavy buckling pattern may develop in the delaminated region.

The interaction between the buckle and the parent laminate or substrate alters this

process, which may affect the stiffness and failure characteristics of the global structure. This phenomenon has been dealt with analytically (e.g. Whitcomb, 1988 ; Chai,

1990; Giannaakopoulos et al., 1995), but only as it relates to delamination propagation. In view of the basic nature of this problem, a more general consideration

seems to be warranted. The following discussion will be limited to a film/substrate

type contact associated with elastic stability (even though such a distinction may be

an artificial one). Siede (1958) studied the response due to longitudinal compression

of an infinitely long, simply supported (along the long axis) plate which is unilaterally

constrained by a Winkler foundation. Assuming a periodic deflection profile along

* Fax : 00972 6407617. E-mail: herzl(a eng.tau.ac.il.

1155

1156

H. CHA1

the long axis, the buckling load was found to depend on the foundation stiffness,

being, in the case of a rigid constraint, 32% greater than that of the unconstrained

plate. The contact regions in this case were limited to periodic lines extending along

the short axis of the plate. This work was later extended by Shahwan and Waas (1991)

to include material anisotropy and other boundary conditions. The more complex

problem of a finite size plate which is constrained by a rigid wall was treated by

Hhatake et al. (1980) using a finite element scheme coupled with the penalty method.

These authors also provide in~brmation on the evolution of the contact region in the

post-buckling regime.

Although the majority of practical film/substrate contact problems are associated

with two- or three-dimensional stress fields, in light of their complexity, analytically

tractable solutions to one-dimensional configurations would be desirable. Indeed,

numerous works are available in this case, the majority of which deal with the response

due to axial or transverse loading of either flat or curved beams under a unilateral

constraint (e.g. Burgess, 1971 ; Soong and Choi, 1986; Steint and Wriggers, 1984;

Plaut and Mroz, 1992). The progression of the film/substrate contact zone with load

was established via the elastica equilibrium equation or other numerical procedures.

No special consideration is given in any of these sources to the important phenomenon

of local instability or bifurcation that may occur when the load becomes sufficiently

large. From our perspective, the unilateral constraint problem is somewhat limited in

scope because it does not generally lead to an ever-repeating buckling mode transition

with increasing load (as, for example, in the case of some two-dimensional plate

problems). An exception to this is the work of Chateau and Nguyen (1991), ~ who

considered a rigid plane type constraint which is located a certain distance from the

axis of the column. Their experiments show that following Euler buckling, a contact

zone develops between the column and the wall. This zone spreads with load until it

buckles, leading to a symmetric two-buckle configuration. Treating each individual

buckle in the new configuration as an inextensional beam which deforms according

to the classical elastica, these authors provide a graph showing the evolution ot+ the

end rotation of the column with axial load.

In this work, the response of a bi-laterally constrained column under axial

compression, see Fig. l, is studied experimentally and analytically. The tests show

that such a constraint leads to an ever-repeating sequence of local bifurcation which

extends the range of behavior possible with the unilateral constraint case. In addition

to resembling some post-buckling features encountered for narrow plates (with or

without a unilateral support), the problem at hand is directly relevant to a range of

technological applications. This includes compliant foil journal bearings (Heshmat et

al., 1983), corrugated fiberboard (e.g. Johnson and Urbanik, 1989), structural core

sandwich panels (e.g. Nordstrand and Carlsson, 1997) and sheet forming (Triantafyllidis and Needleman, 1980; Cao and Boyce, 1997). For such applications, the

evolution with end shortening of both the axial force in the column and the transverse

reaction exerted by the guiding walls are of interest. Both small and large deformation

(elastica type) analyses are performed. It is shown that these analyses are capable of

describing the entire post-buckling behavior, including secondary bifurcation branches.

'The author has become aware of this work during the review of this manuscript.

The post-buckling response of a bi-laterally constrained column

1157

P

I

~ loadin~ block

~t

specimen

specimen

)

i

1/I

\

/

Fig. I. Test fixture for a bi-laterally constrained column.

The buckling tests are reported in Section 2, where the phenomenological aspects

of the deformation process are exposed. This information is then used to obtain

analytically tractable solutions, both under small (Section 3) and large (Section 4)

deformation. The correlation between the analysis and the test results is assessed in

Section 5. In Section 6, the analysis is extended to geometrically imperfect or corrugated columns.

2.

EXPERIMENTAL

Tests are carried out to elucidate the response of a bi-laterally constrained column

under axial compression. Figure 1 shows the loading fixture used. To increase the

range of elastic deformation possible, very slender beams are used. Because this entails

a great sensitivity to geometric imperfections, a high degree of precision in the

machining and alignment of all the relevant components of the test apparatus is

employed. The test columns are cut from a polycarbonate sheet having a Young's

modulus of 2.3 Gpa and a proportional limit of about 1%. Two specimen geometry

are tested, i.e. (b, t, Lo, h) = (I 2, 1.05, 115, 2 mm) and (12, 0.70, 115, 2.35 mm), where

b, t and L0 are the width, thickness and gauge length of the column, in that order,

and h is the net gap between the wall and the surface of the column. The specimens

1158

H. CHAI

with t = 1.05 mm and t = 0.70 mm, designated as " A " and "B", respectively, allow

for the formation of up to three and four buckles, respectively, with no detectable

irreversible deformation.

The specimen, with its clamp type end grips attached, is inserted into the gap

between two parallel steel blocks which surfaces are oiled to reduce friction. This gap

is then adjusted until an intimate contact with the end grips occurs. The load is applied

via a rectangular block which presses down on the upper end grip without introducing

bending into the specimen. The axial load, P, and the end shortening, A, are recorded

during the test. The edge of the column is observed in real time with the aid of a video

camera.

2.1.

Test results

Figure 2 typifies the P vs A response for specimens A and B while Fig. 3 shows

several corresponding video micrographs taken during the tests. The position on the

P vs A curve of each print is identified by the common letters l, II, etc. Referring to

Figs 2a and 3a, the deformation process can be characterized as follows: (1) Contact

between the column and the surface of the lower wall is first formed in Frame II. (2)

The contact points (at the center and the ends of the column) spread into line contact

zones (Frame III). (3) The central contact zone buckles, leading to the instantaneous

formation of two buckles (i.e. n = 2, where n denotes the number of buckles in the

600

.--. 4 0 0

~.~ 200

~

/

o

Frame~_.~I

IV

(a) sample A

i

•- - ~ 3 0

I-i[

4

T3

<

U

20o

lO0 1 ~ ~ ~ 3

O0 ~" ""

f

1

i

2

~

"IV (b) sample B

i

3

I

4

J

5

End Shortening, A (mm)

Fig. 2. Typical compression load vs end shortening test records for specimens A and B; n denotes the

number of waves in the column.

The post-buckling response of a bi-laterally constrained cohmm

. . . . . . .

,

Ill

,.-. . . . . .

,

i

.

L

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Ill

.

IV

. . . . . . . . . . . . . . . . . . . . ". . . . . . . . . . . . . . . . . . . . .

........

-

.......................................

1159

:.

J

-

.

II

Vll

(a) S p e c i m e n A, (b, t. Lo, h) = (12mm, 1.05ram, 115mm, 2mm)

. . . . . . . . . .

~

. . . . . .

nln i

l

-

i~;~;~,~,,::

: .............

;::

• :~--.~

......

11

Ill

IV

V

(b) Specimen B, (b,t, Lo.h) = (12ram, 0.70ram, 115ram, 2.35mm)

Fig. 3. Selected video micrographs corresponding to the test specimens of Fig. 2 : the position of each

frame on the corresponding P vs A record is identified by the common letters 1. I1. etc.

The post-buckling responseof a bi-laterallyconstrained column

I 161

column) having five contact points (Frame IV). As shown in Fig. 2a, during this jump

the end displacement remains constant but the load drops somewhat. (4) As A is

further increased, the contact points once again grow into line contact zones, some

of which are longer than the others (Frame V). Next the system snaps into a threebuckle configuration (Frame VI). A careful examination of the video records revealed

that this snapping was due to the local buckling of the longest of the flattened segments

of the column (i.e. the second from the right). In Frame VII, a cup like deflection

pattern associated with plastic deformation is seen; this pattern initiates from the

loaded end of the column. The behavior for the thinner specimen (Figs 2b and 3b) is

quite similar except that one more buckle is formed before plastic deformation

becomes apparent. Figure 2b also provides information on the response under a

reversed loading. In this case the column, having three buckles (Frame II), was first

unloaded until a jump to a two-buckle configuration occurred and then reloaded to

a complete failure. As shown, this has resulted in a rather unique nonlinear elastic

response. (The slight departure between the first and the second loading paths is likely

due to frictional effects.)

While the aforementioned phenomenological sequence was common to all tests,

there were significant variations of a rather statistical nature in the P vs A curve

among nominally identical samples. This effect is attributed to asymmetry in the

buckling pattern which is evident in some of the prints in Fig. 3. To gain further

information on this, a few tests were halted sometimes during the loading, and the

buckle waveform manually displaced using tweezers. No change in either the load or

the end displacement occurred as a result of the motion of the buckle. The latter

greatly affects the onset of local instability, however, and thus the overall response of

the column. This interesting phenomenon will be discussed further in Section 5,

following the development of the analysis.

3.

SMALL D E F O R M A T I O N ANALYSIS

Let a flat, linearly elastic column of length L0, thickness t, width b and Young's

modulus E be constrained by two rigid and frictionless planes separated by a distance

h0, see Fig. 4a. The column, which initially lies along the surface of the upper wall, is

clamped on both ends. Under axial compression, the column buckles. The postbuckling behavior, which is effected by the interaction of the column with the walls, is

studied as a function of the end shortening, A. The fourth-order, linearized differential

equation for an Euler beam under axial compression is given by

P

y ' " + k 2 y '' = O,

k2 -~ E l -

12P

Ebt 3

(3.1)

where a prime denotes differentiation with respect to x, y is the lateral deflection

and P and I are the compression force and the moment of inertia of the column,

respectively.

H. CHAI

L0

1162

p

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

,

. .

¢

i

¢

¢

¢

¢

t

t

'1

¢

t

i

i

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

~

. . . .

A

T T tt

h0 h

(a)

,[

(

c

)

~

.... a i?iiii

•

......

(t) -

-~L . . . . .

-

"

~

.... ~

....................

1-ii

¢~.t¢'¢t'.

:'6

......

:~: . . . .

~

'

2""'.q

'

=

"

H

.. ~. . . . .. . . . . . . . .. .. 4. / /

""

•

. . . .

........................

:

"

~

Fig. 4. The deformation sequenceof a guided column under axial compression.

3. I.

Pre-contact

Following buckling, the column separates from the upper wall. The mid-span

amplitude, A, continuously increases with A until contact with the lower wall occurs.

The boundary conditions for this loading range (0 ~< A ~< h, see Fig. 4b) are

y(O) = 3"(0) = y(Lo) = y'(Lo) = 0

(3.1.1)

where h is the net gap between the column and the walls, i.e.

h = h0 - t

(3.1.2)

The solution of (3.1) and (3.1.1) is given by

y=

A( 1 - c o s ~2~x~

-0 )

(3.1.3)

with the post-buckling load given by ; = I, where ~ is the normalized square-root

axial force, defined as

kLo

-= 2zt

(3.1.4)

The amplitude A is found from the following geometric compatibility condition

1163

The post-buckling response of a bi-laterally constrained column

(y,)2 dx

A = e.,Lo +

(3.1.5)

0

where e, is the m e m b r a n e compression strain, given by

P

(3.1.6)

e.,. = E b t

and H = L o / 2 . Use of (3.1.3)-(3.1.6) gives

A

2t

.........

=

(3.1.7)

1 ~ r/ ~< 1 + 0 . 7 5 / ~ 2

where

3Lo A

f~ - h / t ,

3.2.

~l -

(3.1.8)

(~t)2

Point contact

One r/is increased from 1 + 0.75/~ 2, the column touches the opposite wall at x = L o / 2 ,

see Fig. 4c. The b o u n d a r y conditions for the free standing segment o f length H

( = L0/2) are

y(0) = y'(0) = y ' ( H ) = 0,

y(H) = h

(3.2.1)

Using (3.1), (3.2.1) and (3.1.5), one finds

y

sin(zc¢~/n) -- z~gS:/n + [1 -cosOzgg/n)] • tan(~g/2n)

h

O <<.~. - x / H

<~ 1

2 tan 2n (3.2.2)

l/cos 2 ~

q = ¢2 +0.75/~2

-

~ tan~]

(3.2.3)

where, for the time being, n = I. Examination of (3.2.2) shows that once ¢ exceeds

two, the column penetrates the walls in the n e i g h b o r h o o d of the contact points. Thus,

the validity of (3.2.2) and (3.2.3) is limited to 1 ~< ¢ ~< 2.

3.3.

L&e contact

Guided by the experimental observations, it is assumed that a line contact develops

over the segments a, b and c, defined in Fig. 4d, once ¢ exceeds two. The independent

b o u n d a r y conditions for the free standing segment o f length H, taking into account

the vanishing of the bending m o m e n t , M, along the contact zones, are

H. C H A I

1164

y(0) = y'(0) = y"(0) = y ' ( H ) = 0,

y(H) = h

(3.3.1)

The solution o f (3.1) and (3.3.1) is

y

( 2 ~ X - sin 27rYe)

h-

2g

0 <~ 2 - x / H ~< 1

(3.3.2)

with the axial load c o n f o r m i n g to

kH

2~ = l

(3.3.3)

H / L o = l/;

(3.3.4)

Equations 3. 1.4 and 3.3.3 give

Using (Yl.5), (3.3.2) and (3.3.4), one finds

9n/~2

~ = - , ~2 ~_ _ _

27t2 ;

(3.3.5)

where, for the time being, n = l.

3.4.

M o d e transition

The contact zones spreads with increasing ~/until the longer o f the flat segments a,

b, c buckles. The tests conclusively show that the system snaps to the next higher

buckling mode, i.e. from n = 1 (Fig. 4d) to n = 2 (Fig. 4e), where n denotes the

n u m b e r o f buckles or waves in the column. F r o m geometric compatibility

a+b+c+2H

= L,~

(3.4.1)

or, using (3.3.4)

a+h+c

...........

L0

1-

2

¢

(3.4.2)

As pointed out in Section 2. I, the buckle waveform m a y travel freely within the length

o f the column. The associated variations in the lengths o f the contact zones (a, b, c)

would affect the onset o f local instability. Nevertheless, the load at which mode

transition occurs can be bounded. The lower limit obviously corresponds to a single

zone, say c (i.e. a = b = 0). Equation 3.4.2 then reduces to

c

Lo

- 1

2

(3.4.3)

or, using (3.1.4),

kc

2-/r = c, - 2

(3.4.4)

On the other hand, the upper limit for m o d e transition occurs if all the flattened

segments are o f equal length, i.e. a = b = c. This gives

The post-buckling response of a bi-laterally constrained column

3c

Lo

- 1--

2

,"

or

kc

2n

-

~- 2

3

1165

(3.4.5)

The most probable configuration corresponds to 2a = 2b = c. We shall refer to this

configuration as "symmetric". In this case, eqn (3.4.2) reduces to

kc

2z =

~-2

--2

(3.4.6)

The flat segment of length c buckles as an Euler column having clamped ends so that

kc/2rt = 1. Therefore, from (3.4.4)-(3.4.6), the transition to the second buckling mode

is bounded in the range 3 ~< g ~< 5, with "symmetric" buckling taking place at ~ - 4.

In practice, the friction between the column and the guiding walls will act to reduce

the mobility of the buckle and thus the degree of arbitrariness in the response of the

column. Section 5 provides some experimental evidence concerning this inherent

scatter. For presentation purposes, we shall adopt throughout this work the results

for "symmetric" buckling.

3.5.

Solutions j b r multiple buckles

Let n buckles exist in a column of length L0 (Fig. 4f), with the buckling configuration

being either a point contact or a line contact. For the former case, one has

H = Lo/2n,

AH = A/2n

(3.5.1)

where H and AH are, respectively, the length and end-to-end shortening of each free

standing segment of the column. It can be easily shown that the deflection of each

segment and the total end shortening are given by (3.2.2) and (3.2.3), respectively,

where n denotes the total number of buckles in the column. Moreover, the transition

from a point to a line contact occurs when ~ = 2n. Similarly, the results for the

"symmetric" line contact case are given by (3.3.2) and (3.3.5), with the transition to

the next buckling mode being at q = 4n. It can be easily shown that the axial load at

the onset of node transition is bounded by 1 + 2 n ~< c ~< 1 +4n. For the "symmetric"

buckling pattern considered (~ = 4n), eqn (3.4.1) reduces to

2 n ( c + H ) = L0

(3.5.2)

Multiplying both sides of (3.5.2) by k / 2 z and noting (3.3.3), the dependence of the

contact zone length on the load is found to be

C

2n Lt~ = 1 - 2n/~

(3.5.3)

Figure 5 shows the variations with r / o f c, and c/H. The results are constructed for

the choice /~ = 3. Also shown is the curve for /~ = 0 corresponding to the upper

bound of the range of behavior possible. (The lower bound is represented by g = 1.)

Following buckling, c~remains fixed ( = 1) until contact with the wall occurs (r/= 7.75).

The point contact solution [dashed line, eqn (3.2.3)] holds true up to g = 2. Thereafter,

a line contact develops [solid line, eqn (3.3.5)]. When ~ = 4, the column snaps into

two buckles (n = 2) during which ~/remains fixed but ~ drops somewhat. Note that

H. CHAi

1166

d~

II

d

4

¢.)

10

h/t=0

3

/

2-..

.

~

J

@

~

..

SS"

/

5

/

¢)/

4~ 0

¢..

~D

.-

ill/i//"

r©

t'q

,fi

, / J / . ' . . ...............,"

O

,P ......... ,

2

..

I.......... /

.:,

.......

Z

@

Z

~.~,"

o

0

,

I

100

,

"%~*"

,

t

I

,

,

200

,

I

,

300

L

,

,

0

400

Normalized end shortening 1"1(= 3 L ~ )

'

\

(~t) 2

Fig. 5. The normalized square root axial load (g) and the normalized length of the line contact zone (c/H)

vs the normalized end shortening (q); h/t = 3. The dashed and the solid lines correspond to the point

contact and the line contact configurations, respectively,while n denotes the total number of waves in the

column. The upper curve corresponds to the limit case hit = O.

the new c o n f i g u r a t i o n is a p o i n t contact. W h e n g reaches four, a line contact forms.

The next mode transition (i.e. to n = 3) occurs at g = 8, although the transition n o w

is to a line contact. This process continues indefinitely unless plasticity or some other

failure m e c h a n i s m intervenes. It should be noted that the response of the c o l u m n

depends o n the l o a d i n g direction. If, following a j u m p from the nth to the next

buckling mode, the c o l u m n is u n l o a d e d rather than loaded, one eventually returns to

a lower buckling m o d e t h r o u g h a different path which describes a rather u n c o m m o n

n o n l i n e a r elastic behavior.

W h e n the buckle snaps, it is of interest to determine whether the new configuration

is a point contact or a line contact. It can be easily shown that this choice is dictated

by the sign of D in the following e q u a t i o n

D - ,q2 ( n 2 - 1 - 2 n ) + 4 . 3 8 5 ( 3 n 2 - l - 2 n )

(3.5.4)

in which the j u m p is to a line contact if D > 0 a n d to a p o i n t c o n t a c t if D < 0. It is

seen that regardless of/~, the t r a n s i t i o n is to a point contact if n = 1 a n d to a line

contact if n >~ 3. F o r n = 2, the t r a n s i t i o n is to a p o i n t contact if/~ < 5.54 a n d to a

line contact if,q > 5.54.

3.6.

Lateral reaction

The lateral forces exerted on the c o l u m n once c o n t a c t with the walls occurs are of

particular interest if the walls are flexible (as for corrugated fiberboard a n d structural

The post-buckling response of a bi-laterally constrained column

15

1167

h/

/r

s, /

//

/

ig

i/I

3/ ~

,f

jl

5

2

.......

Small deformation analysis

Large deformation analysis

/t

I

~0

0

I

i

i

i

[

0

i

i

i

i

50

i

i

i

i

i

100

[

i

i

150

Normalized total lateral reaction force, R (= R ~ ' )

Fig. 6. The normalized square root axial load vs normalized total lateral reaction. The orientation of the

slanted lines connecting the different buckling modes depends on

which was taken as three for

illustration purposes.

h/t,

core sandwich plates) or when frictional effects are significant. These forces, which

m a y move during the loading, are limited to a set of discrete points acting at the ends

o f the free standing segments of the column. Their resultant, R, is given by

R = 2nV(0) = 2 n E / y ' ( 0 ) ,

(3.6.1)

where V(0) is the internal shear force at each end of a segment. Using (3.2.2) and

(3.3.2), one has

4n 2

/~ =

1

--

rcc

for point contact

(3.6.2)

tan

/~ = 2n~

for line contact

(3.6.3)

where

/~ =

R L0

-Ph

(3.6.4)

Figure 6 (dashed lines) shows the development of R with g for a continuously

increasing q. Note that the transition to higher buckling m o d e s occur along the slanted

lines m a r k e d by an arrow. The orientation of these lines depend on /~, which was

taken as three in the illustration. The total reaction force generally increases with 7,

and it m a y exceed the axial force if n and h/Lo are sufficiently large.

H. CHAI

1168

I

I

.....

..1..........................

....................

Iy

~A0

(a)

J.........

. .... J

. . . .

N

(c)

p

.L~Y

:x

- v~o x---t

Fig. 7. Notations for a bi-laterally constrained column ; large deformation analysis.

4.

LARGE DEFORMATION ANALYSIS

The previous analysis becomes progressively inaccurate as the buckling wave number or the angle of rotation of the column is increased. Because this effect is more

severe for a line type contact, the analysis will be limited to that case. Referring to

Fig. 7 for notation, the equilibrium differential equation for a typical free-standing

segment is given by

V(s) = EIO"

(4.1)

where the differentiation is with respect to the arc length, s, and O(s) and V(s) are the

angle of rotation and the internal shear force, respectively. From equilibrium

V(s) = Vo cos 0 - Psin 0

(4.2)

Z,, =_ V(s = 0)

(4.3)

where

Since the bending moment at the ends of the segment vanishes (i.e. M ==-EIO' = 0 at

s = 0 and s = L, where L is the length of the free standing segment), one has from

equilibrium

V0 = P/~

(4.4)

ft = h / H

(4.5)

where

and H is the projected length of the buckle. Using (4.4), (4.2) and (4.1), one has

0" = k 2 (/~ cos 0 - sin 0)

(4.6)

where k is defined in eqn (3.1). The solution of (4.6) satisfying a zero bending moment

as s = 0 is given by

The post-buckling response of a bi-laterally constrained colunm

dO

ds

-

~//2k ~/(cos 0 + h sin 0 - 1)

1169

(4.7)

Making use of

dx

ds

dv

dTx

cos0,

sin0

(4.8)

one has for the arc length S and the horizontal and vertical distances, X and Y,

respectively (see Fig. 7c)

~o,,_ (12cos/~.~.~.~O,

si_n 0) d 0

J0~o) x / c o s O + h s l n O - 1

_- x/~k ~.s,x,,'.

jo

(ds, dx, dy)

(4.9)

Except for the term associated with h, these integrals are identical to that for the

elastica problem discussed in Timoshenko and Gere (1961). Substituting

0=q~+~,

a=tan

1/~

(4.10)

and employing standard trigonometric identities for cos 0 and sin 0, one can show

that

- 1 + c°s 0 +/~ sin 0 = 2w/] + / ~ ( sin2 }c~ - s i n 2 ~ )

(4.11)

where, from the right hand side of (4.10)

1

(4.12)

sin ~ = sin ~" sin qS.

(4.13)

Substituting

one has

-

1 + cos 0 + fi sin 0 = (x/i +/~2 _ 1) cos: ~b

(4.14)

Putting this in (4.9), one has

ffc~)

~1~l~OS~ si n O)

1 -- sm"

= (S, X, Y)-k "(1 +/~2)o.25

(4.15)

sin- q5

Since O(s = 0) = 0, (4.10) and (4.13) imply that qS(s = 0) = - n / 2 . The upper limit of

the integrals in (4.15) is determined from the vanishing of the bending moment (and

hence of 0') at both the left end (s = 0) and the mid-point (s = L/2) of the free

standing segment of the column. Equations 4.7 and 4.14 thus, imply that ¢(L/2) = n/2.

Therefore,

- ~ / 2 ~< ¢(s) ~< 7r/'2, 0 ~< s ~< L/2

(4.16)

1170

H. CHAI

To evaluate (4.15), one needs to express cos0 and sin0 in terms of 4~. Using (4.10)

and (4. ! 3), one finds

c~

c~

c o s O = II --2 sin2 ~. sin2 q~-- 2/~ sin ~- sin ~b•

c~

1

1 --sin2 g. sin2 q~ ,

~1

z

J ,¢/' 1 +/~2

(4.17)

A similar expression for sin0 can be found with the aid of (4.14) and (4.17). Introducing these expansions in (4.15), one has

kS

27z

,

[F(~b, ~/2) + F(x/2, ~/2)]

2rr(l +/~2) ,,4

(4.18)

[

2~ - 27r(1 _}_/~2)3/4 2E(~b, ~/2) +2E(m/2, ~/2)

-F(go,~/'2)-F(g/2,~/2)+2hsin}.cos(o

k Y (l q.-h2)l/4{

2~z

-

-

rr

o~

E(4~, ~/2) + E(rt/2, ~/2) - cos 2 ~" [F(4~, ~/2) + F(rc/2, ~/2)]

+

(4.19)

}

k(s-x)

~/~---

(4.20)

where F and E denote elliptic integrals of the first and second kind, respectively,

defined by (e.g. Abramowitz and Stegun, 1972)

F(~b, ~/'2) = f e

dq~

(4.21)

J,

1 -

sin" ~- sin-

4~

E(q~, c~/2) = I+ X/(1 - sin2 ~"

:~ sin2 4~) d~b

(4.22)

When ~b = =/2, one has

kL

2F0t/2, :~/2)

2~

kH

2~

-

-

x//l~-2r

212E(~/2, ~/2) - F(~/2, ~/2)] (1 - 2r)3.2

=

(4.23)

(4.24)

where

r --= sin2~ =

1--

(4.25)

The post-buckling response of a bi-laterally constrained column

1171

0 (s=L/2), deg.

"~\'

2

90

,

180

'/

kH..--X \

s

0

,

~

,

,

.

/~" 0

i

I

.

.

.

0.5

.

1.0

kH/2rc or H/L

Fig. 8. The variations with h/H of the ratio of projected length to arc length, H/L, the normalized square

root axial, kH/2rr, and the midpoint rotation angle of the free standing segment of the column, O(s = L/2).

i.

Lo

'1

Fig. 9. The buckle waveform for two levels of end shortening; h/Lo = 20.15. The ends of the column for

each load are indicated by tic marks.

Since 0 ~< r ~< 0.5 for all values of h, the series representation in terms o f r tor E and

F converge rapidly for all/~. Their expansion for/~ < 1 leads to

kL

- 1 -0.1875/~ 2 +0.103/~ 4 + 0 ( h 6)

2Tt

(4.26)

kH

27~ - ! -0.9375/~ 2 +0.830h 4 +0(/~ 6)

(4.27)

These asymptotic expansions are found to be accurate to within 2.6% o f the full term

solution if/~ ~< 0.6.

Figure 8 shows the variations of the loading p a r a m e t e r kH/2g, the ratio H / L and

the mid-point rotation, O(s = L/2), with/~. The small deformation solution ( H / L = 1)

seem to hold well up to h ~ 0.1 and O(s = L/2) ~ 30'. As/~ is increased, the axial load

in the column diminishes, a p p r o a c h i n g zero for/~ ~ ~ . Figure 9 shows the buckling

w a v e f o r m for two mid-point rotation angles, i.e. 0 = 88 and 136 '~, for which tabulated

data are available ( A b r a m o w i t z et al., 1972). These two choices, corresponding to

h = 0.97 and 2.48, respectively, have identical column length, Lo; the ends of the

deformed state are denoted by tic marks. As shown, the buckle tends to resemble an

S shape as the end shortening is increased.

1172

H. CHAI

0

1

. . . .

2

I

0.12

/ '

Y'

~

/

'

'

'

~

1

'

'

'

/

0.04

O0

'

'

'

'

0.5

'

'

1'.0 '

'

'

(=h/H)

Fig. 10. The variations with the parameter h/L~of h/H and c/H at the onset of mode transition. The dashed

lines are the predictions of the small deformation analysis.

4. I.

Mode transition

As for the small d e f o r m a t i o n analysis, m o d e transition is taken to occur when the

flattened segment o f length c buckles as an Euler column (i.e. kc/2n = 1). F o r a

column with n buckles, 2n(c + L) = Lo. This can also be written as

c

L0 /~

L

H-

h 2n

H'

or

c

1

Lo-2n

h L1

Lo Hh

(4.1 .I)

Thus, m o d e transition occurs when

2n \ t7 2,1

H}

1

(4.1.2)

F o r a column with a given h/Lo ratio, the onset of local instability can be determined

as follows: starting from n = 1, c = 0 and L = Lo/2, one finds iteratively from Fig. 8

the equilibrium values of,~ and H/L. (Note at this step that h/Lo = h/2L = 0.5hH/L).

Next, h is given a small increment (i.e. H is reduced), and the concurrent values of

H/L and kH/2n determined from Fig. 8. Using eqn (4.1.1), c/H is then found. This

incrementing process continues until eqn (4.1.2) is satisfied, at which point m o d e

transition occurs. Figure I 0 shows the dependence of/~ and c/H at the onset o f m o d e

transition on the p a r a m e t e r h/Lo. The results significantly depart from their small

deformation counterparts (i.e. c/H = 1,/~ = 4h/Lo), shown by the dashed lines, once

h/Lo is increased from a b o u t 0.05. Moreover, it is seen that no local instability is

possible if h/Lo > 0.141.

4.2.

End-shortening ~s axial force

The end shortening for a column of length L0 having n buckles is given by

(

A = 2n L - H +

f

e, ds+cr,,

)

(4.2.1)

The post-buckling response of a bi-laterally constrained column

1173

where ~x is given by (3.1.6) and ~,~and N are the membrane strain and the longitudinal

compression force (see Fig. 7c), respectively, in the free standing segment:

N

P(cos 0 + h sin 0)

~•~ - b t E -

(4.2.2)

btE

Making use of (4.7), one has

; fds , r, L, cosO+,s,nO,

e~ds-=

•

e~d0-

d0

(4.2.3)

12~/5j0(~-=0, ~ f i c o s 0 + / ~ s i n 0 - 1)

Using results from previous Sections, one finds

~z2t2(l +/~2) \2Jz/

j g~ ds . . . . . . . . . . . . . . . . .

o

3H

,,,

(4.2.4)

from which

(4.2.5)

Noting that

kLo

k H Lo

--- . . . . . . . . .

2~

2g H

k H Lo

(4.2.6)

2zt h

eqn (4.2.5) can be expressed as

(4.2.7)

Figure 11 (solid lines) shows the variations with r/of c / H and c. The results, specified

~. 12

6

@

"P 4

,,./

~

~

100

200

"

300

400

500

~

600

4~ 2

700

q (= 0tt)2 )

Fig. 11. The variations with the normalized end shortening of the normalized square root axial load and

the normalized length of the contact zone ; h/L,~ = 20.15. The dashed and the solid lines correspond to the

small and the large deformation analyses, respectively•

1174

H. CHA!

to /~ = 3 and Lo/h = 20.15, are constructed as follows: starting with n = 1 and c = 0,

one finds from Fig. 8 (as described in Section 4.1) that /~ = 0.1. Introducing the

corresponding values of H/L and kH/2g in (4.2.6) and (4.2.7), ¢ and r/can be found.

Next,/~ is given a small increment and concurrent values of H/L, kH/27r, O, c, and t/

are determined. This process continues until condition (4.1.2) is met, at which point

the buckle divides into two buckles, i.e. n = 2, under a constant t?. The iterative

process above is then continued until the desired value of ~t is reached. Figure 11

shows that the small deformation analysis (dashed lines) holds fairly well up to

the second buckling mode. Starting with n = 3, however, that analysis leads to a

progressively larger error. In particular, for the present choices of/~ and Lo/h, the

large deformation analysis prohibits mode transition beyond n = 2. Also, under a

force-controlled loading, a global collapse of the column is now predicted once ¢

reaches 10.8.

4.3. Lateral reaction

The total lateral reaction force for n buckles is given by

R = 2nV(0) = 2nPh

(4.3.1)

or, using (4.2.6) and the right hand side of (3.1)

/~ -

2n;

(kH/27r)

or/~ -

2n L0

-

h h

(4.3.2)

where /~ is defined in eqn (3.6.4). Figure 6 shows the variation o f / ? with ¢ for the

column of Fig. 11 (i.e. Lo/h = 20.15, t~ = 3). As shown, the lateral reaction, and,

consequently, the frictional forces that may act at the contact points, become significantly greater than their small deformation counterparts starting with the formation of three buckles.

5.

COMPARISON BETWEEN THEORY AND EXPERIMENTS

The line contact analysis (Section 3.5) shows that asymmetry in the buckling pattern

may substantially alter the response of the column. Geometric imperfections and

friction between the column and the guiding walls are important factors affecting this

asymmetry. The effect of geometric imperfection is touched upon in Section 6. The

role of friction appears to be highly involved, and will be discussed here only briefly.

Friction reduces the mobility of the buckle waveform and thus the scatter in the

response of the column. On the other hand, it leads to a gradual reduction of the axial

load down the column, which increases asymmetry. The analysis shows that the

relative magnitude of the lateral reaction, and thus the friction acting on the column,

increases with the end shortening or the wave number of the buckle. For example,

assuming a friction coefficient of 0.3, the total lateral force at the transition from

n = 3 to n = 4, in the case of specimen A, is 38% of the axial load. Once the column

snaps, the resulting rapid stress waves alter the existing distribution of frictional

forces. The latter develop once again upon reloading, however. Because the guiding

The post-buckling response of a bi-laterallyconstrained column

1175

Table 1. Mode transition loads*

Axial

Sample force (N)

A

B

Mode transition, n ~ n + l

2--.3

0~1

1~2

Pexp

8-8.4

Ptheory

7.94

2.3 2.6

2.36

70, 70.6, 82.4,

88.2, 90

71 198,(127)

29.2,29.4,41.8

21.2---59,(37.7)

P~xp

Ptheory

294, 358, 386,

412, 428

198-643,(508)

129,129,165

59-191,(148)

3--*4

389 1341,(1143)

230,243

116-399 (339)

* The first two values for P~h~or~are the lower and upper bounds while the value enclosed by

parenthesis corresponds to "symmetric" buckling.

walls in the present experiments were lubricated prior to testing, the frictionless

contact analysis (Section 3) may reasonably well apply. Table 1 summarizes the

snapping loads for each waveform encountered in the several tests that were conducted. The experimental loads seem fairly well contained by the lower and upper bounds

of the theoretical predictions (i.e. 1 + 2 n ~< g ~< 1 +4n). One also observes that the

predictions for the "symmetric" buckling (g = 4n) better correlate with the test results

as compared with the upper bound.

The experimental data allow yet for a more quantitative assessment of the analysis.

For a line contact, one has, according to (3.3.3) and the right hand side of (3.1)

P = Ebt3rt2/(3H2)

(5.1)

This relationship was checked out by measuring P and H during a test. Determining

H was proven difficult because of the smallness of the clearance between the walls

and the ends of the free standing segments. To overcome this, two 7 #m metal foils

were gently inserted between a given segment and the walls, one on each end, and the

length between the ends of the foils measured. The true value of H was then calculated

with the aid of the deflection profile given in (3.3.2). As shown in Table 2, the

correlation between the experiments and the analysis [i.e. eqn (5.1)] seem satisfactory.

6.

THE CORRUGATED COLUMN

The problem treated is similar to that of Section 3 except that the column has an

initial deflection (see Fig. 12) of the form

h

Y0 = ~ ( I - cos 27tx/Lo)

(6.1)

Note that this profile coincides with the deflection of the flat column at the onset of

contact with the guiding walls, a choice made for comparison purposes. For the sake

of simplicity, the analysis is limited to small deformations, a shallow imperfection

(i.e. h/Lo << 1), "symmetric" buckling and the first buckling mode. The governing

differential equation in this case is given by

1176

H. CHA1

Table 2. C o m p a r i s o n o f p o s t - b u c k l i n g data, S a m p l e A *

H (mm)

55.1

46.8

41.1

37.8

27.5

26.1

22.8

20.6

18.8

18.1

19.3

17.3

15.6

P~xp (N)

P~xp/Pthe,,,~

32

44

59

70

142

169

219

269

305

328

278

381

450

1.22

1.18

1.18

I. 15

1.05

0.98

1.0

0.99

1.06

1.05

1.09

1.0

1.04

Number of

buckles

One

One

One

One

Two

Two

Two

Two

Two

Two

Three

Three

Three

* All results pertain to line contact buckling.

L

_P

--~. c/2 ~-~--a-e

Yl

.

....

.1

- ........................

' ' ~ ~ ~ y

ly o

]h

r ........

--q c/2 ~--

.,. Y ~ e ~

~..;.,~"p

" "

-

c

Fig. 12. Notations for the corrugated column ; only one waveform is shown.

- Ely'~' = M ( x )

= P y + Mr, + V o x

(6.2)

where y~ is the deflection relative to Y0, Y is the total deflection (i.e. y = Y0+)q) and

M0 and V0 are the bending m o m e n t and the shear force, respectively, at the ends o f

the free standing segment o f the column. Using (6.1), eqn (6.2) can be written as

•

6.1.

1+k-y] = -2hk z

cos2~zx/L,

(6.3)

P o i n t contact

Referring to Fig. 12 with c = 0, the b o u n d a r y conditions are

y, (0) = y, (H) = y, (H/2) = 3,] (0) = y] (H) = 0

The solution of (6.3) and (6. I. 1) is found to be

(6.1.1)

The post-buckling response of a bi-laterallyconstrained column

¢2 I(l_

f

y _

h

~

( 1 - ¢ 2) ~ sin2 2

1

J

1177

c°s ~XL" t a n 2 + sin ~ ¢ ~ - ~¢*1 t

2 (tan 2-~ - ~;)

O~=x/H~<

1

(6.1.2)

where g is defined in (3.1.4). Equation (6.1.2) is limited to ~ < 1.8232 (as compared

with two for a flat column) because for larger ¢ the deflection penetrates the wall

boundaries near the contact points. The end shortening is given by

A = 2GH+

i

ll

}

((y')2-y2) dx

(6.1.3)

where e,; is given by (3.1.6). Using (6.1), (6.1.2) and (6.1.3), the normalized end

shortening is found to be

3]12¢2 I

2~3

r/ = g2 q-4(~--.7~)2 2-- g-' + rc (tan--2"7~c__ 2) 2

•

2x¢

n2~g

tan2

-1

+2(rc¢-slnrcg)-4sin4-~-.tan 2

......... _4___ t a n ~

(6.1.4)

(1 -c~2)

6.2.

Line contact

The boundary conditions for the free standing segment shown in Fig. 12 are

Yl (c/2) = y, (H/2) = .v'~(///2) = y'(c/2) = y'(c/2) = 0

(6.2.1)

where H = Lo/2. Using this in (6.3), one finds

y

(h/2)

-

cosec sin{~c,(Yc-0.5)}

(1-¢2)g 2 sin{n¢(?-0.5)}

cosmrc

( 1 - g 2)

+

2(.~-e)

(1-27)

(1-2,~) cos~(

(1-27)

¢2

?<~2~x/H~< i-?

(6.2.2)

where g and e (-c/Lo) are related through

costa

rff1-2c-) F

cos~

_~

l "4- ~2

-~L?

sin

~?-2¢(1 _g2)

tan(~¢(0.5-- ?))J = 0

(6.2.3)

H. CHAI

1178

4

c/Lo

0.2

0.3

0.1

0

t.P 2

I

i

i

l

I

0

I

I

l

I

i

0.5

1.0

(rl - g2) / 1~2

Fig. 13. The variations with the normalized square root axial load of the normalized axial shortening and

the normalized length of the contact zone for a corrugated (dashed lines) and a flat (solid lines) column.

Figure 13 (upper solid line) shows the variation o f ~ with ,; as obtained from a

numerical solution of (6.2.3). F o r g = 0, ¢ = 1.8232, which is consistent with the

results o f Section 6.1. Starting from approximately g = 0.1, the results virtually

coincide with their flat column counterpart (dashed line). Consequently, k H / 2 n = 1

in that loading range. As for the flat column case, m o d e transition occurs when the

flattened segment of length c buckles as an Euler column (i.e. g = 4).

The end shortening is found from

A = L,,~;,.+

f

tt c 2

ILo,'2

(y'): dx-

'2

0 , ; ) 2 dx

(6.2.4)

)

which leads to

?/ = g2 _ 3/~2

3]~2

{[(1 --2g)nc+sinng(l --2g)]

+ 4n(l _g2)2

+n(1-2g)+sin2ng+8

COS2 ne

~53sin2 rig(0.5-- ~)

(COS~/~)

1+

~-

[(l - ~2)2 - c O s n e ' ( l + ¢4)/~2]~

n(1 2 ) ) .................. J

(6.2.5)

Figure 13 (lower dashed line) shows the variation o f ~ with q. The latter is normalized

in such a way as to yield only the end shortening due to bending. The response o f the

flat (lower solid line) and the corrugated columns seem to defer mainly in the horizontal shift (i.e. q = g2+0.75/~2) needed to bring the flat column into contact with the

guiding walls.

6.3.

L a t e r a l reaction

The concentrated lateral force exerted by the wall on each end o f the free standing

segments o f the column, R, is given by E/y"', (0) and EIy'"~ (c/2) for the point and the

The post-buckling response of a bi-laterally constrained column

1179

line contact cases, respectively. Using (6.1.2), (6.2.2) and (6.2.3), the total force is

found to be

=

/? -

1

4g 2

(~-~-

1) (1 - 2

for point contact

(6.3.1)

for line contact

(6.3.2)

he\

nTtan2)

1+

(1

ng

where R is defined in (3.6.4). For the line contact case, there will be an additional

transverse force/unit length, q, acting along the contact zones which is due to the

initial curvature of the column

d2M

q-

-

dx 2

E/yg"

(6.3.3)

Using (6.1), one finds

q Lo

P

h

=

2n 2

- cos 2nx/Lo

(6.3.4)

g2

The total force due to the distributed pressure, F, is given by

i

F= 2

ci2

qdx

,)o

or

F - LoF

hP

2n

_2 sin ne

-

(6.3.5)

The total transverse force for the line contact problem is thus given by

4

{

[

/~r=(*q+F)=(~--2~ i 1+ 1+

n(l-20

2

_]cosn~)

tannC]~cc~

(6.3.6)

Figure 14 (solid line) shows the variation of Rr with g. The main contribution

comes from the concentrated shear forces. Unlike for the flat column (dashed line),

the transverse reaction is developed immediately upon the application of load. The

effect of the initial deflection or imperfection is seen to diminish rapidly once a line

contact is developed (i.e. ,7 = 1.8232).

7.

SUMMARY AND CONCLUSIONS

The response of a bi-laterally constrained, linearly-elastic column under a monotonically increasing end shortening is studied experimentally and analytically. Both

small and large deformation analyses are employed. The interaction of the column

H. CHAi

1180

/P

3-

t~

///

2

J

I I

1

t

o

[

2

t

I

4

It

I

I

6

I

8

Lateral Reaction, P-T

Fig. 14. The variation with the normalized square root axial load of the normalized total transverse reaction

force for a corrugated (dashed line) and a flat (solid line) column.

with the rigid and frictionless walls following buckling gives rise to an interesting

sequence of events, including the formation of discrete contact points between the

column and the walls, their growth into line contact zones, and the snapping of the

buckled column into a new waveform due to local instability. This process continuous

indefinitely unless some failure mechanism intervenes. The experiments conclusively

show that the system snaps to the next higher up wave number even though the new

equilibrium state may not be associated with the largest possible energy release. The

response of the column is greatly affected by the loading direction. Unloading a

column having multiple buckles gives rise to an interesting nonlinear elastic behavior

which may not be easily produced otherwise.

The specifics of the column response, which are dictated by the slenderness ratio of

the column, the wall to wall gap and other factors, are completely determinable from

the equilibrium differential equation of the column. This is except for a certain degree

of indeterminacy in the line contact regime which is due to the fact that the buckle

waveform may travel freely within the length of the column. Such a movement, while

inconsequential to the potential energy of the system, does affect the onset of local

instability and thus the overall response of the column. Nevertheless, the range of

possible variations can be bounded analytically, the predictions of which are borne

out reasonably well by the experiments. The elastica analysis identifies the applicability

range of the small deformation solution and exposes some new features, including

cession of the mode transition process when h/H, the ratio of wall gap to [¥ee standing

segment length, becomes sufficiently large. A closed-form asymptotic representation

of the elastica solution is obtained which is accurate for all practical purposes up to

h/H = 0.6. Geometric imperfections and friction between the column and the guiding

walls may alter the behavior of the column. Some insight into the role of geometric

imperfections can be gained from the results of the corrugated column.

In addition to being potentially useful to the understanding of more complex

The post-buckling response of a bi-laterally constrained column

1181

systems (such as narrow plates, with or without lateral constraints), the present onedimensional treatment is directly relevant to a range of technological applications,

including corrugated fiberboard and corrugated sandwich plate structures. The relatively large area under the axial load vs end shortening curve seem to offer a viable

source for energy absorption. For such applications, an incorporation o f plasticity

into the analysis would be necessary. The lateral reaction which is developed between

the column and the guiding walls rapidly increases with the end shortening. U n d e r

certain conditions, this reaction may be of the same order of magnitude as the axial

force. This m a y be of a special concern if the guiding walls are flexible, as is the case

for corrugated plyboard.

REFERENCES

Burgess, 1. W. (1971) The buckling of a radially constrained imperfect circular ring. hit. J.

Mech. Sci. 13, 741 753.

Cao, J. and Boyce, M. C. (1997) Wrinkling behavior of rectangular plates under lateral

constraint. International Journal ~4[Solids and Structures 33, 153-176.

Chai, H. (1990) Three-dimensional analysis of thin-film debonding. International Journal q/~

f¥acture 46, 23%256.

Chateau, X. and Nguyen, Q. S. (1991) Buckling of elastic structures in unilateral contact with

or without friction. Eur. J. Mech. A/SolMs 1, 71 89.

Giannaakopoulos, A. E., Nilsson, K. F. and Tsamasphyros, G. (1995) The contact problem

at delamination. Journal ~[~Applied Mechanics 62, 989-996.

Heshmat, H., Walowit, J. A. and Pinkus, O. (1983) Analysis of gas lubricated compliant thrust

bearings. Journal ~[ Lubrication Technology 105, 638-646.

Hhatake, K., Oden, J. T. and Kikuchi, N. (1980) Analysis of certain unilateral problems in

von Karman plate theory by a penalty method Part 2, approximation and numerical

analysis. Computer Methods" #~ Applied Mechanic and Engineerin9 24, 317-337.

Johnson, M. W., Jr and Urbanick, T. J. (1989) Analysis of the localized buckling in composite

plate structures with application to determining the strength of corrugated fiberboard.

Journal of Composites Technoloqy and Research 11, l 21 127.

Nordstrand, T. M. and Carlsson, L. A. (19971 Evaluation of transverse shear stiffness of

structural core sandwich plates. Composite Structures 37, 145--153.

Plaut, R. H. and Mroz, Z. (1992) Uni-directional buckling of a pinned elastica with external

pressure. International Journal ¢~/Soli(Ls' and Structures 29, 2091-2100.

Shahwan, K. W. and Waas, A. M. (19911 Elastic buckling of infinitely long specially orthotropic

plates on tensionless foundations. Journal ~[Applied Mechanics 113, 396-403.

Siede, P. (1958) Compressive buckling of a long simply supported plate on an elastic foundation.

Journal o["the Aeronautical Sciences. 382-394.

Soong, T. C. and Choi, Injae (1986) An elastica that involves continuous and multiple discrete

contacts with a boundary, hit. J. Mech. Sci. 28, 1- 10.

Steint, E. and Wriggers, P. (1984) Stability of rods with unilateral constraints, a finite element

solutior,. International Journal (~f Solids and Structures 19, 205-211.

Timoshenko, S. P. and Gere, J. M. (1961) Theo O, of Elastic Stability. McGraw-Hill.

Triantafyllidis, N. and Needleman, A. (198(1) An analysis of wrinkling in the swift cup test. J.

Eng. Mat. Tech. 102, 241-248.

Whitcomb, J. D. (1988) Instability-related delamination growth of embedded and edge delamination, NASA Technical Memorandum 100655.