WORK INSTRUCTION

advertisement

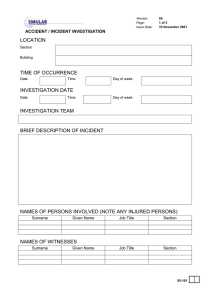

WORK INSTRUCTION 1. Conducting an Accident/Incident Investigation Version: 03 Page: 1 of 2 Issue Date: 26 October 2000 Authorised by: Marjorie Dickenson PURPOSE The purpose of accident investigation is undertaken to identify causes with the aim of preventing a recurrence. It should: Identify other potential causes of the accident/incident. Comply with statutory requirements e.g., OHS Act 2000, Notification of Accidents Regulation 10990. Ensure remedial actions have been/will be taken. An accident investigation has the following objectives: Identify all of the factors that contributed to the accident/incident. Ensure that responsibility for issues raised / corrective actions are allocated to appropriate personnel. Ensure that the issues raised / corrective actions are addressed. Identify the OH&S Management systems that have allowed the situations/conditions to occur. 2. SCOPE The work instruction applies to the investigation of all accidents and incidents. 3. REFERENCES Occupational Health & Safety Act 2000, Notification of Accidents Regulation 10990 Form – Accident / Incident Investigation. 4. RESPONSIBILITY Manager/Supervisor of the injured person Undertake accident/incident investigation OH&S Representative Undertake accident/incident investigation Persons with engineering or other specialist skills, if appropriate Undertake accident/incident investigation Personnel conducting the accident / incident investigation must have knowledge of the workplace and the procedures concerned, and appropriate technical knowledge in the fields of: causes of accidents; equipment and processes; personnel management; and ability to gather evidence objectively and to determine the underlying causes of accidents. 5. ACTION / METHOD An effective system of investigation relies on the following strategies: 1. Prompt reporting of accidents - it is important that evidence is not disturbed prior to the investigation. 2. Immediate control actions - to ensure that further accidents do not occur. 5.1. Levels of Accident Investigation There are two levels of accident investigation: 1. Immediate Causes (situations immediately preceding the event) a. Unsatisfactory Conditions such as: Buildings and Structure - stairways and paths, electrical/water supply, warnings signs, etc. Equipment - controls, isolating/safety devices, defective equipment, etc. 03-010 Conducting an Accident/Incident Investigation Version: 03 Page: 2 of 2 Issue Date: 26 October 2000 Authorised by: Marjorie Dickenson WORK INSTRUCTION b. 2. 5.2. Procedural - work practices, procedures, etc. Environmental - ventilation, noise, lighting, fumes/dust, etc. Unsatisfactory Practices such as: Buildings and Structures - failure to remedy slippery surfaces, failure to comply with access/egress restrictions. Equipment - inadequate PPE, incorrect tool or equipment failure to report obvious hazard, etc. Procedural - incorrect lifting techniques, failure to wear PPE, variations in safe working practices, etc. Environmental - failure to activate emergency, ventilation, fume, dust, noise controls. Underlying (REAL) Causes Failure of one or more management systems which allowed the unsatisfactory conditions/practices to be present. Preventative Systems: Risk identification, assessment and control, standard work procedures, maintenance and testing procedures, hazard reporting and investigation, etc. Support Systems: Induction/Specific/ongoing training. System Breakdown Management: Emergency procedures, accident investigation, workers compensation and rehabilitation. Evaluation Systems: OH&S inspections, system reviews, internal audits, quality control evaluation. How to Complete an Accident/Incident Investigation Using the SimuLab form 05-101, Accident / Incident Investigation: STEP 1: Get the facts Note observations. Eye Witnesses. Photo/sketches. STEP 2: Determine the sequence of events (who, what, when, where, why) Identify all conditions at the time of the incident. Identify all variations from standard practices. STEP 3: Identify the Management Systems Failures for each of the above categories Consider possible remedies. Select the best solution in terms of effectiveness, cost, meeting acceptable standards. STEP 4: Determine Remedial Action This may include: Modifications to the workplace or equipment. Changes in work practices. Provision of training. STEP 5: Follow-up and Evaluate Effectiveness. Acceptability. 03-010