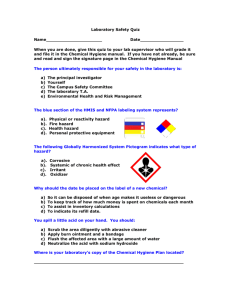

Safety Orientation for Faculty, Staff, and Students

advertisement