Document 12787063

advertisement

PULP &

PAPER

PULPWOOD \Norld

I A1

JI�T

BC PROT!:C EO '( /1

L.a',v (WLE 17, U.S CU l:)

Shelterwood

cutting

studied to see if young-growth hemlock can be

regenerated by series of successive cuttings

About This File: This file was created by scanning the printed

publication. Misscans identified by the software have been

corrected; however, some mistakes may remain.

Ie

S,

-Portland, Ore. A STUDY NOW UNDERWAY at the Hem­

lock Experimental Forest near Grays

Harbor in western Washington is de­

signed to test shelterwood cuttings as

a means of regenerating coastal west­

ern hemlock. Hemlock Experimental A report by

FRANCIS R. HERMAN

Pacific Northwest Forest and

Range Experiment Station

U. S. Forest Service

Portland, Ore.

I. o

I,

u

e

##M+m1#M#f�f#+#!tf

TO CUTTIN3

FOREST WITH CLOSED C ANOPY PRIOR

tt t!i ++++1

TREES

SELECTED

RETAINED TO

LtAtltfl!.tU.t.U,U!

SEED

CUTOJER

hi.H u.i.H 1

.. U . .... h ...

LEAVE

TREES AFTER

AREA

.. t • • •

SECOND

.. . ,!t..

CUT

..

.LHHuUHlHh U.t!u.WH,••l1Uhh. tU..h.. !UU1H.Uh•••t\i....uh11o

•

•

ESTABLISHED REGENERATION

AFTER

THIRD CUT

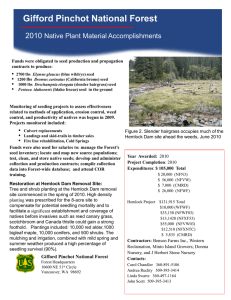

SHElTERWOOD MANAGEMENT SYSTEM, showing successive stages of regen­

eration in western hemlock forest.

PULP & PAPER - June 11, 1962

Forest is owned by St. Regis Paper

Co. and leased to the U.S. Forest

Service under a cooperative agree­

ment to conduct research aimed at

securing the greatest possible con­

tinuous yield. Logging on the experi­

mental forest is done by St. Regis and

research is conducted by the Pacific

Northwest Forest and Range Experi­

ment Station, Portland, Ore.

In the U.S. Forest Service report,

"Timber Resources for America's Fu­

ture," we are told that more than 18$

of the national pulpwood output is

produced in the Pacific Northwest. To

continue to furnish this proportion of

America's pulpwood requirements in

the year 2000, Pacific Northwest for­

ests must produce perhaps as much

as three and one-half times the pres­

ent output. Even so, an estimated na­

tional demand for 89 million cords of

pulpwood may require the United

States to import nearly 15 million

cords. Successful methods of obtain­

ing quick regeneration and maintain­

ing optimum stocking on all forest

lands will assist in preventing possible

shortages in wood products.

The wood of western hemlock is

admirably suited for producing good

pulp and lumber. Many mills in the

Pacific Northwest look to hemlock to

furnish at least a portion of their

cordwood and sawlogs. Some mills

in western Washington are currently

utilizing hemlock in preference to

other species. Western hemlock is

blessed with many attributes that

make it a good candidate for man61

I'

·

.

.

tics is bci

o[ 2U to :

ou cuttiug

7 acres ea

tcrruption

cuts on ;

shelterwood cutting

complettxl

plan in t

early 2,1

370,000 I

moved in

the shelt.

second an

partments

complete

SEED TRAP makes it possible to estimate amount, viability

and distribution of hemlock seed for any of several shel­

terwood cutting intensities.

agement. It is a prolific producer of

seed and, when provided with its

proper

environmental

condition,

grows rapidly, tall, and straight.

Clear cutting of old-growth

hemlock commonly has been accepted

as the only method that will provide

coilditions conducive to reestablish­

ment of hemlock. Is it certain, how­

ever, that clear-cutting management

of young-growth western hemlock will

provide the best conditions for stand

regeneration? Examination of recently

cutover young-growth hemlock forest

land reveals an abundance of weeds

and brush but only a sparse co\·cr of

new hemlock seedlings. Would some

form of partial cutting, such as the

sheltenvood systcm, prove more suc­

cessful than clear cutting in providing

TRACTOR AND SULKY used for skidding tree-length logs

from shelterwood compartment to roadside landing for

bucking into pulpwood or sawlogs.

quick and abundant regeneration?

Early in this century, logging, for­

est fires, and windstorms in western

Washington left some scattered old

hemlock trees and provided environ­

mental conditions suitable for the es­

tablishment of extensive, even-aged

stands of nearly pure young-growth

hemlock. The exact nature of these

environmental conditions is unknown.

These older trees provided seed and

some degree of shelterwood protec­

tion for the young forest. We cannot

turn back the pages of history and

conveniently look in upon acciden­

tally

created

growing conditions.

!lowever, we can artificially create

varied sets of conditions and measure

resulting

environmental

influences

conducive to establishment of a new

forest.

Shelterwood cutting system

is being tested on the Hemlock Ex­

perimental Forest, 15 miles north of

Hoquiam, Wash.-an "experimental

island" within a large area of young­

growth western hemlock. The original

forest was logged near the tum of the

century, and the bulk of the present

stand is now about 60 years old. A

few scattered, older western hemlocks

that escaped the early logging are

found throughout the area. The stand

averages 270 stems per acre in trees

6 to 30 in. in diameter, and volumes

exceed 43,000 bd. ft. per acre. Here

on 68 acres in this nearly pure stand

of young-growth western hemlock, ef­

fects of a wide range of shelterwood

cuttings on regeneration are being

studied.

Comparison of 12 cutting intensi­

Shelten

from clen

the time \

cut over.

moved b}

ings inste.

a new cn

surviving

nifies, sh<

ter or pre

trees shat

teet new

light an.

extremes.

light also

undesirab

might dt

young fOl

Shelter

esters to

trees for

and gro\\

providin

seed, the

their rat.

in quanl

rotations.

and sele.

tained t

managen

Unlike

health b

cure all a

ment is'

undoubt.

ciated \'

shelterw.

poses of

Foremos

damage

ing succ.

establish

damage<

subs QU'

should I

of timb

measurc

tivc abl

seedling

Facto

dance (

quality

RESIDUAL SHELTERWOOD stand after initial cutting has

23 trees per acre. Research will show if this is lighter

shelterwood stand than is desirable.

62

AFTER INITIAL CUTTING this stand has 54 trees per acre.

Second cut in 5 years will leave half these trees to pro­

vide seed and soil protection.

PULP & PAPER - June 11,

need to

thev ar'

scale 0

vironml

PULP &

ties is being made in residual stands

of 20 to 200 trees per acre. Logging

on cutting compartments of from 5 to

7 acres each began in 1960. After in­

terruption by winter weather, initial

cuts on all 12 compartments were

completed according to prescribed

plan in the late summer of 196!.

Nearly 2,000 cords of pulpwood and

370,000 bd. ft. of sawlogs were re­

moved in Ulis first cut. Accordin g to

the shelterwood management plan,

second and third cuttings on all com­

pmtments at intervals of 5 years will

complete thc cutting schedule.

09s

for

em

Exof

Ital

ng­

nal

Ule

ent

A

cks

are

md

oos

nes

ere

l1ld

ef­

lod

'ng

Isi­

,.

I

\

r

e.

)-

Shelterwood management differs

from clear cutting in that it delays

the time when the forest is completely

cut over. Seed-bearing trees are re­

moved by two or more successive fell­

ings instead of by single cutting. Thus

a new crop establishes itself from the

survivin g seed trees. As the term sig­

nifies, shelterwood also provides shel­

ter or protection. Crowns of retained

trees shade the forest Aoor and pro­

tect new seedlings from bright sun­

light and detrimental temperature

extremes. The limited intensity of sun­

light also controls the development of

undesirable brush and weeds that

might delay the establishment of a

young forest.

Shelterwood cutting permits for­

esters to select and retain certain

trees for their seed-bearing ability

and growth potential. In addition to

' providing an abundant supply of

seed, the released trees win increase

their rate of wood production-both

in quantity and quality. Shortened

rotations, improved yield volumes,

and selected auality all may be ob­

tained through careful shelterwood

management.

Unlike the claims made for many

health tonic elixirs that purportedly

cure all ailments. sheltenvood manage­

ment is not said to be perfect. There

undoubtedly will be problems asso­

ciated with the apolication of the

shelterwood system. One of the pur­

poses of the studv is to evaluate these.

'

Foremost is the possihility of logj:(ing

damage to established seedlings dur­

ing successive cuttin)!s. Young growth

established after a first cut may be

damaged by felling and skidding in

subsequent cuts. Amount of damage

should be associated with the amount

of timbl'r cut ea ch time. The final

IlwaSUl"(' of sncce ss will hc the rela­

tivc abundance of healthy hemlock

secdIinl!s.

Fad rs conh'ibnting to an abun­

dance of well-distributed and high­

quality western hemlock seedlings

need to he' known and evaluated if

the'v an' to 1)(' C'ncol1raged in large­

scal(, operations. These include en­

yironn1C'nt:ll innucnees sllch as compcPULP & PAPER

­

June 11, 1962

tition from other plant species, light

intensity, aspect, slope, and seedbed

as well as the factors of seed fall,

germinative capacity, and seedling

survival.

In an effort to discover the quantity

of seed that falls under each intensity

of cutting, simple but effective seed

traps made of wire screen fitted into

a wood frame are placed within each

shelterwood-cutting compartment. A

number of these traps scattered over

a known area give an estimate of the

available seed supply per acre. Con­

tents of Ule traps are collected and

examined several times a year.

Logging costs and returns

for the entire shelterwood manag

ment cutting period are being kept.

Because work is less concentrated

under shelterwood than under clear­

cutting management, logging costs

may be somewhat higher. Even extra

cost may be justified if healthy re­

generation can be obtained more

quickly under one Ulan under an­

other cutting treatment.

On other portions of the Hemlock

Experimental Forest, periodic tbin­

nings have been carried out since

1950. These thinnings are designed

to remove the least desirable mem­

bers of the stand and promote d

velopment of the better members of

the crop. The thinnings are stimulat­

ing good crown development that will

produce good seed crops later on.

These stands are being groomed for

application of the best management

-be it she1terwood or some other r

generation cutting method.

It is from thinning experiments that

we get an inkling of the growth ca­

pacity of young-growth western hem­

lock. The net mean annual increment

to date has been 158 cu. ft. or 828

bd. ft. per acre. The experimental for­

est is growing rapidly, however, and

the thinned stands show a current net

periodic yearly increment of 179 cu.

ft. or 1,490 bd. ft. per acre.

Time is not far off when young­

growth westell1 hemlock stands will

be called upon to bear a major por­

tion of the rapidly increasing demand

for cellulose. Some of these stands,

though only 40 to 60 years old, even

now furnish pulpwood to the ever­

increasing capacity of pulp and paper

mills. Foresters must learn to man­

agc this young crop of wood to main­

taill wood growth at least cqual to

that of demand. Studies at Hemlock

Experiment:ll Forest are designed to

provide foresters with management

guides. If shc1terwood management

provides the key to quick, adequate

regeneration of w estern hem lock, a

shelterwood l'utting guide will be

available for :lpplication hy the end

•

of tIl{' stl1dy period.

APA

release

reviews

For further information on publications

described below, write:

M1ElUCAN PULPWOOD ASSOCIATION

220 E. 42nd St., New York 17, N.Y.

(Please identify by number in brackets)

Experimental tractor

designed by a forest engineer at

Catawba Timber Co. (Bowaters Caro­

lina) is a four-wheel, rubber-tired

unit for hauling pulpwood. Basic

chassis is a Massey Ferguson model 65

diesel farm tractor, from which the

front wheels have been removed. An

integral pallet cart is attached to this

unit with a "wasp-waist" universal

hjtch. A "Big Stick" mast and boom

loader (TR 59-R-30) have been fitted

on the basic unit.

In operation, a cable is fastened to

pulpwood bolts, then moved by re­

mote control to a position near the

machine, at which point wood is

manually controlled onto the pallet.

Pallets that are carried to unloading

area, dumped and reloaded on the

unit, can carry up to n cords of pulp­

wood. Release is illustrated. (TR-62­

R-9)

"Ergonomics"

in forestry is defined as measur

ment of work in terms of the quantity

of heat to which it is equivalent. In

Swedish forestry, for the past 20 years,

a basic tool for determining labor

capability has been physiological re­

search. This release states what differ­

ent ergonomic methods can do, how

they do it and results from their ap­

plication. Although ilie Swedish find­

ings are spelled out in word and by

graph, the APA comments that "the

need for determining physiological

and psychological demands on forest

workers seem very remote." (TR 62­

R-I0)

Nylon safety pads

for knees of work pants have been

demonstrated to cut lost-time acci­

dents from chain-saw injuries 10-20%

at one company, while reducing them

almost 35% at another, according to

this release. Chain saw "ccidcnts ;\rL'

rep ort ed to have increasc>cJ from ] 6

of all injuries in 1957 to 31% last year.

Many companies report that chain

saw accidents are primarily in the

klH.'e :lrca.

An Eastern Canadian company is

marketing tlwse knee pads at a r ea ­

sonable price; a U.S. l'ompany is

contemplating their manufacture if

there is illterest shown. (TR 62-H-12)

63