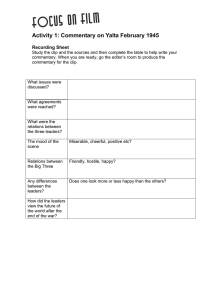

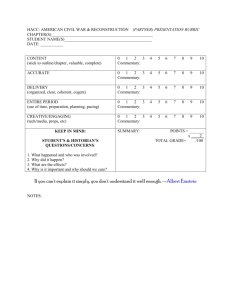

1991 COMMENTARY ADDENDUM to the on the

advertisement