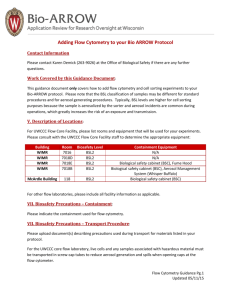

BIOSAFETY STANDARD FOR SORTING OF UNFIXED CELLS Ingrid Schmid , Claude Lambert

advertisement