10 ISPE Tampa Conference

advertisement

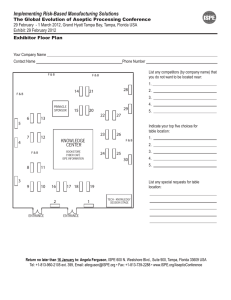

22-25 February • Grand Hyatt Tampa Bay • Tampa, Florida, USA www.ISPE.org/2010tampaconference Sponsorship and Table Top Exhibit Opportunities Available ISPE Tampa Conference Applying Solutions to Emerging Industry Challenges Seminars • Aseptic Processing of Sterile Products: Innovations, Regulatory Guidance and Compliance in a Practical World • Inspection Readiness Workshop: From Site Preparation to Successful Execution • Oral Solid Dosage: New Guidance You Can Use Right Now • Lean Project Delivery: Leveraging New ISPE Guides on Commissioning and Qualification and GAMP®5 • Managing the Risks and Challenges of Syringe Processing • Containment Technology Forum: Basics and Beyond • Technology Transfer: Focus on the Business Process and Practical Execution • Beyond Book-learning: Practical Application of Good Engineering Practice and Maintenance Guides Training Courses • HVAC for Pharmaceutical Facilities • Practical Application of Computerized Systems Compliance: Applying the GAMP 5 Guide: A Risk-Based Approach to Compliant GxP Computerized Systems 10 ISPE 2010 Tampa Conference At-A-Glance Table of Contents 22-25 February 2010 Knowledge Elements Reference Chart Conference Seminar Descriptions Training Course Descriptions 3 4-11 12-13 Registration Form 14 General Information 15 Table Top Exhibits and Sponsorships 15 Career Café Visit the Career Café to see the latest positions available from leading pharmaceutical and biotechnology employers and suppliers. Visit www.ISPE.org/careers for more details. Grand Hyatt Tampa Bay Tampa, Florida, USA Monday, 22 February Tuesday, 23 February Wednesday, 24 February Exhibits Open 17.00 – 18.30 Exhibits Open 07.30 – 16.00 Exhibits Open 07.30 – 16.00 Aseptic Processing of Sterile Products: Innovations, Regulatory Guidance and Compliance in a Practical World (E01) New Members and first time attendees are cordially invited to this special networking breakfast hosted by the Membership Development Committee (MDC). Meet fellow Society Members and Tampa Conference attendees to foster new relationships, learn how to make the most out of your ISPE membership, and to ask questions. Bring plenty of business cards for networking. Managing the Risks and Challenges of Syringe Processing (E05) Inspection Readiness Workshop: From Site Containment Technology Forum: Preparation to Successful Execution (E02) Basics and Beyond (E06) OSD – New Guidance You Can Use Right Now (E03) Technology Transfer: Focus on the Business Process and Practical Execution (E07) Lean Project Delivery: Leveraging New ISPE Guides on Commissioning and Qualification and GAMP® 5 (E04) Beyond Book-learning: Practical Application of Good Engineering Practice and Maintenance Guides (E08) HVAC for Pharmaceutical Facilities (T14) (Monday, Tuesday, and Wednesday) New Member/First Time Attendee Orientation Monday Thursday, 25 February Practical Application of Computerized Systems Compliance: Applying the GAMP®5 Guide: A Risk-Based Approach to Compliant GxP Computerized Systems (T11) Opening Reception in Exhibit Hall 17.00 - 18.30 Networking Reception 17.00 - 18.30 Certified Pharmaceutical Industry ProfessionalTM (CPIPTM) Workshops Introduction Workshops - Monday and Wednesday, 08.00 - 09.00 These complimentary, one hour workshops provide an overview of the CPIP — a pharmaceutical industry focused, international, competency-based credential made available through the ISPE Professional Certification Commission. Topics include: CPIP introduction, eligibility criteria, and the application and examination process. www.ISPE-PCC.org How-to Workshops - Tuesday and Thursday, 08.00 - 09.00 These complimentary, one hour workshops explain how to submit an eligibility application and prepare for the examination. Topics include: obtaining a university transcript, completing the professional experience forms, using the CPIP Study Guide, and organizing study groups. www.ISPE-PCC.org 2 Applying Solutions to Emerging Industry Challenges 22-25 February 2010 • Grand Hyatt Tampa Bay • Tampa, Florida, USA Knowledge Elements Reference Chart 1 2 Technical Knowledge Competency Areas 3 4 5 Product Development Facilities and Equipment A B C A B C D Formulation, clinical phases, and manufacture A B C A B C A B A B Materials management Technology transfer Production scale-up and optimization Design and construction/installation Commissioning and qualification as a risk management strategy Operation and maintenance Controls and automation Information Systems Supply Chain Management Production Systems 6 Regulatory Compliance (Drugs, Env., Health, and Safety) 7 Quality Systems Tampa Conference Seminars or Training Courses Operational economics Warehouse and distribution management Production unit operations - drug (small molecule) and biologics Production management Production control Government regulations Standards, practices, and guides Risk management and Quality Management System (QMS) Systems validation Technical Knowledge Competency Areas 1 2 3 4 5 6 7 A B C A B C D A B C A B C A B A B Aseptic Processing of Sterile Products: Innovations, Regulatory Guidance and Compliance in a Practical World X X X Inspection Readiness Workshop: From Site Preparation to Successful Execution X OSD – New Guidance You Can Use Right Now X Lean Project Delivery: Leveraging New ISPE Guides on Commissioning and Qualification and GAMP® 5 Managing the Risks and Challenges of Syringe Processing X X X Containment Technology Forum: Basics and Beyond Technology Transfer: Focus on the Business Process and Practical Execution Beyond Book-learning: Practical Application of Good Engineering Practice and Maintenance Guides Practical Application of Computerized Systems Compliance: Applying the GAMP® 5 Guide: A Risk-Based Approach to Compliant GxP Computerized Systems X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X All Tampa Conference seminars (and one training course) contain knowledge related to the seven technical knowledge competency areas for the CPIPTM certification program, an international credential made available through the ISPE Professional Certification Commission. Completion of any of these seminars does not guarantee successful completion of the certification exam. Visit www.ISPE-PCC.org for details. Applying Solutions to Emerging Industry Challenges 22-25 February 2010 • Grand Hyatt Tampa Bay • Tampa, Florida, USA 3 Aseptic Processing of Sterile Products: Innovations, Regulatory Guidance and Compliance in a Practical World (E01) Seminar Content Level Fundamental • Intermediate • Advanced Attend this two-day seminar to learn about the latest commercially proven solutions in aseptic processing. Learn from experts working in similar environments to yours, participate in in-depth case study presentations and discussions, and network with attendees and presenters. Topics will cover a range of technologies for sterile products, from compounding to inspection, and include: • Inspection perspectives with respect to regulatory and industry guidance • Meeting Annex 1 capping requirements • Aseptic fill/finish processing • The “c” in cGMPs? • Risk-assessment • Trends in advanced aseptic processing: isolators and RABS • X-Ray for inspection of opaque and freeze dried products Leaders • Paul Gold, Director Drug Product Equipment Technology, Global Manufacturing Services, Pfizer Global Manufacturing, USA • Manmohan Sihra, Director Aseptic Process Design, Bristol-Myers Squibb, USA How You Will Benefit At the conclusion of this session, participants will be able to: Speakers Confirmed to Date • Massimiliano Barberis, Associate Director, Engineering & Maintenance, Drug Product, Bristol-Meyers Squibb, ITALY • Michael Baumstein, Analyst/Microbiologist, Pfizer, USA • Jeffrey Jackson, Director, Sales North America, Bosch Packaging Technology, USA • Madhav Kamat, Senior Principal Scientist, Bristol-Myers Squibb, USA • Jack Lysfjord, Principal Consultant, Lysfjord Consulting LLC, USA • Jerold Martin, Senior Vice President, Global Scientific Affairs, Pall Life Sciences, USA • Michael Miller, Ph.D., President, Microbiology Consultants, LLC, USA • Michael De La Montaigne, President, Eisai Machinery USA, Inc., USA • Thomas Ofsharick, GMP Compliance Manager, GlaxoSmithKline, USA • John Shabushnig, PhD, Senior Manager, Pfizer Quality Operations Center, Microbiology and Aseptic Support, Pfizer Inc., USA •Robert Tomaselli, Director, Quality & Process Technologies, Johnson & Johnson, USA • Paul Zielinski (BMS) Associate Director, World Wide Quality and Compliance, Bristol-Myers Squibb, USA Who Should Attend Professionals from engineering, operations, quality, planning and project management Community of Practice (COP) www.ISPE.org/COPs Sterile Products Processing Related Technical Documents, Articles, and Publications www.ISPE.org/Publications ISPE Baseline® Guide: Volume 3 - Sterile Manufacturing Facilities Knowledge Competency Elements These are detailed on page 3. Updates and Agenda Online at www.ISPE.org/2010tampaconference • Understand different approaches to compliance with EU Annex 1 in regards to capping environmental requirements • Understand and effectively apply new developments in product inspection • Contrast and analyze alternative approaches to fill/finish operations • Apply new technologies in aseptic manufacturing 4 22-23 February 1.2 CEUs Applying Solutions to Emerging Industry Challenges 22-25 February 2010 • Grand Hyatt Tampa Bay • Tampa, Florida, USA Inspection Readiness Workshop: From Site Preparation to Successful Execution (E02) Seminar Content Level Fundamental • Intermediate • Advanced Would you know the details of planning for an inspection? This two-day workshop will not only give you the tools to prepare your organization for a regulatory inspection, but will also give you a chance to practice these skills in a safe and mentoring environment. This is a highly-interactive workshop. Attend, be engaged, practice in a safe setting, and learn. We have all heard the adage “fail to plan, plan to fail,” and in no area is this more relevant than inspection readiness. In our current economic climate, regulatory approval and time to market play a major role in overall product success. Your competitors are actively monitoring the outcomes of regulatory inspections and will try to use this information to their advantage. This workshop will prepare you to plan for inspections accurately and execute them effectively by knowing what to expect and how to best respond. The two-day, interactive workshop addresses the following topics: • Understanding the purpose of the inspection and your regulatory filing • Conducting a quality systems gap assessment for inspection preparation • Inspection logistics and site preparations • Preparing computer and automated systems for regulatory review • Special considerations for laboratories and process equipment • Utilizing inspection results for competitive advantage • Interview techniques including how to conduct a site tour and how to give a software demonstration 22-23 February 1.2 CEUs How You Will Benefit At the conclusion of this session, participants will be able to: • Comprehensively understand a site inspection readiness program • Describe regulatory authorities’ audit processes and the purpose of an inspection • Utilize the tools needed to accomplish tasks related to inspection readiness • Describe specific roles and responsibilities during an audit • Understand the inspection intricacies associated with laboratories and process equipment • Establish yourself as an expert in your functional area • Formulate effective responses to various types of questioning used by the FDA and other regulators • Guide auditors to focus on your quality system’s strengths instead of weaknesses Who Should Attend Professionals from quality assurance, quality control, engineering, regulatory compliance, quality systems, validation, IT, laboratory, as well as manufacturing supervisors, and area leaders/managers Communities of Practice (COPs) www.ISPE.org/COPs Commissioning and Qualification, and Operations Management Knowledge Competency Elements These are detailed on page 3. Updates and Agenda Online at www.ISPE.org/2010tampaconference Leaders and Speakers • Rebecca Waterbury, ChE, JD, Regulatory Compliance International, Abbott Vascular, BELGIUM (Leader) • Philip Russ, Principal Consultant, Innovative Consultants, LLC, USA (Leader) • Kimberly Snyder, Senior Technical Manager, Genentech USA Applying Solutions to Emerging Industry Challenges 22-25 February 2010 • Grand Hyatt Tampa Bay • Tampa, Florida, USA 5 Oral Solid Dosage – New Guidance You Can Use Right Now (E03) Planned and Implemented by the ISPE OSD Community of Practice (COP) Seminar Content Level 22-23 February 1.2 CEUs How You Will Benefit At the conclusion of this session, participants will be able to: Fundamental • Intermediate • Advanced Examine and extract critical perspectives from warning letters and apply new industry guidance to benefit your company. This seminar covers key topics of risk assessment, adulteration, compliancefocused processes, as well as other key topics vital for multi-product production and development. It also focuses on the entirely new and FDA-reviewed, ISPE Baseline® Guide: Volume 2 – Oral Solid Dosage Forms (Second Edition), and incorporates ideas related to problems identified in regulatory warning letters from global agencies. Breakout sessions using the new OSD Guide will allow you to discuss with subject matter experts solutions to real problems faced in an OSD environment. An FDA speaker has been invited, and the seminar will be lead by members of the OSD Guide writing team. Note: OSD Guide will be provided as part of seminar registration. Leaders • Stephen Yu, Principle Process Engineer, BE&K, USA • Julian Wilkins, Vice President, PharmaConsult US Inc., USA • Understand the importance of the new OSD Guide • Understand how it can help you avoid compliance issues • Be able to incorporate its elements to improve quality and reduce costs Speakers Confirmed to Date • Peter Beke, Facilities Eng Manager, Catalent Pharma Solutions, USA • J ean-Pierre Bovee, Deputy Director Automation, Sanofi Winthrop Industrie, FRANCE • J ack Chu, PE, Manager, Merck & Co Inc, USA •R ichard Denk, Director, Pharma Dept, Hecht Technologie GmH/ Kmpt AG, GERMANY • David Jaworski, Consumer Safety Officer, DHHS/FDA/CDER/OC/CMPQ/DCMBNOTE: David will be presenting via web conference • Steven Ostrove, PhD, President, Ostrove Associates Inc, USA • John Patterson, Director, IT Compliance, Merck & Co Inc, USA • Sunil Chand Singhai, Vice President, Dr Reddys Laboratories Ltd, INDIA • Purna Thakker, Pfizer • C. Alexander Heisterkamp, IV, Director, Project Eng, Pfizer, USA • Robert Matje, Senior Director, Pfizer, USA • Richard Nielsen, Senior Engineer, Catalent Pharma Solutions, USA Who Should Attend Anyone involved in OSD manufacturing especially those in generic and contract manufacturing who may be a risk target of the agencies Community of Practice (COP) www.ISPE.org/COPs Oral Solid Dosage Related Technical Documents, Articles, and Publications www.ISPE.org/Publications ISPE Baseline Guide®: Volume 2 – Oral Solid Dosage Forms (Second Edition) (Available November 2009) Knowledge Competency Elements These are detailed on page 3. Updates and Agenda Online at www.ISPE.org/2010tampaconference 6 Applying Solutions to Emerging Industry Challenges 22-25 February 2010 • Grand Hyatt Tampa Bay • Tampa, Florida, USA Lean Project Delivery: Leveraging New ISPE Guides on Commissioning and Qualification and GAMP® 5 (E04) 22-23 February 1.2 CEUs Planned and Implemented by the ISPE Commissioning and Qualification (C&Q) and GAMP COPs Seminar Content Level Fundamental • Intermediate • Advanced If you could start your project over again, what would you do differently? Attend this seminar to know how to best approach planning, design, and commissioning and verification of an integrated system with integrated deliverables, and how to — at the same time — meet the intent of the ISPE Baseline® Guide: Science and Risk-Based Approach for the Delivery of Facilities, Systems, and Equipment and GAMP®5. Successful project delivery for packaged equipment with embedded control systems requires a range of subject matter expertise. Traditional delivery of such systems often involves each of the functional area experts working within their own silo — producing documents and executing tests to meet their functional needs. Furthermore, the approach to such testing is often equipment-centric and not process-centric. Join members of the GAMP and C&Q COPs for details on how to leverage these Guides to benefit your projects: • GAMP 5: Risk-Based Approach to Compliant GxP Computerized Systems • ISPE Baseline Guide: Science and Risk-Based Approach for the Delivery of Facilities, Systems, and Equipment Day one of this highly-interactive seminar examines equipment with an embedded control system and interaction with process/sequence controls to demonstrate a holistic project delivery approach that integrates multi-system lifecycle activities to remove unnecessary work. At each phase of system delivery, a traditional approach will be challenged and a synergistic approach proposed. Workshops at each planning step discuss how to optimize required activities. Day two features case studies, workshops, and application of risk-based approaches. Each day, audience response polling systems will be used so session leaders can direct seminar discussion to best meet attendee needs. Leaders • Timothy Howard, PE, CPIP, Director, Commissioning Validation Services, Commissioning Agents, Inc., USA • Gregory Ruklic, Principal Engineer Technology & Compliance, Wyeth BioTech, USA How You Will Benefit At the conclusion of this session, participants will be able to: • Understand basic concepts of ASTM E 2500 and GAMP 5 methodology and be able to effectively apply them • Apply knowledge gained from the risk assessment process to design a specification and verification process • Understand different techniques available to conduct a risk assessment • Analyze case studies for successful methods and activities that may be applied to your particular situation Speakers Confirmed to Date • Steven Coates, Director Computer Systems QA, Wyeth, USA • Kevin Martin, Vice President, CimQuest-Vantage LLC, USA • Armen Nahabedian, Director, Commissioning and Qualification, Wyeth, USA • Ivan Soto, Validation Manager, Amgen Inc., USA Who Should Attend Professionals in commissioning, quality assurance, project delivery, automation engineering, IT, and validation Communities of Practice (COPs) www.ISPE.org/COPs Commissioning and Qualification, and GAMP Related Technical Documents, Articles, and Publications www.ISPE.org/Publications • GAMP 5: Risk-Based Approach to Compliant GxP Computerized Systems • ISPE Baseline Guide: Science and Risk-Based Approach for the Delivery of Facilities, Systems, and Equipment (anticipated publication Q1/Q2 2010) • Commissioning and Qualification: A New ASTM Standard – GMP Regulations by Robert E. Chew and David Petko • November/December issue of Pharmaceutical Engineering focused on Integrated Commissioning and Qualification • ASTM E 2500 • ISPE Good Practice Guide: Applied Risk Management for Commissioning and Qualification (anticipated publication Q2 2010) Knowledge Competency Elements These are detailed on page 3. Updates and Agenda Online at www.ISPE.org/2010tampaconference Applying Solutions to Emerging Industry Challenges 22-25 February 2010 • Grand Hyatt Tampa Bay • Tampa, Florida, USA 7 Managing the Risks and Challenges of Syringe Processing (E05) Planned and Implemented by the ISPE SPP Community of Practice (COP) Seminar Content Level 24-25 February 1.2 CEUs How You Will Benefit At the conclusion of this session, participants will be able to: Fundamental • Intermediate • Advanced Attend this seminar for global case studies and interactive workshops on the recent technologies and solutions. From the initial decision on which syringes to process — bulk syringes or presterilized syringes in tubs — to the latest inspection systems and laser marking technology, this seminar will present the latest technologies and trends in many aspects of syringe processing. Whether you are in clinical operations or highvolume pharmaceuticals and biologicals, have existing operations, or are starting new ones, this seminar will provide information and practical implications that can improve quality and increase productivity. With syringe filling growing, many companies are either starting syringe operations or increasing their throughput. It is estimated that there are over 2 billion syringes processed annually now. Technologies surround syringe processing operations and are improving with new and improved equipment and solutions. • Analyze technologies to improve syringe operations •Effectively manage risk • Solve manufacturing challenges •Implement effective commissioning and qualification practices • Strengthen supply chain security with newly available technologies Speakers Confirmed to Date • Ty Bolt, Component Consultant, Elanco Animal Health, A Division of Eli Lilly and Company, USA •Paolo Golfetto, Head of R&D, Glass Division, Nuova Ompi, ITALY • Karen Hirshfield, Director Regulatory, DHHS/FDA/CDER/OC/DMPQ/RSB •Didier Laeckmann, Director, New Product Introduction and Process Validation, Catalent Pharma Solutions, BELGIUM •Philippe Leyvraz, CEO, Frewitt Printing SA, SWITZERLAND • Susan Martin, PhD, Senior Principal Consultant, Pharmaceutical R&D, Global Biologics, Pfizer, Inc. • Tom Nikolai, Section Head, Biologics, Parenteral Products, Manufacturing Science and Technology, Abbott • Thomas Schoenknecht, Director - Drug Product and Device Development, Amgen • Oliver Vogt, Director, Process & Equip Engineering, Hospira, Inc., USA • Wolfgang Weikmann, Director for Validation/Qualification and Visual Inspection, Vetter, GERMANY •Scott Young, PhD, Program Director, Crystal Zenith Platform, West Pharmaceutical Services, USA Who Should Attend Case studies and working sessions will examine the risks and challenges surrounding syringe processing. Professionals in syringe technology of any type, as well as those from quality assurance, quality control, C&Q, maintenance, engineering, supply chain, materials management, product development, clinical operations, contract manufacturing, and outsourcing to a contract manufacturer Leaders Community of Practice (COP) www.ISPE.org/COPs • Nancy St. Laurent, CPP, Senior Supervisor Process Engineering, Parsons, USA • Joerg Zimmermann, Director of Production, Vetter, GERMANY Sterile Products Processing Knowledge Competency Elements These are detailed on page 3. Updates and Agenda Online at www.ISPE.org/2010tampaconference 8 Applying Solutions to Emerging Industry Challenges 22-25 February 2010 • Grand Hyatt Tampa Bay • Tampa, Florida, USA Containment Technology Forum: Basics and Beyond (E06) Planned and Implemented by the ISPE Containment Community of Practice (COP) Seminar Content Level • Two tracks or day one: Fundamental • Together or day two: Intermediate Fundamental • Intermediate • Advanced Facing pharmaceutical containment challenges? Whether you are looking for basic information or a more detailed level of understanding on challenges and solutions for contained powder processing, this seminar provides up-to-date information on hazardous compound handling processes. On the first day, you can attend either a fundamental or intermediate track. Either prepares you to get the most out of a second day packed with case studies. Take away a better understanding of implementation of containment systems and strategies that are based on real world experience. Don’t miss opportunities to hear from, and network with, industry experts in the field of containment. Effective process and equipment design as well as effective containment practices at the shop floor level will protect product from cross-contamination as well as providing operator protection. Seminar topics include containment basics, occupational exposure values, hierarchy of control, technology examples, contained sampling, and effective measurement/ testing methods. Day two will include case studies on various types of facilities, and will illustrate concepts in practice. 24-25 February 1.2 CEUs (2 CM Points Awarded for Industrial Hygienists; Award #09-3708) Leaders • Beth Brock, PE, Consultant Engineer, Eli Lilly & Co., USA • Alan George, Product Manager, ILC Dover, USA How You Will Benefit At the conclusion of this session, participants will be able to: • Recognize that different types of toxicology limits are set for worker, product, and environmental protection • Recognize or describe the following containment concepts: Contain at the source; Containment challenge; Material migration; and Risk • Identify containment technologies and their position in the containment hierarchy • Recognize applications of hierarchy of containment solutions to real-world containment challenges • Describe how other industry professionals solved containment challenges • Understand new technologies available and how they impact containment and cross-contamination Speakers Confirmed to Date • Paul Egee, Product Manager, IMA North America, USA • Michelle Frisch, Senior Manager, Global Technical Systems, Powder Systems, Ltd., USA • Jonathan Lind, Distinguished Project Engineer, Roche Colorado Corp., USA • Edwin Melendez, Consumer Safety Officer, DHHS/FDA/CDER/OC/DMPQ/ICB • Steven Meszaros, Director EHS, Wyeth, USA • Jimmy Moreno, PE, Senior Project Engineer, Schering-Plough, USA • Christa Myers, Chemical Process Engineer, CRB Consulting Engineers, Inc., USA • James Wood, PE, Associate Senior Consultant Engineer, Eli Lilly & Co., USA Who Should Attend Project/process/manufacturing engineers, environment and health/safety professionals, quality assurance, professionals from production/manufacturing operations, professionals from process development, owner/operator, consultants, and CMOs Hear the FDA’s perspective, and participate in a Q&A session on risk-based approaches for multi-product facilities and highlyhazardous compound containment topics. Community of Practice (COP) www.ISPE.org/COPs This seminar is designed for process and plant engineers, quality and health and safety professionals, and production managers, among others, and will provide a basic understanding of powder containment concepts as well as fresh engineering solutions. www.ISPE.org/Publications Containment Related Technical Documents, Articles, and Publications • ISPE Baseline® Guide: Volume 1 – Active Pharmaceutical Ingredients • ISPE Knowledge Briefs: Risk-Based Approaches to Cross-Contamination; Containment Hierarchy of Controls; and Dry Powder Sampling and the Containment of Hazardous Compounds Knowledge Competency Elements These are detailed on page 3. Updates and Agenda Online at www.ISPE.org/2010tampaconference Applying Solutions to Emerging Industry Challenges 22-25 February 2010 • Grand Hyatt Tampa Bay • Tampa, Florida, USA 9 Technology Transfer: Focus on the Business Process and Practical Execution (E07) Seminar Content Level 24-25 February 1.2 CEUs How You Will Benefit At the conclusion of this session, participants will be able to: Fundamental • Intermediate • Advanced It is easy to underestimate the effort required for effective technology transfer. As more companies look to outsource manufacturing operations across the globe, the timeliness and value of getting it right is crucial. Technology transfer is more than just the transfer of a product and/or a manufacturing process. It is a key tool in a company’s strategic operation that must be understood in order to effectively manage. It is difficult, in part, because it continues to be underestimated. This seminar provides an interactive workshop focused on the execution and management of technology transfer, both from a business process and technical standpoint. It looks at tools and approaches that foster success. Using the ISPE Good Practice Guide: Technology Transfer as a reference tool, subject matter experts will address: • Structuring an approach to the business process of technology transfer • Formation of a team • Establishment of good communication tools • Setting objectives and acceptance criteria • Good documentation • Knowledge transfer across companies, continents, and cultures • Analytical methods transfer • Regulatory compliance; understanding the regulatory environment The use of a case study scenario as the platform for a series of interactive group workshop activities will bring a real world element to this seminar, and challenges attendees to consider both the business process and technical aspects at the same time. • Understand critical elements of technology transfer • Define goals and objectives that relate to the project objective • Identify critical business process elements • Develop a successful team • Develop effective communication tools • Understand the critical elements of knowledge transfer • Identify key regulatory issues • Develop effective documentation • Address key business management challenges in technology transfer • Pull all of the above into an effective technology transfer program Program Committee Members • Noel Dinan, Technical Director, API, Schering-Plough, USA • Michael Denault, Principal, Denault Associates, USA • Marcella Goodnight, Manager, Genentech, USA • Larry Kranking, President, Aveta Lifesciences, USA, USA •D r. Elaine Morefield, Supervisory Chemist, DHHS/FDA/CDER/OPS/ONDQA/ DPA II • Daniel Moskey, Associate Director, Vacaville Technology, Genentech, Inc., USA • Jeffery Odum, Principal, NCBioSource, USA • James Phillips, Senior Manager - Manufacturing Sciences, Biogen Idec, USA • Patrick Wong, PE, Director, Asian Operations, IPS, USA Who Should Attend Development engineers, process engineers, project managers, quality assurance and quality control personnel, validation specialists, technology services managers, process/development chemists, and production managers Community of Practice (COP) www.ISPE.org/COPs Process/Product Development Related Technical Documents, Articles, and Publications www.ISPE.org/Publications ISPE Good Practice Guide: Technology Transfer Knowledge Competency Elements These are detailed on page 3. Updates and Agenda Online at www.ISPE.org/2010tampaconference Leader • Michael Denault, Principal, Denault Associates, USA 10 Applying Solutions to Emerging Industry Challenges 22-25 February 2010 • Grand Hyatt Tampa Bay • Tampa, Florida, USA Beyond Book-learning: Practical Application of Good Engineering Practice and Maintenance Guides (E08) Planned and Implemented by the ISPE C&Q, GAMP, and Project Management Communities of Practice (COPs) Seminar Content Level Fundamental • Intermediate • Advanced Why are there new guides? How will this information make a difference to my current role? Take advantage of interactive workshops and the expertise of practitioners as attendees and leaders solve real-life challenges. Even if you haven’t read the guides, you will be able to work with leaders who collaboratively lead the guide team, and other SMEs and attendees through case studies, topicfocused presentations, and interactive workshops. This two-day seminar aids the attendees with hands-on applications to demonstrate how each of these Guides will help you in your work. Good Engineering Practice (GEP), as a broad collection of engineering and risk management activities, is becoming recognized in the pharmaceutical and life sciences industries as an essential foundation upon which efficient operations and regulated activities are built. The ISPE Good Practice Guide: Good Engineering Practice provides definitions, examples, and execution guidance for lifecycle engineering management applications. Maintenance has been recognized as an activity critical to the ongoing success of manufacturing operations in achieving productivity goals and sustaining product quality. Effective maintenance programs employ multiple elements including maintenance planning and scheduling, risk assessments, maintenance approach, task execution and record keeping among many others. The ISPE Good Practice Guide: Maintenance provides definitions, examples, and guidance for development and execution of effective, comprehensive maintenance programs. 24-25 February 1.2 CEUs How You Will Benefit At the conclusion of this session, participants will be able to: • Identify the fundamental components of a comprehensive GEP and an effective maintenance program • Understand the importance of GEP as an essential foundation to an effective manufacturing operation • Analyze and understand the benefits and challenges associated with maintenance programs • Interpret and understand how to utilize the GEP and Maintenance Good Practice Guides to develop or improve engineering and maintenance program activities in your own organization • Deliberate on the current trends associated with GEP and maintenance activities Presentations and Speakers Confirmed to Date • FDA Invited • Donna DeFreitas, Senior Associate, Genesis Engineers Inc, USA • Mark Foss, Head of Engineering, Boehringer Ingelheim Ltd, UNITED KINGDOM • Keith Gibbs, Corporate Manager, C&Q, Yonkers Industries, USA • Bob Lennon, Director, Americas Region, Abbott Laboratories, USA Who Should Attend Professionals from engineering, maintenance, engineering excellence, quality, operations, commissioning and qualification, validation, capital projects, and project management Communities of Practice (COPs) www.ISPE.org/COPs Commissioning and Qualification, GAMP, Project Management, and Operations Management Related Technical Documents, Articles, and Publications www.ISPE.org/Publications ISPE Good Practice Guide: Good Engineering Practice and ISPE Good Practice Guide: Maintenance Knowledge Competency Elements These are detailed on page 3. Updates and Agenda Online at www.ISPE.org/2010tampaconference Leaders • Daniel Franklin, Regional Manager, Compliance Services, IPS, USA • Remitha Jones, Principal Engineer, Abbott, USA Applying Solutions to Emerging Industry Challenges 11 22-25 February 2010 • Grand Hyatt Tampa Bay • Tampa, Florida, USA HVAC for Pharmaceutical Facilities (T14) Training Course Course Content Level Fundamental • Intermediate • Advanced This course will provide a detailed description of HVAC system fundamentals, including a discussion of primary system components such as fans, coils, humidifiers, and filters. Participants will receive an overview of critical parameters for products and processes that can be affected by HVAC, and explore the basic concepts of controlling these parameters using properly designed HVAC control systems. Participants will discuss what HVAC can and cannot do to maintain good manufacturing practices (GMPs) as they are addressed for facilities designed to manufacture bulk pharmaceutical chemicals (BPC), oral solid dosage (OSD) products, sterile products, and bulk biopharmaceuticals. HVAC systems for production laboratories and warehouse facilities utilized for the storage of product, raw materials, and components are also covered. On completion of facility-specific systems, the requirements for commissioning and qualification are explored with emphasis on distinguishing between critical and noncritical parameters. Other course topics include HVAC controls, monitoring of critical parameters, and system construction. Dust collection systems and laboratory fume hoods are not covered, as these systems are addressed by other sources. The course concludes with suggestions for system maintenance. Take Back to Your Job How To ... • Define basic HVAC system concepts • Discuss HVAC system-critical parameters that must be controlled and monitored • Distinguish among pharmaceutical cleanroom air classifications and explain how they are applied • Explain the role of HVAC in protecting products • Examine typical HVAC system designs used for bulk, oral solid dosage, sterile, biopharmaceutical, and packaging and warehousing operations • Understand the basics of process laboratory HVAC • Describe HEPA filter theory, application, monitoring, testing, and repair • Cite HVAC maintenance requirements Who Should Attend • Project engineers, HVAC technicians and mechanics, HVAC control designers, commissioning personnel, government agency inspectors, quality assurance specialists, and manufacturing managers • Professionals needing a thorough understanding of HVAC systems utilized in pharmaceutical operations • Engineering professionals and other consultants who work with the pharmaceutical industry Instructor Norm Goldschmidt, Principal/Founder, Pharma Engineering Advisors, USA Community of Practice (COP) www.ISPE.org/COPs HVAC Related Technical Documents, Articles, and Publications www.ISPE.org/Publications ISPE Good Practice Guide: Heating, Ventilation, and Air Conditioning Attendees will be provided with updates to course materials if GMPs or technology related to meeting GMPs change within 12 months of attending the course (email address required). Participants should be familiar with basic pharmaceutical product forms and GMPs. Note: Course registrants receive a copy of the ISPE Good Practice Guide: Heating, Ventilation, and Air Conditioning. 12 22, 23 and 24 February 2.0 CEUs Applying Solutions to Emerging Industry Challenges 22-25 February 2010 • Grand Hyatt Tampa Bay • Tampa, Florida, USA Practical Application of Computerized Systems Compliance: Applying the GAMP®5 Guide: A Risk-Based Approach to Compliant GxP Computerized Systems (T11) — Training Course Course Content Level Fundamental • Intermediate • Advanced This highly-interactive workshop provides hands-on experience in applying practical techniques and solutions to solve computerized systems compliance challenges. Participants will discuss and analyze case studies, apply newly acquired knowledge to hypothetical case-study systems, and have the opportunity to discuss their own real-life challenges with other participants and an expert trainer. Participants should come prepared to work in groups to devise workable and creative solutions to realistic problems and case study scenarios, facilitated by the instructor. GAMP guidance aims to achieve computerized systems that are fit for intended use and meet current regulatory requirements, by building upon existing industry good practice in an efficient and effective manner. The course outlines the importance of applying a documented and justified risk-based approach to computer systems compliance. Highlights of the course include: • Overview of key themes/concepts in GAMP 5 • Understanding the process and overall GxP Risk • Effective planning for compliance • Supplier assessment and leveraging supplier knowledge and documentation • The key role of clear and complete user requirement specifications • Choosing a suitable specification and verification approach • GAMP 5 quality risk management approach (based on ICH Q9) • Specific risk assessment tools for computerized systems • Selecting a suitable lifecycle and scaling the lifecycle based on risk, complexity, and novelty • Developing a strategy and writing a computerized system validation plan • Writing high-quality test scripts • Maintaining the control in operation – a scaleable approach • Regulatory hot topics 24-25 February 1.5 CEUs This course was developed by members of the ISPE GAMP Community of Practice. GAMP was established by industry leaders to interpret and improve the understanding of regulations governing the use of computerized systems in pharmaceutical manufacturing. Note: Course registrants receive a copy of the GAMP® 5 Guide: A Risk-Based Approach to Compliant GxP Computerized Systems. Take Back to Your Job How To ... •Build upon and expand understanding of the regulatory requirements and expectations for the compliance of computerized systems used in pharmaceutical manufacturing • Apply this understanding to example systems and case studies • Analyze case studies and apply the GAMP 5 process for achieving compliance and fitness for intended use • Apply quality risk management and risk assessment concepts Who Should Attend • Quality assurance and quality control specialists, validation specialists, manufacturing supervisors, technical support personnel, engineers, MIS professionals and all levels of management who need a practical understanding of computerized system compliance • Computer system vendors or consultants, engineering contractors, and validation service companies • Those who have previously attended a GAMP Basic Principles training course or those whose practical experience has provided the equivalent level of knowledge Instructor James W. (Jim) John, Project Manager, Altus Automation, a ProPharma Group Company, USA Community of Practice (COP) www.ISPE.org/COPs GAMP Related Technical Documents, Articles, and Publications www.ISPE.org/Publications GAMP® 5 Guide: A Risk-Based Approach to Compliant GxP Computerized Systems Knowledge Competency Elements These are detailed on page 3. Important Course Notes This course includes a pre-recorded, Web-based session providing a review of basics prior to the classroom course. Applying Solutions to Emerging Industry Challenges 13 22-25 February 2010 • Grand Hyatt Tampa Bay • Tampa, Florida, USA ISPE 2010 Tampa Conference Applying Solutions to Emerging Industry Challenges Registration Form • 22-25 February 2010 Please type or print clearly. ONLINE: www.ISPE.org/2010TampaConference FAX: +1-813-264-2816 MAIL: ISPE, 3109 W. Dr. Martin Luther King Jr. Blvd., Suite 250, Tampa, Florida, 33607 USA ISPE ID # _______________________________ Check here if you were previously an ISPE Member. First Name __________________________________________________MI _________ Last Name ______________________________________________________________ Informal Badge Name ______________________________________________________ Chapter/Affiliate _________________________________________________________ Job Title ___________________________ Email Address __________________________________________________Company ______________________________________ Business Address ________________________________________________________________________________________________________________________________ City __________________________________________State/Province__________________ Zip+4/Postcode ____________________ Country ___________________________ Business Tel _____________________________________________________________ Business Fax ___________________________________________________________ Emergency phone for last minute meeting updates: Cell Phone ______________________________________ or Home Phone ________________________________________ I wish to keep my data confidential and it is given only for use by ISPE and its local Chapters and Affiliates. I do not wish my information to be printed in the Membership Directory or on Conference Attendee Listings. First Time Attendee New Member New Member/First Time Attendee Orientation HOTEL: Hotel accommodations and hotel fees are separate from Conference registration fees. For room reservations at the Conference venue, Grand Hyatt Tampa Bay, call tel: +1-813-874-1234. When making your reservation by phone, mention ISPE for a discounted rate of $229 single/double (total with tax $256.48). This rate is good until 26 January 2010, or until the room block is full, whichever comes first. Please contact the hotel as early as possible to make your reservations to ensure you are in the headquarters hotel. Please Select Your Seminars of Choice E01 Aseptic Processing of Sterile Products: Innovations, Regulatory Guidance and Compliance in a Practical World - Monday and Tuesday E05 Managing the Risks and Challenges of Syringe Processing - Wednesday and Thursday E02 Inspection Readiness Workshop: From Site Preparation to Successful Execution - Monday and Tuesday E06 Containment Technology Forum: Basics and Beyond Wednesday and Thursday E03 Oral Solid Dosage: New Guidance You Can Use Right Now Monday and Tuesday E07 Technology Transfer: Focus on the Business Process and Practical Execution - Wednesday and Thursday E04 Lean Project Delivery: Leveraging New ISPE Guides on Commissioning and Qualification and GAMP®5 Monday and Tuesday E08 Beyond Book-learning: Practical Application of Good Engineering Practice and Maintenance Guides Wednesday and Thursday INDIVIDUAL SEMINAR REGISTRATION FEES — PLEASE CIRCLE PAYMENT Discounts cannot be combined. Regular/Onsite (After 25 January) First Two-day Seminar Fee Current Member New Member* (Fee includes one-year ISPE Membership, a $215 value) Nonmember $ 1,350 $ 1,565 $ 1,645 Additional Two-day Seminar Fee (save 20%) Current Member Nonmember $ 1,080 $ 1,315 Student Member Fee $ 150 Regulatory Authority/Government — Two-day Seminar Fee $ 675 Academia/Emerging Economy Member — Two-day Seminar Fee $ 675 Committee Member — Two-day Seminar Fee $ 525 Please Select Your Training Course(s) of Choice and Circle Payment PLEASE NOTE: Multiple attendees from a company who register at the same time qualify for a discount. The following savings are taken from fees: 3-5 delegates 10%, 6-10 delegates 15%, and 11+ delegates 20%. Regular/Onsite (After 25 January) T14 HVAC for Pharmaceutical Facilities Monday, Tuesday, and Wednesday Current Member New Member* (Fee includes one-year ISPE Membership, a $215 value) Nonmember $ 2,285 $ 2,500 $ 2,625 T11 Practical Application of Computerized Systems Compliance: Applying the GAMP®5 Guide: A Risk-Based Approach to Compliant GxP Computerized Systems - Wednesday and Thursday Current Member New Member* (Fee includes one-year ISPE Membership, a $215 value) Nonmember $ 1,910 $ 2,125 $ 2,230 T04 Pharmaceutical Water Generation Monday and Tuesday Current Member New Member* (Fee includes one-year ISPE Membership, a $215 value) Nonmember $1,910 $2,125 $2,230 SPECIAL LUNCH REQUIREMENT — Vegetarian Kosher Gluten Free PAYMENT METHOD — REGISTRATIONS REQUIRE PAYMENT ATTACHED Substituting for __________________________________ (NONMEMBERS SUBSTITUTING FOR A MEMBER MUST PAY THE DIFFERENCE IN FEES.) Check enclosed payable to ISPE # __________________ in the amount of $ ________________ (must be drawn on a US bank) Bill credit card — circle type: VISA MC AMEX Card number _____________________________________________________ Exp. date _______________________ Name of cardholder___________________________________________________________________________ (AS IT APPEARS ON CARD) Please send registration form with payment to: ISPE Headquarters, 3109 W. Dr. Martin Luther King Jr. Blvd., Ste. 250,Tampa, Florida 33607 USA Tel: +1-813-960-2105 • Fax: +1-813-264-2816 • FEIN #59-2009272 • www.ISPE.org Cardholder signature ___________________________________________________________________________________________ TPACONF09-Broch2 *To activate your membership please download a membership application at www.ISPE.org/membership and return it to ISPE with this conference registration form. Membership is non-transferable. This is a 30-day limited offer from time of conference end date. Registration is confirmed only when payment is received. Conference Cancellations - Cancellations must be made in writing. If cancellations are received by 1 February 2010, a full refund, minus a 10% handling fee (maximum of $100), will be issued. After that time, no refunds will be granted. If you are unable to attend, substitutions will be accepted. However, nonmembers substituting for a Member must pay difference in fees prior to the start of the event. ISPE is not responsible for lost airfare due to cancellations. Regform_update.indd 1 1/28/2010 9:19:33 AM General Information How to Register ISPE Bookstore Online: Visit www.ISPE.org/2010tampaconference Visit the ISPE Bookstore at Tampa Conference to stock up on the latest technical publications from ISPE. Members receive a 20 percent discount onsite. Via Fax: Complete the registration form and fax it to: +1-813-264-2816 Via Mail: Complete the registration form and mail it with payment to: ISPE Headquarters, 3109 W. Dr. Martin Luther King Jr. Blvd., Suite 250, Tampa, Florida 33607 USA Questions? Call ISPE at tel: +1-813-960-2105, or email: ask@ispe.org Written confirmation will be sent to you after your registration is processed (time permitting). In order to be listed in the official delegate roster, you must be registered and paid by 11 February. Conference Fees Include Exhibit Hall access, continental breakfasts, refreshment breaks, lunches, and networking receptions. Hotel accommodations and hotel fees are separate from Conference registration fees. For room reservations at the Conference venue, Grand Hyatt Tampa Bay, call tel: +1-813-874-1234. When making your reservation by phone, mention ISPE for a discounted rate of $229 single/double (total with tax $256.48). This rate is good until 26 January 2010, or until the room block is full, whichever comes first. Please contact the hotel as early as possible to make your reservations to ensure you are in the headquarters hotel. We thank you for staying at the Hyatt as this enables ISPE to meet contract requirements. Complimentary daily Internet cards are available for ISPE attendees at the hotel front desk. Conference Schedule The registration desk will be open: Sunday 15.00 - 17.00; Monday Wednesday 07.30 - 17.30; and Thursday 07.30 - 16.00. Seminars are scheduled to begin at 09.00 and conclude at 17.00 from Monday to Wednesday. Thursday seminars begin at 08.00 and conclude at 16.00. Morning and afternoon breaks are scheduled daily. Lunch will be served each day. A la carte lunch tickets may be purchased separately onsite. Conference Cancellations Cancellations must be made in writing. If cancellations are received by 1 February, a full refund, minus a 10% handling fee (maximum of $100), will be issued. After that time, no refunds will be granted. If you are unable to attend, substitutions will be accepted. However, nonmembers substituting for a Member must pay difference in fees prior to the start of the event. ISPE is not responsible for lost airfare due to cancellations. Accreditation ISPE provides continuing education units (ISPE CEUs). ISPE CEUs are nationally recognized units of attendance that identify those individuals continuing their education in their chosen field or profession. For the E06, Containment Technology Forum, CM Points for industrial hygienists have been applied for. Special Requirements If you require special accommodations to participate, such as a wheelchair-accessible room or a sign language interpreter, please attach a written description of your needs to your registration form. If you have questions, please contact ISPE at tel: +1-813-960-2105 or email: ask@ ispe.org. Please mark vegetarian, gluten free, or kosher, if needed, in the Special Meal Requirement box on the registration form. Notice ISPE leaders and speakers are leading professionals in their fields. However, in those rare circumstances where we find it necessary to make subsitutions, every possible effort is made to provide speakers with comparable qualifications. Agendas are subject to change without notice. Every precaution is taken to ensure accuracy, but ISPE cannot accept responsibility for the accuracy of information distributed or contained in these seminars or for any opinion expressed. Delegates’ names and addresses may be given as part of a list to other organizations for purposes related to the field of pharmaceutical manufacturing. If you do not wish to receive other related information, please notify ISPE. Know Before You Go Visit www.ISPE.org/2010tampaconference prior to attending the Conference for all you need to “Know Before You Go.” You will receive an email one week prior to the event with updated details, a delegate roster, and more. Get Your Space at the Table Top Exhibition The Table Top Exhibition is a popular marketing and business development tool that guarantees excellent exposure for your company. Don’t miss out on this opportunity to meet face-to-face with key decision makers in the pharmaceutical and biotechnology manufacturing industries. Exhibit set up will be on Monday, 22 February from 12.00 - 16.00. The exhibits will open on Monday, 22 February from 17.00 - 18.30 with the Opening Reception. Continental breakfast and refreshment breaks will be held in the Exhibit Hall on Tuesday and Wednesday. The fee to exhibit is $2,300 and includes two exhibitor badges for each exhibiting company. The table top exhibition will be limited to 60 companies. Exhibit cancellations made prior to 28 December 2009 will result in a $500 cancellation fee. There are no refunds for exhibit cancellations made after 28 December 2009. Contact John Phillips at jphillips@ISPE.org, or Valerie Adams at vadams@ISPE.org. Sponsorships ISPE Conference Sponsorships offer your company unique opportunities to build and reinforce name recognition, create top-of-mind brand awareness, and develop new business. These sponsorships provide an opportunity for you to connect with a targeted, unique, and global audience, promote the latest technical advancements, and demonstrate your company’s commitment to the education of pharmaceutical and biotechnology manufacturing industry professionals. Host, Platinum, Gold, Silver, and Bronze Top Tier Sponsorships are available as well as cyber café, lanyards, and hotel keycards. Onsite advertising opportunities are also available. Contact John Phillips at jphillips@ISPE.org, or Valerie Adams at vadams@ISPE.org for details. 15 NON-PROFIT ORG. U.S. POSTAGE PAID engineering pharmaceutical innovation TAMPA, FL PERMIT NO. 2661 3109 W. Dr. Martin Luther King Jr. Blvd., Suite 250 | Tampa, FL 33607 The ISPE 2010 Tampa Conference Education Seminars • Aseptic Processing of Sterile Products: Innovations, Regulatory Guidance and Compliance in a Practical World • Inspection Readiness Workshop: From Site Preparation to Successful Execution • Oral Solid Dosage: New Guidance You Can Use Right Now • Lean Project Delivery: Leveraging New ISPE Guides on Commissioning and Qualification and GAMP®5 • Managing the Risks and Challenges of Syringe Processing • Containment Technology Forum: Basics and Beyond • Technology Transfer: Focus on the Business Process and Practical Execution • Beyond Book-learning: Practical Application of Good Engineering Practice and Maintenance Guides Skill-building Training Courses • HVAC for Pharmaceutical Facilities • Practical Application of Computerized Systems Compliance: Applying the GAMP® 5 Guide: A Risk-Based Approach to Compliant GxP Computerized Systems ISPE Membership: Knowledge, Community, Profession, and More Find out what becoming an ISPE Member can do for you. New Member registration fees include a one-year ISPE membership. Visit www.ISPE.org/join to learn more about the many benefits of ISPE Membership. Sponsorship and Table Top Exhibit Opportunities Available! For details, see page 15 of this brochure or contact John Phillips at jphillips@ISPE.org, or Valerie Adams at vadams@ISPE.org for more information. www.ISPE.org/2010tampaconference