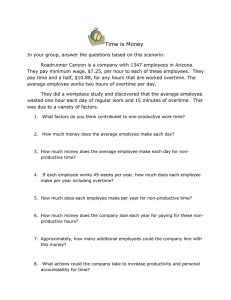

a direct impact on labor costs. Regardless of

advertisement

WHAT ARE YOUR OVERTIME COSTS? a direct impact on labor costs. Regardless of whether a manager’s goal is to minimize the total labor cost or maximize the productivity of that labor employed, he will be confronted with a seemingly unending series of questions regarding wage levels, incentives, labor negotiations, retirement, etc. The agribusiness industry is not unique in its continued reliance on manual labor. Nor is it unique in its attempt to find ways to retain control of wages and enhance the productivity of that labor employed. Thousands of dollars have been invested in new physical plants and equipment by many agribusiness firms, but rare is the firm which has experienced a decrease in its total wage bill as a result of such expenditures. More often in this industry, recently employed technological improvements add to production levels and enhance labor productivity, but seldom reduce the actual size of the labor force. Agribusiness retailers, in particular, are finding that there exists no mechanical substitute for employee-customer contact. Self-service shopping, while it has reduced the labor required in many non-agriculture retail establishments, has not proved suitable to retail farm supply, feed, and fertilizer operations. Numerous other examples can be found within the agribusiness industry where labor has become a high-cost and almost irreplaceable resource. What About Overtime? Of all the labor-related management concerns noted above, overtime is a subject most often overlooked by writers in the field. Yet overtime represents a significant cost to many firms. Many agribusiness firms operate on a highly seasonal pattern, i.e., in response to the resource requirements of agriculture’s seasonal production. During the peak season, management will often find that a 10-hour day, 6-day week is necessary to keep up with the customers’ needs. Almost every sector of the agribusiness industry has at least one period of the year when its work force is compiling large amounts of overtime. Some firms do not pay employees for overtime worked and, instead, attempt to offset the 10-hour days in the spring with a few free days in the off-season. Other employers pay a flat hourly rate regardless of the hours worked. In the future, these two situations will become less and less prevalent. Unionization, federal employment standards, and generally improved levels of concern for labor by management will convert this industry from one where the socalled “busy season” is accepted as a consequence of the job, to one where the standard working day is more strictly adhered to and where substantial pay premiums accompany overtime. Such an Based on my own contacts with agribusiness managers, I could easily conclude that labor and labor-related costs have become their prime administrative concerns. The availability of a work force when needed, employee turnover, employee competence, unionization, fringe benefits, and most recently, employee safety, probably occupy half of a manager’s time. Obviously, therefore, many management decisions have 1 WASHINGTON STATE UNIVERSITY & U.S. DEPARTMENT OF AGRICULTURE COOPERATING adjustment will not be welcomed by everyone in the industry. Some will accept the change reluctantly. Others will succumb only when forceful regulations have been imposed on them by various public institutions. But the change will be no less inevitable and the impact on the industry will be substantial. If they have not already, overtime costs will soon become a real concern to agribusiness managers. large amounts of complex machinery are employed, preventive maintenance is a very important labor-intensive function. Yet, it is a function which can be postponed in the short run. Many in the labor force have discovered that it becomes relatively easy to delay maintenance until the end of the standard working day. During the regular 8 to 5 shift, maintenance is conveniently overlooked, but by the day’s end, employees begin to find numerous adjustments or corrections which must be made prior to the beginning of the next day’s run. The unsuspecting supervisor is “conned” into agreeing with his work crew that overtime must be employed. As a result, the cost of maintenance increases, labor productivity drops, and wages grow. What control does a manager have in the area of overtime expenses? When is overtime warranted and when is it not? How can a manager guard against the excessive use of overtime? These are, or will become, important concerns of modern agribusiness managers. This paper is designed to consider these questions and suggest guidelines by which managers can regain some control over labor costs. Employee Collusion: As a one-time employee of a paperboard manufacturing plant in the Midwest, I have vivid memories of the various schemes employed by my working colleagues for the purpose of generating unnecessary overtime. At the time, I was a young college student who found the overtime pay to be more attractive (and necessary) than an extra hour’s sleep. Anytime a “special order” was received by management, the underground communications channel conveyed this vital information to the crew chiefs within a few short hours. The crew chiefs would then speak with their more “money-hungry” employees and reach an agreement that the special order would become an overtime activity. All this was decided before management even released the specifications of the special order. Management would then poll its more experienced plant employees to determine how the order could best be handled. Of course, all were unanimous in their statements that it could only be handled on an overtime basis. As an employee, this collusion system worked to my advantage -- losing a little sleep, but Overtime Abuse Who determines the size of your employees’ paychecks, you or your employees, themselves? If, as a manager, you abdicate your responsibilities in this area, your employees will soon happily discover that controls are lax and adjust their work habits to their own advantage. And who would blame them! If the decision to work overtime rests with the employees, rationale suggests that they direct their resource (labor) in pursuit of the highest reward. If overtime pays double or time-and-a-half, the answer is very simple, i.e., accelerate their use of overtime whether warranted by the workload or not. As a manager, you should be aware of the means by which employees often abuse overtime privileges. Such abuse may, therefore, be prevented entirely, or stopped upon its discovery. A few such means of abuse are discussed below: Maintenance Postponement: In those sectors of the agribusiness industry where 2 increasing my take-home pay by as much as 50 percent weekly. To my unsuspecting employer, the results were disastrous, i.e., almost all special orders were processed at a net loss, product quality deteriorated, and stoppages due to breakdowns increased. forced to absorb the cost! Many such instances could be reported wherein poor coordination and enforcement resulted in a general work slowdown. Working conditions were also a factor. On many afternoons in August the temperatures in the plant rose to the 100 degree mark. When combined with poorly vented steam from the corrugating machine, the heat made it necessary for employees simply to slow to a snail’s pace. Men lingered at their coffee breaks and worker productivity dropped to nil. To maintain production, working hours were sometimes extended to 9:00 p.m. or began at 6:00 a.m. when the plant temperatures were more moderate. During one such week I accumulated almost 20 hours of overtime! Slowdowns: Work slowdowns are, perhaps, the most common means of generating excessive overtime. Unfortunately, it is also the most difficult thing for management to identify, prove, and bring under control. General work slowdowns are often not even intentional nor the sole fault of employees. To illustrate this fact, I will return again to my personal experiences in the paperboard plant. In general, the total monthly workload at this plant varied little. And yet, during the summer months daily production levels dropped noticeably and substantial overtime was required to keep total production at normal winter rates. Why? The most obvious answer to this question was employee absenteeism. The daily absentee rate rose in direct proportion to the climate. On those warm days, particularly those immediately preceding or following legal holidays, the plant was nearly abandoned. Plant employees, supervisors, and administrators alike simply failed to show up for work. On those days when the shipping clerk failed to show up, his work crew could hardly function. Trucks were misloaded and many outgoing shipments remained on the loading docks for lack of assignment destinations. Backups occurred throughout the plant whenever the dispatcher chose to go fishing, because work orders and crew assignments failed to get from the head office to the plant. On one very pleasant day the supervisor chose to leave for home about mid-afternoon. Strength specifications were left buried on his desk and the entire assembly line was forced to shut down by 3:30 p.m. Union regulations prohibited the release of men after 1:00 p.m. The plant was Some work slowdowns were intentional. One of my colleagues was especially adept at operating a large staple press. Under his control, this machine would produce at such a high rate that loaders, stockers and pallettruck drivers could not keep up with the output. As a result the press operator was asked by his co-workers to slow down because compared with his speed, those on the other similar machines appeared slow and incompetent. Are There Solutions? The insidious thing about the extensive use of overtime is the inevitable decline in per worker productivity combined with a cost that may add as much as 50 percent to your regular weekly labor expense. A processing firm showing a profit at existing production levels and a regular work week may discover that at an overtime wage rate, a net loss is incurred for every unit processed. Can your firm survive at overtime wage rates? Probably not for very long. Hence the best solution to overtime abuse is its prevention. 3 The first guideline for preventing overtime abuse is to establish an accounting system which is “overtime sensitive.” In other words, your accounting system should prevent the inclusion of overtime costs in larger categories where it goes unnoticed or is impossible to separate out. Ask your administrative staff to compile a regular schedule of overtime hours employed, who authorized it, and why. If a particular division or supervisor within your firm reports rising overtime usage, ask for justification. Generally, however, establishing a setting of accountability will, in itself, reduce most overtime abuse. with modest, but regular, overtime supplements to their regular pay. Managers should never allow such supervisors to influence their control of the labor force. Similarly, managers should establish and enforce a regular company policy regulating absenteeism. Make sure that persons at all levels, from the shop apprentice to the plant superintendent, know the policy and the consequences of violating it. In this regard, unionization often works to the advantage of management because labor contracts usually spell out the exact terms of an absentee policy. Further Precautions A second guideline suggests that management never convey to its employees, by directive or by default, the prerogative of approving overtime. Overtime approval should not become routine. It represents the incurrence of additional costs, often not budgeted for, and each decision to use it should rest on the merits of the case. Suppose preventive measures were implemented too late and overtime has already built to an unacceptable level. Then what can be done to regain control? First of all, don’t press the panic button and cut all overtime in one fell swoop. The consequences to such a drastic move may be worse than anticipated. It may deliver a severe blow to the morale of your work force. Furthermore, there are some situations where modest overtime usage is the best option. For example, some overtime in the peak season may be less costly than hiring additional personnel. This is particularly true if the peak season is relatively short and/or additional part-time personnel are difficult to find. Hence, management should inquire as to the reasons underlying the use of overtime, its likely duration, and its impact on the profitability of current (and future) operations. Third, managers should establish realistic time standards for various jobs. Accumulate and report actual labor usage against these standards. If intentional slowdown does occur, management will then be able to rapidly identify it. Wages paid on a piecerate basis sometimes aid in this situation. Employees begin to take pride in themselves for their own productivity and receive rewards in accordance with their efforts. Overtime is often necessary and unavoidable when beginning a new product run, moving to new facilities, or making extensive adjustments in the plant or production processes. But don’t allow it to become a habit. When the real need is eliminated, cut back quickly to the regular work week. Whatever you do, don’t antagonize workers with statements accusing them of making too much money. Such statements are based on false premises. First of all, your firm’s profits and your employees’ earnings are not always diametrically opposed. Many employee incentive plans are based on the Some labor crew supervisors try to gain favor with their people by providing them 4 premise that both could become winners. Second, it should not be company policy to minimize or otherwise restrain the earnings of its employees. To the contrary, company policy should stipulate the avoidance of paying excessively for a particular service. Such a policy is not only more rational, it is also more easily assimilated by a labor force. an overweight individual. The overweight situation is further aggravated by the continued consumption of resources in excess of those required to maintain proper health. Maintenance postponement, employee collusion, and general work slowdowns are all means by which excessive labor resources are absorbed by the corporate body. In such cases, weight controls not only make sense, but may be necessary for the survival of the firm. Prevention is always the best cure and entails tight management controls. If overtime abuse is already suspected, management should investigate the underlying causes before seeking to eliminate it. All areas of the firm and all levels of personnel should be held responsible for any overtime abuse. Under no conditions should the manager antagonize his employees on the subject of excessive wages. Instead, the concept of excessive costs should be used as the basis for a reduction in overtime usage. Finally, if you decide to make overtime cuts in some areas and not others, make sure you are prepared to answer the question of discrimination. Pressure to reduce overtime abuse should be applied equally to all persons, departments and divisions. If overtime appears constantly in one area and not others, you may wish to consider altering your workload assignments. Some firms use a labor pool system whereby personnel can be taken from one area and reassigned to work in another area until the backup has been eliminated and the labor force returned to the regular work week. Summary In the March 1972 issue of Canadian Business, Robert J. Frank states that a firm burdened with overtime abuse is much like Ken D. Duft Extension Marketing Economist 5