ARCHAEOMETALLURGY ARCL3001 Course Handbook for 2015/16

advertisement

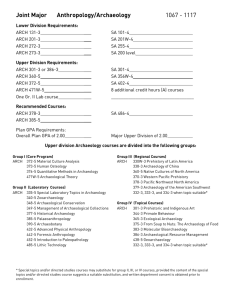

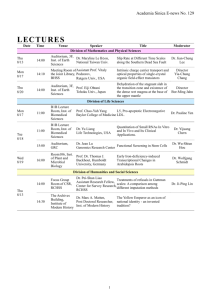

UCL INSTITUTE OF ARCHAEOLOGY ARCL3001 ARCHAEOMETALLURGY Course Handbook for 2015/16 Years 2 and 3 option, 0.5 unit Co-ordinator: Marcos Martinón-Torres m.martinon-torres@ucl.ac.uk Office 112, Tel 020 7679 7496 Term II , Monday 2-4 (plus 4-6 some days), Room B13 Turnitin Class ID: 2970179 – Password IoA1516 ARCL3001 Archaeometallurgy - 3 AIMS The main aim of this course is to familiarise students with the main approaches to the study of archaeological metal artefacts and metallurgical debris, and how these can be used to address questions of archaeological significance. The course will provide students with an overview of the development and spread of mining and metallurgy within their natural and archaeological contexts from the Neolithic up to the Industrial Revolution. This includes an introduction to metals as materials, and how the exploitation and understanding of different metals evolved over time in different regions. Especial emphasis is placed on the understanding of technical processes related to metallurgy, their reconstruction based on the study of archaeological remains, and their interpretation in the relevant social and cultural contexts. The course does not focus on the typological or stylistic study of metal artefacts, nor does it attempt an exhaustive documentation of sites and dates (these aspects can be explored by students in their coursework, depending on their specific interests). While copper/bronze and iron/steel take centre stage as the most important metals, individual sessions will address the less common metals such as tin, lead, silver, zinc, brass and gold. Case studies are drawn from all periods and regions of the world. OBJECTIVES On successful completion of this course a student should have an overview over the general trends of technical and social development in relation to metals. Furthermore, s/he should have acquired a basic understanding of the fundamental physical principles of metallurgy at a level relevant to understanding ancient metallurgy. With a view to being encountered during later archaeological practice, students should understand the general outlines of regional and chronological developments in metallurgy. They should recognise relevant evidence such as slag and technical ceramics related to metallurgy. In particular, they should be able to pose educated questions leading to a scientific investigation of such remains, and be familiar with the various types of answers possible from archaeometric approaches and archaeological interpretations. COURSE INFORMATION This handbook contains the basic information about the content and administration of the course. Additional subject-specific reading lists and individual session handouts will be given out at appropriate points in the course, and made available via Moodle. If students have queries about the objectives, structure, content, assessment or organisation of the course, they should consult the course co-ordinator, Marcos Martinón-Torres (m.martinon-torres@ucl.ac.uk; room 112, telephone 020 7679 7496, internal ext. 27496). TEACHING METHODS The course is taught through lectures and practical sessions, as detailed in the schedule below. There will be some hands-on sessions, including the handling of archaeometallurgical materials and practical introductions to analytical methods, a video forum and a museum visit. In addition, students will be informed of special lectures by external specialists. PREREQUISITES There are no formal prerequisites for this course. WORKLOAD There will be 20 hours of classes (lectures and practical sessions) for this course, as well as a museum visit. Students will be expected to undertake around 70 hours of reading for the course, plus 100 hours preparing for and producing the assessed work. This adds up to a total workload of some 190 hours for the course. ARCL3001 Archaeometallurgy - 4 LIBRARIES AND ONLINE RESOURCES In addition to the Library of the Institute of Archaeology, UCL's Science Library has holdings of particular relevance to this course. Further information on resources is available below, under “Introductory reading”. The current reading list online is available via the Moodle page (see below). You may find links to other Archaeometallurgy reading lists from various pages within the UCL web, but these may be out of date and should not be relied upon. If you haven’t, you should consider joining academia.edu and researchgate.net, where many authors make their papers available as PDFs. On the Moodle page for this course you will find access to the reading lists but also to downloadable handouts and PowerPoint presentations that will be added on a weekly basis, as well as other activities and resources. If you do not appear automatically registered for this course, you will have to self-enrol at www.ucl.ac.uk/moodle using the enrolment key ‘archmetUG’. You are expected to log on the Moodle page at least once a week. METHODS OF ASSESSMENT Assessment of the course is by one essay of 1425-1575 words (50% of final mark), and a 4-6 minute documentary video or an A3 academic poster (50% of final mark). The essay is due on 4 March, and the video on 25 April. The topics for each assessment, as well as further guidance notes and submission procedures, are given at the end of this coursebook. If students are unclear about the nature of an assignment, they should contact the course co-ordinator. The course co-ordinator is willing to discuss an outline of their approach to the assessment, provided this is planned suitably in advance of the submission date. Students are welcome to suggest their own topics, but these should always be agreed with the course co-ordinator in advance. INSTITUTE OF ARCHAELOGY COURSEWORK PROCEDURES General policies and procedures concerning courses and coursework, including submission procedures, assessment criteria, and general resources, are available in your Degree Handbook and on the following website: http://wiki.ucl.ac.uk/display/archadmin. It is essential that you read and comply with these. Note that some of the policies and procedures will be different depending on your status (e.g. undergraduate, postgraduate taught, affiliate, graduate diploma, intercollegiate, interdepartmental). If in doubt, please consult your course co-ordinator. GRANTING OF EXTENSIONS New UCL-wide regulations with regard to the granting of extensions for coursework have been introduced with effect from the 2015-16 session. Full details are available here http://www.ucl.ac.uk/srs/academic-manual/c4/extenuating-circumstances/ Note that course co-ordinators are no longer permitted to grant extensions. All requests for extensions must be submitted on a new UCL form, together with supporting documentation, via Judy Medrington’s office and will then be referred on for consideration. Please be aware that the grounds that are now acceptable are limited. Those with long-term difficulties should contact UCL Student Disability Services to make special arrangements. ARCL3001 Archaeometallurgy - 5 TEACHING SCHEDULE AND GROUPS Most of the lectures and practicals will take place on Mondays, from 2 to 4, in room B13. However, we will have to split you in groups for some sessions, and groups will be assigned different time slots and locations from 2 to 6. It is essential that students attend the session with the group to which they have been assigned. If they need to attend a different group for a particular session, they should arrange to swap with another student from that group, and confirm this arrangement with the co-ordinator. In addition, we will organise a visit to the British Museum at dates to be confirmed . ARCL3001 Archaeometallurgy - 6 ARCL3001 ARCHAEOMETALLURGY SCHEDULE Week 1 Date 11 Jan Topic Introduction. Technical background Mondays in B13. Times: 2-4 2 18 Jan Studying archaeometallurgical remains: handling session 2-4 (G1, G2), 4-6 (G3, G4) 3 25 Jan The inception of metallurgy 2-4 4 1 Feb Copper and bronze 2-4 5 8 Feb Chemical analysis of metal artefacts: theory and practice 2-4 (G3, G4), 4-6 (G2, G1) 15-19 Feb Reading week - no lectures 6 22 Feb Lead and silver SEM analysis of archaeometallurgical remains 2-4 (G1, G2), 4-6 (G3, G4) 2-3 (G3), 3-4 (G4), 4-5 (G1), 5-6 (G2) (meet outside SEM lab in B4) 7 29 Feb Iron and steel 2-4 8 7 Mar Metallurgy, ethnography and ritual 2-4 9 14 Mar Alchemy and metallurgy 2-4 10 21 Mar Gold 2-4 tbc British Museum visit DEADLINES Friday 4 March – Essay deadline Monday 25 April – Video deadline SPECIAL LECTURES – IAMS SUMMER SCHOOL You will be informed of special lectures and seminars related to metallurgy taking place during the year. Of special interest will be the IAMS Summer School on Ancient Mining and Metallurgy, an intensive course that takes place at the Institute in the early summer, is heavily discounted for UCL students, and covers many aspects of archaeometallurgy not discussed in this course. ARCL3001 Archaeometallurgy - 7 INTRODUCTORY READING The following is an outline for the course as a whole, and identifies essential and supplementary readings relevant to each session. Information is provided as to where in the UCL library system individual readings are available. Readings marked with an * are considered essential to keep up with the topics covered in the course. There are three books which are particularly useful, as they cover a good deal of the topics of this course. Both books are suitable for independent reading, sufficiently self-contained, and provide an introduction to the subject as well as offering in-depth follow-up. Unfortunately, the older ones are out of print, but several copies are available in the library. The more recent one is available online, and is an excellent compilation of introductory papers. Tylecote, R. 1987. The early history of metallurgy in Europe. London and New York: Longman. ANCIENT HISTORY A 68 TYL, ISSUE DESK IOA TYL 2 Craddock, P. T. 1995. Early metal mining and production. Edinburgh: Edinburgh University Press. INST ARCH KE CRA, ISSUE DESK IOA CRA 6 Roberts, W. B. and Thornton, C. P. 2014 (eds). Archaeometallurgy in Global Perspective: Methods and Syntheses. New York: Springer. Online A detailed introduction to Archaeometallurgy (with a strong British flavour) can be found in the following volume. Bayley, J., Crossley, D. and Ponting, M. 2008. Metals and metalworking. A research framework for archaeometallurgy. London: Historical Metallurgy Society INST ARCH KEA Qto BAY, ISSUE DESK IOA BAY 2, or online at: http://hist-met.org/arch_comm.html Basic (but very useful) introductions to archaeometallurgy: Rehren, Th. 2008. Metals: chemical analysis, and Metals: primary production, in Pearsall, D. M. (ed.), Encyclopedia of Archaeology, 1614-1620. New York: Academic Press INST ARCH AG PEA Craddock, P. T. 1991. Mining and smelting in Antiquity, in Bowman, S. (ed), Sience and the Past, 5773. London: British Museum Press INST ARCH AJ BOW Killick, D. and Fenn, T. 2012. Archaeometallurgy: the study of preindustrial mining and metallurgy. Annual Review of Anthropology 41, 559–575. Online Lambert, J. B. 1997. Metals, in Traces of the Past. Unraveling the Secrets of Archaeology Through Chemistry, 168-213. Cambridge, Mass.: Perseus Publishing. INST ARCH JD LAM Archaeometallurgy: Guidelines for Best Practice. Historic England, 2015. https://historicengland.org.uk/images-books/publications/archaeometallurgy-guidelines-bestpractice/ ARCL3001 Archaeometallurgy - 8 Collections of articles (and note that there are many more!): Archaeometallurgy in Europe. Proceedings of the International Conference, 24-26 September 2003, Milan, Italy, 2 vols. Milano: Associazione Italiana de Metallurgia INST ARCH KEA 1 ASS Archaeometallurgy in Europe. Proceedings of the Second International Conference, June 2007, Aquileia, Italy. Milano: Associazione Italiana de Metallurgia INST ARCH KEA 1 ASS Cech, B. and Rehren, Th. (eds.) 2014. Early Iron in Europe. Momographies Instrumentum, 50. Montagnac: Editions Monique Mergoil. Craddock, P.T. and Lang, J. (eds.) 2003. Mining and Metal Production through the Ages, London, British Museum Press. INST ARCH KE CRA, ISSUE DESK IOA CRA 7 Hauptmann, A. and Modarressi-Tehrani, D. (eds.) 2015. Archaeometallurgy in Europe. Proceedings of the 3rd International Conference, Deutsches Bergbau-Museum Bochum, June 29 – July 1, 2011. Der Anschnitt Beiheft 26. Bochum: Deutsches Bergbau-Museum Bochum. Hosek, J., Cleere, H., Mihok, L., Pleiner, R. (eds.) 2011. The archaeometallurgy of iron: recent developments in archaeological and scientific research. Prague: Institute of Archaeology of the ASCR. INST ARCH KEB 2 HOS Humphris, J. and Rehren, Th. (eds) 2013. The World of Iron. London: Archetype. INST ARCH KEA 2 Qto HUM La Niece, S., Hook, D.R., and Craddock, P.T. (eds) 2007. Metals and Mines - Studies in Archaeometallurgy, London: Archetype, British Museum. INST ARCH KE Qto LAN, ISSUE DESK IOA LAN 1 Mei, J. and Rehren, Th. (eds) 2009. Metallurgy and civilisation. Asia and beyond. 6th International Conference on the Beginings of the Use of Metals and Alloys (BUMA, Beijing 2006). London: Archetype. INST ARCH KEA Qto MEI Meller, H., Risch, R. and Pernicka, E. (eds.) 2014. Metals of Power – Early gold and silver [Metalle der Macht: Frühes Gold und Silber]. Halle: Landesamt für Denkmalpflege und Archäologie SachsenAnhalt - Landesmuseum für Vorgeschichte Halle. Montero, I. (ed.) 2010. Archaeometallurgy: Technological, Economic and Social Perspectives in Late Prehistoric Europe (TESME). Trabajos de Prehistoria 67/2. INST ARCH Pers, online HMS Datasheets The Historical Metallurgy Society produces excellent introductions to archaeometallurgical topics. These are superb starting points for many of the topics covered in this course. The list below gives the ones available at the moment, but it keeps being expanded: http://hist-met.org/resources/datasheets.html (you should consider joining HMS – a bargain for students!) HMS Datasheet 101 HMS Datasheet 102 HMS Datasheet 103 HMS Datasheet 104 HMS Datasheet 105 HMS Datasheet 106 HMS Datasheet 107 The archaeology of metalworking sites: introduction to the field evidence Metalworking evidence and archaeological project management Geophysical techniques for metalworking sites Introduction to post-excavation and lab techniques for metalworking sites Textures, microstructures and metallography Chemical analysis of metalwork and metalworking debris X-radiography ARCL3001 Archaeometallurgy - 9 HMS Datasheet 108 HMS Datasheet 201 HMS Datasheet 202 HMS Datasheet 203 HMS Datasheet 204 HMS Datasheet 301 HMS Datasheet 302 HMS Datasheet 303 HMS Datasheet 304 HMS Datasheet 305 HMS Datasheet 1 HMS Datasheet 2 HMS Datasheet 3 HMS Datasheet 4 HMS Datasheet 5 HMS Datasheet 6 HMS Datasheet 8 HMS Datasheet 9 HMS Datasheet 10 HMS Datasheet 11 HMS Datasheet 12 HMS Datasheet 14 HMS Datasheet 15 HMS Datasheet 16 Care, curation and conservation of metallurgical samples Metals and their properties Copper: smelting and production of alloys Tin: smelting and production of alloys Other metals: smelting and production of alloys Iron: bloomery smelting and associated processes Steelmaking Iron: hand blacksmithing Foundries Supply, sourcing and production of fuels for metallurgical processes Crucibles and moulds Precious metal refining Iron working processes Geophysical techniques applied to early metalworking sites Bloomery iron smelting, slags and other residues Bloom refining and smithing, slags and other residues Currency Bars and other forms of trade iron Excavation and sampling Hammerscale Metallographic examination Chemical analysis of metalwork and metalworking debris X-radiography and archaeometallurgy The care and curation of metallurgical samples and other residues Metalworking evidence and the management of archaeological sites Technical ceramics Crucibles and technical ceramics generally are key elements of archaeometallurgical research. These are some introductory references covering technical ceramics from many periods. Bayley, J., & Rehren, Th. (2007). Towards a functional and typological classification of crucibles. In: S. LaNiece, D. Hook,&P. Craddock (Eds.), Metals and Mines–Studies in Archaeometallurgy (pp. 46– 55). London: Archetype. Craddock, P. T. 2013. Refractories: ceramics with a purpose. The Old Potter’s Almanack 18/2, 918. Craddock, P. T. 2014. Refractories with a purpose II: ceramics for casting. The Old Potter’s Almanack 19/1, 2-17. Freestone, I. C. and Tite, M. S., 1986. Refractories in the ancient and preindustrial world, in W. D. Kingery (ed), High-Technology Ceramics: Past, Present and Future. The Nature of Innovation and Change in Ceramic Technology, 35-63. (Ceramics and Civilization 3). Westerville (OH): The American Ceramic Society. Kearns, T., Martinón-Torres, M., Rehren, T. 2010. Metal to mould: alloy identification in experimental casting moulds using XRF. Historical Metallurgy, 44 (1), 48-58. Liu, S., Wang, K., Cai, Q. and Chen, J. 2013. Microscopic study of Chinese bronze casting moulds from the Eastern Zhou period. Journal of Archaeological Science 40 (5): 2402–2414. Martinón-Torres, M., Rehren, T. 2014. Technical ceramics. In Archaeometallurgy in Global Perspective: Methods and Syntheses, 107-131. Springer New York. Available online. ARCL3001 Archaeometallurgy - 10 Rehren, Th., 2003. Crucibles as reaction vessels in ancient metallurgy, in P. T. Craddock and J. Lang (eds), Mining and Metal Production through the Ages, 207-215. London: The British Museum Press. Ingots This is a good reference to follow up our handling session on ingots, as it discusses several types. You will find references to more focused studies on earlier ingots under the readings for each session. Craddock, P. and Hook, D. 2012. An economic history of the post-medieval world in 50 ingots: the British Museum collection of ingots from dated wrecks. The British Museum Technical Research Bulletin 6, 55-68. Some more online resources: Arch-metals online discussion list. This is an excellent forum to stay informed of archaeometallurgical events, as well as keeping up with ongoing research and debates. You can subscribe here: https://www.jiscmail.ac.uk/cgi-bin/webadmin?A0=arch-metals Bibliography for archaeometallurgy by Chris http://users.ox.ac.uk/~salter/arch-metals/met-bib-ak.htm Salter (not up to date!): Art and Archaeology Technical Abstracts (AATA): http://aata.getty.edu/NPS/ In addition to these general resources, the last pages of each issue of the journal Historical Metallurgy include abstracts of recent archaeometallurgical publications. In this journal, as well as in Archaeometry, the Journal of Archaeological Science and Archaeological and Anthropological Sciences you will find many relevant archaeometallurgical studies. You should also consider joining the following websites, where you can find numerous papers on all kinds of subjects (including many that we cannot include in our online reading lists owing to copyright restrictions!) www.academia.edu and www.researchgate.net The online reading lists for ARCLG108 and ARCLG109 also include extensive lists of references under many relevant topics. http://readinglists.ucl.ac.uk/lists/8F87D831-523D-A7B8-9635-9B5CA1EED28C.html http://readinglists.ucl.ac.uk/lists/9E4AFD94-259C-8E79-AD23-5D9912488FF6.html In the reading lists for the different lectures you will find monographs and collections of articles that will be of use as initial sources for your essays. The course co-ordinator is willing to give you further directions for relevant literature on specific topics, but you are expected (and encouraged) to do your own bibliographic search in preparation for your essays. Don’t forget that we expect you to develop (and demonstrate) your research skills! ARCL3001 Archaeometallurgy - 11 SESSION 1 : INTRODUCTION. TECHNICAL BACKGROUND Ores, minerals and metals. Prospection. Mining. Beneficiation. Roasting. Smelting and melting. Slag formation. LECTURE The first session is scheduled to identify the students’ background and interests in preparation for the later lectures. You will get an introduction to the course, its structure and aims, and an explanation of what is involved with back up teaching and assessment. We will then turn to the raw materials for metallurgy. Ancient men and women were confronted by a wide range of raw or natural materials, such as wood, bone, stone, shell, etc. Of these, they came to use naturally occurring compounds as pigments, some of which later turned out to yield metals when treated appropriately. In this session, we will discuss how different materials appealed differently to our ancestors, and how they learned to transform natural materials into artificial ones. Ores are a mixture of useable minerals and waste materials. Mining implies the identification of the usefulness of certain minerals, their identification in the field, and the successful extraction from the ground. We will try and understand these processes from the ancient peoples’ point of view, and to then analyse it with our modern understanding of materials. Examples will be used to give a very rough overview of the most important types of ore deposits and mineral species relevant in antiquity. We will discuss the mechanical treatment of these ores and minerals (‘beneficiation’) in order to prepare them for the smelting process. In addition, we will provide some of the technical background to understand processes such as the smelting and melting of metals, and the formation of slag. *Craddock, P. T. 1991. Mining and smelting in Antiquity, in S. Bowman (ed), Science and the Past, 57-73. London: British Museum Press. INST ARCH AJ BOW, ISSUE DESK IOA BOW *Ottaway, B. 2001. Innovation, production and specialization in early Prehistoric copper metallurgy. European Journal of Archaeology 4(1), 87-112. INST ARCH Pers, available online *Tylecote, R. 1987. The early History of Metallurgy in Europe, chapter 4, pp. 106-125. London and New York: Longman. ANCIENT HISTORY A 68 TYL, ISSUE DESK IOA TYL 2 Craddock, P. 1995. Early Metal Mining and Production. Edinburgh: Edinburgh University Press. (chapter 1, pp. 1-22). INST ARCH KE CRA, ISSUE DESK IOA CRA 6 Crew, P. and Crew, S. (eds) 1990, Early mining in the British Isles: proceedings of the Early Mining Workshop at Plas Tan y Bwlch, Snowdonia National Park Study Centre, 17-19 November, 1989). (Plas Tan y Bwlch Occasional Paper, 1) Tan y Bwlch, Gwynedd : Plas Tan y Bwlch, Snowdonia National Park Study Centre. INST ARCH DAA 100 Qto CRE ARCL3001 Archaeometallurgy - 12 Hoover, H. and Hoover, H. 1950 [1556]. Georgius Agricola De Re Metallica. New York: Dover (Book II: pp. 25-42). INST ARCH KE AGR Hunt Ortiz, M. 2003. Prehistoric Mining and Metallurgy in South West Iberian Peninsula. (BAR International Series 1188). Oxford: Archaeopress. INST ARCH DAPA Qto HUN Killick, D. 2014. From ores to metals, in W. B. Roberts and C. P. Thornton (eds). Archaeometallurgy in Global Perspective: Methods and Syntheses, 11-46. New York: Springer. Online Notis, M. R. 2014. Metals, in W. B. Roberts and C. P. Thornton (eds). Archaeometallurgy in Global Perspective: Methods and Syntheses, 47-66. New York: Springer. Online O’Brien, W.F. 1996, Bronze Age Copper Mining in Britain and Ireland. (Shire Archaeology, 71). Princes Risborough: Shire. INST ARCH DAA 150 OBR Patterson, C., 1971. Native copper, silver and gold accessible to early metallurgists. American Antiquity 36, 286-321. Pigott, V. and Weisgerber, G. 1998. Mining archaeology in geological context. The prehistoric copper mining complex at Phu Lon, Nong Khai Province, northeast Thailand, in Th. Rehren, A. Hauptmann, and J. Muhly (eds), Metallurgica Antiqua, 135-162. (Der Anschnitt Beiheft 8). Bochum: Deutsches Bergbau-Museum. INST ARCH KE Qto REH Timberlake, S. 2003. Early Mining Research in Britain: The Developments of the Last Ten Years. In P. Craddock and J. Lang (eds), Mining and Metal Production Through the Ages, 22-42. London: The British Museum Press. INST ARCH KE CRA, ISSUE DESK IOA CRA 7 Timberlake, S. 2003. Excavations on Copa Hill, Cwmystwyth (1986-1999): an early Bronze Age copper mine within the uplands of Central Wales. (BAR British Series, 348). Oxford: Archaeopress. INST ARCH DAA Qto Series BRI 348 ARCL3001 Archaeometallurgy - 13 SESSION 2: PRACTICAL STUDYING ARCHAEOMETALLURGICAL REMAINS HANDLING SESSION In this practical session, we will review the technical concepts introduced last week by handling relevant archaeological materials such as different metals, minerals, crucibles and slag. We will also introduce basic analytical techniques employed for the technological study of archaeometallurgical remains. The references below are overviews of the scientific analysis of archaeometallurgical materials. You will also find relevant references in the introductory reading for this course, with several papers (and HMS datasheets) focused on technical ceramics, ingots, specific kinds of analyses, etc. Craddock, P.T. 1989. The scientific investigation of early mining and smelting, in J. Henderson (ed), Scientific analysis in archaeology, 178-212. Oxford and Los Angeles: Oxford University Committee for Archaeology and UCLA Institute of Archaeology. INST ARCH AJ HEN; ISSUE DESK IOA HEN 13 Hauptmann, A. 2014. The investigation of archaeometallurgical slag, in W. B. Roberts and C. P. Thornton (eds). Archaeometallurgy in Global Perspective: Methods and Syntheses, 91-106. New York: Springer. Online Henderson, J. 2000. The Science and Archaeology of Materials. An investigation of inorganic materials. London and New York: Routledge (chapter 5: Metals, pp. 208-296). INST ARCH JDA HEN, ISSUE DESK IOA HEN 11 Lambert, J. B., 1997. Traces of the Past: Unraveling the Secrets of Archaeology Through Chemisty. Reading (Mass.): Helix Books and Addison-Wesley (chapter 7: Metals, pp. 168-213). INST ARCH JD LAM; TEACHING COLL IoA 2413 Scott, D. 1991. Metallography and microstructure of ancient and historic metals. Marina del Rey, CA: Getty Conservation Institute. INST ARCH KEB Qto SCO, ISSUE DESK IOA SCO 1 and available online ARCL3001 Archaeometallurgy - 14 SESSION 3: THE INCEPTION OF METALLURGY Where: Mostly the Balkans. Also broader Europe and Near East When: Late Neolithic and Chalcolithic SEMINAR AND PRACTICAL SESSION Why was metallurgy invented? How and where did it take place? How many times did this happen? Just as we are interested in finding out how metals were made, so do we want to explain why they were produced in the first instance. Several explanations have been put forward to interpret the inception and spread of metallurgy in different areas of the world. In this session, some of the main theories will be outlined, including discussion about the environmental, social and technical stimuli for metallurgy, and theories about technological diffusion versus autonomous developments. Chernych, E. N. 2002. Some of the most important aspects and problems of early Metal Age studying, in M. Bartelheim, E. Pernicka and R. Krause (eds), The Beginnings of Metallurgy in the Old World, 25-31. Rahden: Leidorf. INST ARCH KE Qto BAR Killick, D. 2001. Science, Speculation and the Origins of Extractive Metallurgy, in D. R. Brothwell and A. M. Pollard (eds), Handbook of Archaeological Sciences, 483-492. Chichester, New York, Weinheim, Brisbane, Singapore, Toronto: John Wiley & Sons, Ltd. INST ARCH AJ BRO Ottaway, B. 2001. Innovation, production and specialization in early Prehistoric copper metallurgy. European Journal of Archaeology 4(1), 87-112. INST ARCH Pers, available online Radivojevic, M., Rehren, Th., Pernicka, E., Sljivar, D., Brauns, M. and Boric, D. 2010. On the origins of extractive metallurgy: new evidence from Europe. Journal of Archaeological Science 37, 27752787. INST ARCH Pers, and available online *Radivojevic, M., Rehren, Th., Kuzmanović-Cvetković, J., Jovanovic, M. and Northover, P. 2013. Tainted ores and the rise of tin bronzes in Eurasia, c. 6500 years ago. Antiquity 87:1030-1045. *Roberts, B. W., Thornton, C. P. and Pigott, V. C. 2009. Development of metallurgy in Eurasia. Antiquity 83(322), 1012-1022. INST ARCH Pers, and available online ARCL3001 Archaeometallurgy - 15 SESSION 4: COPPER AND BRONZE Copper smelting. Early crucibles and furnaces. The emergence of alloys and large-scale metal production and trade. Where: Mostly Europe, Mediterranean, Near East. With a Chinese case study. When: Chalcolithic, Bronze Age and Iron Age (plus glimpses of later periods) LECTURE We will look at the early metallurgy of copper in the Old World, and the development of bronze (an alloy of copper and tin). We will examine a range of case studies illustrating the industrial production of metals for the international trade, and archaeological and analytical approaches to these questions. At a practical level, we will look at early technical ceramics such as crucibles, furnaces and moulds, their technical study and their informative potential as archaeological remains. Some of the main issues and analytical approaches will be illustrated with case studies including the trade of metal ingots in the Mediterranean Bronze Age, and the mass production of bronze weapons in early Imperial China. *Levy, T. E., Adams, R. B., Hauptmann, A., Prange, M., Schmitt-Strecker, S., and Najjar, M. 2002. Early Bronze Age metallurgy: a newly discovered copper manufactory in southern Jordan. Antiquity 76: 425-437. INST ARCH Pers, and available online *Martinón-Torres, M., Li, X. J., Bevan, A., Xia, Y., Zhao, K. and Rehren, Th. 2014. Forty thousand arms for a single Emperor: from chemical data to the labor organization behind the bronze arrows of the Terracotta Army. Journal of Archaeological Method and Theory, 21, 534-562. Online *Pulak, C., 2000. The copper and tin ingots from the Late Bronze Age shipwreck at Uluburun, in Ü. Yalcin (ed), Anatolian Metal I, 137-157. (Der Anschnitt Beiheft 13). Bochum: Deutsches BergbauMuseum. Craddock, P. T. 1999. Paradigms of metallurgical innovation in prehistoric Europe. In A. Hauptmann, E. Pernicka, Th. Rehren and U. Yalcin (eds), The Beginnings of Metallurgy, 175-192. (Der Anschnitt, Beiheft 9). Bochum: Deutsches Bergbau-Museum. INST ARCH KE Qto HAU, ISSUE DESK IOA KE Qto HAU ARCL3001 Archaeometallurgy - 16 Craddock, P. T. 2001. From Hearth to Furnace: Evidences for the Earliest Metal Smelting Technologies in the Eastern Mediterranean. Paléorient 26/2, 151-165. INST ARCH Pers Hauptmann, A. 2003. Developments in Copper Metallurgy During the Fourth and Third Millennia BC at Feinan, Jordan. In P. Craddock and J. Lang (Eds), Mining and Metal Production Through the Ages, 90-100. London: The British Museum Press. INST ARCH KE CRA, ISSUE DESK IOA CRA 7 Hauptmann, A. 2007. The archaeometallurgy of copper: evidence from Faynan, Jordan. Berlin: Springer. INST ARCH DBE 10 HAU Kassianidou, V. and Knapp, A. B. 2005. Archaeometallurgy in the Mediterranean: the social context of mining, technology and trade, in E. Blake and A. B. Knapp (eds), The Archaeology of Mediterranean Prehistory, Oxford: Blackwell, 215-251. INST ARCH DAG 100 BLA, Issue Desk INST ARCH BLA 9 Pearce, M. 1998. Reconstructing prehistoric metallurgical knowledge: the Northern Italian Copper and Bronze Ages. European Journal of Archaeology 1(1), 51-70. INST ARCH Pers, and available online Renfrew, A. C. 1973. Before Civilisation: the Radiocarbon Revolution and Prehistoric Europe. London: Pimlico. INST ARCH DA 100 REN, ISSUE DESK IOA REN 1 Pigott, V. C. 1999. Reconstructing the copper production process as practised among prehistoric mining/ metallurgical communities in the Khao Wong Prachan Valley of central Thailand, in S. M. M. Young, A. M. Pollard, P. Budd, and R. A. Ixer (eds), Metals in Antiquity, 10-21. (BAR International Series, 792). Oxford: Archaeopress. INST ARCH KEA Qto YOU Pigott, V. C. and Ciarla, R. 2007 On the origins of metallurgy in prehistoric Southeast Asia: the view from Thailand, in La Niece, S., Hook, D.R., and Craddock, P.T. (eds), Metals and Mines - Studies in Archaeometallurgy, 76-88. London, Archetype, British Museum. INST ARCH KE Qto LAN, ISSUE DESK IOA LAN 1 Rothenberg, B., 1990, The Ancient Metallurgy of Copper: Archaeology, Experiment, Theory. London: IAMS and Institute of Archaeology, pp. 8-73. INST ARCH DBE 10 Qto ROT ARCL3001 Archaeometallurgy - 17 SESSION 5: CHEMICAL ANALYSES OF METAL ARTEFACTS SEMINAR AND PRACTICAL A lot of time and resources are spent analysing the chemical composition of archaeological metal artefacts but… what’s the point? In this practical session, we will introduce some archaeological questions that can actually be answered through chemical analysis, and discuss some practical examples of how the data can be processed and presented in order to become meaningful. In addition, we will be conducting some chemical analyses by ourselves, employing a portable Xray fluorescence spectrometer (XRF), and trying to make archaeological sense of the results. *Rehren, Th. 2008. Metals: chemical analysis, in D. M. Pearsall (ed), Encyclopedia of Archaeology, 1614-1620. New York: Academic Press. INST ARCH AG PEA Bray, P. J. and Pollard, A. M. 2013. A new interpretative approach to the chemistry of copper-alloy objects: source, recycling and technology. Antiquity 86: 853-867. Bayley, J. and Butcher, S. 2004. Roman Brooches in Britain: A Technological and Typological Study based on the Richborough Collection. London: The Society of Antiquaries of London. Dungworth, D. 1997. Roman copper alloys: analysis of artefacts from Northern Britain. Journal of Archaeological Science 24, 901-910. Dungworth, D. 1997. Iron Age and Roman Copper Alloys from Northern Britain. Internet Archaeology 2. http://intarch.ac.uk/journal/issue2/ ARCL3001 Archaeometallurgy - 18 SESSION 6: LEAD AND SILVER Lead and silver smelting. Cupellation. Where: Europe and South America When: Prehistory to modern times LECTURE Lead and silver are geologically and metallurgically closely related, and are hence treated in one joint session. The vast majority of silver is extracted from lead ores, and lead often appears as a by-product of silver smelting. We will discuss the production and the use of both metals, and find out why they are typically treated at such different levels in archaeology. We will also talk about pewter, a tinlead alloy (or, more recently, tin-antimony alloy) of silvery colour widely used since Roman times. Following and introduction to the metallurgy of lead an silver, different case studies will be presented, including examples from Europe and South America. *Craddock, P., 1995, Early Metal Mining and Production, Chapter 5, Lead and silver, 205-233. INST ARCH KE CRA, ISSUE DESK IOA CRA 6 *Rehren, Th. 2011. The production of silver in South America. Archaeology International 13/14, 7683. *Van Buren, M. and Mills, B. H., 2005. Huayrachinas and Tocochimbos: Traditional smelting technology of the Southern Andes. Latin American Antiquity 16(1), 3-25. INST ARCH Pers Anguilano, L., Rehren, Th., Muller, W. and Rothenberg, B. 2009. Silver production at Rio Tinto during Roman occupation, in J-F. Moreau, R. Auger, J. Chabot and A. Herzog (eds), Proceedings of the 36th International Symposium on Archaeometry, April 2006, Quebec, 433-444. (Les cahiers d'archeologie du CELAT, 25; Series Archeometrie, 7), Quebec: Universite Laval. INST ARCH AJ MOR Bayley, J. 2008. Medieval precious metal refining: archaeology and contemporary texts compared, in M. Martinón-Torres and Th. Rehren (eds), Archaeology, history and science: integrating approaches to ancient materials, 131-150. (UCL Institute of Archaeology Publications). Walnut Creek, CA: Left Coast Press. INST ARCH AJ MAR, ISSUE DESK IOA MAR 9 ARCL3001 Archaeometallurgy - 19 Bartelheim, M., Contreras Cortés, F., Moreno Onorato, A., Murillo-Barroso, M., and Pernicka, E. 2012. The silver of the South Iberian El Argar Culture: A first look at production and distribution. Trabajos de Prehistoria 69: 293-309. INST ARCH Pers, and available online Cochet, A. 2000. Le plomb en Gaule romaine: techniques de fabrication et produits. Montagnac: Monique Mergoil. INST ARCH KEA 4 Qto COC Cohen, C. R., Rehren, Th. and van Buren, M. 2009. When the wind blows: environmental adaptability in current day silver production within the Bolivian Andes, in J-F. Moreau, R. Auger, J. Chabot and A. Herzog (eds), Proceedings of the 36th International Symposium on Archaeometry, April 2006, Quebec, 465-475. (Les cahiers d'archeologie du CELAT, 25; Series Archeometrie, 7), Quebec: Universite Laval. INST ARCH AJ MOR Hunter, F. and Davis, M. 1994. Early Bronze Age lead – a unique necklace from southeast Scotland. Antiquity 68(261), 824-830. INST ARCH Pers, and available online Martinón-Torres, M., Thomas, N. Rehren, Th. and Mongiatti, A. 2008. Some problems and potentials of the study of cupellation remains: the case of post-medieval Montbéliard. ArcheoSciences: Revue d’Archeometrie 32, 59-70. INST ARCH Pers, and available online Murphy, S. and Baldwin, H. 2001. Early lead smelting sites in the Swaledale area of Yorkshire. Historical Metallurgy 35(1), 1-22. INST ARCH Pers Kassianidou, V. 1998. Was silver actually recovered from speiss in antiquity? , in Th. Rehren, A. Hauptmann, and J. Muhly (eds), Metallurgica Antiqua, 69-76. (Der Anschnitt Beiheft 8). Bochum: Deutsches Bergbau-Museum. INST ARCH KE Qto REH Pernicka, E., Rehren, Th., and Schmitt-Strecker, S. 1998. Late Uruk silver production by cupellation at Habuba Kabira, Syria, in Th. Rehren, A. Hauptmann, and J. Muhly (eds), Metallurgica Antiqua, 123-134. (Der Anschnitt Beiheft 8). Bochum: Deutsches Bergbau-Museum. INST ARCH KE Qto REH Rehren, Th. and Prange, M. 1998. Lead metal and patina: a comparison, in Th. Rehren, A. Hauptmann, and J. Muhly (eds), Metallurgica Antiqua, 183-196. (Der Anschnitt Beiheft 8). Bochum: Deutsches Bergbau-Museum. INST ARCH KE Qto REH Rehren, Th., Schneider, J. and Bartels, Chr. 1999. Medieval lead-silver smelting in the Siegerland, West Germany. Historical Metallurgy 33, 73-84. INST ARCH Pers ARCL3001 Archaeometallurgy - 20 SESSION 6b: SEM ANALYSIS OF ARCHAEOMETALLURGICAL REMAINS LAB PRACTICAL The scanning electron microscope is one of the most versatile techniques used in archaeology in general, and archaeometallurgy in particular. This practical session will take place in small groups at the SEM suite of the Wolfson Archaeological Science Laboratories (room B4). You will be introduced to some of the main applications of SEM in archaeometallurgy, including the study of the microstructure and composition of slag, crucibles and metallic artefacts. The references below are some examples of applications, but you will find many more examples of SEM uses in the case studies cited throughout this handbook. Martinón-Torres, M., Uribe-Villegas, M.A. (2015). The prehistoric individual, connoisseurship and archaeological science: The Muisca goldwork of Colombia. Journal of Archaeological Science, 63 136-155. Online Radivojevic, M., Rehren, Th., Pernicka, E., Sljivar, D., Brauns, M. and Boric, D. 2010. On the origins of extractive metallurgy: new evidence from Europe. Journal of Archaeological Science 37, 2775-2787. Online ARCL3001 Archaeometallurgy - 21 SESSION 7: IRON AND STEEL Bloomery iron smelting. Iron smithing. Crucible steel. Cast iron. Where: Europe, Near East, Central Asia and Africa When: Late Bronze Age to Industrial Revolution LECTURE The advent of iron in the Late Bronze Age led to the emergence of an entirely new approach to smelting metal, where the metal itself is never liquid, but remains in a solid state throughout the working cycle. The technological implications of this are discussed, together with the social and economic implications of the much more widespread availability of iron ores as compared to copper and tin ores. The Roman era saw a tremendous expansion of iron production, both within the empire and outside, from Sudan in the South to Norway in the North, and from Britain in the West to Anatolia in the East. At the same time, evidence for iron working, i.e. smithing, becomes ubiquitous. During this session, we will explore the distinguishing features for these two activities, smelting and smithing, and what the archaeological record tells us about them. The technical basis of iron smelting remained unchanged for almost two millennia. Only from about 1000 AD onwards do we witness the appearance of a new, and much more productive, smelting process, resulting first in cast iron which had to be treated further by fining before it could be used for tools and such like. This indirect process, eventually leading up to the Industrial Revolution, is discussed in both technical, social and environmental contexts. *Craddock, P. 1995. Early Metal Mining and Production. Edinburgh: Edinburgh University Press (chapter 7: Iron and Steel, pp. 234-283). INST ARCH KE CRA, ISSUE DESK IOA CRA 6 *Humphris, J. and Rehren, Th. (eds) 2013. The World of Iron. London: Archetype. INST ARCH KEA 2 Qto HUM *Pleiner, R. 2000. Iron in Archaeology - The European Bloomery Smelters. Prague: Archeologicky Ustav AVCR. ISSUE DESK IOA PLE *Pleiner, R. 2006. Iron in Archaeology - Early European Blacksmiths. Prague: Archeologicky Ustav AVCR. INST ARCH KEA 2 Qto PLE Benoit, P. and Fluzin, Ph. (ed) 1995. Paléométallurgie du fer & Cultures. Paris: AEDEH. INST ARCH KEA Qto BEN ARCL3001 Archaeometallurgy - 22 Biggs, L., Bellina, B., Martinón-Torres, M. and Pryce, O. P. 2013. Prehistoric iron production technologies in the Upper Thai-Malay Peninsula: metallography and slag inclusion analyses of iron artefacts from Khao Sam Kaeo and Phu Khao Thong. Archaeological and Anthropological Sciences 5(4): 311-329. Blakelock, E., Martinón-Torres, M., Veldhuijzen, H.A. and Young, T. 2009. Slag inclusions in iron objects and the quest for provenance: an experiment and a case study. Journal of Archaeological Science 36, 1745-1757. INST ARCH Pers, and available online Charlton, M. F., P. Crew, Th. Rehren, and S. Shennan, 2010. Explaining the evolution of ironmaking recipes—An example from northwest Wales. Journal of Anthropological Archaeology, 29, 352-367. Charlton, M. F., Blakelock, E., Martinón-Torres, M. and Young, T. 2012. Investigating the production provenance of iron artifacts with multivariate methods. Journal of Archaeological Science 39, 22802293. INST ARCH Pers, and available online Buchwald, V. F. 2005. Iron and steel in ancient times. Copenhagen: Det Kongelige Danske Videnskabernes Selskab. INST ARCH KEA 2 BUC Crossley, D. 1996. The blast furnace at Rockley, South Yorkshire. Archaeological Journal 152, 291380. INST ARCH Pers Gassmann, G. 2002. Recent discoveries and excavations of 6th-2nd century BC furnaces in SW Germany. Historical Metallurgy 36(2), 71-77. INST ARCH Pers Hayman, R. 2005. Ironmaking. The history and archaeology of the iron industry. London: Tempus. INST ARHC KEA 2 HAY Paynter, S., Blakelock, E. and Belford, P. 2014 (eds). Iron and Ironworking. Historical Metallurgy 48. INST ARCH Pers. Joosten, I. 2004. Technology of Early Historical Iron Production in the Netherlands. (Geoarchaeological and Bioarchaeological Studies 2). Amsterdam: Vrije Universiteit. INST ARCH DAHB Qto JOO Nørbach, L. C. (ed) 2003. Prehistoric and Medieval Direct Iron Smelting in Scandinavia and Europe. Aspects of Technology and Science. Aarhus: Aarhus University Press. INST ARCH KEA 2 NOB Rehren, T., Belgya, T., Jambon, A., Kali, G., Kastovszky, Z., Kis, Z., Kovács, I., Maróti, B., MartinónTorres, M., Miniaci, G., Pigott, P., Radivojević, M., Szentmiklósi, L., Szökefalvi-Nagy, Z.2013. 5,000 years old Egyptian iron beads made from hammered meteoritic iron. Journal of Archaeological Science 40(12), 4785–4792. INST ARCH Pers, and available online Rostoker, W. and Bronson, B. 1990. Pre-Industrial Iron – Its Technology and Ethnology (Archeomaterials monograph 1). Philadelphia: Archeomaterials. ISSUE DESK IOA ROS 3, INST ARCH KEA 2 ROS Rovira, S., Lopez-Medina, M. J., Roman-Diaz, M. P. and Martinez-Padillar, C. 2004. Los Callejones: a Roman Republican iron mining and smelting centre in the south east of the Iberian Peninsula. Historical Metallurgy 38(1), 1-9. INST ARCH Pers ARCL3001 Archaeometallurgy - 23 Sim, D. 1998. Beyond the Bloom - Bloom refining and iron artifact production in the Roman world. (BAR International Series 725). Oxford: Archaeopress. INST ARCH KE Qto SIM Starley, D. 1999. Determining the technological origins of iron and steel. Journal of Archaeological Science 26, 1127-1134. INST ARCH Pers, and available online Tylecote, R. 1987. The early history of metallurgy in Europe. London and New York: Longman (chapter 7: Forging and hammering techniques, pp. 243-279). ANCIENT HISTORY A 68 TYL, ISSUE DESK IOA TYL 2 Veldhuijzen, H.A. and Rehren, Th. 2007. Slags and the city: early iron production at Tell Hammeh, Jordan and Tell Beth-Shemesh, Israel, in: La Niece, S., Hook, D.R., and Craddock, P.T. (eds) Metals and Mines - Studies in Archaeometallurgy, 189-201. London, Archetype, British Museum. INST ARCH KE Qto LAN, ISSUE DESK IOA LAN 1 Waldbaum, J. 1999. The coming of iron in the eastern Mediterranean, in V. Pigott (ed), Archaeometallurgy of the Asian Old World, 27-57. (University Museum Monograph). INST ARCH KEA PIG Wagner, D. B. 2003. Chinese blast furnaces from the 10th to the 14th century. Historical Metallurgy 37(1), 25-37. INST ARCH Pers Wertime, T. A. and Muhly, J. D. (eds) 1980. The coming of the Age of Iron. New Haven and London: Yale University Press. INST ARCH KEA 2 WER; Issue Desk INST ARCH KEA 2 WER ARCL3001 Archaeometallurgy - 24 SESSION 8: METALLURGY, ETHNOGRAPHY AND RITUAL SEMINAR AND FILM SESSION The archaeological and ethnographic record of Sub-Saharan Africa offers an extraordinary demonstration of how metallurgical technologies are adapted to changing environmental and cultural contexts. In spite of the technical constraints, there is scope for substantial cultural variation, as documented across the continent in the multiplicity of furnace shapes and sizes, and the variety of rituals, taboos and beliefs associated to metal smelting and and artefact manufacture in different contexts. This session will start with an overview and some selected case studies of African archaeometallurgy. We will then watch the video Inagina: The Last House of Iron, which records the practical activities of a group of iron smelters working in Mali, and demonstrates how the building of the furnaces and the work involved in the actual smelting and smithing are deeply entwined with ritual, symbolism and gender. This video should prompt some interesting discussion about the the tensions between culture and nature in metallurgical technologies, as well as the advantages and risks of using ethnographic parallels when interpreting archaeometallurgical data. *Iles, L. and Childs, S. T. 2014. Ethnoarchaeological and historical methods, in W. B. Roberts and C. P. Thornton (eds). Archaeometallurgy in Global Perspective: Methods and Syntheses, 193-216. New York: Springer. Online *Killick, D. 2009. Cairo to Cape: the spread of metallurgy through eastern and southern Africa. Journal of World Prehistory 22(4). 399-414. INST ARCH Pers, and available online ARCL3001 Archaeometallurgy - 25 *Rehren, Th, Charlton, M, Chirikure, S, Humphris, J, Ige, A. and Veldhuijzen H.A. 2007 Decisions set in slag: the human factor in African iron smelting, in S. La Niece, D. R. Hook, and P. T. Craddock (eds) Metals and Mines - Studies in Archaeometallurgy, 211-218, London, Archetype, British Museum. INST ARCH KE Qto LAN, ISSUE DESK IOA LAN 1, and online Bisson, M. S. et al. (eds) 2000. Ancient African Metallurgy: The Sociocultural Context. Oxford: Altamira Press. INST ARCH DC 100 BIS Chirikure, S. and Rehren, Th. 2004: Ores, furnaces, slags, and prehistoric societies: aspects of iron working in the Nyanga Agricultural Complex, AD 1300-1900. African Archaeological Review 21, 135152. INST ARCH Pers Herbert, E. W. 1984. Red gold of Africa: copper in precolonial history and culture. Madison: University of Wisconsin Press. Humphris, J., Martinón-Torres, M., Rehren, Th. and Reid, A. 2009. Variability in single smelting episodes - a pilot study using slag from Uganda. Journal of Archaeological Science 36, 359-369. INST ARCH Pers, and available online Iles, L. and Martinón-Torres, M. 2009. Pastoralist iron production in the Laikipia Plateau, Kenya: wider implications for archaeometallurgical studies. Journal of Archaeological Science 36, 23142326. INST ARCH Pers, and available online Killick, D. 2004. What do we know about African iron working? Journal of African Archaeology 2(1): 97-112. INST ARCH Pers Miller, D. 1994. Early metal working in sub-Saharan Africa: A review of recent research. Journal of African History 35, 1-36. ANTHROPOLOGY Pers MacDonald, K.C., Vernet, R., Martinón-Torres, M. and Fuller, D. Q. 2009. Dhar Nema: from early agriculture to metallurgy in southeastern Mauritania. Azania: Archaeological Research in Africa 44(1), 3-48. INST ARCH Pers, and available online Schmidt, P. R. 1997. Iron technology in East Africa: symbolism, science, and archaeology. Bloomington, IN: Indiana University Press; Oxford: James Currey. INST ARCH DCD SCH Thondhlana, T. P. and Martinón-Torres, M. 2009. Small size, high value. Composition and manufacture of copper-base beads from Second Millennium AD northern Zimbabwe. Journal of African Archaeology 7(1), 79-97. INST arch Pers, and available online Woodhouse, J. 1998. Iron in Africa: the metal from nowhere, in G. Connah (ed) Transformations in Africa: essays on Africa’s later past, 160-185. London: Leicester University Press. INST ARCH DC 200 CON, INST ARCH DC 100 CON, ISSUE DESK IOA CON 8 ARCL3001 Archaeometallurgy - 26 SESSION 9: ALCHEMY AND METALLURGY Distillation and cementation. Lab-scale metallurgy. Alchemical laboratories. Where: Europe, Near East, India, China When: Roman times to present day (plus earlier glimpses) LECTURE Historians of science have tended to disregard historical alchemy as a pseudoscientific waste of time that has more to do with ambition and fraud than actual metallurgy and chemistry. While this is certainly the case for present-day alchemy, a focus on archaeological remains shows that alchemists contributed greatly to advances in metallurgy and chemistry, and that we should not regard them as social outcasts. In this session, we will cover some selected case studies of the archaeology of alchemy, with particular emphasis on the metallurgical dimensions of their quest. We will talk about silver and gold but also about brass, and about the challenges of reconstructing changing ideas based on the study of material remains of practical activities. *Craddock, P. (ed). 1998. 2000 years of zinc and brass. (BMOP 50, 2nd edition). London: British Museum. (Read any chapter of your choice) INST ARCH KEA 5 CRA, INST ARCH KEA 5 Qto CRA *Martinón-Torres, M. and Rehren, Th. 2005. Alchemy, chemistry and metallurgy in Renaissance Europe. A wider context for fire assay remains. Historical Metallurgy 39(1), 14-31. INST ARCH Pers, and available online Craddock, P. and Eckstein, K. 2003. Production of brass in Antiquity by direct reduction. In P. Craddock and J. Lang (eds), Mining and Metal Production Through the Ages, 216-230. London: The British Museum Press. INST ARCH KE CRA, ISSUE DESK IOA CRA 7 Martinón-Torres, M. and Rehren, Th. 2002. Agricola and Zwickau: theory and practice of Renaissance brass production in SE Germany. Historical Metallurgy 36, 95-111. INST ARCH Pers Martinón-Torres, M. and Rehren, Th. 2009. Post-medieval crucible production and distribution: a study of materials and materialities. Archaeometry, 51(1), 49-74. INST ARCH Pers, and available online ARCL3001 Archaeometallurgy - 27 Martinon-Torres, M. (2012). The archaeology and alchemy and chemistry in the early modern world: an afterthought. Archaeology International, 15 33-36. Online. Martinón-Torres, M. 2012. Inside Solomon’s House: An Archaeological Study of the Old Ashmolean Chymical Laboratory in Oxford. Ambix 59/1, 22-48 Martinón-Torres, M., Rehren, Th. and von Osten, S. 2003. A 16th century lab in a 21st century lab: archaeometric study of the laboratory equipment from Oberstockstall (Kirchberg am Wagram, Austria). Antiquity 77(298). Available online Ponting, M. J. 2002. Keeping up with the Romans? Romanisation and Copper Alloys in First Revolt Palestine. IAMS 22, 3-6. INST ARCH Pers Rehren, Th. 1996. Alchemy and fire assay – an analytical approach. Historical Metallurgy 30, 136142. INST ARCH KEA Qto YOU Rehren, Th. 1999. The same… but different: A juxtaposition of Roman and Medieval brass making in Central Europe. In S. Young et al. (eds.), Metals in Antiquity, 252-257. (BAR International Series, 792). Oxford: Archaeopress. INST ARCH KEA Qto YOU Rehren, Th. and Martinón-Torres, M. 2008. Naturam ars imitata: European brassmaking between craft and science, in M. Martinón-Torres and Th. Rehren (eds), Archaeology, History and Science: Integrating Approaches to Ancient Materials, 167-188. (UCL Institute of Archaeology Publications). Walnut Creek, CA: Left Coast Press. INST ARCH AJ MAR, ISSUE DESK IOA MAR 9 Zacharias, S. 1989. Brass making in medieval western Europe. In M. L. Wayman (ed), All That Glitters: Reasings in Historical Metallurgy, 35-40. Montreal: The Metallurgical Society of the Canadian Institute of Mining and Metallurgy. INST ARCH KEA WAY, INST ARCH TYLECOTE WAY Zhou, W., Martinón-Torres, M., Chen, J., Liu, H. and Li, Y. 2012. Distilling zinc for the Ming Dynasty: the technology of large scale zinc production in Fengdu, southwest China. Journal of Archaeological Science, Journal of Archaeological Science 39, 908-921. Available online ARCL3001 Archaeometallurgy - 28 SESSION 10: GOLD The value and properties of gold. Coinage. Gold alloys and gilding techniques Where: Mediterranean, Central Europe and (mostly) America When: Pre- and Post-Columbian LECTURE The metallurgy of America developed independently from European and Asian influences. Thus, a number of characteristic differences is discussed, trying to explain them from their social and environmental context. Given the importance of gold and gold alloys in South American metallurgy, this session will also address some general issues related to this metal. Against this background, we will then look at the crucial role played by metals in the relationship beween Europeans and indigenous peoples during the contact period in the Caribbean, and how metals illustrate completely different perceptions of matter and value systems. *La Niece, S. and Meeks, N. 2000. Diversity of Goldsmithing Traditions in the Americas and the Old World, in C McEwan (ed), Precolumbian Gold. Technology, Style and Iconography, 220-239. London: British Museum Press. INST ARCH DF 300 MCE *Martinón-Torres, M., Valcárcel Rojas, R., Cooper, J. and Rehren, Th. 2007. Metals, microanalysis and meaning: a study of metal objects excavated from the indigenous cemetery of El Chorro de Maíta, Cuba. Journal of Archaeological Science, 34, 194-204. INST ARCH Pers, and available online La Niece, S. and Craddock, P. T. 1993 (eds). Metal plating and patination: cultural, technical and historical developments. Oxford, Boston: Butterworth-Heinemann. Lechtman, H., 1973, The gilding of metals in pre-Columbian Peru. In: W. Young (ed.) Application of Science in Examination of Works of Art, 38-52. Boston: Museum of Fine Arts. INST ARCH K BOS Lechtman, H N, 1984. Pre-Columbian Surface Metallurgy. Scientific American, 250(6), 56-63. PHYSICAL SCIENCE Pers, GEOSCIENCE Pers Leusch, V. Armbruster, B., Pernicka, E. and Slavcev, V. 2015. On the invention of gold metallurgy: the gold objects from the Varna I Cemetery (Bulgaria) – Technological consequence and inventive creativity. Cambridge Archaeological Journal 25/1, 353-376. Online. ARCL3001 Archaeometallurgy - 29 Lleras-Pérez, R. 1999. Prehispanic metallurgy and votive offerings in the Eastern Cordillera Colombia. (BAR International Series 778). Oxford: Archaeopress. INST ARCH DGA Qto LLE Martinón-Torres, M. and Rehren, Th. 2007. Trials and errors in search of mineral wealth: metallurgical experiments in early colonial Jamestown. Rittenhouse: the Journal of the American Scientific Instrument Enterprise 21: 82-97. Martinón-Torres, M., Cooper, J., Valcárcel Rojas, R. and Rehren, Th. 2008. Diversifying the picture: Indigenous responses to European arrival in Cuba. Archaeology International 10, 37-40. INST ARCH Pers, and available online Martinón-Torres, M., Valcarcel Rojas, R., Guerra, M. F. and Saenz Samper, J. 2012 Metallic encounters in Cuba: the technology, exchange and meaning of metals before and after Columbus. Journal of Anthropological Archaeology, 31/4, 439-454. INST ARCH Pers, and available online. McEwan, C. (ed) 2000. Precolumbian Gold: Technology, Style and Iconography. London: British Museum Press. INST ARCH DF 300 MCE Ramage, A. & Craddock, P. (eds) 2000. King Croesus’ Gold – Excavation at Sardis and the History of Gold Refining. London: British Museum Press. INST ARCH DBC 10 RAM Schrimptff, M. C. (ed) 2005. Calima and Malagana. Art and Archaeology in Southwestern Colombia. Bogotá: Pro Calima Foundation. INST ARCH DGA CAR Uribe Villegas, M. A. and Martinón-Torres, M. 2012. Composition, colour and context in Muisca votive metalwork (Colombia, AD 600-1800). Antiquity 86 (333), 772–791. INST ARCH Pers, and available online Williams, D. and Ogden, J. 1994. Greek Gold: Jewelry of the Classical World. New York: Abrams. YATES QUARTOS T 50 WIL, YATES T 50 WIL ARCL3001 Archaeometallurgy - 30 BRITISH MUSEUM VISIT Date to be confirmed We will organise a visit to selected rooms of the British Museum, with a focus on archaeometallurgical remains. The specific rooms will be decided based on the students’ interests. ARCL3001 Archaeometallurgy - 31 ASSESSMENT Assessment of the course is by one essay of 1425-1575 words (50% of final mark), and a 4-6 minute documentary video or an A3 academic poster (50% of final mark). The essay is due on 4 March, and the video on 25 April. ASSESSMENT 1: STANDARD ESSAY Essay topics are negotiable, and students are encouraged to suggest their own. What follows is a list of possible general topics, with some introductory reading (in addition to that given for relevant lectures), but you will be expected to carry out further bibliographic research. Essays may concentrate on specific aspects of these topics, or on completely different ones, by prior discussion with the course co-ordinator. In all cases, it is expected that students will combine their own ideas with reference to published case studies. Please make sure that your essay is well-structured (including subheadings), and try to show some originality or insight: having done your literature review… where do we go from here? what are the main questions remaining? who do you agree or disagree with, and why? Discuss the technological choice and use of different alloys in Andean South America (or any other period or area of your choice, by previous discussion with course co-ordinator). Lechtman, H. 1988. Traditions and Styles in Central Andean Metalworking, in R. Maddin (ed), The Beginning of the Use of Metals and Alloys, 344-378. Cambridge: MIT Press. Lechtman, H. 1993. Technologies of Power: The Andean Case, in J. S. Hendrson and P. J. Netherly (eds), Configurations of Power in Complex Society, 244-280. Ithaca: Cornell University Press. Shimada, I, Gordus, A, Griffin, J A, and Merkel, J F, 1999, Sicán alloying, working and use of precious metals: an interdisciplinary perspective, in S M M Young, A M Pollard, P Budd and R A Ixier (eds.), Metals in Antiquity, 301-309. (BAR – International Series, 792). Oxford: Archaeopress. Uribe Villegas, M. A. and Martinón-Torres, M. 2012. Composition, colour and context in Muisca votive metalwork (Colombia, AD 600-1800). Antiquity 86 (333), 772–791. What’s the point of studying ethnographic remains of metallurgical activities? Discuss potentials and risks, by making reference to specific case studies Killick, D. 1991. The relevance of recent iron-smelting practice to reconstructions of prehistoric smelting technology, in P. D. Glumac (ed), Recent Trends in Archaeometallurgical Research, 47-54. (MASCA Research Papers in Science and Archaeology, 8/1). Philadelphia: University Museum. Killick, D. 1995. Variation in African iron-smelting practice: implications for the study of Prehistoric iron technology in Europe, in P. Benoit and Ph. Fluzin (eds), Paleométallurgie du Fer & Cultures. Belfort: AEDEH. ARCL3001 Archaeometallurgy - 32 Van Buren, M. and Mills, B. H., 2005. Huayrachinas and Tocochimbos: Traditional smelting technology of the Southern Andes. Latin American Antiquity 16(1), 3-25. With reference to case studies, discuss the potentials, achievements and limitations of experimental archaeometallurgy Bareham, T. 1994. Bronze casting experiments. Historical Metallurgy 28 (2), 112-116. Crew, P. 1991. The experimental production of prehistoric bar iron. Historical Metallurgy 25, 21-36. Dungworth, D. and Doonan, R. C. P. 2013. Accidental and Experimental Archaeometallurgy. HMS Occasional Publication 7. Ottaway, B. S. and Wang, Q. 2004. Casting Experiments and Microstructure of Archaeologically Relevant Bronzes. (BAR International Series 1331). Oxford: Archaeopress. Pryce, T.O., Bassiakos, Y., Catapotis, M. and Doonan, R. C. 2007/ “De Caerimoniae”: technological decisions in copper smelting furnace design at early bronze age Chrysokamino, Crete. Archaeometry 49(3), 543–557. How can archaeometallurgy benefit from the application of modern analytical techniques? (you may choose to focus either on the study of metallurgical debris or on metallic artefacts, and you must refer to case studies different from those cited in this introductory reading) Craddock, P. T. 1989. The scientific investigation of early mining and metallurgy, in J. Henderson (ed), Scientific Analysis in Archaeology and its Interpretation, 178-212. (Monograph 19; Archaeological Research Tools 5). Oxford and Los Angeles: Oxford University Committee for Archaeology and UCL Institute of Archaeology. Henderson, J. 2000. The Science and Archaeology of Materials. An investigation of inorganic materials. London and New York: Routledge (chapter 5: Metals, pp. 208-296). Lambert, J. B., 1997. Traces of the Past: Unravelling the Secrets of Archaeology Through Chemistry. Reading (Mass.): Helix Books and Addison-Wesley (chapter 7: Metals, pp. 168-213) What are the social implications of the inception and spread of metallurgy? Discuss, with reference to any area of your choice. Shennan, S. 1999. Cost, benefit and value in the organization of early European copper production, Antiquity, 73, 352-363. Matthews, R. and Fazeli, H. 2004. Copper and complexity: Iran and Mesopotamia in the fourth millennium B.C. Iran. Journal of the British Institute of Persian Studies 42, 61-75. Diaz-Andreu, M. and Montero, I. 2000. Metallurgy and social dynamics in the later prehistory of Mediterranean Spain, in C. F. E. Pare (ed), Metals Make the World Go Round. The Supply and Circulation of Metals in Bronze Age Europe, 116-132. Oxford: Oxbow Books. Mei, J. 2009. Early metallurgy in China: some challenging issues in current studies, in J. Mei and Th. Rehren (eds), Metallurgy and Civilisation: Eurasia and Beyond, 9-16. London: Archetype The origins of metallurgy in Africa: invention or diffusion? (you can focus on other regions, such as Britain or China) Alpern, S. 2005. Did they or didn’t they invent it? Iron in Sub-Saharan Africa. History in Africa 32: 41-94. Holl, A. F. C. 2009. Early West African Metallurgies: New Data and Old Orthodoxy. Journal of World Prehistory 22 (4), 415-438. Killick, D. 2009. Cairo to Cape: the spread of metallurgy through eastern and southern Africa. Journal of World Prehistory 22(4), 399-414. ARCL3001 Archaeometallurgy - 33 Why do we know so little about the origin of the Bronze Age tin? What is the current evidence and argument? Begemann, F., Kallas, K., Schmitt-Strecker, S., and Pernicka, E. 1999. Tracing tin via isotope analyses. In: A. Hauptmann et al. (eds), The Beginnings of Metallurgy, 277-284. (Der Anschnitt, Beiheft 9). Giuimlia-Mair, A. and Lo Schiavo, F. (eds) 2003. The Problem of Early Tin (BAR International Series 1199). Oxford: Archaeopress Haustein, M., Gillis, C., and Pernicka, E. 2010. Tin isotopy – a new method for solving old questions. Archaeometry 52/5, 816-832. Yener, K. A. 2000. The Domestication of Metals: The Rise of Complex Metal Industries in Anatolia (c. 4500-2000 B.C.).Amsterdam: E.J. Brill. What can we learn from the analysis of gold artefacts? Guerra, M. F., Calligaro, Th., and Perea, A. 2007. The treasure of Guarrazar: tracing the gold supplies in the Visigothic Iberian Peninsula. Archaeometry 49(1), 53-74. Martinón-Torres, M., Uribe-Villegas, M.A. (2015). The prehistoric individual, connoisseurship and archaeological science: The Muisca goldwork of Colombia. Journal of Archaeological Science, 63 136-155. Online McEwan, C. (ed) 2000. Precolumbian Gold: Technology, Style and Iconography. London: British Museum Press. Williams, D. and Ogden, J. 1994. Greek Gold: Jewelry of the Classical World. New York: Abrams. Is it possible to provenance iron objects to their source of origin? Blakelock, E., Martinón-Torres, M., Veldhuijzen, H.A. and Young, T. 2009. Slag inclusions in iron objects and the quest for provenance: an experiment and a case study. Journal of Archaeological Science 36, 1745-1757. Coustures, M.P., Béziat, D., Tollon, F., Domergue, C., Long, L., Rebiscoul, A., 2003. The use of trace element analysis of entrapped slag inclusions to establish ore - Bar Iron links: Examples from two Gallo-Roman ironworking sites in France (Les Martys, Montagne Noire and Les Ferrys, Loiret). Archaeometry 45, 599-613. Desaulty, A-M., Dillmann, P., L’Heritier, M., Mariet, C., Gratuze, B., Joron, J-L. and Fluzin, P. 2009. Does it come from the Pays de Bray? Examination of an origin hypothesis for the ferrous reinforcements used in French medieval churches using major and trace element analyses. Journal of Archaeological Science 36, 2445-2462. Høst-Madsen, L. and Buchwald, V.F., 1999. The characterization and provenancing of ore, slag and iron from the Iron Age settlements at Snorup. Historical Metallurgy 33, 57-67. Schwab, R., Heger, D., Hoppner, B. and Pernicka, E. 2006. The provenance of iron artefacts from Manching: a multi-technique approach. Archaeometry 48, 433-452. ARCL3001 Archaeometallurgy - 34 ASSESSMENT 2: A DOCUMENTARY VIDEO Are you ready to make history? For the first time in the history of UCL (believe it or not!), we are asking all the students in a course to submit videos as a form of course assessment. The rationale behind this is the hope that this will help you develop your digital literacy, expand your transferable skills, and prompt you to engage with a different type of audience (namely, the public, i.e. the main owners of the heritage we study). Your task will be to create a 4-6 minute documentary video on any archaeometallurgical topic of your choice, aimed at general, educated but non-specialist audiences. I would normally expect you to select a metal object, artefact type, relevant collection, metallurgical process or site that is somehow accessible to you (e.g. at the Institute’s collections, London museums, etc) and build your story around that. Having said this, you may wish to take a different angle (but you should discuss this with me). The only prerequisite is that the video contains educational, factual, accurate information relevant to this course – but obviously this should not curtail creativity and originality. For many of you, this may be the first time you make a video, from storyboarding through shooting and up to post-production, but we don’t want you to feel overwhelmed by the technicalities. Instead, we would like to turn this into an opportunity for you to learn new skills. For this purpose, we have created two model videos and extended guidance to take you through the various steps. This is in the form of a tutorial wiki that you can access from Moodle (and which you are welcome to contribute to!) or directly from UCL Confluence. In addition, I will be available throughout the term to provide individual support as needed. Making documentary videos (a basic tutorial): https://wiki.ucl.ac.uk/pages/viewpage.action?pageId=36285513 Further tips on audio and video: https://wiki.ucl.ac.uk/display/UCLELearning/Audio+and+video Submission and assessment You are strongly encouraged (though not obliged) to upload your video to a website where anyone can watch it, such as Youtube, Vimeo, or your own blog page. In addition, you should submit it as a CD or memory stick, together with a relevant cover sheet, stapled to a ca. 200 word abstract for your video and a list of sources employed (including publications, interviews, etc.). I would be grateful if you could also add a ca. 500 word evaluation of your own experience making the video (expectations, challenges, skills learned, overall experience…) – but this will not be formally assessed. Please also indicate if you agree to your video being uploaded to Youtube or similar after the course has ended. This is not compulsory, but we would like to publish them online in order to help democratise access to knowledge. You do not need to submit the video to Turnitin. I will confirm later on whether or not you need to submit anonymously. The marking criteria for this assignment are detailed in the special coversheet that is available via Moodle. In general, the video assessment will cover the following aspects (though not all of them have equal weight) Content: breadth and depth of research, clarity of information Technical quality: organisation of the material, quality visuals and sound ARCL3001 Archaeometallurgy - 35 Educational objectives: clarity of the educational aim, and coherence Planning and presentation of the research Visual interpretation and originality Creativity and impact on viewer Overall communication Credits and references The credits of your film should include the following statement: “This educational film is an unrevised version submitted by XXXXX for assessment at the undergraduate Archaeometallurgy course at the UCL Institute of Archaeology, 2016” ARCL3001 ARCHAEOMETALLURGY SCHEDULE Week 1 Date 11 Jan Topic Introduction. Technical background Mondays in B13. Time: 2-4 2 18 Jan Studying archaeometallurgical remains: handling session 2-4 (G1, G2), 4-6 (G3, G4) 3 25 Jan The inception of metallurgy 2-4 4 1 Feb Copper and bronze 2-4 5 8 Feb Chemical analysis of metal artefacts: theory and practice 2-4 (G3, G4), 4-6 (G2, G1) 15-19 Feb Reading week - no lectures 6 22 Feb Lead and silver SEM analysis of archaeometallurgical remains 2-4 (G1, G2), 4-6 (G3, G4) 2-3 (G3), 3-4 (G4), 4-5 (G1), 5-6 (G2) (meet outside SEM lab in B4) 7 29 Feb Iron and steel 2-4 8 7 Mar Metallurgy, ethnography and ritual 2-4 9 14 Mar Alchemy and metallurgy 2-4 10 21 Mar Gold 2-4 tbc British Museum visit DEADLINES Friday 4 March – Essay deadline Monday 25 April – Video deadline Co-ordinator Marcos Martinón-Torres m.martinon-torres@ucl.ac.uk Turnitin Class ID: 2970179 – Password IoA1516