Michael A. Viliardos for

advertisement

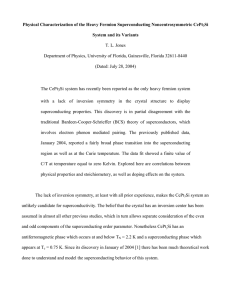

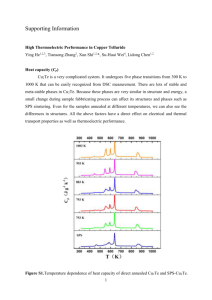

AN ABSTRACT OF THE THESIS OF Michael A. Viliardos for the degree Master of Science in Mechanical Engineering presented on July 23, Title: Thermal Annealing of Mo/Si 1992 . Multilayers to Assess the Stablity Relevant to Soft X-ray Projection Lithography. Redacted for Privacy Abstract approved: Michael E. Kassner The thermal stability of sputtered Mo/Si multilayers (ML) was investigated by annealing at 260-342°C for 0.5-3000 hours. Two distinct stages of interlayer growth were seen: primary region of ~3A, and a slower secondary growth region. The interlayer growth rate from deposition of Mo-on-Si was -200 times greater than the growth rate from deposition of Si-on-Mo in the secondary region. The interdiffus ion coefficient, Do~100cm2/s, and activation energy, Ea~2.5eV, for the Mo-on-Si secondary stage growth are comparable to values for diffusion of Si in h-MoSi2. Annealing of the ML causes the normal incidence reflectivity to decrease. a THERMAL ANNEALING OF Mo/Si MULTILAYERS TO ASSESS THE STABILTY RELEVANT SOFT X-RAY TO PROJECTION LITHOGRAPHY by Michael A A. Viliardos THESIS submitted to Oregon State University in partial fulfillment of the requirements for the degree of Master of Science Completed July 23, 1992 Commencement June 19 93 APPROVED: Redacted for Privacy Professor of Mechanical Engineering in charge of major Redacted for Privacy Head of department of Mechanical Engineering Redacted for Privacy Dean of Graduate Schocgl Date thesis is presented: July Typed by Michael Viliardos for Michael 23, 1992 A. Viliardos ACKNOWLEDGMENTS Special assistance. thanks to M. I also wish my committee the providing the needed data: and LAXS; D. Gaines, R. many people Financial T. study was provided by Lawrence Livermore National to Burhanuddin. members for Thanks S. thank W. Laboratory. and to their Kennedy, this Warnes, Kassner and B. Rosen for all who support assisted in U. Cheng for the HREM micrographs Spitzer, M. for the NIR measurements for BESSY. Krumrey, and P. Muller I also wish to thank my wife and friends for their support and assistance. TABLE OF CONTENTS INTRODUCTION 1 EXPERIMENTAL PROCEDURE 7 Specimen Fabrication X-ray Diffraction 7 10 Heat 11 Treatment High Resolution Electron Microscopy 12 Normal 14 Incidence Reflectance RESULTS 20 Unannealed Samples Annealing Experiments 20 21 Diffusion Normal Incidence Reflectance 22 25 Stability 26 CONCLUSIONS 41 FUTURE WORK 42 BIBLIOGRAPHY 43 LIST OF FIGURES Figure Page 1. Arrhenius plot of log D versus 1/T for the research of other investigators. 2. Side and top schematic of the ML deposition system. 16 3. Cleavage pattern of ML coated wafer. 18 Side and top schematic of the BESSY 19 4. 6 refleetometer. 5. HREM micrographs of a) unannealed ML sample 28 compared to those annealed at 316°C for b)l hour, c)40 hours, d)80 hours. 6. HREM micrographs of annealed MLs with similar interlayer growth at different temperatures and times a) 160h @ 260, & 298, c)lh @ 316, and d)lh @ 342°C. 7a. 7d. 8. 34 316°C. Interlayer growth rates of Mo/Si MLs annealed at 33 298°C.. Interlayer growth rates of Mo/Si MLs annealed at 32 260°C. Interlayer growth rates of Mo/Si MLs annealed at 7c. b)60h Interlayer growth rates of Mo/Si MLs annealed at 7b. 31 35 342°C. Arrhenius plot of log D versus 1/T for this study compared with that of other 36 investigations. 9. Arrhenius plot of log G (growth rate) versus 1/T for the primary surge region. 10a. Measured NIR data of annealed specimens 37 39 at 316°C compared with the "theoretical" reflectivity. 10b. Measured NIR data of annealed specimens at 342°C compared with the "theoretical" reflectivity. 40 LIST OF TABLES Table 1. £a.g_e_ Summary of previous investigators' annealing 5 experiments. 2. Listing of the average pre-annealed lambda 17 (A) and gamma (y) for the seven ML samples produced. 3. SAXS and HREM results for the seven 27 unannealed specimens. 4. HREM results for the annealed ML samples at 260, 298, 316, and 342°C. 29 5. NIR data for unannealed ML samples and annealed ML samples at 316 and 3 42°C including peak reflectivity, peak position, and full 38 width half maximum. Thermal Annealing Stability of Mo/Si Relevant Multilayers to Soft to Assess X-ray the Projection Lithography. INTRODUCTION Since the on reducing through advent the the of feature use of features use soft of shorter x-ray 0.5 the light. projection reflective possible by using circuitry. wavelength microns, but like method light in to multilayer two method x-rays. lithography optics this One (SXPL). focus (ML) the is the is limited consist of produce stack. The bilayer period, This, x-rays is however, which are Multilayers alternating materials or the approach coatings. typically a One This can be mitigated by wavelengths, requires of researchers have worked Visible and UV light has been used to of by diffraction of size shorter lithography process. achieve computers, the built up distance to from the center of one material to the center of the next layer of the same material, hundred. several The to of the ML is number upwards of of tens of angstroms to several layers a hundred. deposited number combinations index of component are chosen refraction, like to C, vary from The materials used are a high atomic number component like Mo, atomic can Si, maximize W, Ru, B4C, the or Cr, or Be. and a low Material difference of while minimizing the absorption. While the reflectivity from a single layer is low (-10^), reflectivity from all the the the from a ML is high because the reflected fields boundaries add in phase, like a quarter wave stack. Interfacial reflectivity by reflections. are roughness destroying Other factors substrate roughness, thickness and density. affected because by the they by unstable and will great interest chemical their of the MLs demonstrate two nature, and are and many are the material strongly and thermodynamically it is of stability of ways thermal layer to the produce evaporation, sputtering. superior of materials any temperature, methods deposition, the the the reflectivity width, the structural there vapor sputtered very interdiffuse at Some coherence influence between Currently, multilayers. that affects Because the reflectivity is to determine multilayers. phase interfacial interface are, greatly In general, formation and consequently higher x-ray reflectivity. Several stability researchers of Mo/Si reflectivity of -70%. to other types of MLs et al. [2], relatively 400°C. and the due to the studied the theoretical [1]. maximum Notable studies include Holloway et al. annealing [3]. times These and works involved temperatures Holloway, et al., above interface was wider, deposited at 450°C, on Mo found that the Mo deposited and continued to grow even though interface Holloway, et had al. , no apparent detected MoSi2 interfaces with selected area electron diffraction. et thermal All the works involve sputtered Mo and Si deposited Si Also, recently This is quite favorable when compared Stearns short on a Si wafer. on Si ML have al. , found growth of the interlayers growth. in the Stearns, characterized by amorphization and silicidation at 400°C. Also, the normal incidence reflectivity of the MLs was degraded with increased annealing temperatures. couples have interface. [5], found These Guivarc'h, summary of Other researchers working with Mo-Si growth of h-MoSi2 include Cheng, et al. these works [6], et (hexagonal) al. [4], Nechiporenko, is presented at the et al. [7]. A Gage, et Gage, et al. in Table 1. al., found that Si was the predominant moving species through the use of markers. An Arrhenius plot of log D versus studies can be seen in Figure 1. 1/T slope of all the the various The activation energies for the various studies are nearly identical, the for points. as can be seen by There is, however, much variation in the results for diffusion coefficients among the various the studies. deposited This ML can structure deposition parameters. during sputtering interlayers variations [8]. are be attributed as well as For instance, has been Other different shown differences differences in in the higher argon pressure to factors to cause that measurement thicker could initial cause techniques these and data analysis. The purpose interdiffusion of this behavior of study Mo-Si is ML to investigate structures relevant the to soft x-ray projection lithography over a wide range of times at relatively low temperature of interest are composed of (260-342°C) . 40 layer The ML structures pairs of having thicknesses of -30 and 40 A respectively. Mo and Si These MLs are designed for an optimum norma], incidence reflectivity of -65% at 130 A. in this study the MLs were annealed at 260, 298, 342°C 316, and for times up to 3000 hours. The objective is to ascertain the low temperature stability by determining a diffusion coefficient and an activation energy. Also, any stress Information extrapolated stability of relaxation obtained to the Mo/Si at involved these relevant ML for will lithography as reflective coatings. in identified. temperatures temperature use be soft to will be determine the X-ray projection Table 1: Summary of previous investigators' annealing experiments ML Mo/Si studies Holloway, et al. Stearns, et al. ML period (A) # of layers Anneal temperatures (°C) Anneal times (h) Diffusion coeffecient (m2/s) Activation energy (eV) couples Cheng, et al. Gage.et al. Guivarc'h, et al. 130 1 10 NA NA NA 30.5 30 NA NA NA 400-500 200-800 560-580 850-1 100 475-1000 30 sec 0.5 0- 1 0-25 0-9 7x10"19 4x10-22 1x10"3 1x10-9 2x10-7 2.0 NR 2.3 2.1 2.4 NA (not applicable) NR (not reported) (_n -5 "I T ' 'T"" I | D Stearns (thick) A Holloway (thick) • Holloway (thin) •o (Si in h-MoSi2> o» Q Gage Nechiporenko Cheng n Guivarc'h ♦ -10 • *faB E o ^ -15 A CD O -20 Ea = 2.5 eV -25 0.5 1.0 1.5 2.0 103/T[K-1] Figure 1: Arrhenius plot of log D versus 1/T for the research of other investigators. 7 EXPERIMENTAL PROCEDURE Specimen Fabrication The multilayers alternately polished thick. used sputtering single in Mo crystal this and (100) study were Si onto silicon a fabricated by 75 wafer mm diameter 0.020 inches There was no attempt to remove the -20 A of native oxide prior purchased to deposition of the ML. The wafers from International Wafer Service with a were specified flatness of 5 microns and an RMS roughness of 3-7 A over 200 microns. The deposition system is illustrated consisted of a cylindrical chamber 36 16 inches tall. in Figure 2. It inches in diameter and The top was removable via a hydraulic hoist and was sealed with an o-ring. The system was evacuated to 50 mTorr using a two stage Alcatel model 2033 mechanical pump with an oil trap. mm diameter The chamber was then evacuated using a 200 Helix cryo-torr Four 500 W quartz chamber to facilitate After 2 0 minute a 8 high vacuum cryogenic pump. lamps were placed symmetrically about the removal bake, of water followed by from the an overnight the system. pump, the chamber base pressure was typically 5 x 10~8 Torr. The about substrate its chamber followed a planetary motion. central central axis, axis. which The in turn substrate was It revolved mounted rotated about face down on a spinner motor assembly which was mounted onto a 2 8.5 diameter platter at assembly consisted of a radius a Canon of 15 d.c. inches. motor The the inch spinner CNG26-02301 Y520 which was tube. encapsulated in a 0.75 inch I.D. stainless steel One end was sealed with a 2.7 5 inch knife edge flange and copper gasket. A ferrofluidic feedthrough MB-250-KN-089 from Corp. Ferrof luidics was used rotation to the substrate fixture. V and spun at bottom of ~4 Hz. The the platter, the targets. to transmit The platter was motor The motor operated at 40 substrate was which was the -6 cm aligned with from the supported by a the surface of central shaft which entered the chamber through the lid via a ferrofluidic feedthrough from Ferrofluidics Corp., Platter rotation was provided compumotor with 100:1 reduction, part number 54-116298A. by a Parker A/AX03-135 and controlled with a Schwab SC386-25U IBM compatible microcomputer. The sputtering magnetrons located in 180 degrees apart. toroidal array linear array. of sources were the bottom of The magnetic Al-Ni-Co tube that was effluent to the target was clamped to the paste as an a central larger than the target It approached within 5 mm of the This effectively confined the target top of interlayer electrical conductivity. the Si surrounding Shielding in the shape of a slightly bottom of the rotating platter. silver the chamber and placed The inner and outer arrays were separated by a surrounded each magnetron. sputtered planar field was generated from a magnets channel used for water cooling. square rectangular to area. A 12.7 x 25.4 cm each magnetron body using provide good thermal Each target was 99.99% pure, target being doped with 10 ppm boron. and with The Mo target was 6.35 mm thick, while the Si target consisted of a 3.12 mm Si plate soldered to a 3.12 mm Mo backing plate using a melting temperature indium alloy. surface of controlled power each target was independently supplies, capable The magnetic -300 G. by Advanced of operating field at the Each Energy in source MDX-10K constant current or voltage mode at a power up to 5 kw. the MLs current were deposited and voltage in from the each constant supply was d.c. power, In this study power was low mode. monitored The by the microcomputer. Argon was provided by boil through a Matheson model the chamber from 8301 off from a dewer and passed thermal purifier. the bottom at two symmetrical It entered points near each target. The pressure was maintained at 1.75 mTorr during deposition, with Comptech model cryogenic a variable CVO-6-5M, pump. A vane-type placed between Vacuum General manometer measured the pressure throttle the model chamber 80-6B valve, and the capacitance and provided adjustments to the throttle valve. The Ar flow was held constant by a Vacuum General mass were model KM-4 controller. then ignited and maintained at for the first Si and Mo stabilized platter was held deposition was targets. target and targets, for The sputtering levels of respectively. 5 minutes, stationary. The during which After 280 the 5 sources and 110 W sources the were substrate minute period, initiated by rotating the substrate over the The platter was 1.10 rpm over rotated the Mo at 0.89 target rpm and over swept the out Si 110 10 degrees centered between the on target the respective regions, The platter made a total of of the multilayer. the targets. platter In moved at the 5.00 70° rpm. 40 revolutions during deposition The chamber was backfilled with nitrogen to atmospheric pressure at the end of the deposition and the sample was removed. Seven ML coated wafers were produced for this study and are listed in Table 2. The samples had a bilayer spacing (A) in the range of 69.4 to 70.0 A and a Mo to bilayer thickness (y) ratio of -0.44. X-ray Diffraction The angle X-ray (SAXS) diffraction consisted and large angle (LAXS). obtain Bragg diffraction peaks determined. obtained Rotoflex Information with LAXS. diffractometer (X=1.542 A) in two types: small SAXS was performed to from which the ML period was about SAXS of the was crystalline performed the phases using a was Rigaku 0-26 geometry with a Cu Ka source operating at 20 kV and 20 mA. The sample holder consisted of a precision stage driven by piezoelectric actuators providing tilt and translation. to measurement, parallel to incident beam. was X-ray aligned beam The and sample with the located was then in The sample, surface the of center rotated from prior the of ML the grazing incidence to -4° in q and the analog results were recorded on a chart recorder. with the chart The sample was scanned at 1/8° per minute, recorder set at a 1 second time constant and 11 at 20 mm/min chart speed. Throughout the scan, the detector count rate was adjusted to maintain each diffraction peak in the upper half of the chart paper to improve the resolution. LAXS Sciences was at performed Arizona at State the Center University. for A Solid Rigaku State Rotoflex diffractometer with computer control with a Cu Ka (^=1.542 A) source operating at 50 kV and 30 mA was used. scanned from 20 to 50° in 20. The sample was Scans were repeated 10 times and combined to increase the signal to noise ratio. Peat Treatment Each prepared wafer was cleaved into ten 12x24 mm pieces as shown in Figure 3 and individually numbered. accomplished by bending moment performed on scratching the causing each encapsulated in the piece wafer and 16 mm O.D. sample edge to then Cleaving was and applying a fracture. they Pyrex glass were tubes SAXS was individually at a pressure less than 10~5 Torr to avoid oxidation. Heat treatment accelerate the a was performed diffusion performed in timer was placed in the on process. Lindberg model same 51894 The electrical from A to was continuous circuit to verify The temperature of furnace was monitored using K type thermocouples placed in close proximity to the encapsulated samples. were sample annealing furnace. that power was maintained to the furnace. the each placed the in the bottom furnace of the center furnace on wire to The samples racks ensure ~3 a inches uniform 12 temperature. 260, 298, The 316, samples were annealed at and 342°C for various times. temperatures of Five minutes was added to the anneal times to allow for heat up of the sample as it was samples introduced were air temperature) . into the quenched The furnace. (~5 samples Once minutes were to removed annealed, cool from to their the room Pyrex capsules by rapidly heating the end opposite the sample with a propane torch causing pressure equalization. the sample facing cracks downwards onto the wafer left unannealed determine if sample the form which allowed for The tube was then cracked open with fragments was to to avoid surface. to be One used encapsulation distributing as sample a from control process glass each and affected to the multilayer. High Resolution Electron Microscopy The microstructure of HREM. The samples were (half of an original the sample pieces each were other. and was the ML samples was studied using prepared sample). then bonded with After A cut in epoxy drying mechanically polished to (HREM) from a x 12 mm sample 2 mm piece was cleaved from half with lengthwise. the ML overnight, fit 12 the The surfaces two facing specimens were a slot in a steel holder which then was inserted into a brass tube and glued in place with epoxy. using The assembly was then sectioned into -0.5 mm pieces a diamond saw. mechanically polished, The individual on both sides, to a sections thickness of were -120 13 microns. After polishing, the sections were dimpled on one side using a Gatan model 656 dimple grinder until the center thickness of thickness was the specimen was -25 microns. determined by back lighting the observing a dull red appearance. The proper specimen and The sample was then placed in an Gatan dual ion mill, model 600, equipped with a liquid nitrogen cold stage. The sample was milled from both sides at 5 kv and 1 mA at an angle of 14 degrees until perforation was achieved. 100°C during completed, The sample temperature was the preparation. Once maintained below the preparation was the sample was screened in a JEM 200 CX at 200 kV to ensure that the ML structure was visible. Subsequently, the specimen was viewed in a JEM 4000EX transmission electron microscope operated at 400 kv Electron Microscopy microscope has a at located at the Facility for Arizona point to State point University. resolution of This 1.67 A. Selected area electron diffraction (SAED) and high resolution images were obtained for analysis. HREM analysis of the individual was performed layers. to determine the The micrographs were thickness digitally scanned at 300 dots per inch (dpi) using an area about 1.5 by 2.5 inches. Three to six scans from different regions were made for each sample. gray scale image. This converted the picture to a 256 Thickness Image version 1.04 by National Services Branch (NIMH). substrate [111] measurements were made Institute of using Health Research The scale was set using the silicon direction as a reference. Density slices 14 were made in which a range of gray scale values are assigned a single color as an aid to measurement. establish boundaries between each layer. measurements were made for the Mo, layers, thus providing 15 to This helped to For each scan, five Mo-on-Si, Si, and Si-on-Mo 3 0 measurements. These were averaged and the standard deviation was determined. Normal Incidence Reflectance The effects reflectance of properties (NIR) annealing were the determined radiation. These beamline the VUV Radiometric of on measurements ML soft using synchrotron were performed Laboratory Electron Storage ring Synchrotron facility X-ray at using the the Berlin (BESSY). The X- ray wavelength was varied from 110 to 170 A by rotating a toroidal grating with a resolution of 0.5 A. Higher order contributions were reduced by using a 1 micron Be filter. The the was microns beam size at sample reduced through the use of a circular aperture. to 200 A 12 x 12 mm sample was placed in a standard mount which consisted of a circular aluminum disk with a recessed pocket for each sample, and a stainless steel cover to hold the samples in place. mount held two samples and was attached to vacuum chamber. translating the Each the holder in the The holder was capable of rotating and samples as shown in Figure 4. The vacuum chamber was pumped using a turbomolecular and ion pump to the mid 10-7 Torr range. from normal. X-ray reflectance was measured at 0.8° A channel electron multiplier detector was used 15 and operated in the linear range of the photon counting mode [9]. A reference scan was first made with the sample out of the beam. The sample was then placed in the beam and the detector moved such that similar geometries were maintained. Two or three points were measured on each sample to check for spatial variations. The reflectivity was dividing the sample scan by the reference scan. obtained by 16 Side View Spinner notor assembly <^J> • Vacuun chanber Substrate platter Plasna Substrate Target Shielding n Magnetron source \, J Top View Lanps Viewport II ° \\ Throttle valve Cryo Figure 2: Side and top schematic of ML depostion system. 17 Table 2: Listing of the average pre-annealed lambda gamma (y) for the seven ML samples produced. Sample Lambda (A) Gamma 0529A 69.7 0.43 0530A 69.6 0604A 70.0 0.43 0.47 0605A 69.8 69.4 0.47 1014A 69.5 0.45 1015A 69.0 0.46 1011A 0.48 (A) and 18 6 1 2 7 8 3 4 5 9 10 Figure 3: Cleavage pattarn of ML coated wafer, 19 Side View Manipulator Aperture stop r Sample n holder \f=D Detector Vacuun chamber Top View X-rays Figure 4: Side and top schematic of the BESSY reflectometer. 20 RESULTS Unannealed Samples The six unannealed specimens were removed capsules and SAXS was performed on each one. reported in table 3. from their The results are The period of the ML remained the same indicating that the ML were unaffected by the encapsulation process. errors Slight in position. initial sample in the period can be attributed to alignment or in determining the peak HREM was performed on the samples to determine the structure thicknesses. Table shifts 3. the ML and to measure the layer The measurements for each sample are listed in Sample unannealed of 0604A9, specimens is which is illustrated representative in Figure 5. of the It was found that the ML consisted of an amorphous layers of silicon and crystalline respectively. layers These of Mo, layers of were amorphous region of mixed Mo and Si. forms a thicker structure of heavier Mo greater deposited Mo occurring region the amorphous atoms depth mixed Si and separated deposition deposition relatively flat and abrupt. by a perhaps adatoms [10, of the A, thin The Mo on deposited Si due to 11] . to the ML. intermix The forms a thin interlayer due to during -23.3 and greater momentum of allowing the Mo during -30.5 Si on open the to a the little mixing The layers are LAXS performed on these samples show a peak at 40.0° corresponding to the (110) Mo peak. The HREM pictures show random crystallites in the Mo layer only. In the scanned images, individual atomic planes are easily 21 identified. annealed This is samples the starting and is condition consistent characterizations of the microstructure [2, Annealing remaining temperatures (260, 42 samples 298, 316, were and 342°C) samples were annealed at hours, all with 3, the other 10, 12-14]. Experiments The Nine of 260°C annealed at for various for times up four times. to 3000 eleven samples were annealed at 2 98°C up to 500 hours, thirteen samples at 316°C up to 100 hours, and 9 samples at 342°C for times up to 20 hours. caused a higher contraction of density the ML period due to silicides discussed subsequently. Annealing of these samples at the interfaces formation of which will be HREM measurements show the growth of each interlayer and the reduction in thickness of the pure materials. Continued annealing of the samples causes increased interlayer growth and further reduction in the ML period. mixture The but interlayer with is initially an increased annealing times, becomes crystalline. this Mo-Si region The thickness is shown as a function of the annealing time in Figure 5. at 316°C for 1, amorphous These samples were annealed 40, and 90 hours. The Mo-on-Si interlayer grew faster than the Si-on-Mo interlayer during annealing. With sufficient annealing time the ML structure consists of thin layers of crystalline Mo separated by thick layers of hMoSi2 • The Si layer has interlayer growth. been completely consumed by the Analysis of the LAXS results confirm the increasing crystallinity of the interlayer region. A single peak is observed which shifts with increasing annealing time. This single peak is composed of a (110) Mo peak at 40.0° and a (111) h-MoSi2 peak at 41.6°. decrease of the (110) The shifting is due to the bcc-Mo peak and the increase of (111) h-MoSi2 peak with increasing annealing time. comparison of amounts crystalline regions of analysis results was are the HREM pictures performed on presented in layer has been measured, deviation. the Table confirm the in the Visual increasing interlayers. HREM annealed samples, and 4. of The along with the the thickness the each associated standard As can be seen, each interlayer grows with time, eventually consuming the pure Si layers and leaving a thin Mo layer. Similar temperatures are interlayer shown in growth Figure 6. trends at These different samples were annealed at 260°C for 160 hours, 298°C for 60 hours, for 1 hour, It can be seen that the ML and 342°C for 1 hour. 316°C structure is similar for specimens having different annealing temperatures and times. This suggests that the mechanisms at work are similar at all the temperatures studied. Diffusion The Mo-Si interlayer growth rate was plotted as difference of the square of the interlayer width w2(0)] [3] versus time t using the HREM results. the [w2(t) - The w2 (t) and the w2(0) refer to the square of the interlayer thickness at time t and t=0 (unannealed), respectively. Figure 7 shows 2 5 this for (a) 260°C, '• c) (b) 298°C, 316°C, both the thin and thick interlayers. and (d) 342°C for At the temperatures studied, the thick interlayer had a greater growth rate than This disparity was also observed in the the thin interlayer. study by Holloway et al In Figure 7, two [2]. This will be discussed later. distinct regions can be seen. The initial growth of -3A is observable at all temperatures and for both the thin and thick interlayers. growth may be different from the This rapid primary secondary growth which suggests that different kinetics may be relevant. In describing the second stage kinetics interlayers diffusion it was assumed that limited with of the Mo-Si the interlayer growth is constant concentrations at the juncture of the Mo-Si interlayer and the elemental layers. Also, the concentration gradient through the interlayer was assumed to be linear. annealing at time coefficient D(t') The Mo-Si interlayer width w(t) t can be which AC interlayer. is to the interdif fusion by the following: w2(t) = w2(0) + 2 AC in related after the change D(t') dt \ in (1) concentration across the Integrating this, assuming D(t') to be constant (confirmed by the linear plots of [w2(t) - w2(0)] versus t, seen in figure 5), the relationship: D = [w2(t) is apparent. The - w2(0) ] / 2t , (2) interdiffusion coefficient described as an Arrhenius equation : D = D0 exp [-Ea/kT], (3) can also be 24 where D0 is the temperature independent diffusion constant and Ea is the activation Figure 8, log D as second stage determined growth interlayers and energy rates is compared for interdiffusion. from equation plotted versus to the 2 using 1/T results for of In the both other investigators. Linear regression was performed on the data to determine the slope (Ea) and the intercept (D0). The thick interlayer (Mo-on-Si) diffusion coefficients are -200 times greater than those for energy the for thin both, interlayer however, temperature range studied. (Si-on-Mo) . is nearly The activation identical over the The activation energy was found to be Ea~2.5eV, and the interdiffusion coefficient was Do~100 cm^/s for the second stage growth of the thick interlayer. These values are comparable to bulk diffusion values of h-MoSi2 in Si[4-7] and Mo/Si multilayer interdiffusion [2,3]. The interdiffusion coefficient for the thin interlayer was found to be Do-0.05 cm2/s. could be attributed to a The difference between the two chemical diffusion could form during the deposition process. barrier that Such a barrier would have to form as the ML sample passed from one target to the other. most Partial oxidation of the Mo surface would be the likely candidate for a chemical diffusion barrier. Recent work at ASU, however, has not detected any impurities using energy dispersive x-ray spectroscopy and electron energy loss spectroscopy using a VG-501 STEM operating at 100 kV with an estimated probe size of 10 A and and a minimum 25 resolution of 5 atomic percent oxygen. A similar plot for the primary surge region can be seen in Figure 9. The disparity in growth rates is not seen in the surge region. Ea~1.6 eV. stress The activation energy for this region is A possible mechanism for this region could be relaxation Normal Incidence Reflectivity (NIR) Normal incidence X-ray reflectance was performed on the relevant annealed samples, was not too great. i.e. those with a contraction that More than a few A of contraction shifts the bandwidth of the mirror, making it useless. Also, the interlayer growth that occurs with this contraction quickly degrades the reflectivity. samples measured, Table 5 has a listing of the the peak reflectivity, and peak location. This data was compared to the theoretical reflectivity using a matrix method modified to incorporate non-ideal interfaces [15] . Theoretical obtained using stoichiometry, roughness). fits of interlayer and by experimental NIR regions uniform assuming of abrupt data comparison of used (no Best fitting of the unannealed data was obtained the experimental data for the specimens at also MoSi2 interfaces using optical constants determined by Windt [16]. shows a were a linear (a) to 316°C and (b) concentration Figure 10 the theoretical 342°C. gradient The model through the interface. This close fit of the model with the data tends to the support assumption of a linear gradient made in equation 1. The NIR of all the samples was found to decrease with increased annealing time and temperature. A correlation between the two temperatures can be drawn because the samples annealed at different times and temperatures had similar decrease in reflectivity. For example, the samples that had similar interlayer growth, like the 0.5h at 342°C and the 5h at 316°C, had nearly the same decrease and shift in peak reflectivity. Stability To assess the stability of the ML, one must establish the operating temperature of the coatings. expected to be near ambient temperature [17]. first This is From NIR, the increase in interlayer thickness that degrades the ML is ~3A. This would require using Ea from the primary surge region. Using this value and a conservative temperature of 50°C the time for the calculated. interface to grow a given amount can be The time for a ML to degrade was found to be much beyond the expected operating life of one year. Table 3: SAXS and HREM results for the seven unannealed specimens. SAXS (A) HREM (A) As deposited Post encapsu- Thin 1 Standard Thick Standard Standard Mo Standard Deviation _Lay_er_ 23.16 OevjaLon 0.99 "~ 22.59 G.75 Sample Lambda 0529A4 69.6 69.6 0.0 5.13 0.44 10.11 0.51 30.25 0.99 0530A1 69.5 69.7 -0.2 4.69 0.56 9.65 0.63 31.63 0.64 70.1 70.1 0.0 4.93 0.80 9.97 0.77 30.88 1.31 22.92 69.7 \A2 69.6 0.1 5.85 0.46 10.67 0.80 28.61 1.16 23.28 i ia 0604A9 0605A1 ation Lambda Difference interlayer Deviation interlayer Deviation layer 1011A2 69.6 69.6 0.0 4.56 0.52 9.31 0.89 31.53 1.21 24.13 o.8'; 1014A1 69.5 69.5 0.0 4.93 0.49 10.45 0.89 30.21 1.44 23.41 69.2 1.00 69.1 0.1 4.90 0.56 9.58 0.85 30.92 0.99 23.54 0.95 1015A2 :o W8&W& '^^^^^T^^^^W^W^'':^-^^'" " * >»v - * ^ >• , >- ;: / , , > > fsftG&lKS*, PSs?»*> •' ;'; •'^.x>•; s- >••»•>, Figure 5: HREM micrographs of a) unannealed ML sample compared to those annealed at 316°C for b) 1 hour, c) 40 hours, d) 80 hours. CO 00 Table 4: HREM results for the annealed ML samples at 260 and 298°C. Time Thin Standard Sample interlayer Deviation 1014A10 5.26 0.55 10.88 0605A2 6.36 0.50 Thick Standard Si Standard Mo Standard Layer Deviation Layer Deviation 0.65 29.30 0.94 22.28 0.59 11.57 0.95 26.98 0.99 22.10 0.90 22.06 1.03 interlayer Deviation 260°C 1h 10h 40h 0605A4 7.09 0.44 12.09 0.93 25.75 1.14 80h 0605A5 7.67 0.58 14.01 0.78 25.09 0.70 20.41 1.34 160h 0605A6 7.68 0.60 14.25 0.44 24.66 0.58 20.42 0.71 500h 1015A6 7.76 0.48 14.42 0.76 22.61 0.90 20.38 0.96 1000h 1015A7 7.80 0.55 14.59 1.37 22.65 0.99 19.80 1.31 2000h 1015A8 7.88 0.50 15.15 0.50 22.47 0.42 19.19 0.44 3000h 1015A9 8.06 0.75 15.78 0.92 21.62 1.31 18.62 1.07 1h 1014A8 5.18 0.55 10.90 0.87 28.82 0.87 22.33 1.24 5h 0529A2 7.20 0.59 12.83 0.59 26.12 0.69 20.66 0.87 298°C 25 h 1014A6 7.71 0.45 13.92 0.42 23.73 0.57 20.55 0.57 60h 0529A3 8.66 0.73 14.20 0.54 22.26 0.87 20.33 1.08 160h 0529A6 9.39 0.76 15.23 0.73 20.07 1.10 20.19 0.93 225h 1014A7 9.41 0.74 18.10 1.33 18.91 1.36 17.67 1.15 312h 1014A3 9.36 0.58 18.97 0.68 18.20 0.95 16.92 0.87 384h 1014A2 9.79 0.74 21.83 2.39 15.44 1.81 15.12 1.21 450h 1014A4 10.38 0.63 24.80 1.70 11.46 2.07 13.36 1.25 500h 1014A5 10.41 0.52 24.21 1.30 10.78 1.09 12.80 1.06 to u CM o CO <x> CO (3 0) rH e CO J (1) CD c (0 a> o 10 4-1 J-J CO i—I 0) u m 2 oi 01 r—I c ;r CO « -y •o Thin C "O itnerlaye Th © iS 00 Q b— ca _i C S T3 o C "O a> -;r ca ra jE >- 2 CO O CO •o c0 — c _J 05 £ "O JiS CO Q k_ -^ CO c: ca >• CD -a -:r o JC c 5 & ca "D CO Q W_ c E a ca CO a> E \- O o CO LD Iso *— lrt a> oo o o *- O Lfj o m r- <— «* o * co •<t CO CD o o co r-^ o CM CM CO CO <T> CD o o en CO CO co CO CO r- r-* •<* Is- CM r~ — T_ r*- ir_ t_ 00 T— m en CO in CD o m IsCM ^ CO cd co in co -^ t - •* in •r- '" CM CD '~ •>!• O CD ,_ •«- co U) rf in cn 00 o CM CD Ism ID o o 00 r^ -«t co r- o r^ •<iCM r^- o CM in in r- CO oo co CO co CO ••- in o 00 oo in o in CM - en o in in co co CD tt CM Is- 00 •* CM o o in CM •* CM C3 ti- CM CO CO ^« -* CD ^~ T_ 00 T— n CD •>- CM •* *- co CM r CD- <D in •t r- r^ 00 Is- •* T~ o Is- in Is- CD m r- o co in OO O CD en CD CO CM v^ en o Tj- n- •* T- '- CM CM CD n C\J CO •r- CO CM •«t in CM in Is- ,— ,_ - r^ CO 00 CD co y— t- *- - CM CM o CD -3- co - r- CM CM in T— 'dCM T— '- T~ 00 <» ? Is Ig sz cm «? sz in sz T~ o o CO o in o CD CD o Is- o in CM o too r> CD CO CO co -<fr CO CM CM in o o yCD r- o O Is- Is- rai CD CM o r-- T- - CD CO CO "<t rn o CD ,_ Is- o o CD CM CO o N- CD CO m r~- *— CO in o m CO in CO o o Is- CD o en CD CD CO in en CM CD o CM en Is- CO in o 00 in 00 o CD in < _ r^ 1— < o in sz r-^ in o CD < r— in sz o sz CM in T— T— < CM m o T~ sz CM en < o sz d in T— i— < CM T— < in CM ID Is00 co o CO in 00 en CO co i^ CM •<* cd •<* o O "3" CM CO CM en co CD CM CM CM CM o CM CO ^- ,— CO in r~» •* CO cm •* T~ CD cd in •<*• en CO in CO CO CO Iso T~ m CO CO in en o CO CO CD t en o o Is- O Isco CD o n en Is- • < O CO CD CM in o sz o T- *r o en o *" •<t N- CM n oo CO CO *- CD -r- co < Tf O CD O SZ o co O -~ o in oo •tf T— T_ i— o Iso o •f o in o o •* Is- CO CD rn o cd in «tf ^~ < in CD T— < T— < T~ T— < y— -* < o sz O XT o Is- o sz o in CD O o T- < i- O < o CO Tt •»- i- < o in sz o m CNJ Tt T- o SZ <tf o CD O t- o i- x: x: in o ^ 3 0 ^fcv,^te4r^Urti.fiifci.^ Figure 6: HREM micrographs of annealed MLs with similar interlayer growth annealed at dif ferent times and temperatures a) 160h @ 260, b) 60h @ 298, c) lh @ 316, and d) lh @ 342°C. 200 a) T = 260 °C o Thick (Mo-on-SI) • Thin (Si-on-Mo) 100 CM 1000 2000 3000 t(hours) Figure 7a: Interlayer growth rates of Mo/Si MLs annealed at 260 °C. , 550 ,....T—, r__, j ,_ i ' r "• '•> -r~>—r— o • 450 - • i—-'• O b) T = 298 °C 500 . , ...^—, O Thick (Mo-on-Si) A Thin (Si-on-Mo) - 400 « • O 350 tM °< 300 CM 5 250 200 CM 150 100 • A A • 50 F -j—I—i—I—i—l—i—I—i—I—i 0 50 I i I i I i • i 100 150 200 250 300 350 400 450 500 550 t(hours) Figure 7b: 2 98 °C. Interlayer growth rates of Mo/Si MLs annealed at 3 4 -i—i—•—i—i—i—i—i—•—|—i—|—i—|—i—|—i—f—,—p 500 c)T = 316°C 400 CM - O Thick (Mo-on-SI) A Thin (Si-on-Mo) 300 CM I ~ 200 100 b°° A A .. 10 A . 0 c—>—'—•—'—•—'—'—i—•—i—i—i—i—i 0 A A 20 30 40 50 60 i i • i • i • I 70 80 90 100 110 t (hours) Figure 7c: Interlayer growth rates of Mo/Si MLs annealed at 316 °C. 1—r-T .... 550 500 450 - - • r _, 1 T_. _, r •i - • i « ... T — , . . i i — O m d) T = 342 °C O O Thick (Mo-on-SI) A Thin (SI-on-Mo) - • O 400 350 O - - CM 300 - O CM 250 o - 200 - 150 h • 100 -oo A A A A 50 I . I . I . i 8 10 i 12 i i 14 • 16 t(hours) Figure 7d: 342 °C. Interlayer growth rates of Mo/Si MLs annealed at to CM E o o Figure 8: Arrhenius plot of log D versus 1/T for this study compared with that of other investigations. "<"7 •10 T >~ 2 q Thick (Mo-on-Si) a, Thin (Mo-on-Si) o A -11 2 •12 E O O -13 O A Ea = 1.6eV -14 - •15 1.5 1.6 1.7 1.8 1.9 2.0 103/T[K-1] Figure 9: Arrhenius plot of log G (growth rate) versus 1/T for the primary surge region. Table 5: NIR data for unannealed ML samples and annealed ML samples at 316 and 342°C including peak reflectivity, peak position, and full width half maximum. Sample Lambda %R Peak FWHM 1011A2 69.6 60.0 135.5 5.4 5h @ 316°C 1011A3 66.5 52.9 130.0 4.5 50h @ 316°C 1011A7 64.2 41.0 126.3 3.6 Unannealed 1011A2 69.6 60.0 135.5 5.4 0.5h @ 342°C 1011A9 66.4 49.6 130.0 4.6 Figure 10a Unannealed Figure 10b 0.6 \ Data 5h / i Model / i\ / i\ / 0.5 - Unann ealed thin thick 0.4 // // // t 50h 1 \ 1 \ ' i 8.7 \ thick 14.5 0.3 i \ t \ i \ \ ' 1 \A i' 1/ \ ' I A i / 5h o i \ / \ ~ thin i \ / / 4.6 9.3 \ Unannealed V I 1 \ I \ 1 \ 1 I ii / >/\ / CD 50h CD thin 1 1 /i y I \ 11/ 9.8 1 t /1 '/'\ '/ '1 11 thick 18.1 0.2 1 1 1 / '\ / i\ \ 1 \ 1 \ j - a)T = 316°C I 1 \ ' \ 0.1 0.0 -i 115 120 125 130 135 1 1 r 1 140 1 1 r 145 X-ray Wavelength (A) Figure 10a: Measured NIR data from annealed ML specimens at 316 °C compared with the "theoretical" reflectivity. 6 i CO CD 0 +-• CO ^ i—r Q i b aled 4.6 9.3 o 8.5 i LO •*- 13.7 j*: co *" o c +"' £ c o ~ i i sz'sz'sz i CO -c -c c D -r—i—i—r in i o o i i i i i i ! - m 0) 0) T5 o o (J Csl (0 CO c 0> o a CO 0) rH a 1X5 CD US c O J-i 4-i iT3 'I! VC M X! •H b CD o s (0 QJ u i <N i CO i CM CO II h- i S2 i A)jAj}33||ey >i 4-) > •H j_> •H CJ (1) CD U <d -U -H o 4J 41 CONCLUSION Mo/Si effective multilayers x-ray (MLs! reflectors were at a fabricated wavelength that of are -135.4. Experiments were performed to determine the thermal stability of these MLs. at The annealing experiments on Mo/Si multilayers temperatures of distinct 260-342°C for 0.5-3000 hours indicate two stages of thermally activated The primary stage occurs quickly interlayer growth. to ~3A thick, while the secondary growth is slower and the diffusion coefficient D is constant with time. thick interlayer The interdiffusion coefficients for the (Mo-on-Si) are 200 times greater the thin interlayer (Si-on-Mo). than for The secondary stage of the thick interlayer growth interdiffusion coefficient Do~100 cm2/s, and the activation energy Ea~2.5 eV are comparable to bulk diffusion of Si in h-MoSi2. The x-ray reflectance of the multilayer decreased with increased annealing time and temperature due to growth of the interlayer region. 42 FUTURK WORK The work that remains to be done is extended annealing at temperatures energy remains below 2 60r"'C determine if the activation Also, further- investigation into the primary stage growth remains. The mechanisms involved in both stages constant. to have yet to be identified, interlayer grows more than the other. as well as why one 43 BIBLIOGRAPHY 1) 2) D. Stearns, B. Rosen, S. Verne.:: High performance multilayer mirrors for soft x-ray projection lithography, Proc SPIE 1547, 2 (1991). K. Holloway, K.B. Dc, R. Sinclair: Interfacial .reactions on annealing molybdenum-silicon multilayers, J. Appl. Phys. 65, 474 (1989). 3) D.G. Stearns, M.B. Stearns, Y. Cheng, J.H. Stith, N.M. Ceglio: Thermally induced structural modification of MoSi multilayers, J. Appl. Phys. 67, 2415 (1990). 4) J.Y. Cheng, H.C Cheng, L.J. Chen: Cross-sectional transmission electron microscope study of the growth kinetics of hexagonal MoSi2 on (001) Si, J. Appl. Phys. 61, 5) 2218 (1987). P.R. Gage, R.W. Barlett: Diffusion kinetics affecting formation of silicide coatings on molybdenum and tungsten, 6) Tran. Metall. A. Guivarc'h, Boulet, P. P. Auvray, Henoc, G. Soc. AIME 233, (1965). L. Berthou, M Le Cun, J.P. Pelous: Reaction kinetics of molybdenum thin films on silicon (111) Appl. Phys. 49, 233 (1978). 7) 832 surface, J. E.P. Nechiporenko, N.S. Poltavtsev, V.L. Kapustin, Yu.T. Kondoratov:Range of Homogeneity of molybdenum disilicide, Izv. Akad. Nauk SSSR Noeg. Mater. 9, 1829 (1973). 8) D.G. Stearns, R.S. Rosen, S.P. Vernon: High performance multilayer x-ray optics, in Soft X-ray Projection Lithography, 9) M. Krumrey, Technical Digest Series, M. Kuhne, P. Muller, OSA 48 F. Scholze: (1991). Precision soft x-ray reflectometry of curved multilayer optics, Proc. SPIE 1547, 136,(1991). 10) A.K. Petford-Long, M.B. Stearns, C.H. Chang, S.R. Nutt, D.G. Stearns, N.M. Ceglio, A.M. Hawryluk: High resolution electron microscopy study of x-ray multilayer structures, J. Appl. Phys. 61, 1422 (1987). 11) W.L. Morgan, D.B. Boercker: Simulating growth of Mo/Si multilayers, Appl. Phys. Lett. 59, 1176 (19991) 12) R.S. Rosen, M.A. Viliardos, M.E. Kassner, D.G. Stearns, S.P. Vernon: Thermal stability of Mo/Si multilayers, Proc SPIE 1547, 212 (1991). 44 13) O.B Loopstra, W.G. Sloof, Th. H. de Kejing, S. Radelaar, A.E.T. Kuiper, R.A.M. Welters: Composition, microstructure, and properties of crystalline molybdenum silicide thin films produced by annealing of amorphous Mo/Si multilayers, J. Appl. Phys. 63, 4960 (1988). 14) S. Ogura, M. Hayashida, A. Ishizaki, Y. Kato, J. Wood: Evaluation of alternative Mo-Si multilayer for soft xray mirrors by electron microscopy and x-ray diffraction, Proc SPIE 984, 133 (1988). 15) D.G. Stearns: The scattering of x-rays from nonideal multilayer structures, J. Appl. Phys. 65, 491 (1989). 16) D.L. Windt: XUV optical constants of single-crystal GaAs and sputtered C, Si, Cr3, Mo, and W, Appl. Optics 30, 15 (1991). 17) N.M Celgio, A.M. Hawryluk: Soft x-ray projection lithography system design and cost analysis, Proc SPIE 1547, 82 (1991).