Condensation on Superhydrophobic Surfaces: The Role

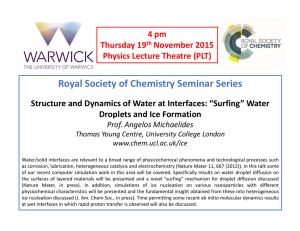

advertisement