Document 12446530

advertisement

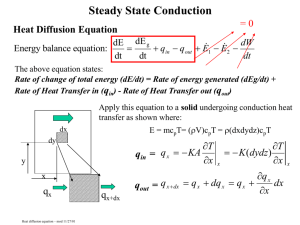

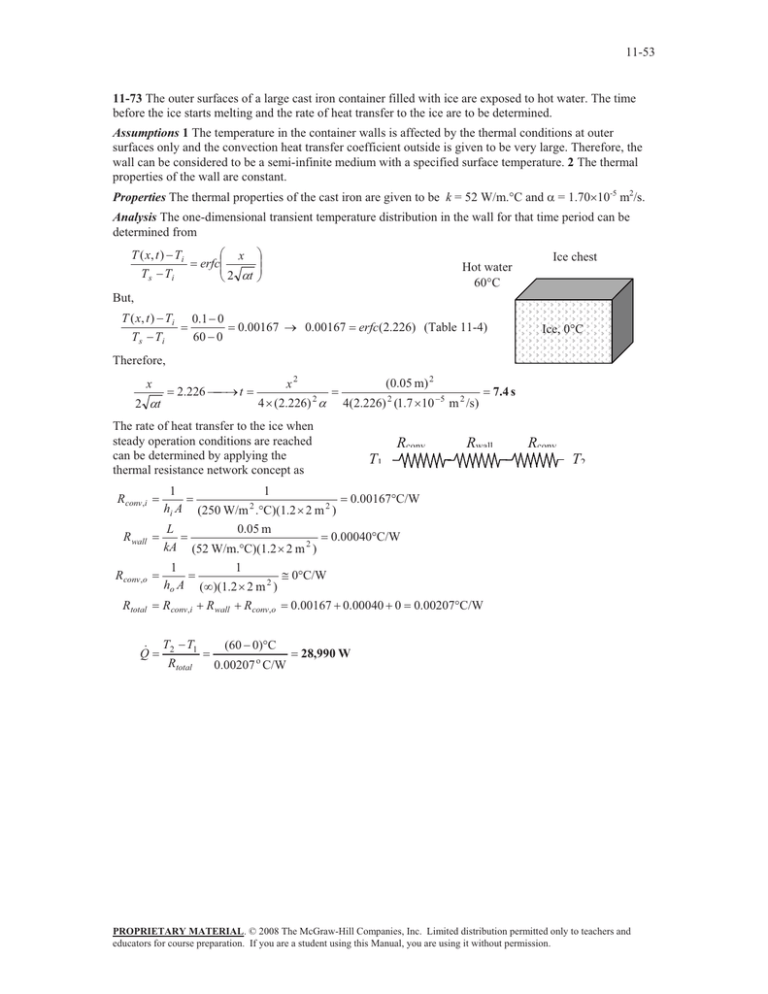

11-53 11-73 The outer surfaces of a large cast iron container filled with ice are exposed to hot water. The time before the ice starts melting and the rate of heat transfer to the ice are to be determined. Assumptions 1 The temperature in the container walls is affected by the thermal conditions at outer surfaces only and the convection heat transfer coefficient outside is given to be very large. Therefore, the wall can be considered to be a semi-infinite medium with a specified surface temperature. 2 The thermal properties of the wall are constant. Properties The thermal properties of the cast iron are given to be k = 52 W/m.qC and D = 1.70u10-5 m2/s. Analysis The one-dimensional transient temperature distribution in the wall for that time period can be determined from § x · ¸ erfc¨¨ ¸ © 2 Dt ¹ T ( x, t ) Ti Ts Ti Hot water 60qC Ice chest But, T ( x, t ) Ti Ts Ti 0.1 0 60 0 0.00167 o 0.00167 erfc(2.226) (Table 11-4) Ice, 0qC Therefore, x 2 Dt 2.226 o t x2 (0.05 m) 2 4 u (2.226) 2 D 4(2.226) 2 (1.7 u 10 5 m 2 /s) The rate of heat transfer to the ice when steady operation conditions are reached can be determined by applying the thermal resistance network concept as Rconv,i R wall Rconv,o Rtotal Q 1 hi A T1 Rconv Rwall 7.4 s Rconv T2 1 0.00167qC/W (250 W/m .qC)(1.2 u 2 m 2 ) 0.05 m L 0.00040qC/W kA (52 W/m.qC)(1.2 u 2 m 2 ) 1 1 # 0qC/W ho A (f)(1.2 u 2 m 2 ) Rconv,i R wall Rconv,o 0.00167 0.00040 0 0.00207qC/W T2 T1 Rtotal 2 (60 0)qC 0.00207 o C/W 28,990 W PROPRIETARY MATERIAL. © 2008 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and educators for course preparation. If you are a student using this Manual, you are using it without permission.