For Con-Tech Lighting Recessed Track Housing System for Single- or... INSTALLATION PROCEDURES:

advertisement

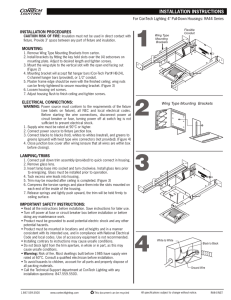

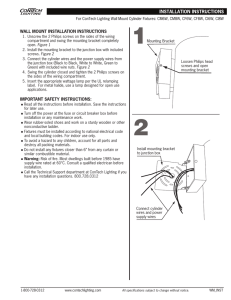

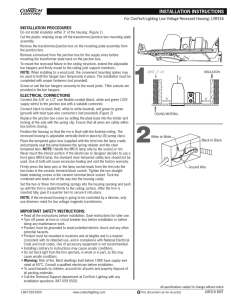

For Con-Tech Lighting Recessed Track Housing System for Single- or Two-Circuit Track INSTALLATION PROCEDURES: 1. Recessed track housing may be suspended with the provided RAH-10 mounting tabs (use 4 for 4' sections and 6 for each 8' section) or with wood screws into wood furring. 2. Mounting tabs are attached to the housing system by bending the tab portion at a right angle (where it joins the perforated RTH-4/RTH-8 section) and inserting the tab into the channel in each side of the housing extrusion. Attach tabs to any firm component of the ceiling system. LA-10 a. Wood furring: drill holes in the top of the housing extrusion and mount with #10 wood screws. b. T-bar ceiling: suspend housing to permanent ceiling, making sure the bottom of the housing is level with the LT-4/LT-8 RAH-11 bottom of the T-bar. Use bottom outer edge of housing as LT-24/LT-28 “T-bar” for that side of the ceiling tile. 3. The recessed track housing may be cut in the field to required lengths. A straight squared cut is necessary to insure proper fit. Included Parts (RTH-4 and RTH-8): 4. The bottom edges of the housing flange should overlap the (4) 6-1/4" mounting tabs ([6] are provided for 8' sections), (2) 3" ceiling surface. connecting tabs with locking screws, (4) 1-1/2" tabs for depth 5. The 1-1/2" tabs must be inserted into the channel inside of adjustment of single circuit track, and (2) 1-3/8" tabs for mounting the housing to create a depth adjustment when single-circuit end piece track is installed. These parts are discarded when two-circuit track is installed. 6. When using two or more recessed track housings in a run, use the two 3" connecting tabs which slide into the slots in the side of the housing. Place the connecting tab into the slot on one housing and tighten set screw. Insert connecting housing over protruding connecting tab, pull flush, and tighten screw. 7. Each run, or individual track housing, is completed with a dead end piece (RAH-11) mounted to the extrusion sides with the two brackets provided. The short portion of the bracket is inserted into the end piece, the two long tabs will fit into the open end of the housing and are locked into place with the screws provided. Track Installation 1. Firmly insert the end feed (LA-10 or LA-210) into single- or two-circuit track (the small arrow on the lead end should point to the polarity line), remove cover to access wiring connections and tighten locking screw. 2. Mounting holes are provided to install the track into the housing (2 per 4' section and 3 per 8' section). If other than standard length is used, align the track with the start of the recessed track housing and mark hole locations to drill for mounting screws and mount track into the extruded housing. 3. When more than one track length is used in a run, the mini connector (LA-2 or LA-202) may be used to connect track sections. No additional connector housings are required. If an additional feed is required in a straight run then use the full size straight connector (LA-12 or LA-212) with the RAH-2 connector housing. 4. Keep track end cap (provided with each track) in place when making the connection, then remove for on-going connection). The last piece of track in a run should have the end cap left in place. 5. Replace cover of all end feeds and/or connectors. Electrical Power Connection 1. Attach flex or conduit to the knock out provided in the recessed end feed housing (RAH-10) or any of the other connecting housings. 2. Pull the power leads through and connect to terminal screws provided in Con-Tech Single- or Two-Circuit end feeds (LA-10 or LA-210) or any of the feed connectors (LA-12, LA-212, LA-13, etc.). 3. Electrical installation must be made in accordance with local codes. IMPORTANT SAFETY INSTRUCTIONS: • Read all the instructions before installation. Save instructions for later use. • Turn off the power at fuse or circuit breaker box before installation or maintenance work. • Wear rubber soled shoes and work on a sturdy wooden or non-conductive ladder. • Product must be mounted in compliance with National Electrical Code and local building codes. For indoor use only. • Do not exceed the nominal supply voltage or amperage ratings. • Installing contrary to instructions may cause unsafe conditions. • Warning: Risk of fire. Most dwellings built before 1985 have supply wire rated at 60°C. Consult a qualified electrician before installation. • Avoid hazards to children: account for all parts and properly dispose of all packing materials. • Call the Technical Support department at Con-Tech Lighting with any installation questions. All specifications subject to change without notice. 1-847-559-5500 www.con-techlighting.com This document can be recycled. RTH INST