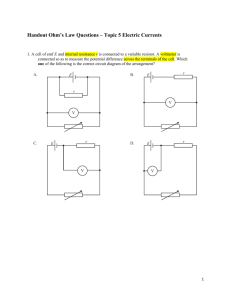

Constant force extensional rheometry of polymer solutions Please share

advertisement