Analysis of Shape and Load-Displacement Response of Convertible Car Hoods.

advertisement

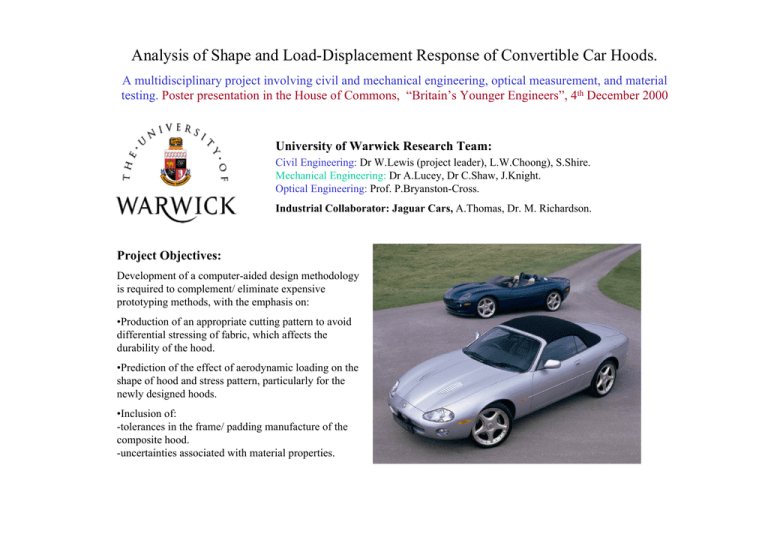

Analysis of Shape and Load-Displacement Response of Convertible Car Hoods. A multidisciplinary project involving civil and mechanical engineering, optical measurement, and material testing. Poster presentation in the House of Commons, “Britain’s Younger Engineers”, 4th December 2000 University of Warwick Research Team: Civil Engineering: Dr W.Lewis (project leader), L.W.Choong), S.Shire. Mechanical Engineering: Dr A.Lucey, Dr C.Shaw, J.Knight. Optical Engineering: Prof. P.Bryanston-Cross. Industrial Collaborator: Jaguar Cars, A.Thomas, Dr. M. Richardson. Project Objectives: Development of a computer-aided design methodology is required to complement/ eliminate expensive prototyping methods, with the emphasis on: •Production of an appropriate cutting pattern to avoid differential stressing of fabric, which affects the durability of the hood. •Prediction of the effect of aerodynamic loading on the shape of hood and stress pattern, particularly for the newly designed hoods. •Inclusion of: -tolerances in the frame/ padding manufacture of the composite hood. -uncertainties associated with material properties. Structural Analysis: Single layer hoods, ‘rag-tops’. •The novel design methodology uses the principle of a minimal surface to calculate the shape. •The calculated shape is consistent with a constant tension field (as found in natural structures such as soap films) -a desirable feature from the point of view of durability. Double layer ‘composite’ hoods (with padding between the inner and outer layers of fabric). •Shape is pre-determined by designers. Stress field is found by computation involving iterative methods and making use of non-linear material properties. •Anisotropic material properties are to be taken into account to provide a cutting pattern for the fabric. •Load-displacement response to aerodynamic loading is found by fluid-structure interaction involving coupling between the structural solver and fluid dynamic simulations. •Successful experimental work on small-scale models was carried out to test the methodology and involved optical measurement. •Resultant forces on the supporting structures, i.e. the padding and the hood frame, are provided. •Work on the cutting pattern completes the progress. A soap film will naturally form a minimal surface. Such surfaces use a minimum amount of material and have a constant value of surface tension. Materials testing: Results are shown for 5 uniaxial tests and 4 biaxial tests in warp and weft directions respectively •The graphs show highly anisotropic and non-linear fabric properties which needed to be established from tests. •Properties vary significantly from one sample to another. •The knowledge of material properties is essential in determining the best cutting pattern for the hood fabric. Uniaxial tests (weft) 60 35 50 30 40 true 30 head 20 Stress (kN/m) Stress (kN/m) Uniaxial tests (warp) 10 25 20 true 15 head 10 5 0 0 0 4 8 12 16 20 24 0 5 10 15 25 30 Combined biaxial test results -weft Combined biaxial test results -warp 18 55 50 45 40 35 30 25 20 15 10 5 0 y = 0.874x - 0.3756 16 y = 1.8644x + 16.132 14 Stress (kN/m) Stress (kN/m) 20 Strain (%) Strain (%) y = 3.6212x + 9.393 12 10 y = 2.1666x - 15.338 8 6 4 y = 8.0382x + 0.0257 y = 0.2579x - 0.2186 2 0 0 2 4 6 8 10 True Strain (%) 12 14 16 18 0 2 4 6 8 10 True Strain (%) 12 14 16 18 1200 Fluid Dynamics Modelling: 1000 •Predicts aerodynamic loading on the hood. front •Pressures generated from 3D modelling are used to determine the forces acting on the hood and displacements. 800 600 400 Initial prediction of pressure field in the centre-line plane for turbulent flow over the passenger compartment of the car. 200 0 0 500 1000 1500 side Computed contours of pressure over the hood Optical measurement -flat roof model: •Used to test the methodology adopted, using a small scale physical model in a wind tunnel. •Measurement of the displacement of the membrane was made at several wind speeds using Infra-red proximity probes. •Plots show the initial shape of the membrane (with zero pretension), and its deformed shape at a wind speed of 9.57m/s. Tensions in fabric under wind loading: warp-weft alignment 1100 -6 0 0 1000 -4 0 0 -2 0 0 x(mm) z(mm) 900 800 0 200 700 400 600 600 500 200 400 600 800 1000 y (m m ) 1200 1400 200 1600 Displacement of hood fabric under aerodynamic loading: Contour plot of hood displacement under wind loading 18 600 16 14 400 12 front of hood 200 10 8 0 6 -200 4 2 -400 0 -600 -2 200 400 600 800 1000 1200 1400 1600 400 600 800 1000 y (m m ) 1200 1400 1600