SFK MAJOR HAZARD COMMISSION Guideline

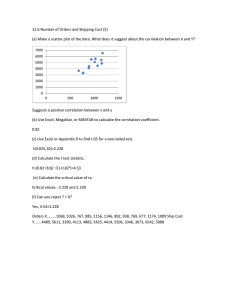

advertisement