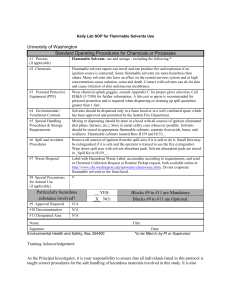

Western Carolina University General Use Standard Operating Procedure for Flammable and

Western Carolina University

General Use Standard Operating Procedure for Flammable and

Combustible Materials

1. Contact Information

Name of Responsible Person:

(PI, Supervisor, or

Autonomous Researcher)

Location of Procedure:

(Building and room)

Applicable Chemicals in Use:

Safety Office: 227-7443

2. Process or Experiment Description

This standard operating procedure (SOP) is intended to provide general guidance on how to safely work with flammable materials. This general use SOP only addresses safety issues specific to flammability hazards of chemicals. In some instances, several general use SOPs may be applicable for a specific chemical (i.e., both general use SOPs for flammable liquids and particularly hazardous substances would apply to benzene). If you have questions concerning the applicability of any item listed in this procedure contact the Principal Investigator/Laboratory Supervisor of your laboratory or Safety Office at x7443

3. Control of Hazards

Hazards:

For the purposes of laboratory safety, both flammable and combustible liquids are considered fire hazards. Flammable liquids have a flash point of less than 100 °F and combustible liquids have a flash point of between 100-200 °F.

Control of Hazards - General

• Do not heat flammable chemicals with an open flame.

• For highly flammable chemicals, avoid static electricity or hot surfaces as they can serve as ignition sources.

• Do not use electrical devices with cracked or frayed electrical wiring.

• When transferring flammable liquid from a bulk container (generally greater than five gallons), the containers must be electrically bonded and grounded.

• Transfer flammable liquids from containers of five gallon-capacity or less inside a laboratory hood (or other area with similar ventilation) to prevent accumulation of flammable concentration of vapors.

Engineering/Ventilation Controls

Flammable and combustible chemicals should be used in lab fume hoods (or other well ventilated areas) whenever possible, especially when used in larger quantities (> 500mL) or when using above room temperature and/or pressure.

If the process does not permit the handing of large quantities of flammable liquids in your fume hood, contact the

Safety Office to review the adequacy of all ventilation measures.

NOTE: Certain flammables that are also considered particularly hazardous substances (i.e., benzene) may require use of a fume hood (due to toxicity potential).

Personal Protective Equipment

• At minimum, safety glasses, long pants, and closed toed shoes are to be worn when entering laboratories having hazardous chemicals in use.

• When handling flammable or combustible chemicals or contacting potentially contaminated surfaces, protective

gloves are to be worn. For proper selection of glove material, review chemical SDS and glove manufacturer guidelines.

• Goggles (vs. safety glasses) are appropriate in processes where splash or spray is foreseeable.

• For flammable and combustible chemicals that are toxic via skin contact/absorption, additional protective clothing

(i.e., faceshield, apron, oversleeves) is appropriate where chemical contact with body/skin is foreseeable.

4. Special Handling Procedures and Storage Requirements.

Storage:

Maximum Container Size for Point of Use Storage:

The potential fire hazard depends on the flash point and the quantity of liquid being used. The following table gives the maximum size container allowed for each class of liquid:

Type IA IB IC II III

Glass or Plastic 1 gal. 1 gal. 1 gal. 1 gal. 1 gal.

Metal

Safety Cans

1 gal. 5 gal. 5 gal. 5 gal. 5 gal.

2 gal. 5 gal. 5 gal. 5 gal. 5 gal.

Maximum Quantities:

The potential fire hazard also depends on the total quantity of flammable and combustible liquids present within a containment unit and the type of containers in which the liquids are stored. The maximum quantity allowed per unit is as follows:

Shelf or open storage/use

Glass, plastic, or metal can

Safety cans

10 gallons

25 gallons

Approved storage cabinets

Class I & II

Class III (Max 2 per unit)

60 gallons

120 gallons

Inside Storage Room (meeting NFPA Code recommendations)

With sprinkler

Without sprinkler

4-10 gal/ft

2-4 gal/ft 2

2

It should be emphasized that the quantity of flammables on hand must be kept to a minimum and that only in unusual circumstances will the maximum quantities be permitted. The following guidelines have been adopted by the

University:

• If a one gallon quantity of one specific liquid represents more than a thirty day supply of a Class IA or IB flammable, one-pint (IA) or one-quart (IB) shall be used.

• Multiple cans and/or bottles of any one specific flammable will not be permitted in open storage or storage cabinet if it represents more than a thirty day supply of that flammable.

• Deviations from these guidelines may be granted in exceptional cases following approval by the Safety Office.

Gasoline must be stored and transported on campus in safety cans. The use of safety cans in laboratories is encouraged where practicable. Class I liquids shall not be transferred between metal containers unless the containers are electrically interconnected by direct bonding or by indirect bonding through a common ground. The maximum impedance of the bond shall not exceed 6 ohms.

Storage Cabinets: Storage cabinets constructed to NFPA standards should be used when required. Storage cabinets are not permitted in hallways. A central storage room is preferable to storage cabinets in each laboratory and should be considered when practical.

Refrigerator Storage: Flammable liquids must not be stored in domestic type refrigerators. Domestic type refrigerators should not be purchased for laboratory use, even if flammable storage is not contemplated, since future research

needs may require the use of flammables. Safety refrigerators, which have the electrical contacts (door switch, light, thermostat, etc.) removed or exteriorized, are recommended for laboratory use. "Explosion Proof" refrigerators are not recommended except in unusual circumstances, such as in an inside storage room (for flammables) or in potentially hazardous atmospheres. Domestic type refrigerators currently in laboratories should be labeled

"DANGER/UNSAFE FOR STORAGE OF FLAMMABLES" and also “NOT FOR FOOD STORAGE.”

Handling:

Use prudent practices to minimize the fire risk and exposures to flammable and combustible liquids:

• All sources of ignition (e.g., Bunsen burners, hot plates, open flames, electrical equipment that is not intrinsically safe, etc.) should be eliminated from areas in which flammable or combustible materials are used.

• Utilize a chemical fume hood or other local exhaust to capture vapors when significant quantities of flammable substances are being used.

• Ensure proper grounding and avoid creating static electricity. Confirm that metal containers have been grounded before transferring flammable liquids

• Keep containers of flammable chemicals closed at all times when not in use.

• Avoid wearing plastic or rubber aprons when utilizing flammable and combustible liquids.

Note: Due to the potential fire hazard, the use of portable containers of liquefied gases having a water capacity greater than 2½ pounds (Nominal 1 pound LP-Gas capacity) must be approved by the Safety Office

Stationary liquefied petroleum gas installations shall be in accordance with applicable OSHA, DOT, and North Carolina

State Building Code regulations.

5. Spill and Accident Procedures

The designation of a spill as a minor or major spill will depend upon the hazard of the chemical in question, as well as the risks involved within the laboratory environment. The quantities that justify considering a spill as a “major spill” will be left up to the discretion of the PI.

Minor Spills

1.

Notify fellow workers in vicinity of spill.

2.

Secure area, by restricting access and posting signs.

3.

Remove any potential ignition sources and unplug nearby electrical equipment.

4.

In case of an injury or chemical contamination: a.

Wear PPE and move victim from spill area. b.

Locate nearest emergency safety shower or eyewash. Remove contaminated clothing and flush affected areas with copious amounts of water for 15 minutes. c.

If first aid trained, administer first aid as appropriate. Assist person to University Health Services for treatment. If possible, bring chemical label or SDS.

5.

Gather chemical’s SDS for a hazard assessment and other pertinent information.

6.

If the area’s ventilation system recirculates the air throughout the building, contact Facilities Management at x7224 to have the ventilation shut down to prevent the spread of vapor throughout the building. In addition, close any open doors to also help prevent the spread of vapors

7.

Locate an appropriate Spill Kit, if available.

8.

Don appropriate personal protective equipment (PPE) which usually includes chemical splash goggles, gloves, apron or lab coat. If high splash potential exists, also wear a face shield and protective clothing.

9.

Confine and contain spill. Cover spill with appropriate absorbent material and neutralizing agent (when applicable).

10.

Clean up spill using a scoop or other suitable item and place material in appropriate disposal container.

11.

Decontaminate spill surface with mild detergent and water, as appropriate. Carefully remove PPE, place nonreusable items in disposal container and thoroughly wash hands.

12.

Complete a hazardous waste label and affix label to container.

13.

Replenish spill kit.

14.

If the areas ventilation was turned off, have it reactivated and allow the area an hour to circulate before reentry.

Major Spills

1.

Notify and evacuate fellow workers to a safe area. Post signs. DO NOT ATTEMPT TO CLEAN A MAJOR SPILL!

2.

If spill poses a fire hazard, activate nearest fire alarm. Call University Police at x8911 and give details of spill including specific location, chemical, quantity, and if anyone is injured.

3.

University Police will contact the Safety Office and either Safety Office staff or outside personnel will respond to the spill.

4.

Staff knowledgeable about the spill should provide responders with all pertinent information and SDSs.

5.

The responders or designee will inform staff when it is safe to re-enter spill area.

6.

Investigate cause of spill. Document spill, response and follow-up with staff and Safety Office.

6. Waste Disposal

Many flammable and combustible liquids will likely be considered hazardous waste. Refer to the WCU CHP and chemical SDS sheets for determination.

7. Minimum Training Requirements

• Chemical Safety for Laboratories

• Laboratory-specific training

• Fire Extinguisher training

8. Approval Request

Reference the WCU CHP to determine the need for prior approval for high risk procedures. Approval must be granted from the PI and the Safety Office and documented in writing.

9. Decontamination Procedures

Personnel: If immediate medical attention is required, call x8911 during normal business hours or x9-911 outside of normal business hours. Remove any contaminated clothing, and IMMEDIATELY flush contaminated skin with water for at least 15 minutes following any skin contact. For eye exposures, IMMEDIATELY / flush eyes w/ water for at least 15 minutes.

Consult SDS for guidance on appropriate first aid. Where medical attention is required, ensure to bring along

SDS(s) of chemical(s) to aid medical staff in proper diagnosis and treatment.

Area: Decontamination procedures vary depending on the material being handled. The toxicity of some materials can be neutralized with other reagents. All surfaces should be wiped with the appropriate cleaning agent following dispensing or handling. Waste materials generated should be treated as a hazardous waste.

10. Designated Area

For flammable and combustible liquids that are also considered particularly hazardous substances, a designated area shall be established per the other applicable SOP(s).