Reliability-Based Optimization Using Evolutionary Algorithms Please share

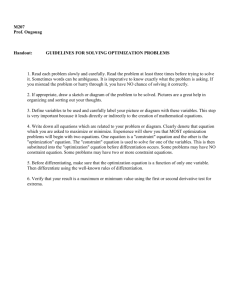

advertisement