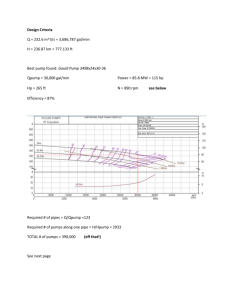

Georgia Vegetable Extension-Research Report 2001

advertisement