Resilient Modulus and Strength of Base Course with Recycled Bituminous Material 2007-05

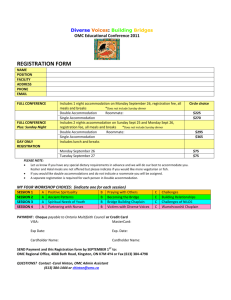

advertisement