Development of a Concrete Maturity Test Protocol

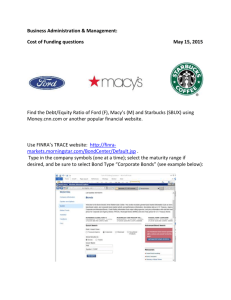

advertisement