PCC Surface Characteristics – Rehabilitation MnROAD Study

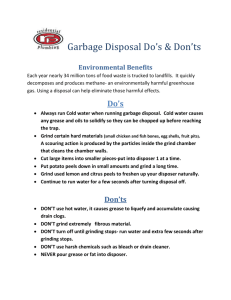

advertisement