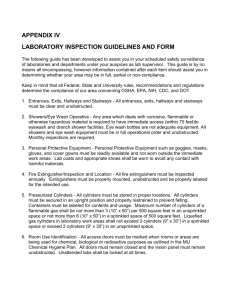

Safety and Risk Management Office Laboratory Safety Inspection Checklist

advertisement

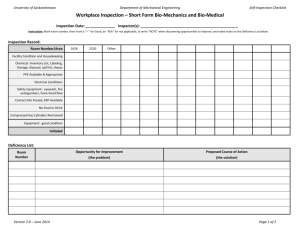

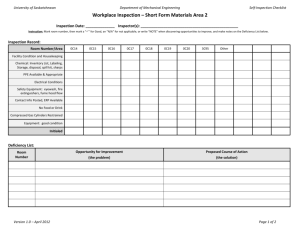

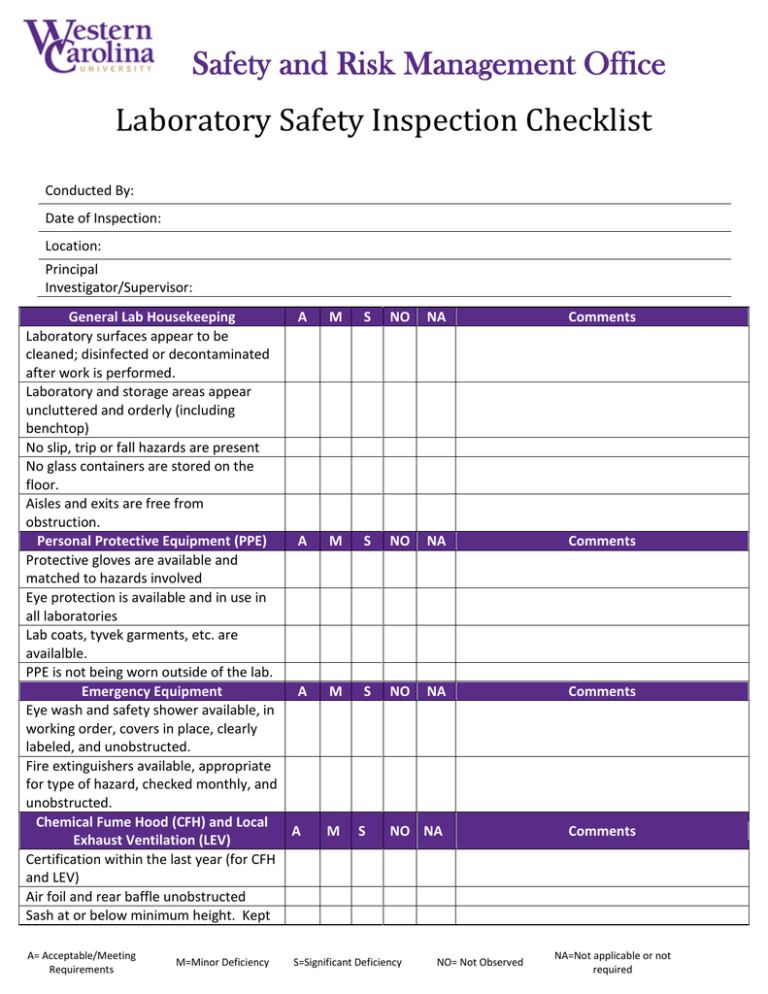

Safety and Risk Management Office Laboratory Safety Inspection Checklist Conducted By: Date of Inspection: Location: Principal Investigator/Supervisor: General Lab Housekeeping A Laboratory surfaces appear to be cleaned; disinfected or decontaminated after work is performed. Laboratory and storage areas appear uncluttered and orderly (including benchtop) No slip, trip or fall hazards are present No glass containers are stored on the floor. Aisles and exits are free from obstruction. Personal Protective Equipment (PPE) A Protective gloves are available and matched to hazards involved Eye protection is available and in use in all laboratories Lab coats, tyvek garments, etc. are availalble. PPE is not being worn outside of the lab. Emergency Equipment A Eye wash and safety shower available, in working order, covers in place, clearly labeled, and unobstructed. Fire extinguishers available, appropriate for type of hazard, checked monthly, and unobstructed. Chemical Fume Hood (CFH) and Local A Exhaust Ventilation (LEV) Certification within the last year (for CFH and LEV) Air foil and rear baffle unobstructed Sash at or below minimum height. Kept A= Acceptable/Meeting Requirements M=Minor Deficiency M S NO NA Comments M S NO NA Comments M S NO NA Comments NO NA Comments M S S=Significant Deficiency NO= Not Observed NA=Not applicable or not required Safety and Risk Management Office closed when not in use. CFH not being used as storage. No blockage in front of CFH Gas Cylinders A All cylinders are properly chained/secured. Cylinder caps are in place on reserve cylinders. Cylinders are properly marked with contents and empty cylinders are labeled “EMPTY” Full and empty cylinders are stored separately. Chemical Storage and Hazard A Communication Inventory and SDS binders are complete. Primary and secondary chemical containers are labeled with identity, appropriate hazard warnings, and expiration dates. Peroxide formers are labeled with date opened. Incompatible materials are segregated properly. No hazardous chemicals are stored above eye level. No chemicals are stored in the floor. Chemical containers are kept tightly closed. Unnecessary, unused, or outdated materials are removed from laboratories and chemical storage areas. Flammable liquid storage cabinets are proper labeled, close properly, and have no materials stored on top of them. Waste Management A Hazardous waste containers are labeled with contents, date, and generator name and kept closed. Hazardous wastes are not accumulated for longer than 60 days in the laboratory. Waste streams are separated as necessary (Solid vs liquid, hazardous vs. non-hazardous, halogenated vs. nonhalogenated, etc.) A= Acceptable/Meeting Requirements M=Minor Deficiency M M M S S S NO NA Comments NO NA Comments NO Comments S=Significant Deficiency NA NO= Not Observed NA=Not applicable or not required Safety and Risk Management Office Syringes and other sharp waste is disposed of in sharps container. General Practice and Procedures A M Food for human consumption stored outside the lab. Food products used in the laboratory (baking soda, vinegar, corn syrup, etc) must be labeled “Lab Use Only” No evidence of eating, drinking, smoking, applying cosmetics, or mouth pipetting. Refrigerators, microwave oven(s), etc labeled “Not for Food Use, Lab Use Only.” Proper signage – UV, Laser, Radioactive, Biohazard, etc on door and laboratory equipment. Lab SOPs are present and signed off on Fire Protection and Means of Egress A M Sprinkler heads are free and unobstructed with 18 inch clear plane below sprinkler heads. All fire-doors are self-closing and kept closed. Fire pull stations are accessible and unobstructed. Emergency evacuation routes are posted in common hallways. Electrical Yes Equipment does not have frayed or damaged wiring Extension cords are not being used as permanent wiring. Power strips are suitable for the load involved and are plugged directly into the outlet (not “daisy-chained”). Cold Room Yes Cold room has emergency release. No cardboard storage Asphyxiants and hazardous gases in ventilated rooms only. Special Hazards/Concerns A= Acceptable/Meeting Requirements M=Minor Deficiency S NO NA Comments S NO NA Comments No N/A Comments No N/A Comments S=Significant Deficiency Registered w/ Safety Office NO= Not Observed NA=Not applicable or not required Y N Safety and Risk Management Office Biosafety Level 2 Safety Checklist Only complete this section for BSL-2 Laboratories Yes No N/A Comments Access to laboratory: Appropriate biohazard sign posted on laboratory door. Information is accurate and current. Sign is legible and not defaced. Laboratory design: Laboratory has limited access (locking door), non-porous furniture, and a Handwashing sink near the exit. Decontamination: Decontaminate is effective for organism(s) in use and work surfaces decontaminated before and after each procedure, daily, and after spills. Waste: Double bags are used and individually sealed. Boxes are not overfilled (weigh <30 lbs). Boxes are properly labeled and closed. Mixed waste is biologically decontaminated prior to disposal as chemical or radiological waste. PPE: Gloves are worn when handling infectious materials or contaminated equipment. Hands are washed after removing gloves, working with infectious agent, and before leaving lab. Hand soap is available at all times. Biological safety cabinet (BSC): Certification has been completed within the last year, front grill and exhaust filters are unobstructed, open flames not used in cabinet. Vacuum lines have in-line filters and disinfectant traps. Traps on floors have secondary containment. Practices: BSC used when potential for creating infectious aerosols/splashes exists (Centrifuge cups and rotors opened only in BSC). Biosafety manual and SOP available in the lab. Needle-locking syringes/single use needles used with infectious agents. Infectious materials transported outside the lab in approved safety carriers. A= Acceptable/Meeting Requirements M=Minor Deficiency S=Significant Deficiency NO= Not Observed NA=Not applicable or not required Safety and Risk Management Office Laser Safety Checklist Only complete this section for laboratories that contain laser devices Yes No N/A Comments SOP is kept with laser equipment and has all authorized users and training dates listed. Laser (Class 3b or 4) has been registered with the Safety Office Protective housing is intact. Access to laser controlled to prevent persons from accidental exposure to laser beams by posting/controlling entrance. Laser controlled areas are posted with appropriate signage. Beam stops present at end of all beam paths and non-combustible? A= Acceptable/Meeting Requirements M=Minor Deficiency S=Significant Deficiency NO= Not Observed NA=Not applicable or not required