MODULAR STORAGE MAGAZINE, BOX-TYPE STD 421-80-07 WITH 10’-8" DOOR G-001 4

advertisement

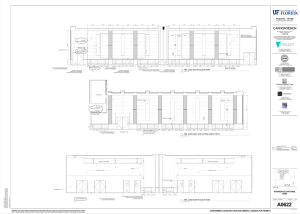

A 5 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 Sheet 1 A Sheet reference number: G-001 of 24 STANDARD DESI GN DRAW I NGS -FI NAL 1 Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on RSW Dat e: Dr awi ng code: Revi si ons MODULAR STORAGE MAGAZINE, BOX-TYPE STD 421-80-07 WITH 10’-8" DOOR Descr i pt i on Dat e US Army Corps AS SHOW N No. Appr . D Checked by: C 2 DECEM BER 2011 2 Scal e: Dat e: 3 JM U JM U 4 Dr awn by: Desi gned by: 5 COVER SHEET M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 B U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A *** SAFETY FIRST *** 1 US Army Corps of Engineers Huntsville Center D of Engineers Huntsville Center C B *** SAFETY FIRST *** 4 5 3 2 GENERAL ABBREVIATIONS 1 US Army Corps DRAWING SYMBOLS of Engineers REFERENCE NO. 1 A-104 A-104 A-101 A-501 SHEET WHERE ELEVATION IS DRAWN SHEET WHERE DETAIL IS TAKEN SHEET WHERE DETAIL IS DRAWN Revi si ons SHEET WHERE ELEVATION IS TAKEN Dat e 1 D DETAIL REFERENCE No. Descr i pt i on ELEVATION REFERENCE 2 DECEM BER 2011 CUTTING PLANE STRUCTURAL A ELECTRICAL SHEET REF. NO. DRAWING CODE SHEET TITLE G-001 1 XXXXXX COVER SHEET G-002 2 XXXXXX INDEX, SYMBOLS, & ABBREVIATIONS S-001 3 XXXXXX GENERAL NOTES S-101 4 XXXXXX FOUNDATION PLAN S-102 5 XXXXXX ROOF FRAMING PLAN S-201 6 XXXXXX ELEVATIONS S-202 7 XXXXXX ELEVATIONS S-301 8 XXXXXX BUILDING SECTION S-302 9 XXXXXX BUILDING SECTION S-303 10 XXXXXX SECTIONS S-501 11 XXXXXX TYPICAL DETAILS S-701 12 XXXXXX DOOR FRAME ELEVATION & DETAILS S-701 (A) 13 XXXXXX DOOR FRAME ELEVATION & DETAILS S-702 14 XXXXXX DOOR ELEVATIONS S-702 (A) 15 XXXXXX DOOR ELEVATIONS S-703 16 XXXXXX DOOR SECTIONS S-703 (A) 17 XXXXXX DOOR SECTIONS S-704 18 XXXXXX DOOR DETAILS S-704 (A) 19 XXXXXX DOOR DETAILS S-705 20 XXXXXX HIGH SECURITY HASP S-705 (A) 21 XXXXXX INTERNAL LOCKING DEVICES E-101 22 XXXXXX LIGHTNING PROTECTION SYSTEM E-102 23 XXXXXX LIGHTNING PROTECTION SYSTEM E-103 24 XXXXXX LIGHTNING PROTECTION SYSTEM 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 Dat e: Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on Checked by: A Sheet reference number: G-002 Sheet 2 5 B 1 of 24 STANDARD DESI GN DRAW I NGS -FI NAL GENERAL SHEET NO. M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 DISCIPLINE I NDEX,SYM BOLS, & ABBREVI ATI ONS DRAWING INDEX B Dr awn by: SECTION CUT RSW SHEET WHERE SECTION IS DRAWN JM U SHEET WHERE SECTION IS TAKEN Dr awi ng code: Dat e: A-104 A-104 AS SHOW N 1 C Scal e: REFERENCE NO. JM U C REFERENCE NO. Desi gned by: D ABOVE FINISHED FLOOR ALUMINUM APPROXIMATELY BUILDING BOTTOM BEARING CAST-IN-PLACE CONTROL JOINT CENTER LINE CONCRETE MASONRY UNIT CENTER POINT COLUMN COORDINATE CONCRETE CONTINUE, CONTINUOUS DIAMETER DIAGONAL DIMENSION EACH ELEVATION EACH FACE EXPANSION JOINT EQUAL EACH WAY EXISTING EXTERIOR FOOTING FIELD VERIFY GALVANIZED HEADED HEIGHT INTERIOR INSIDE DIAMETER LONG-LEG HORIZONTAL LONG-LEG VERTICAL MINIMUM MANUFACTURER NOT TO SCALE ON CENTER OUTSIDE DIAMETER OPPOSITE HAND RADIUS REINFORCEMENT REQUIRED SQUARE FEET SHEET SIMILAR SLAB-ON-GRADE STIFFENER TYPICAL UNLESS OTHERWISE NOTED VERIFY IN FIELD WELDED WIRE FABRIC WELDED WIRE REINFORCEMENT WITH WORKING POINT U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A AFF ALUM APPROX BLDG BOTT BRG CIP CJ CL CMU CP COL COORD CONC CONT DIA DIAG DIM EA ELEV EF EJ EQ E.W. (E) OR EXIST EXT FTG FV GALV HD HT INT ID LLH LLV MIN MANF NTS O.C. OD OH R REINF REQ’D SF SHT SIM SOG STIFF TYP UNO VIF WWF WWR W/ WP Appr . Huntsville Center *** SAFETY FIRST *** 4 6.4 BOLTED CONNECTIONS SHALL CONFORM TO RCSC’S "SPECIFICATION FOR STRUCTURAL JOINTS USING ASTM A325 OR A490 BOLTS". ALL BOLTS SHALL BE 3/4" DIAMETER UNLESS OTHERWISE NOTED. 3.1 SEE CIVIL DRAWINGS AND SPECIFICATIONS (PART OF SITE ADAPTION) FOR EARTHWORK PREPARATION OF FOUNDATIONS INCLUDING THE REMOVAL OF ORGANIC MATERIALS, COMPACTING SOILS BENEATH STRUCTURES, BACK FILL REQUIREMENTS FOR OVER EXCAVATION AND REMOVAL OF UNSUITABLE MATERIALS. 1. AMERICAN CONCRETE INSTITUTE (ACI 318) 2. AMERICAN INSTITUTE OF STEEL CONSTRUCTION 3. AMERICAN WELDING SOCIETY, A.W.S. 3.2 MAXIMUM ASSUMED NET SOIL BEARING PRESSURE USED FOR DESIGN: 3000 PSF . B. LIVE LOADS D 3.3 ASSUMED UNIT WEIGHT OF SOIL USED FOR DESIGN: 110 PCF ROOF---------------------100 PSF FLOOR-------------------100 PSF 3.4 ALL FOUNDATION BEARING SURFACES SHALL BE REVIEWED BY THE GEOTECHNICAL ENGINEER PRIOR TO PLACING CONCRETE TO ENSURE THEIR COMPLIANCE WITH THE PRESSURES NOTE ABOVE. SNOW LOAD: GROUND SNOW LOAD (Pg) = 60 PSF IMPORTANCE FACTOR (I) = 1.1 EXPOSURE CATEGORY (Ce) = 1.0 THERMAL CATEGORY (Ct) = 1.0 3.5 ALL FOOTINGS SHALL PROJECT AT LEAST 1’-6" INTO UNDISTURBED NATURAL SOIL OR COMPACTED ENGINEERED FILL HAVING A SOIL BEARING PRESSURE THAT MEETS OR EXCEEDS THAT SPECIFIED ABOVE. 3.6 ALL DISTURBED EARTH UNDER FOOTINGS SHALL BE REPLACED WITH LEAN CONCRETE. US Army Corps 6.5 WELDED CONNECTIONS SHALL CONFORM TO AWS D1.1 "STRUCTURAL WELDING CODE-STEEL". MINIMUM SIZE FILLET WELDS SHALL BE 3/16" UNLESS OTHERWISE NOTED AND ELECTRODES SHALL BE E70xx. WELDERS SHALL BE QUALIFIED IN ACCORDANCE WITH AWS. BASIC WIND SPEED: 130 MPH IMPORTANCE FACTOR (I): 1.15 EXPOSURE CATEGORY: C ENCLOSURE CLASSIFICATION: ENCLOSED 6.7 ALL EXTERIOR STEEL EXPOSED TO THE WEATHER SHALL BE HOT DIPPED GALVANIZED, UON. MEMBERS NOT REQUIRED FOR CORROSION PROTECTION SHALL RECEIVE ONE COAT OF STANDARD PRIMER PAINT. DO NOT PRIME OR PAINT SURFACES WHICH ARE TO RECEIVE FIELD WELDED HEADED SHEAR STUDS. PROVIDE 3" MINIMUM CONCRETE COVER FOR ALL STEEL BELOW GRADE AND PAINT WITH 2 COATS OF COAL TAR EPOXY. EPOXY SHALL MEET THE REQUIREMENTS OF PAINT SPECIFICATION SSPC-PAINT 16. 6.8 ALL STIFFENERS AND GUSSETS PLATES SHALL BE MINIMUM 3/8" THICK, UNLESS OTHERWISE NOTED. 7.0 STRUCTURAL PRECAST CONCRETE 2.3 IT IS THE CONTRACTOR’S RESPONSIBILITY TO DETERMINE CONSTRUCTION METHODS, PROCEDURES, AND SEQUENCES TO ENSURE STABILITY AND SAFETY DURING CONSTRUCTION. THE CONTRACTOR SHALL TAKE NECESSARY PRECAUTIONS TO PROTECT AND MAINTAIN THE STRUCTURAL INTEGRITY OF ALL NEW AND EXISTING CONSTRUCTION AT ALL STAGES. 2.4 SECTIONS AND DETAILS SHOWN ON THE STRUCTURAL DRAWINGS SHALL BE CONSIDERED TYPICAL FOR SIMILAR CONDITIONS THAT DO NOT HAVE A SPECIFIC SECTION INDICATED. 2.5 THE CONTRACTOR SHALL COORDINATE STANDARD DRAWINGS WITH THE VENDOR/MANF. SHOP DRAWINGS TO VERIFY SIZES AND LOCATIONS OF OPENINGS, SLEEVES, INSERTS, DEPRESSIONS, FINISHES, SLOPES, ETC. ANY DISCREPANCY SHALL BE BROUGHT TO THE ATTENTION OF THE CONTRACTING OFFICIER. 2.6 SEE CIVIL SITE LAYOUT DRAWINGS (PART OF SITE ADAPTION) FOR ACTUAL FINISHED FLOOR ELEVATIONS (F.F.E.) FOR ALL BUILDINGS. ELEVATIONS SHOWN IN STRUCTURAL DOCUMENTS WILL BE BASED ON REFERENCED F.F.E. EQUAL TO 100’-0", U.O.N. 4.8 PROVIDE REINFORCING BARS IN CONCRETE FOOTINGS TO MATCH THE SIZE AND SPACING OF THE HORIZONTAL REINFORCING AT ALL CORNERS AND INTERSECTIONS OF STRIP FOOTINGS. PROVIDE LEG LENGTH EQUIVALENT TO CLASS "A" TENSION LAP SPLICE U.O.N. 4.10 FOOTINGS AND SLABS SHALL HAVE NO HORIZONTAL JOINTS (POURED TO THEIR FULL DEPTHS IN ONE OPERATION). ANY STOP IN CONCRETE WORK SHALL BE BULKHEAD AND KEYED, U.O.N. 2. FOUNDATIONS SHALL BE REVISED TO REFLECT SPECIFIC SITE SOIL CONDITIONS INCLUDING LOCAL SITING, TOPOGRAPHIC CONDITIONS, AND FROST PENETRATION DEPTHS. 4.11 REINFORCEMENT SHALL NOT BE BENT OR STRAIGHTENED IN A MANNER THAT WILL DAMAGE THE MATERIAL. BARS WITH WITH KINKS OR IMPROPER BENDS SHALL NOT BE USED. 3. STRUCTURAL COMPONENTS, WITH THE EXCEPTION OF THE FOUNDATION (FOOTINGS), SLAB-ON-GRADE, AND WING WALLS SHALL NOT BE MODIFIED WITHOUT THE APPROVAL OF THE CONTRACTING OFFICIER, WHO SHOULD CONSULT WITH THE U.S. ARMY ENGINEERING AND SUPPORT CENTER, HUNTSVILLE (STRUCTURAL BRANCH). STRUCTURE HAS BEEN DETERMINED TO BE ADEQUATE FOR THE DESIGN CRITERIA LISTED ON THIS SHEET. 4.13 A CLASS C FINISH IS REQUIRED FOR EXPOSED FORMED SURFACES OF PRECAST PANELS. A CLASS D FINISH IS REQUIRED FOR SURFACES WHICH WILL BE BELOW GRADE OR NOT EXPOSED TO VIEW AFTER FINAL ASSEMBLY. 4. SHEETS S701 - S705 (HIGH SECURITY HASP) AND S701(A) - S705(A) (ILD) IDENTIFY TWO DIFFERENT LOCKING SYSTEMS. THE DESIGNER SHALL VERIFY WITH THE CONTRACTING OFFICIER THE CORRECT LOCKING SYSTEM REQUIRED AND REMOVE THE REDUNDANT SHEETS FROM THE CONSTRUCTION CONTRACT DOCUMENTS FOR THE SYSTEM NOT USED. 4.13 REFER TO GEOTECHNICAL REPORT FOR RECOMMENDATIONS RELATIVE TO SUBGRADE PREPARATION FOR SLAB ON GRADE WORK. 2.8 CONTRACTOR SHALL PROVIDE TEMPORARY SHORING AND BRACING OF ALL STRUCTURAL WORK, AND SOIL EXCAVATION AS REQUIRED. SHORING AND BRACING SHALL NOT BE REMOVED UNTIL ALL FINAL CONNECTIONS HAVE BEEN COMPLETED IN ACCORDANCE WITH THE DRAWINGS, AND MATERIALS HAVE ACHIEVED DESIGN STRENGTH. STRUCTURAL DESIGNATION (7-BAR) NOTES: 6.0 STRUCTURAL STEEL 6.1 STRUCTURAL STEEL FABRICATION, ERECTION, AND CONNECTION DESIGN SHALL CONFORM TO A.I.S.C.’S "SPECIFICATION FOR STRUCTURAL STEEL BUILDINGS." A 6.2 STRUCTURAL STEEL SHALL CONFORM TO THE FOLLOWING ASTM DESIGNATIONS: W SHAPES............................................................................ASTM A992 STEEL CHANNELS, ANGLES, PLATES AND BARS: .........ASTM A36 RECTANGULAR, SQUARE, AND ROUND HSS..................ASTM A500, GRADE B STEEL PIPE (HSS)...............................................................ASTM A53, GRADE B 1. ANY DEVIATION FROM THE STANDARD APPROVED DESIGN DRAWINGS FOR THE CONCRETE HEADWALL, STEEL DOOR, CONCRETE ROOF OR THEIR SUPPORTS WITHOUT WRITTEN APPROVAL FROM THE DEPARTMENT OF DEFENSE EXPLOSIVE SAFETY BOARD (DDESB) MAY REQUIRE THE MAGAZINE TO BE CONSIDERED AN UNDEFINED MAGAZINE AND MAY SEVERELY RESTRICT THE ALLOWABLE STORAGE CAPACITY. 2. IF CONSTRUCTED PER THESE DRAWINGS, FACILITY MEETS BLAST-RESISTANT DESIGN CRITERIA FOR A 7-BAR STRUCTURAL DESIGNATION PER DOD 6055.09-M. THIS DESIGNATION IN NO WAY IMPLIES VALIDATION OF THE DESIGN AGAINST OTHER LOAD CASES. 6.3 STRUCTURAL FASTENERS SHALL CONFORM TO THE FOLLOWING ASTM DESIGNATIONS: THREADED RODS..............................ASTM A36 HEADED STUDS.................................ASTM A108, GRADES 1015 TO 1020 (60 KSI TENSILE STRENGTH) 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 1. THIS STANDARD DESIGN DRAWING DATED DECEMBER 2, 2011; STD 421-80-07 SHEETS 1-24, UPDATE AND SUPERSEDE THE STANDARD DESIGN OF AIR FORCE MODULAR STORAGE MAGAZINE, BOX TYPE, STD 421-80-06 (MODIFIED). 2 1 Dat e: Dr awi ng code: Dat e: 4.9 PROVIDE DOWEL TO FOUNDATION WITH 90 DEGREE HOOK TO MATCH SIZE AND SPACING OF VERTICAL REINFORCING AT ALL PEDESTALS, WALLS, AND COLUMNS. 1. THE MAGAZINE HAS BEEN ANALYZED FOR THE LOADS LISTED ON THIS SHEET AND DETERMINED TO BE ADEQUATE UNDER THESE LOADINGS. HOWEVER, THE DESIGNER SHOULD VERIFY THE STRUCTURE FOR THE SITE-SPECIFIC LOADING CRITERIA. IF SITE-SPECIFIC LOADS EXCEED THESE LISTED ON THIS SHEET, THE DESIGNER SHOULD ADDRESS ALL DEFICIENCIES THAT DONT MEET CURRENT BUILDING CODES. 4.12 REINFORCEMENT SHALL BE CONTINUOUS THROUGH ALL CONSTRUCTION JOINTS, BUT DISCONTINUOUS THROUGH ALL CONTROL JOINTS, U.O.N.. 2.7 ANY DISCREPANCIES BETWEEN DRAWINGS, SPECIFICATIONS, REFERENCE STANDARDS, OR GOVERNING CODE, THE MORE STRINGENT REQUIREMENTS SHALL GOVERN. CONTRACTOR SHALL NOTIFY THE CONTRACTING OFFICIER OF DISCREPANCIES AND OBTAIN DIRECTION PRIOR TO PROCEEDING. DESIGNER NOTES: TO BE REMOVED WHEN PREPARING CONSTRUCTION DRAWINGS FOR SITE ADAPTION OF THIS DESIGN. B A Sheet reference number: S-001 Sheet 3 of 24 STANDARD DESI GN DRAW I NGS -FI NAL 2.2 THE STRUCTURE (MEMBERS AND CONNECTIONS) HAS BEEN DESIGNED TO SUPPORT IN-PLACE DESIGN LOADS ONLY. THE CONTRACTOR SHALL BE RESPONSIBLE FOR LIMITING CONSTRUCTION LOADS SUCH THAT THESE LOADS DO NOT EXCEED THE DESIGN LOADS NOTED ABOVE. Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on CONCRETE CAST AGAINST EARTH:......................................3 INCHES FORMED CONCRETE EXPOSED TO EARTH OR WEATHER: NO. 6 BAR AND LARGER.............................................2 INCHES NO. 5 BAR AND SMALLER.....................................1 1/2 INCHES CONCRETE NOT EXPOSED TO WEATHER: SLABS, WALLS, JOISTS...............................................1 INCHES BEAMS AND COLUMNS.........................................1 1/2 INCHES SLAB ON GRADE.......................................MID-DEPTH OF SLAB RSW 2.1 CONTRACTOR SHALL VERIFY ALL DIMENSIONS AND SITE CONDITIONS PRIOR TO CONSTRUCTION/FABRICATION. CONTRACTOR SHALL NOTIFY CONTRACTING OFFICIER OF ANY DISCREPANCIES PRIOR TO CONSTRUCTION. GENERAL NOTES 4.7 CONCRETE COVERAGE OF REINFORCEMENT U.ON.: Checked by: 2.0 GENERAL 8.1 ALL METAL PARTS, TO INCLUDE REINFORCEMENT IN FLOOR, PRECAST WALLS AND ROOF PANELS, LOUVERS, VENTILATORS, DOORS AND DOOR FRAME, SHALL BE MADE ELECTRICALLY CONTINUOUS BY BONDING (BRAZING OR WELDING) AT 5 LINEAR FEET INTERVALS. ELECTRICAL CONTINUITY SHALL BE PROVIDED ACROSS FLOOR EXPANSION AND ISOLATION JOINTS TO FOUNDATION PEDESTALS AND PRECAST ROOF PANELS, AND BETWEEN PRECAST WALLS AND CONCRETE PEDESTAL FOOTING SHALL BE PROVIDED DURING CONSTRUCTION. ACCEPTABLE CONTINUITY METHODS ARE REINFORCING BARS, COPPER STRAPS, ETC. SEE ELECTRICAL DRAWINGS FOR ADDITIONAL INFORMATION REGARDING LPS. M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 4.6 REINFORCING SHALL BE CONTINUOUS WITH CLASS "B" TENSION LAP SPLICES, U.O.N. 8.0 LIGHTNING PROTECTION SYSTEM (LPS) JM U 4.5 FABRICATE AND PROVIDE BAR SUPPORTING ACCESSORIES IN ACCORDANCE WITH ACI MANUAL OF STANDARD PRACTICE AND C.R.S.I. SPECIFICATIONS. REINFORCING SHALL NOT BE WELDED IN ANY MANNER U.O.N. IN CONSTRUCTION DOCUMENTS. Desi gned by: »¿SOIL DENSITY (˛‡): 110 »¿ANGLE OF INTERNAL FRICTION OF THE SOIL (ˇ) : 30 DEG EFP: 60 PSF PER FOOT OF DEPTH 7.5 ALL GROUT SHALL BE NON-SHRINK, NON-METALLIC WITH F’c = 6000 PSI. AS SHOW N 7.4 CONCRETE SHALL HAVE A MINIMUM COMPRESSIVE STRENGTH AT TWENTY-EIGHT DAYS OF 4000 PSI. C Scal e: 4.3 REINFORCING BARS SHALL BE DEFORMED TYPE CONFORMING TO ASTM A615 GRADE 60 U.O.N. 4.4 WELDED WIRE REINFORCEMENT SHALL CONFORM TO ASTM A185. MINIMUM LAP AND EMBEDMENT TO BE THE GREATER OF ONE CROSS WIRE SPACING PLUS 2" OR 6", WHICHEVER IS GREATER. 5 Descr i pt i on 7.3 THERE SHALL BE NO FIELD CUTTING OF PRECAST ELEMENTS WITHOUT THE APPROVAL OF THE CONTRACTING OFFICIER. JM U 4.2 ALL CONCRETE SHALL HAVE A MINIMUM COMPRESSIVE STRENGTH OF 4000 PSI AT 28 DAYS, U.O.N. ALL CONCRETE SHALL CONFORM TO ASTM C94. 7.2 THE PRECAST MANUFACTURER SHALL BE RESPONSIBLE FOR COORDINATION OF ALL DISCIPLINES AS THEY EFFECT THE PRECAST ELEMENTS. Dr awn by: ACI 301---------------"STANDARD SPECIFICATIONS FOR STRUCTURAL CONCRETE" ACI 315---------------"MANUAL OF STANDARD PRACTICE FOR DETAILING REINFORCED CONCRETE STRUCTURES" ACI 318---------------"BUILDING CODE REQUIREMENTS FOR STRUCTURAL CONCRETE" No. OCCUPANCY CATEGORY=III Ie= 1.25 Ss= 0.65 Sds= 0.49 S1= 0.18 Sd1= 0.19 SITE CLASS: C BASIC SEISMIC-FORCE RESISTING SYSTEM= IMTERMEDIATE PRECAST SHEAR WALLS SEISMIC DESIGN CATEGORY= C ANALYSIS PROCEDURE = EQUIVALENT LATERAL FORCE PROCEDURE 7.1 ALL PRECAST ELEMENTS NOT DETAILED ON DRAWINGS SHALL BE DESIGNED FOR THE SPAN AND CONCRETE AND CONSTRUCTION LOADING CONDITIONS SHOWN ON THE DRAWINGS BY A LICENSED STRUCTURAL ENGINEER. ALL DESIGN CALCULATIONS, INCLUDING THE DESIGN OF ALL STRUCTURAL ELEMENTS AND LIFTING POINTS SHALL BE SUBMITTED TO THE CONTRACTING OFFICIER FOR REVIEW PRIOR TO THE START OF FABRICATION. 2 DECEM BER 2011 4.1 ALL CONCRETE WORK INCLUDING DETAILING, FABRICATION, PLACEMENT OF REINFORCING, MIXING, HANDLING, PLACING, FINISHING, AND CURING SHALL CONFORM TO THE FOLLOWING DOCUMENTS: E. SOILS B D 4.0 CONCRETE D. EARTHQUAKE: C Huntsville Center 6.6 UNLESS SPECIFICALLY DETAILED ON THE CONTRACT DRAWINGS, ALL FRAMED BEAM CONNECTIONS SHALL BE DESIGNED BY A QUALIFIED PROFESSIONAL ENGINEER EMPLOYED BY THE FABRICATOR. STANDARD BEAM CONNECTIONS (NON-COMPOSITE) SHALL BE DESIGNED BASED ON A REACTION EQUAL TO ONE-HALF THE MAXIMUM TOTAL UNIFORM LOAD CAPACITY FROM AISC’S "MAXIMUM TOTAL UNIFORM LOAD" TABLE MULTIPLIED BY A FACTOR OF 1.2, UNLESS REACTIONS ARE SHOWN ON STRUCTURAL DRAWINGS. MINIMUM REACTION TO DESIGN FOR SHALL BE (12.0 KIPS). C. WIND LOAD: 3.7 CONCRETE SHALL NOT BE PLACED OVER FROZEN SOIL OR FOOTING EXCAVATIONS SUBJECTED TO WATER. of Engineers Appr . A. BUILDING CODES AND SPECIFICATIONS: 1 Dat e 3.0 FOUNDATIONS 2 Revi si ons 1.0 DESIGN CRITERIA: 3 U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A 5 *** SAFETY FIRST *** 4 5 3 2 1 26’-4" 8" 25’-0" 8" US Army Corps B DRAIN TO REAR IF REQ’D of Engineers Huntsville Center 1 S101S201 TYP. Appr . S101S303 D 2 DECEM BER 2011 SCALE:14"=1’-0" Dat e: A 1. TOP OF SLAB (FINISH FLOOR ELEVATION) = 100’-0" U.O.N. S101S202 C.J. B 6. SIZE, LOCATION, AND QUANTITY OF TILT-UP BRACE ATTACHMENT POINTS AND LIFTING INSERTS TO BE DETERMINED BY CONTRACTOR/PRECAST MANF.. 20’ 0"M I N.-80’ 0"M AX. ( NOM I NAL BUNKER LENGTH) C. J. S101S301 7. IT IS THE RESPONSIBILITY OF THE SITE ADAPTION ENGINEER TO MODIFY THESE DRAWINGS TO MEET LOCAL SITING, FOUNDATION, AND TOPOGRAPHIC CONDITIONS. 8. PANELS MAY BE PRECAST BY A MANUFACTURER SPECIALIZING IN PRECAST OR PRECAST AT THE JOB-SITE. 2 TYP. S101S303 3 JM U Checked by: 5. WATERPROOF ALL SURFACES OF THE SHELTER WHICH WILL BE IN CONTACT WITH EARTH FILL AFTER SHELTER IS ERECTED. A Dr awn by: Desi gned by: 4. PROVIDE 24" OF EARTH COVER MINIMUM ON ROOF. U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A 1" SLOPE FROM CENTER 1" SLOPE FROM CENTER JM U 3. PLACE CONTROL JOINTS IN SLAB-ON-GRADE AT 18’-0" O.C. (MAX.). CONTROL JOINTS SHALL BE COMPLETED AS SOON AS POSSIBLE. RSW 2. SLAB-ON-GRADE: 6" CONCRETE ON 4" CAPILLARY WATER BARRIER AND VAPOR BARRIER, REINFORCED WITH 6x6 W2.9xW2.9 WWF SUPPORTED 2" FROM TOP OF SLAB UNO. B TYP. A A 20’-0" B A S101S303 S101S303 S101S302 8’-10" 26’-1" A B S101S303 S101S303 8’-10" Sheet reference number: 8" DIA. PIPE BOLLARD WITH DOOR BUMPER (INDUSTRIAL GRADE) AND CHAIN (OPTIONAL) S-101 S101S201 5 4 A 20’-0" (NOTCH FOR DOOR FRAME) A FOUNDATI ON PLAN M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 10’ 2" 0" 2’ 7" 2’ EY L L A V 4’ 0" VA L L EY 1" SLOPE 1" SLOPE 5’ 7" S101S303 Sheet 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 1 of 24 STANDARD DESI GN DRAW I NGS -FI NAL Dat e: C. J. FOUNDATION PLAN Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on N C AS SHOW N CONTROL JOINT (C.J.) SEE TYP. DETAILS Dr awi ng code: WALL JOINT, TYP. SEE ELEVATIONS Scal e: 1" SLOPE FROM CENTER No. RI DGE 6" DIA. CONT. FOOTING DRAIN. ELEVATIONS, SLOPES, AND OUTLETS TO BE ESTABLISHED WHEN STRUCTURE IS SITE ADAPTED. SEE SECTIONS FOR MORE DETAILS. 1" SLOPE FROM CENTER C Descr i pt i on Revi si ons Dat e D *** SAFETY FIRST *** 4 5 3 2 1 US Army Corps of Engineers Huntsville Center 1" OVERHANG 26’-4" Appr . 26’-6" 1" OVERHANG D D Dat e B S102 S201 PRECAST ROOF PANEL SPAN Revi si ons 8" DEPTH GAUGE, TYP AT 9 LOCATIONS. PLACE 3 ON EACH LONGITUDINAL EDGE AND 3 DOWN THE MIDDLE OF THE ROOF COIL, INSERT TYP. AT ROOF PANELS BY PRECAST MANF. 4 Descr i pt i on S102S303 2 DECEM BER 2011 No. PRECAST ROOF PANEL, SEE TYP. DETAILS 3. SIZE, LOCATION, AND QUANTITY OF TILT-UP BRACE ATTACHMENT POINTS AND LIFTING INSERTS TO BE DETERMINED BY CONTRACTOR/PRECAST MANF.. S102 S301 4. IT IS THE RESPONSIBILITY OF THE SITE ADAPTION ENGINEER TO MODIFY THESE DRAWINGS TO MEET LOCAL SITING, FOUNDATION, AND TOPOGRAPHIC CONDITIONS. B PRECAST ROOF PANEL SPAN 3’-0" 5. PANELS MAY BE PRECAST BY A MANUFACTURER SPECIALIZING IN PRECAST OR PRECAST AT THE JOB-SITE. 4’-0" 6. PROVIDE ELECTRICAL CONTINUITY WITHIN THE PRECAST ROOF PANELS BY WELDING AT 5 LINEAR FEET INTERVALS ACROSS TOP OF STIRRUPS TO END ANGLES IN ONE DIRECTION. IN THE OTHER DIRECTION, WELD #4 BAR FROM BOTTOM PLATE TO #4 REINF. 3’-0" PRECAST ROOF PANEL SPAN 2’-6" VENTILATOR, SEE TYP. DETAILS 3’-0" (TYP.) PORTAL WALL CAP PANEL A A JM U M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 (TYP.) Dat e: B A A S102S302 S102 S201 Sheet reference number: S-102 Sheet 5 5 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 1 of 24 STANDARD DESI GN DRAW I NGS -FI NAL 2. WATERPROOF ALL SURFACES OF THE SHELTER WHICH WILL BE IN CONTACT WITH EARTH FILL AFTER SHELTER IS ERECTED. ROOF FRAM NG PLAN 1. PROVIDE 24" OF EARTH COVER MINIMUM ON ROOF. Checked by: PRECAST ROOF PANEL SPAN Dr awn by: JM U SCALE:14"=1’-0" U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A Desi gned by: ROOF FRAMING PLAN RSW N S102S202 A Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on Dat e: 20’ 0"M I N.-80’ 0"M AX. ( NOM I NAL BUNKER LENGTH) A Dr awi ng code: TYP. S102S303 AS SHOW N 5 PRECAST ROOF PANEL SPAN C Scal e: C *** SAFETY FIRST *** 4 5 3 2 1 US Army Corps of Engineers Appr . Huntsville Center 43’-9" D 28’-7" 7’-7" D-RING ANCHOR, BOLTED TO CIP CONC. WALL FOR DOOR CATCH WHEN DOOR IS OPEN, TYP. (IF BOLLARD OPTION ISN’T CHOSEN) Descr i pt i on A A B S201S303 S201S302 S201S303 S201S303 SCALE:14"=1’-0" S101S201 S102 A S201S302 VENT ASSEMBLY, SEE TYP. DETAILS B EXTENTS OF FRONT WALL ELEVATION BEYOND. LIFTING INSERT (TYP.), BY PRECAST MANF. 26’-4" A WALL ELEVATION SCALE:14"=1’-0" Dat e: AS SHOW N M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 9’ 0" 11’ 0" 12’-2" BACK WALL PANEL No. A WALL ELEVATION B A B Sheet reference number: S101S201 S102 S-201 Sheet 6 5 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 1 of 24 STANDARD DESI GN DRAW I NGS -FI NAL A Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on (NOTCH FOR DOOR FRAME) RSW 4" ELEVATI ONS 20’-0" Dr awi ng code: 8’-10" JM U S201S303 PRECAST MANF.: COORDINATE LOCATION OF WEEPS TO MINIMIZE INTERFERENCE WITH REINF. AND HEADED STUDS 26’-1" Desi gned by: B 8’-10" Checked by: 20’-0" 4" CAST-IN-PLACE CONCRETE WALL C Scal e: C 1’ 0" 1’ 3" 3" DIA. PVC WEEPS FINISHED GRADE 2 DECEM BER 2011 1’-6" 3" DIA. PVC WEEPS U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A 9’-0" D-RING ANCHOR, WELDED TO DOOR FOR DOOR CATCH WHEN DOOR IS OPEN, TYP. LIFTING INSERT (TYP.), BY PRECAST MANF. Dat e: SEE ELEVATION A/S701 FOR DOOR FRAME ELEV. PORTAL WALL PANEL 11’ 4" RIGHT DOOR, SEE ELEV. B/S702 DOOR HANDLE, SEE DETAIL 12/S704 OR 1/S704 (A) 4" 11’ 4" LEFT DOOR, SEE ELEV. A/S702 10’ 1" BETWEEN DOORS JM U 1/2" MARGIN PORTAL WALL PANEL Revi si ons PANEL-TO PANEL TBD DOOR HANDLE, SEE DETAIL 8/S704 (HASP OPTION) 3/8" 3/8" 2’ 6" CAP WALL PANEL 3’ 10" PRECAST ROOF PANEL BEYOND 3" MI N. 8" DIA. PIPE BOLLARD WITH DOOR BUMPER (INDUSTRIAL GRADE) AND CHAIN (OPTIONAL) Dat e VENT ASSEMBLY, SEE TYP. DETAILS Dr awn by: 7’-7" D *** SAFETY FIRST *** 4 5 3 2 1 US Army Corps of Engineers Appr . Huntsville Center VENT ASSEMBLY, SEE TYP. DETAILS A SEE DETAIL 4/S303 S202 S301 Descr i pt i on 2 DECEM BER 2011 No. 2’-0" 2’ 0" SIDE WALL PANEL 11’ 0" LIFTING INSERT, (TYP.), BY PRECAST MANF. PANEL-TO PANEL PANEL JOI NT EXTENTS OF SIDE WALL PANEL Revi si ons PRECAST ROOF PANELS, SEE TYP. DETAILS 3/8" 3/8" D Dat e D Dat e: RSW Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on A B ELEVATI ONS M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 B A Sheet reference number: S-202 Sheet 7 5 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 1 of 24 STANDARD DESI GN DRAW I NGS -FI NAL Dr awn by: U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A Desi gned by: Dr awi ng code: S101S202 S102 JM U SCALE:14"=1’-0" Dat e: A WALL ELEVATION Checked by: (TYP. SIDE WALL PANEL LENGTH) AS SHOW N LENGTH AS REQ’D Scal e: 20’-0" C JM U C *** SAFETY FIRST *** 4 5 3 2 1 L3 1/2"x 3 1/2" x 3/8 x 24’-0" LG. W/ 3/4" DIA. x 5" LG. EPOXY ANCHORS AT 1’-0" O.C. 1/4 6" TYP. EA. EMBED PRECAST ROOF PANEL, SEE TYP. DETAILS US Army Corps PROVIDE HIGH -STRENGTH NON -SHRINK GROUT #4 BAR AT 5’-0" O.C. WELDED TO CHANNELS AND REINF. FOR ELECTRICAL CONTINUITY. of Engineers Huntsville Center 1/4 PRECAST ROOF PANEL, SEE TYP. DETAILS 2" WATERPROOFING MEMBRANE (60 MIL) 1/2" DIA. x 8" HEADED STUDS AT 12" O.C. D Appr . PROVIDE HIGH -STRENGTH NON -SHRINK GROUT D L6x4x1/2" x 26’-0" LONG (LLV) C6x13 CONT. Dat e 1/4 1/4 C8x18.75 CONT. 1/4 1/4 1/2" DIA. x 8" HEADED STUDS AT 12" O.C. REASONABLY COHESIVE SOILS ONLY. SOLID OR WET CLAY SHALL NOT BE USED. HSS 8x8x1/4 DOOR FRAME PRECAST PORTAL WALL CAP PANEL NOTE: EARTH FILL SHALL CONTAIN NO STONES HEAVIER THAN 10 POUNDS OR LARGER THAN 6" (15.2) IN ANY DIMENSION 6" (TYP.) WATERPROOFING MEMBRANE (60 MIL), TYP. AT ROOF AND WALLS 2 LAYERS 30# FELT MOP IN PLACE WITH COAL TAR PITCH 2 MIN. 1 No. #5 HORZ. AT 12" O.C., TYP. Revi si ons 1" 2" L6x4x1/2" x 26’-0" LONG (LLV) SET FIRMLY AGAINST ROOF PANELS #4 BAR AT 5’-0" O.C. WELDED TO CHANNELS AND REINF. FOR ELECTRICAL CONTINUITY. Descr i pt i on C6x13 CONT. DEPTH GAUGE, SEE DETAIL F/S501. REFER TO ROOF PLAN FOR LOCATIONS 2’ 0"M I N. 1/ 2" 3/16" THICK BENT PL. CONT. 25" 8. 3/16 2" GRIND SMOOTH & SEAL WELD 1 5/8" 2 DECEM BER 2011 #4 BAR AT 5’-0" O.C. WELDED TO CHANNELS AND REINF. FOR ELECTRICAL CONTINUITY. 1/2" DIA. x 8" HEADED STUDS AT 12" O.C. C8x18.75 CONT. 1 1/2" DIA. WEEPS AT 1’-8" O.C. 1/2" x 10" PL. CONT. W/ 1/2" DIA. x 6" HEADED STUDS AT 12" O.C. NOTE: PROVIDE RAMPS, I.E., PRESSURE TREATED 2x MEMBERS SLOPED AS REQUIRED TO ALLOW FORKLIFTS TO SAFELY TRANSPORT MUNITIONS OVER DOOR SILL. TYP. #6 DOWELS AT 12" O.C. 6" DIA. PERFORATED FOOTING DRAIN PIPE, TYP. (TURN PERFORATIONS DOWN) L6 x 3 1/2 x 3/8 (LLV) W/ 1/2" DIA. x 4" HEADED STUDS AT 12" O..C. FILTER FABRIC #5 DOWELS x 8’-0" LONG AT 1’-0" O.C. HSS 6x8x1/4 5 1/2 " 3/8 3/8 SLAB-ON-GRADE SEE PLAN 8 1/2 " WRAP END OF WEEPS WITH FILTER FABRIC, TYP. SL OPEDN. 1’ 6" 2’ 1" 11 1/ 2" 1 1’ 0" CONCRETE APRON, MAINTAIN SLOPE AWAY FROM DOOR FOR 13’-0" MIN.. 1’ 11 1/ 2" 1 42 " OPEDN. SL #4 BAR AT 5’-0" O.C. BRAZED OR WELDED TO WWF, REINF., AND HEADED STUDS 3 #4 BARS AT 3’-0" O.C. 2’-0" 6 #5 BARS CONT AS SHOWN A S101 S302 S102 S201 SECTION GRAVEL MATERIAL (GW) SCALE: 3/4"=1’-0" #6 CONT. AT 12" O.C. TOP AND BOTT. 2’-5" 1’-6" #5 TRANSVERSE BARS AT 12" O.C. TOP AND BOTT. #6 HORZ. CONT. AT 12" O .C. 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 Dat e: RSW Checked by: A Sheet reference number: 1’-7" 5’-6" 5 B 1 S-302 Sheet 9 of 24 STANDARD DESI GN DRAW I NGS -FI NAL 6" SAND MATERIAL (SW) B BUI LDI NG SECTI ON #7 VERT. AT 12" O.C., TYP. M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 11’ 0" #5 HORZ. AT 12" O.C. W/ SEISMIC HOOK EACH END, TYP. U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A (TYP.) EXTENTS OF DOOR FRAME, SEE DETAILS ON S701 A JM U JM U PRECAST WALL PANELS 8" Desi gned by: NOTE: STAGGER REBAR LAYERS TO FORM A 6"x6" SQUARE MESH PATTERN OF #5 AND #7 REBAR. DOOR, SEE ELEVATIONS ON S702 AS SHOW N WATERPROOFING MEMBRANE (60 MIL), TYP. AT ROOF AND WALLS 10" SEE DETAIL 4/S303 Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on #4 STIRRUPS AT 4" O.C., TYP. TOP & BOTT. ENCLOSE HORZ. REINF. WITHIN 1" STIRRUPS 7" (TYP.) Dr awn by: PRECAST ROOF PANELS, SEE TYP. DETAILS Dat e: (2) #5 HORZ. CONT. TOP & BOTT. TYP. AT TOP AND BOTTOM OF WALLS C Scal e: C Dr awi ng code: #7 VERT. AT 12" O.C., TYP. *** SAFETY FIRST *** 4 5 3 2 1 US Army Corps of Engineers Huntsville Center 1’-2" NOTE: STAGGER REBAR LAYERS TO FORM A 6"x6" SQUARE MESH PATTERN OF #5 AND #7 REBAR. WATERPROOFING MEMBRANE, TYP. #6 BARS AT 6" O.C. (WALL HT. > 9’-0") #6 BARS AT 12" O.C. (WALL HT. < 9’-0") S101 S303 S201 NOTES: DETAIL 5 SCALE: 3/4"=1’-0" S102 S303 SCALE: 3/4"=1’-0" Desi gned by: JM U 1. THE SAND AND GRAVEL MATERIALS SHOWN IN THE SECTIONAL VIEW THROUGH WING WALL SHOULD BE TERMINATED AT THE POINT WHERE THE WING WALL HEIGHT IS INSUFFICIENT TO MAINTAIN THE 2’-3’ COHESIONLESS FILL MATERIAL. PLACE COVER OVER AT LEAST 6" OF SAND MATERIAL. PAST THIS POINT, AN ADDITIONAL 6" OF SAND MATERIAL SHOULD BE ADDED TO "CLOSE IN" THE END OF GRAVEL MATERIAL. 2. AS AN OPTION, DEPENDING ON THE SITE SPECIFIC CONDITIONS, THE WEEPHOLES THROUGH THE WING WALLS MAY BE REPLACED WITH PERFORATED PIPE DRAINS PLACED IN THE GRAVEL MATERIAL RUNNING LATERALLY BEHIND THE WING WALLS AND PORTAL WALL PANELS AND CONNECTED TO THE PERIMETER FOOTING DRAIN. FOUNDATION STEM WALL, SEE SECTIONS B 2 LAYERS #30 FELT MOP IN PLACE WITH COAL TAR PITCH FOUNDATION STEM WALL, SEE SECTIONS WATERPROOFING MEMBRANE (60 MIL), TYP AT WALLS & ROOF. ON-SITE CAST WALL, SEE SECTIONS FOR REINF. 1’-0" WATERPROOFING MEMBRANE (60 MIL), TYP AT WALLS & ROOF. 1/2" DIA. x 8" HEADED STUDS AT 12" O.C. #4 BAR AT 5’-0" O.C. WELDED TO CHANNELS AND REINF. (EA. FACE) FOR ELECTRICAL CONTINUITY. 1/2" x 10" PL. CONT. W/ 1/2" DIA. x 6" HEADED STUDS AT 12" O.C. 1/4 5/8" GAP WATERPROOFING MEMBRANE (60 MIL), TYP AT WALLS & ROOF. 1/4 1/4 DOOR FRAME, SEE DETAILS ON S701 L4x3x3/8 x 0’-8" LG. SEE PLAN FOR SPACING 3/8 NOTE: WELD SIDE WALL PANEL TO DOOR FRAME PRIOR TO PLACEMENT OF PORTAL WALL PANEL 3/8 3/8 3/8 4"x0’-6"x3/8" PL. AT EACH EMBED C8x18.75 CONT. PRECAST WALL PANELS, SEE SECTONS FOR REINF. 1’-6" C8x18.75 CONT. TYP. WATERPROOFING MEMBRANE (60 MIL), TYP AT WALLS & ROOF. 1/2" x 10" PL. CONT. W/ 1/2" DIA. x 6" HEADED STUDS AT 12" O.C. PRECAST WALL PANEL, SEE SECTIONS FOR REINF. #4 BAR AT 5’-0" O.C. WELDED TO CHANNELS AND REINF. (EA. FACE) FOR ELECTRICAL CONTINUITY. 8" PRECAST WALL PANELS, SEE SECTONS FOR REINF. 1/2" DIA. x 8" HEADED STUDS AT 12" O.C. #4 BAR AT 5’-0" O.C. WELDED TO CHANNELS AND REINF. (EA. FACE) FOR ELECTRICAL CONTINUITY. REFER TO DETAIL 5/S303 FOR PLAN VIEW SLAB EDGE AT DOOR OPENING 1/4 1/4 1/2" DIA. x 8" HEADED STUDS AT 12" O.C. C8x18.75 CONT. PRECAST ROOF PANELS, SEE TYP. DETAILS 1/2" x 10" PL. CONT. W/ 1/2" DIA. x 6" HEADED STUDS AT 12" O.C. #4 BAR AT 5’-0" O.C. WELDED TO CHANNELS AND REINF. (EA. FACE) FOR ELECTRICAL CONTINUITY. PROVIDE HIGH -STRENGTH NON -SHRINK GROUT A 1 S101 S303 DETAIL DETAIL 2 SCALE: 3/4"=1’-0" S101 S303 3 SCALE: 3/4"=1’-0" S101 S303 DETAIL SCALE: 3/4"=1’-0" 4 S102 S303 S202 S302 DETAIL B SCALE: 3/4"=1’-0" Sheet reference number: S-303 Sheet 10 of 24 5 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 1 A STANDARD DESI GN DRAW I NGS -FI NAL SCALE: 3/4"=1’-0" SECTION M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 B U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A S101 S303 S201 SECTION Dat e: 10’-2" Dat e: VARIES 10’-2" TO 2’-0" Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on 6’-3" C RSW C 1’-6" PRECAST ROOF PANELS #4 BAR TO ANGLE SECTI ONS 1’ 0" 1’ 0" L4x3x3/8 x 0’-8" LG. SEE PLAN FOR SPACING Dr awi ng code: VARIES 2’-10" TO 3" #6 BARS AT 12" O.C. 2’-5" Revi si ons 4"x0’-6"x3/8" PL. AT EACH EMBED Checked by: #6 HORZ. CONT. AT 12" O .C. 1/4 #5 BARS x 36" LONG AT 12" O.C. AS SHOW N #6 TRANSVERSE BARS AT 24" O.C. TOP AND BOTT. 5" GRAVEL MATERIAL (GW) (SEE NOTES 1 & 2) Scal e: FINISHED GRADE JM U #5 DOWELS AT 24" O.C. WRAP END OF WEEP WITH FILTER FABRIC Dr awn by: #6 HORZ. CONT. AT 12" O .C. SAND MATERIAL (SW) (SEE NOTES 1 & 2) 3" DIA. PVC WEEP Descr i pt i on #4 BAR AT 5’-0" O.C. BRAZED OR WELDED TO PEDESTAL REINFORCEMENT, AND HEADED STUDS 6" No. TYP. #4 A706 REBAR TYP., PLACE 1 1/2" FROM TOP OF ROOF PANEL. 2 DECEM BER 2011 1/2" x 10" PL. CONT. W/ 1/2" DIA. x 6" HEADED STUDS AT 12" O.C. CLASS "D" FINISH " 4 2 3/8 3/8 #5 VERT. AT 12" O.C. 2 4 " #4 BAR AT 5’-0" O.C. WELDED TO CHANNELS AND REINF. (EA. FACE) FOR ELECTRICAL CONTINUITY. 3"M I N. 6" SAND MATERIAL (SW) C8x18.75 CONT. #6 BARS AT 6" O.C. (WALL HT. > 9’-0") #6 BARS AT 12" O.C. (WALL HT. < 9’-0") CLASS "C" FINISH 45 ” #7 VERT. AT 12" O.C., TYP. 1/2" DIA. x 8" HEADED STUDS AT 12" O.C. 1’ 3" Dat e #5 HORZ. AT 12" O.C. W/ SEISMIC HOOK EACH END, TYP. PRECAST WALL PANELS A D 8" VARI ES 12’ 7"TO 2’ 6" D Appr . 3/4" CHAMFER #5 HORZ. AT 12" O.C. *** SAFETY FIRST *** 3 2 SAWCUT JOINT 1/4" WIDE x 1/4 SLAB THICKNESS. FILL WITH JOINT FILLER REINF. DISCONT. AT JOINT of Engineers Appr . Huntsville Center Dat e USE EITHER AT CONTRACTOR’S OPTION CONCRETE LAP LENGTHS SHALL BE INCREASED 20 PERCENT WHERE EPOXY COATING IS USED. (3 EQ. SP.)(2 EQ. SP.) Dat e: 6" 2 1/8 " TYP. TYP. TYP. 2" 6 3/ 4" TYP. TYP. 3 3/4 " MARK AND LABEL PIPE IN 1" INCREMENTS TO INDICATE HEIGHT ABOVE TOP OF CONCRETE L 3 1/2" x 6" x 3/8" LLH x 26’-4" LG. (TYP.) 1/2" DIA. x 4" LG. HEADED STUDS AT 12" O.C. (START 8" FROM END) Y 10 3/8 " 3" DIA. PVC PIPE BONDED TO FIBERGLASS PLATE. PAINT PIPE BRIGHT ORANGE (4) #10 BARS CONT. AS SHOWN, TYP. 6 1/4 " METAL FLASHING 4 1/2 " 4 1/2 " 1" RADIUS, TYP. 1’ 0" 1’ 0" 1" RADIUS, TYP. 3 3/ 4" 1’ 0" 3" TBD I N FI ELD 1’-2 1/4 " #4 STIRRUPS SEALANT #4 STIRRUPS 6 1/4 " 6 1/4 " TOP OF PRECAST ROOF PANEL #4 STIRRUPS STIRRUP TYPE "1" STIRRUP TYPE "2" STIRRUP TYPE "3" SCALE: 3/4"=1’-0" SCALE: 3/4"=1’-0" SCALE: 3/4"=1’-0" D 18"x18"x3/8" FIBERGLASS PLATE 1" RADIUS, TYP. DEPTH GAUGE DETAIL WATERPROOFING MEMBRANE (60 MIL) TYP. AT WALLS & ROOF SCALE: 3/4"=1’-0" F S501 B S501 2 1/2 " 8 3/4 " 8’-4" 3’-4 1/2 " (10 SPACES AT 10" O.C.) NOTE: PROVIDE ELECTRICAL CONTINUITY BY WELDING VERTICAL AND HORZ. REINFORCEMENT TO VENT PIPE (3 SPACES AT 1’-1 1/2" O.C.) 3’-4 1/2 " 8’-4" (3 SPACES AT 1’-1 1/2" O.C.) 8 3/4 " 2 1/2 " (10 SPACES AT 10" O.C.) # 6 BAR CONT., TYP. (NO SPLICE ALLOWED) 1’ 4" #4 STIRRUPS, SEE CROSS SECTION 1’-2 1/2 " A TYPI CAL DETAI LS 26’-6" M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 TYPICAL VENT DETAIL 135 DEGREE HOOK 4 1/ 2" 1’ 6" SCALE: 3/4"=1’-0" 5 3/32" C REMOVABLE CAP 4 1/2 " 87 8" CROSS SECTION 1/4 SCALE: 3/4"=1’-0" 9" 10" 3" L4x3x3/8 x 0’-8" LG. (LLV) SEE PLAN FOR SPACING 2 " T YP. 1/2 CUBIC YARD CAPILLARY WATER BARRIER MATERIAL AT OPEN END OF PIPE PRECAST WALL PANELS SEE SECTIONS 3 1/8 " 3" 5 1/ 8" 5 1/16 " 12" SCH. 20 (MIN.) GALVANIZED STEEL PIPE TYP. Y 3" 10 5/8 "7 3/8 " 1’-6" 1/2" DIA. ROD WELDED INSIDE OF PIPE ON CENTERLINE EACH DIRECTION TO FORM A CROSSING PATTERN TYP. 8" # 6 BAR CONT., TYP. 10" L4x3x3/8 x 0’-8" LG. (LLV), SEE PLAN FOR SPACING (4) 1/2" DIA. x 6" HEADED STUDS AT EQ SPACING B 3 11/16 " 4"x6"x3/8" PL. AT EA. EMBED STIRRUP TYPE "1" STIRRUP TYPE "2" 9 1/ 4 "6 3/ 4" STIRRUP TYPE "3" 1/4" x 19" DIA. STEEL FLANGE PAIR W/ (2) RUBBER GASKETS, SEE DETAIL A ON THIS SHEET. 2 LAYERS OF STRIP IN FELTS MOP IN WITH HOT ASPHALT BOND #4 BAR AT 5’-0" O.C., TYP. FOR ELECTRICAL CONTINUITY #4 HORZ. REINF. AT STIRRUP SPACING 9 1/ 4" EARTH FILL LINE ABOVE GRADE 1’ 0"M I N. C Dat e: 10’-2 3/8 " (4) 1/4" DIA. SELF-TAPPING SCREWS 2 DECEM BER 2011 WHEN LAPPING TWO DIFFERENT SIZE BARS, USE THE LARGER OF THE LAP SPLICE DIMENSION OF THE SMALLER BAR OR THE DEVELOPMENT LENGTH OF THE LARGER BARS Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on HAND- TOOL AREAS INACCESSIBLE BY SAW RSW SAWCUT JOINTS AS EARLY AS ALLOWED Dr awi ng code: NOTES: REFER TO GEOTECHNICAL REPORT FOR THE SUBGRADE PREPARATION AND EARTHWORK RECOMMENDATIONS. TOP BARS ARE HORIZONTAL REINF. WITH MORE THAN 12" ON CONCRETE CAST BELOW THE REINF. S501 JM U GALVANIZED DUCT CAP W/ INSECT SCREEN S501 Desi gned by: S501 C SCALE: 3/4"=1’-0" 15" 19" 24" 29" 42" 48" 54" 61" Checked by: SCALE: 3/4"=1’-0" SLAB CONTROL JOINT DETAIL B 1’ 6" SCALE: 3/4"=1’-0" 3/4" DIA. x 1’-6" SMOOTH DOWELS AT 12" O.C. CENTERED ON CONTROL JOINT PLACED AT MID-DEPTH OF SLAB. PAINT ONE SIDE OF DOWEL WITH ASPHALT PAINT AND OILED ALL AROUND TO PREVENT BOND WITH CONCRETE. 2 19" 25" 31" 37" 54" 62" 70" 79" No. SLAB-ON-GRADE DETAIL A 6" KEYED CONTROL JOINT SUB-GRADE MATERIAL AS APPROVED VENTILATOR FLAME PLATE DETAIL 6" 19" 25" 31" 37" 54" 60" 78" 85" OTHER BARS AS SHOW N SLAB REINF., SEE PLAN #3 #4 #5 #6 #7 #8 #9 #10 TOP BARS Dr awn by: 4" CAPILLARY WATER BARRIER 3" NOTE: CLASS 150 FORGED FLANGES MAY BE SUBSTITUTED FOR FABRICATED PLATE FLANGES 1 BARS B Scal e: NO. fc= 4000 PSI JM U PIPE FLANGE fc= 4000 PSI TOP BARS OTHER B A A 24" 19" 15" 32" 25" 19" 40" 31" 24" 48" 37" 29" 70" 54" 42" 80" 62" 48" 101" 78" 60" 111" 85" 66" Revi si ons BAR SIZE Descr i pt i on #4 BAR AT 5’-0" O.C. BRAZED OR WELDED TO WWF. FINISH FL. DEVELOPMENT LENGTHS SPLICE LENGTHS U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A 1 7/16" DIA. HOLES AT 1 9/16" O.C. SAWCUT JOINT 1/4" WIDE x 1/4 SLAB THICKNESS. FILL WITH JOINT FILLER REINF. DISCONT. AT JOINT VAPOR BARRIER D SAWED CONTROL JOINT SLAB REINF., SEE PLAN SLAB REINF., SEE PLAN FLAME PLATE US Army Corps " 1 ’ -0 1 ID /4 (12) 1" DIA. HOLES FOR 7/8" DIA. S.S. BOLTS ON 17" DIA. BOLT CIRCLE (TYP.) D 3/4" DIA. x 1’-6" SMOOTH DOWELS AT 12" O.C. CENTERED ON CONTROL JOINT PLACED AT MID-DEPTH OF SLAB. PAINT ONE SIDE OF DOWEL WITH ASPHALT PAINT AND OILED ALL AROUND TO PREVENT BOND WITH CONCRETE. #4 BAR AT 5’-0" O.C. BRAZED OR WELDED TO WWF. 1/4" THICK x 19" DIA. STEEL PLATE (TYP.) 1 SECTION Y-Y #10 BARS CONT., TYP. (NO SPLICE ALLOWED) SCALE: 3/4"=1’-0" PRECAST ROOF PANEL DETAIL SCALE: 3/4"=1’-0" Sheet reference number: E S-501 S501 NOTES: PROVIDE ELECTRICAL CONTINUITY WITHIN THE PRECAST ROOF PANEL BY BONDING AT 5 LINEAR FEET INTERVALS ACROSS TOP OF STIRRUPS TO END ANGLES IN ONE DIRECTION. IN THE OTHER DIRECTION, FROM BOTTOM PLATE TO #4 REINFORCEMENT 5 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 Sheet 11 of 24 1 A STANDARD DESI GN DRAW I NGS -FI NAL 4 5 *** SAFETY FIRST *** 4 5 3 2 1 1/2" THICK PL. CONT. TYP. US Army Corps of Engineers 1/2" THICK STIFF. PL. (2 PER HINGE) 1/4 1/4 1/4 D 3 1 16" D TYP. Appr . HSS 3x1 1/2x 3/16 x 6" LONG, SEALED ON INSIDE END. Huntsville Center Dat e W12x40 26’-0" (DOOR FRAME WIDTH) DOOR FRAME HINGE PL., SEE DETAIL 2/S701 6" DOOR FRAME HINGE PL., SEE DETAIL 2/S701 SECTION No. TYP. 1/4 B 1/2" THICK STIFF. PL. (2 PER HINGE) 6 5/8 " 2 S701 S701 HSS 3x1 1/2x 3/16 x 4 1/2" LONG, SEALED ON INSIDE END HSS 3x1 1/2x 3/16 x 4 1/2" LONG, SEALED ON INSIDE END 1" 6" ( TYP. ) SCALE: 1 1/2"=1’-0" 6" 2 1/8 " DOOR FRAME HINGE PL. DETAIL S701S701 1’ 2 3/ 8" 2.016" DIA. 2 1/8 " (TYP.) 2 DECEM BER 2011 1 3/16 " W12x40 8" HSS 8x6x1/4 (END TO BE CAPPED W/ 1/4" PL. & WELD TO BE GROUND SMOOTH.) HSS 8x6x1/4 (END TO BE CAPPED W/ 1/4" PL. & WELD TO BE GROUND SMOOTH.) 1/2" THICK PL. CONT. 1/4 1/4 DOOR FRAME HINGE PL., SEE DETAIL 2/S701 1/2" THICK STIFF. PL. SIDE VIEW DOOR FRAME ELEVATION SCALE: 3/4"=1’-0" NOTE: THE 3" AND 1" DOOR OVERLAP AT THE TOP AND BOTT. OF THE DOOR FRAME, RESPECTIVELY SHALL NOT BE REDUCED AS THIS IS IMPERATIVE TO CARRY OUT THE DESIGN INTENT. A S201 S701 Dat e: Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on Dr awi ng code: AS SHOW N Scal e: Dat e: 1/2" RADIUS, TYP. GUSSET PL. A JM U RSW B DESIGNER NOTE: TO BE REMOVED WHEN PREPARING CONSTRUCTION DRAWINGS FOR SITE ADAPTION DESIGN DOOR FRAME HINGE PL. DETAIL SCALE: 1 1/2"=1’-0" 5 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 3 S701 S701 SHEETS S701 - S705 (HIGH SECURITY HASP) AND S701(A) - S705(A) (ILD) IDENTIFY TWO DIFFERENT LOCKING SYSTEMS. THE DESIGNER SHALL VERIFY WITH THE CONTRACTING OFFICIER THE CORRECT LOCKING SYSTEM REQUIRED AND REMOVE THE REDUNDANT SHEETS FROM THE CONSTRUCTION CONTRACT DOCUMENTS FOR THE SYSTEM NOT USED. 1 Sheet reference number: S-701 Sheet 12 of 24 A STANDARD DESI GN DRAW I NGS -FI NAL (TYP.) 2" 5 7/16 " 45 DEGREE x 1", TYP. DOOR FRAM E ELEVATI ONS AND DETAI LS 2" 1/2" THICK PL. CONT. 4" 1" M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 ( TYP. ) B 2’ 8" 4" 3/4 " TYP. 7" DOOR FRAME HINGE PL., SEE DETAIL 2/S701 9 3/8 " S701 S701 Checked by: 1/4 3/4 " 1 JM U GUSSET PL., SEE DETAIL 1/S701 SCALE: 1 1/2"=1’-0" Desi gned by: TYP. GUSSET PL. DETAIL C U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A DOOR, SEE DOOR ELEV. ON S702 1" 3 3/ 4" S701S701 DOOR FRAM E CENTERLI NE HINGE PL., SEE DETAIL 2/S701 10’ 4"( OPENI NG HEI GHT) 3 NOTE: PROVIDE HEAVY DUTY WEATHER STRIPPING/ SEALING AROUND INSIDE PERIMETER OF DOOR GAPS 11’ 6"( DOOR FRAM E HEI GHT) ( TYP. ) W12x40 GUSSET PL., SEE DETAIL 1/S701 ( TYP. ) 2’ 8" 2’ 8" 8"x 1’-4 1/2"x 1/2" THICK PLATE, TYP. 8" TYP. 1/4 10 3/ 4" HSS 8x8x1/4 10" 8"x 1’-4 1/2"x 1/2" THICK PLATE, TYP. C 1/2 " 10" 3/16 1" TYP. ( TYP) TYP. 6 3/8 " S701 S701 Descr i pt i on TYP. 1/4 B SCALE: 1 1/2"=1’-0" 7 7/ 16 " TUBE TO PLATE HSS 8x8x1/4 (END TO BE CAPPED W/ 1/4" PL. & WELD TO BE GROUND SMOOTH.) 8" 1/4" CAP PLATE, TYP. WELD ALL AROUND W/ 3/16" WELD. 3" TOP VIEW ( TYP. ) 1’ 1 5/ 8" HSS 3x1 1/2x 3/16 x 6" LONG, SEALED ON INSIDE END. Dr awn by: HSS 8x8x1/4 (END TO BE CAPPED W/ 1/4" PL. & WELD TO BE GROUND SMOOTH.) 6" GUSSET PL. BELOW 1/2 1/2 TYP. 12’-6" Revi si ons 6" *** SAFETY FIRST *** 4 5 3 2 1 1/2" THICK PL. CONT. TYP. US Army Corps 1/4 1/4 LOCK BOLT RECEIVERS, 1.5" I.D. x 1.88" O.D. x 5" LG. of Engineers Huntsville Center TYP. Appr . 1 7/ 8" 1/2" THICK STIFF. PL. (2 PER HINGE) 1/4 D D 12’-4 3/8" 6" DOOR FRAME HINGE PL., SEE DETAIL 2/S701 8" No. (TYP.) 2" TYP. 5 7/16 " 45 DEGREE x 1", TYP. 6 5/8 " 2 1/8 " 1/4 (TYP.) B DOOR FRAME HINGE PL. DETAIL 1/2" THICK STIFF. PL. (2 PER HINGE) S701S701 SCALE: 1 1/2"=1’-0" 2 S701 S701 1’-7 5/8 " LOCK BOLT RECEIVERS, 1.5" I.D. x 1.88" O.D. x 5" LG. SEALED ON INSIDE END LOCK BOLT RECEIVERS, 1.5" I.D. x 1.88" O.D. x 5" LG. SEALED ON INSIDE END 1" 1/4 W12x40 1/2" THICK PL. CONT. 6" ( TYP. ) 1’ 2 3/ 8" 8" HSS 8x6x1/4 (END TO BE CAPPED W/ 1/4" PL. & WELD TO BE GROUND SMOOTH.) HSS 8x6x1/4 (END TO BE CAPPED W/ 1/4" PL. & WELD TO BE GROUND SMOOTH.) 1/2" THICK STIFF. PL. SIDE VIEW DOOR FRAME ELEVATION SCALE: 3/4"=1’-0" NOTE: THE 3" AND 1" DOOR OVERLAP AT THE TOP AND BOTT. OF THE DOOR FRAME, RESPECTIVELY SHALL NOT BE REDUCED AS THIS IS IMPERATIVE TO CARRY OUT THE DESIGN INTENT. A S201 S701 GUSSET PL. A DESIGNER NOTE: TO BE REMOVED WHEN PREPARING CONSTRUCTION DRAWINGS FOR SITE ADAPTION DESIGN DOOR FRAME HINGE PL. DETAIL SHEETS S701 - S705 (HIGH SECURITY HASP) AND S701(A) - S705(A) (ILD) IDENTIFY TWO DIFFERENT LOCKING SYSTEMS. THE DESIGNER SHALL VERIFY WITH THE CONTRACTING OFFICIER THE CORRECT LOCKING SYSTEM REQUIRED AND REMOVE THE REDUNDANT SHEETS FROM THE CONSTRUCTION CONTRACT DOCUMENTS FOR THE SYSTEM NOT USED. 5 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** SCALE: 1 1/2"=1’-0" Dat e: AS SHOW N Dr awi ng code: B 1/4 1/4 DOOR FRAME HINGE PL., SEE DETAIL 2/S701 2 1/4 " Scal e: 1" 2.016" DIA. 2 1/8 " 1/2" THICK PL. CONT. 3/4 " TYP. 1/2" RADIUS, TYP. 4" Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on DOOR FRAME HINGE PL., SEE DETAIL 2/S701 9 3/8 " RSW GUSSET PL., SEE DETAIL 1/S701 3/4 " S701 S701 3 Sheet reference number: S701 S701 S-701 (A) Sheet 13 2 1 of 24 A STANDARD DESI GN DRAW I NGS -FI NAL 2" 1/4 SCALE: 1 1/2"=1’-0" 1 DOOR FRAM E ELEVATI ONS AND DETAI LS ( TYP. ) B 2’ 8" 4" TYP. GUSSET PL. DETAIL Checked by: HINGE PL., SEE DETAIL 2/S701 DOOR, SEE DOOR ELEV. ON S702 DOOR FRAM E CENTERLI NE ( TYP. ) 2’ 8" S701S701 1" JM U 10’ 4"( OPENI NG HEI GHT) 3 NOTE: PROVIDE HEAVY DUTY WEATHER STRIPPING/ SEALING AROUND INSIDE PERIMETER OF DOOR GAPS Dr awn by: GUSSET PL., SEE DETAIL 1/S701 C M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 W12x40 2 DECEM BER 2011 ( TYP. ) 2’ 8" 8"x 1’-4 1/2"x 1/2" THICK PLATE, TYP. Dat e: 1/4 10 3/ 4" TYP. 10" 10" HSS 8x8x1/4 1/4 C 3" 8"x 1’-4 1/2"x 1/2" THICK PLATE, TYP. 3 3/ 4" 3/16 1/2 " TYP. 7" TYP. 1" ( TYP) LOCK BOLT RECEIVERS, 1.5" I.D. x 1.88" O.D. x 5" LG. SEALED ON INSIDE END 8" ( TYP. ) 1’ 1 5/ 8" TYP. 1/4 6 3/8 " S701 S701 Descr i pt i on HSS 8x8x1/4 (END TO BE CAPPED W/ 1/4" PL. & WELD TO BE GROUND SMOOTH.) 1 7/8 " B SCALE: 1 1/2"=1’-0" 7 7/ 16 " TUBE TO PLATE 11’ 6"( DOOR FRAM E HEI GHT) TOP VIEW SECTION 1/4" CAP PLATE, TYP. WELD ALL AROUND W/ 3/16" WELD. JM U 6" DOOR FRAME HINGE PL., SEE DETAIL 2/S701 Desi gned by: HSS 8x8x1/4 (END TO BE CAPPED W/ 1/4" PL. & WELD TO BE GROUND SMOOTH.) U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A 7 5/8 " GUSSET PL. BELOW 1/2 1/2 TYP. Revi si ons 26’-0" (DOOR FRAME WIDTH) Dat e W12x40 *** SAFETY FIRST *** 4 5 3 2 1 US Army Corps of Engineers 4’-7" TYP. 1’-0" C6x13 3/8 3/8 2 1/4"x4"x3/8" PL. 3/8 3/8 3"x4"x3/8" PL. L2x2x3/8" x 4" LG UPPPER LOCK BAR, SEE DETAIL 5/S704 3/8 3/8 TYP. PIN 1/2" DIA. x 2 3/16" LG. CAD PLATED (TYP.) 3/8 2’ 8" 2’ 8" 1/2" THICK PL. SPACER, SEE DETAIL 2/S704 B B S702S703 S702S703 2 1/4" 10’ 8"( DOOR HEI GHT) A 3/16 6’-0" x 10’-6" x 3/8" PL. EACH SIDE 2’ 8" 9’ 8" 2’ 8" 6’-0" x 10’-6" x 3/8" PL. EACH SIDE OH S702S703 C 6’-0" x 10’-6" x 3/8" PL. EACH SIDE S702S703 HSS 6x2x1/4 C6x13 LATCH BAR, SEE DETAIL 1/S704 NOTE: 3/8" INTERIOR PL. NOT SHOWN 12’-0" LOWER LOCK BAR, SEE DETAIL 5/S704 CHANNEL WEB C6x13 C6x13 3/8 4" 4" C6x13, COPE AS REQ’D 1’ 4" 2" 1/4 CHANNEL FLANGES 1’ 4" B 1/4 1/2" x 6" WIDE SEAL PLATE 6’-0" x 10’-6" x 3/8" PL. EACH SIDE 2’ 8" 2’ 8" HSS 6x2x1/4 " 2 12’-0" 1 1/2 " 1 1/2 " 3" 1’-0" 4’-7" 1’-0" 1’-0" 4’-7" LOCK BAR, SEE DETAIL 5/S704 1’-0" B C6x13 3 3/4 " 12’-2" (DOOR WIDTH) L2x2x3/8" x 4" LG LEFT DOOR ELEVATION "INSIDE VIEW" SCALE: 3/4"=1’-0" A GUSSET HINGE PL., SEE DETAIL 10/S704 S201 S702 1/4 1/4 NOTE: 1. SEE DOOR PLATE ELEVATION E/S703 FOR INNER DOOR SUPPORT FRAMING. SCALE: 3/4"=1’-0" B 3"x4"x3/8" PL. NOTE: 3/8" INTERIOR PL. NOT SHOWN S201 S702 NOTE: 1. SEE DOOR PLATE ELEVATION E/S703 FOR INNER DOOR SUPPORT FRAMING. C6x13 1/4 2. SEE DOOR LOCKING DEVICES ON SHEET S705 FOR ADDITIONAL REQUIREMENTS. RIGHT DOOR ELEVATION "INSIDE VIEW" HINGE PIN TO PLATE 2. SEE DOOR LOCKING DEVICES ON SHEET S705 FOR ADDITIONAL REQUIREMENTS. DOOR HINGE PLATE SEE DETAIL 9/S704 A BEARING, THRUST 5" O.D. x 2 1/32" I.D. x 5/8" OIL IMPREGNATED SINTERED BRASS, SEE DETAIL 13/S704 3/8 SHEETS S701 - S705 (HIGH SECURITY HASP) AND S701(A) - S705(A) (ILD) IDENTIFY TWO DIFFERENT LOCKING SYSTEMS. THE DESIGNER SHALL VERIFY WITH THE CONTRACTING OFFICIER THE CORRECT LOCKING SYSTEM REQUIRED AND REMOVE THE REDUNDANT SHEETS FROM THE CONSTRUCTION CONTRACT DOCUMENTS FOR THE SYSTEM NOT USED. 1/4 HINGE PIN, SEE DETAIL 4/S704 4 A DESIGNER NOTE: TO BE REMOVED WHEN PREPARING CONSTRUCTION DRAWINGS FOR SITE ADAPTION DESIGN 3/8" THICK PLATE 5 DOOR ELEVATI ONS 3 3/4 " 4" 12’-2" (DOOR WIDTH) M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 4" 3 1/4 " C RSW 1/2" THICK PL. 3 " 10’ 8"( DOOR HEI GHT) 1/2" THICK PL. L3x2x1/2 AT 45 DEGREES Checked by: C 2 DECEM BER 2011 3/8 3/8 Dat e: TYP. 3/8 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 1 Sheet reference number: S-702 Sheet 14 of 24 STANDARD DESI GN DRAW I NGS -FI NAL 2" 3/8 3/8 Dat e: 4" 4" 3" Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on PLATE TO CHANNEL Dr awi ng code: 3/8 3/8 AS SHOW N MITER CHANNELS AT CORNERS, TYP. PLATE TO CHANNEL C6x13 TOP VIEW Scal e: C6x13, TYP. C6x13 1/2" THICK PL. JM U 3/8 3/8 1/2" THICK PL. Dr awn by: TOP VIEW 6’-0" x 10’-6" x 3/8" PL. EACH SIDE Revi si ons 6’-0" x 10’-6" x 3/8" PL. EACH SIDE 1/2" THICK PL. JM U 1/2" THICK PL. 1" HSS 6x2x1/4 3/8 1/2" THICK PL. 3/8 3/8 3/8 3/8 Dat e TYP. 3/8 3/8 1’-0" HINGE PLATE SEE DETAIL 9/S704 Descr i pt i on 1’-0" 6" 3/8 3/8 3/8 3/8 6" 2 3/4 " PLATE TO PLATE 4’-7" D 12’-2" (DOOR WIDTH) Desi gned by: 1’-0" 3 3/4 " U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A 1/2" x 6" WIDE SEAL PLATE 3 3/4 " No. 12’-2" (DOOR WIDTH) 3/8 3/8 1 1/ 16" 1/4 PLATE TO CHANNEL GUSSET HINGE PL., SEE DETAIL 10/S704 1" D PLATE TO TUBE Appr . Huntsville Center *** SAFETY FIRST *** 4 5 3 2 1 1/2" THICK PL. TYP. US Army Corps of Engineers HSS 6x2x1/4 TYP. 4’-7" PLATE TO PLATE 3/8 1/2" THICK PL. PLATE TO CHANNEL 1/2" THICK PL. 6’-0" x 10’-6" x 3/8" PL. EACH SIDE 1/2" THICK PL. TOP VIEW C6x13 1/4 3/8 3/8 PLATE TO CHANNEL Descr i pt i on 1" 6" MITER CHANNELS AT CORNERS, TYP. 2" 4" 4" No. LATCH BOLT GUIDE, SEE ILD MANF. DWGS 2’ 8" 1/2" THICK PL. 1/2" THICK PL. Dat e: A S702S703 C HSS 6x2x1/4 1/4 CHANNEL WEB C6x13 C6x13, COPE AS REQ’D 4" 4" 2" LATCH BOLT GUIDE, SEE ILD MANF. DWGS CHANNEL FLANGES 1 1/2 " 1 1/2 " 1’-0" 3 3/4 " 4’-7" 1’-0" 3 1/4 " 1’-0" 4’-7" 12’-2" (DOOR WIDTH) 12’-2" (DOOR WIDTH) SCALE: 3/4"=1’-0" LEFT DOOR ELEVATION "INSIDE VIEW" B SCALE: 3/4"=1’-0" S201 S702 3 3/4 " 1/4 1/4 A S201 S702 HINGE PIN TO PLATE NOTE: 1. SEE DOOR PLATE ELEVATIONS E/S703 & F/S703 FOR INNER DOOR SUPPORT FRAMING. NOTE: 1. SEE DOOR PLATE ELEVATIONS E/S703 & F/S703 FOR INNER DOOR SUPPORT FRAMING. 1/4 2. SEE DOOR LOCKING DEVICES ON SHEET S705 FOR ADDITIONAL REQUIREMENTS. 2. SEE DOOR LOCKING DEVICES ON SHEET S705 FOR ADDITIONAL REQUIREMENTS. DOOR HINGE PLATE SEE DETAIL 2/S704 A RSW JM U 1’-0" GUSSET HINGE PL., SEE DETAIL 3/S704 RIGHT DOOR ELEVATION "INSIDE VIEW" 3/8" THICK PLATE DESIGNER NOTE: TO BE REMOVED WHEN PREPARING CONSTRUCTION DRAWINGS FOR SITE ADAPTION DESIGN BEARING, THRUST 5" O.D. x 2 1/32" I.D.x 5/8" OIL IMPREGNATED SINTERED BRASS, SEE DETAIL 6/S704 C6x13 SHEETS S701 - S705 (HIGH SECURITY HASP) AND S701(A) - S705(A) (ILD) IDENTIFY TWO DIFFERENT LOCKING SYSTEMS. THE DESIGNER SHALL VERIFY WITH THE CONTRACTING OFFICIER THE CORRECT LOCKING SYSTEM REQUIRED AND REMOVE THE REDUNDANT SHEETS FROM THE CONSTRUCTION CONTRACT DOCUMENTS FOR THE SYSTEM NOT USED. 3/8 3/8 1/4 HINGE PIN, SEE DETAIL 4/S704 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 1 A Sheet reference number: S-702 (A) Sheet 15 5 B DOOR ELEVATI ONS 3’ 2" B 1/4 1/2" x 6" WIDE SEAL PLATE M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 6’-0" x 10’-6" x 3/8" PL. EACH SIDE 1’ 4" 2’ 8" 9" 1’-3" 1’ 4" 2’ 8" HSS 6x2x1/4 U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A 6’-0" x 10’-6" x 3/8" PL. EACH SIDE Checked by: TYP. Dr awn by: JM U S702S703 3/8" CAP PL., TYP. TYP. Desi gned by: 1’ 8" 1’ 8" S702S703 B 2’ 0" EXTENTS OF EXTERIOR DOOR PLATE D S702S703 9’ 8" OH 2’ 0" B 6’-0" x 10’-6" x 3/8" PL. EACH SIDE S702S703 2’ 8" 6’-0" x 10’-6" x 3/8" PL. EACH SIDE 2’ 8" 10’ 8"( DOOR HEI GHT) 1/2" THICK PL. C of 24 STANDARD DESI GN DRAW I NGS -FI NAL 3/8 2’ 8" C Dat e: TYP. 3/8 3/8 Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on TYP. 3/8 2 DECEM BER 2011 3/8 3/8 Dr awi ng code: 3/8 3/8 DOOR HINGE PLATE SEE DETAIL 2/S704 3/8 3/8 HSS 6x2x1/4 PLATE TO TUBE D AS SHOW N TOP VIEW 1’-0" TYP. 3/8 TYP. 1/2" THICK PL. C6x13, TYP. 3/8 3/8 4’-7" 1/2 " 3/8 3/8 6’-0" x 10’-6" x 3/8" PL. EACH SIDE 1/4 1/4 1’-0" 2 3/4 " 3/8 6" TYP. 1/2" x 6" WIDE SEAL PLATE 1’-0" 3 3/4 " Scal e: 3/8 3/8 1’-0" DOOR HINGE PLATE SEE DETAIL 2/S704 12’-2" (DOOR WIDTH) GUSSET HINGE PL., SEE DETAIL 3/S704 Dat e 12’-2" (DOOR WIDTH) 1/4 1" 3 3/4 " PLATE TO TUBE 6" GUSSET HINGE PL., SEE DETAIL 3/S704 Revi si ons 1/4 D Huntsville Center Appr . 3/8 *** SAFETY FIRST *** 4 3 2 1 HANDLE, SEE DETAIL 8/S704 Appr . D S703 S703 .509" x .523 O.D. x 1/8" THICK LOCK WASHER, CAD PLATED 1/4 1/2"-13UNC-2A x 1 1/4" LG SCREW, CAD PLATED DOOR HINGE PL., SEE DETAIL 9/S704 3/8 3/8 3/16 GUSSET HINGE PL., SEE DETAIL 10/S704 SECTION A SCALE: 1 1/2"=1’-0" S702 S703 SECTION B SECTION C SCALE: 1 1/2"=1’-0" S702 S703 NOTE: L3x2x 1/2" (LATCH STOP ANGLE) NOT SHOWN FOR CLARITY SCALE: 1 1/2"=1’-0" S702 S703 D S703 S703 2 DECEM BER 2011 SCALE: 1 1/2"=1’-0" 1/2"-13UNC-2A x 1 1/4" LG SCREW, CAD PLATED NOTE: THE HANDLE IS TURNED UP IN THE "UNLOCK" POSITION 1/2" x 6" x 9’-8" PLATE SECTION SHAFT, SEE DETAIL 6/S704 SPACER, SEE DETAIL 2/S704 1/4 4-12 L2x2x1/4 x 0’-2" LG., TYP. 6" 45 1/4" x 6" WIDE BAR 1/2 NOTCH PL., TYP. 1" DIA. HOLES AS REQ’D TO FILL DOOR W/ INSULATION. OMIT IF NOT REQUIRED. (NOT ALL HOLES SHOWN) X Desi gned by: .28" COPE 6" WIDE BAR AS REQ’D TO ALLOW CONNECTION TO WEB OF CHANNEL PLATE TO ANGLE 3/8" THICK INSIDE PLATE NOTE: CROSS BAR NOT SHOWN FOR CLARITY X SECTION X-X L2x2x1/4, TYP. B SCALE: 1 1/2"=1’-0" Y 1/4 L2x2x1/4 x 0’-2" LG., TYP. 1/4" x 6" WIDE BAR .28" 1/2 NOTCH PL., TYP. NOTE: CROSS BAR NOT SHOWN FOR CLARITY 1/2 M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 1/2" DIA. HOLE IN INTERIOR PLATE FOR PLUG WELD, TYP. AT L2x2x1/4 45 1/4 3. 1" Y 1/4" x 6" WIDE BAR CONT. EACH DIRECTION. SLOT EACH BAR AT INTERSECTION TO ALLOW BARS TO INTERLOCK AND FIT FLUSH. 3/8" THICK EXT. PLATE 4-12 PLATE TO ANGLE 3/8" THICK INSIDE PLATE SECTION Y-Y INT. PLATE TO ANGLE, TYP. SCALE: 1 1/2"=1’-0" A SCALE: 3/4"=1’-0" SHEETS S701 - S705 (HIGH SECURITY HASP) AND S701(A) - S705(A) (ILD) IDENTIFY TWO DIFFERENT LOCKING SYSTEMS. THE DESIGNER SHALL VERIFY WITH THE CONTRACTING OFFICIER THE CORRECT LOCKING SYSTEM REQUIRED AND REMOVE THE REDUNDANT SHEETS FROM THE CONSTRUCTION CONTRACT DOCUMENTS FOR THE SYSTEM NOT USED. E S702 S703 NOTE: RIGHT DOOR PLATE ELEVATION IS THE SAME AS THE LEFT 5 4 A DESIGNER NOTE: TO BE REMOVED WHEN PREPARING CONSTRUCTION DRAWINGS FOR SITE ADAPTION DESIGN 1 1/2 " LEFT DOOR PLATE ELEVATION "INSIDE VIEW" B 6" 3 SIDES C 3 SIDES 1/4 3. 1" 1" 1/2" THICK PL. 3/8" THICK EXT. PLATE " /4 . 1 P Y T 6 Dat e: " /4 1 6 EXTENTS OF 3/8" THICK PLATE T Y P . EXTENTS OF DOOR FRAME " -0 . ’ P 1 Y T 1 ’ T -0" Y P . 1 ’ -1 " C 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 1 Sheet reference number: S-703 Sheet 16 of 24 STANDARD DESI GN DRAW I NGS -FI NAL TYP. PLATE TO CHANNEL WASHER, SEE DETAIL 3/S704 AS SHOW N EXTERIOR TUBE SUPPORT, SEE DETAIL 11/S704. INSTALL THE FIRST TUBE SUPPORT 21.5" FROM THE BOTTOM OF THE DOOR FRAME WITH THE REMAINING TUBE SUPPORTS INSTALLED EVERY 16.81" APART. INTERIOR .509" x .523 O.D. x 1/8" THICK LOCK WASHER, CAD PLATED Dat e: 2 3/4 " Scal e: 3/8 3/8" THICK PL. (OUTSIDE) Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on C6x13 CONT. JM U PLATE TO PLATE SPACER, SEE DETAIL 2/S704 1/2" DIA. x 2 3/16" LG. PIN, CAD PLATED (TYP.) RSW 1/4 LATCH BAR, SEE DETAIL 1/S704 DOOR SECTI ONS 1/4 1/4 .515" x 7/8" x 1/16 THICK FLAT WASHER, CAD PLATED (TYP.) Dr awi ng code: HSS 6x2x1/4 Checked by: 1/8 Dr awn by: BAR TO CHANNEL Dat e TYP. D ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A 1/2 " WASHER, SEE DETAIL 3/S704 .09" DIA. x 1 1/2" LG. COTTER PIN, CAD PLATED (TYP.) Revi si ons 1/4 6’-0" x 10’-6" x 3/8" PL. EACH SIDE SLEEVE, SEE DETAIL 7/S704 Descr i pt i on PLATE TO TUBE 1/2" THICK STIFF. PL. (2 PER HINGE) Huntsville Center 3/8" THICK PL. (OUTSIDE) SHAFT, SEE DETAIL 6/S704 HANDLE, SEE DETAIL 8/S704 LATCH BAR, SEE DETAIL 1/S704 LOCK BAR, SEE DETAIL 5/S704 6’-0" x 10’-6" x 3/8" PL. EACH SIDE 3/8 INTERIOR 1/2" THICK PL. of Engineers No. D DOOR FRAME ASSEMBLY, SEE DETAIL B/S701 FOR INFORMATION 1/2" THICK PL. EXTERIOR JM U 1/2"x 12" x 10’-0" PLATE EACH SIDE 6" x 1/4" BAR (SKEWED), COPE ENDS AS REQ’D TO ALLOW CONNECTION TO WEB OF CHANNEL US Army Corps U.S.ARM Y CORPS OF ENGI NEERS 5 *** SAFETY FIRST *** 6" x 1/4" BAR (SKEWED), COPE ENDS AS REQ’D TO ALLOW CONNECTION TO WEB OF CHANNEL 6’-0" x 10’-6" x 3/8" PL. EACH SIDE 1/2 " 1/2 " BAR TO CHANNEL TYP. LEFT DOOR D 1/2" THICK PL. 3/8" THICK PL. 1/2" THICK STIFF. PL. (2 PER HINGE) HSS 6x2x1/4, WITH 3/8" CAP PL. EACH END 1/8 INTERIOR 1/2" 1’-5" 11" HSS 6x2x1/4 TYP. RIGHT DOOR 3/8" THICK PL. 2 3/4 " TYP. PLATE TO CHANNEL DOOR HINGE PL., SEE DETAIL 2/S704 3/8 3/8 LEFT DOOR D 3/8" THICK PL. INTERIOR ILD SYSTEM, SEE ILD MANUF. DRAWINGS TYP. TUBE SUPPORT, SEE DETAIL 5/S704. INSTALL THE FIRST TUBE SUPPORT 21.5" FROM THE BOTTOM OF THE DOOR FRAME WITH THE REMAINING TUBE SUPPORTS INSTALLED EVERY 16.81" APART. EXTERIOR Huntsville Center EXTERIOR ILD SYSTEM, SEE ILD MANUF. DRAWINGS C6x13 CONT. 3/8 1/2" THICK PL. of Engineers 1/4 1/4 PLATE TO PLATE US Army Corps EXTERIOR 1/4 HSS 6x2x1/4 DOOR HANDLE, SEE DETAIL 1/S704. MOUNT VERT. AT 44" ABOVE BOTTOM OF DOOR TO CENTER OF HANDLE L3x3x3/8 Revi si ons RIGHT DOOR 1 1/2" THICK PL. GUSSET HINGE PL., SEE DETAIL 3/S704 Dat e PLATE TO TUBE,TYP. 1/4 DOOR FRAME ASSEMBLY, SEE DETAIL B/S701 FOR INFORMATION 6’-0" x 10’-6" x 3/8" PL. EACH SIDE 3/8 2 1’ 8" 1/2"x 12" x 10’-0" PLATE EACH SIDE INTERIOR 3 Appr . 4 5 1/2" x 6" x 9’-8" PLATE SECTION A SCALE: 1 1/2"=1’-0" S702 S703 SCALE: 1 1/2"=1’-0" S702 S703 SECTION C D SCALE: 1 1/2"=1’-0" S702 S703 S702 S703 3 SIDES 1/4 L2x2x1/4 x 0’-2" LG., TYP. 1/4" x 6" WIDE BAR .28" 3. 1" INT. PLATE TO ANGLE, TYP. 1/2 NOTCH PL., TYP. 1 1/2 " A LEFT DOOR PLATE ELEVATION "INSIDE VIEW" SCALE: 3/4"=1’-0" E S702 S703 SCALE: 3/4"=1’-0" PLATE TO ANGLE 3/8" THICK INSIDE PLATE NOTE: CROSS BAR NOT SHOWN FOR CLARITY LEFT DOOR PLATE ELEVATION "OUTSIDE VIEW" 3/8" THICK EXT. PLATE 4-12 SECTION Y-Y F SCALE: 1 1/2"=1’-0" S702 S703 NOTE: RIGHT DOOR PLATE ELEVATION IS SIMILAR (DOOR NOTCH IS GREATER) NOTE: RIGHT DOOR PLATE ELEVATION IS SIMILAR (DOOR NOTCH IS GREATER &1/2" THICK COVER PL. TERMINATES FOR ILD HANDLE AND KEYS) 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 Dat e: Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on Checked by: Dr awn by: DESIGNER NOTE: TO BE REMOVED WHEN PREPARING CONSTRUCTION DRAWINGS FOR SITE ADAPTION DESIGN SHEETS S701 - S705 (HIGH SECURITY HASP) AND S701(A) - S705(A) (ILD) IDENTIFY TWO DIFFERENT LOCKING SYSTEMS. THE DESIGNER SHALL VERIFY WITH THE CONTRACTING OFFICIER THE CORRECT LOCKING SYSTEM REQUIRED AND REMOVE THE REDUNDANT SHEETS FROM THE CONSTRUCTION CONTRACT DOCUMENTS FOR THE SYSTEM NOT USED. 5 A 1 Sheet reference number: S-703 (A) Sheet 17 of 24 STANDARD DESI GN DRAW I NGS -FI NAL 1/4 6" 1/2" DIA. HOLE IN INTERIOR PLATE FOR PLUG WELD, TYP. AT L2x2x1/4 B DOOR SECTI ONS Y DOOR HANDLE, SEE DETAIL 1/S704 MOUNT VERT. AT 44" ABOVE BOTTOM OF DOOR TO CENTER OF HANDLE 1/4" x 6" WIDE BAR CONT. EACH DIRECTION. SLOT EACH BAR AT INTERSECTION TO ALLOW BARS TO INTERLOCK AND FIT FLUSH. JM U 1/2" THICK PL. CONT. ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A Y 1/2" THICK SEAL PL. (NOT REQUIRED FOR RIGHT DOOR) M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 SCALE: 1 1/2"=1’-0" JM U SECTION X-X Desi gned by: 3/8" THICK INSIDE PLATE NOTE: CROSS BAR NOT SHOWN FOR CLARITY RSW PLATE TO ANGLE U.S.ARM Y CORPS OF ENGI NEERS 1/2 NOTCH PL., TYP. L2x2x1/4, TYP. 1/2 Dr awi ng code: 1/4" x 6" WIDE BAR X X 6" 45 .28" 1" DIA. HOLES AS REQ’D TO FILL DOOR W/ INSULATION. OMIT IF NOT REQUIRED. (NOT ALL HOLES SHOWN) 45 AS SHOW N L2x2x1/4 x 0’-2" LG., TYP. C Scal e: 3 SIDES 1/4 4-12 3. 1" 1/4 COPE 6" WIDE BAR AS REQ’D TO ALLOW CONNECTION TO WEB OF CHANNEL B 2 DECEM BER 2011 3/8" THICK EXT. PLATE Dat e: 6 1 /4 T Y P " . 1 ’ -1 " T Y P . 1 ’ T -0" Y P . 1" 1/2" THICK PL. 1 /4 " . P Y T 6 6 " -0 . ’ 1 P Y T " /4 1 " -1 ’ 1 1/2" THICK PL. " /4 . 1 P Y T EXTENTS OF 3/8" THICK PLATE 6 C " -0 . ’ P 1 Y T EXTENTS OF DOOR FRAME 1 T ’ Y 0" P . No. SCALE: 1 1/2"=1’-0" SECTION B Descr i pt i on SECTION *** SAFETY FIRST *** 4 1/ 2" 2 2" DIA. (+0.000/-0.002) 2 1/8 " US Army Corps of Engineers 3 1/2" DIA. Huntsville Center 3/8" RADIUS 3/4 " 1 1/4 " .516" DIA. 45 DEGREE x 1/2", TYP. 4" TAP FOR 1/4" GREASE FITTING. PROVIDE GREASE FITTING AND GREASE AFTER ASSEMBLY 1" DRILL 1/4" DIA. D Dat e 45 DEGREES x 3/8" 1" 3" 1.016" DIA. 1 1/ 2" . 766 SQ. 3/ 4" D 1/ 2" 6" Appr . 1 1/2" DIA. 3/4 " 1 4"DI A. 7 1/2 " 3 15 5 .516" DIA. TYP. LATCH BAR DETAIL SCALE: 3"=1’-0" SPACER DETAIL 1 SCALE: 3"=1’-0" S702 S704 WASHER DETAIL 2 SCALE: 3"=1’-0" S702 S704 HINGE PIN DETAIL 3 SCALE: 3"=1’-0" S702 S704 Revi si ons 2 1/2 " 4 S702 S704 Descr i pt i on 3/16" RADIUS, TYP. 1" No. 1’-2 1/2 " 1’ 2" 1/2"x 1" x 8" LONG BAR, CENTERED ON UPPER LOCK BAR ONLY .516" DIA. 3/4 " 1’ 2" 1" SCALE: 3"=1’-0" SCALE: 3"=1’-0" S702 S704 SLEEVE DETAIL 6 SCALE: 3"=1’-0" S703 S704 HANDLE DETAIL 7 SCALE: 3"=1’-0" S702 S704 S703 S704 3" 3/4" DIA. ROD, MOUNT VERT. AT 44" ABOVE BOTTOM OF DOOR TO CENTER OF HANDLE 3/4 " 1" 4" 1" 1 1/4 " 3" 6" 3" 1" 1 1/ 2" 1" 2.015" DIA. DOOR HINGE PL. DETAIL SCALE: 3"=1’-0" THRUST BEARING 5" O.D. x 2 1/32" I.D. x 5/8" OIL IMPREGNATED SINTERED BRASS 1" 3" 8" 8" 8" 1/2" THICK PLATE 60 4" RADIUS, TYP. BORE AND TAP FOR 1/4" GREASE FITTING 8" FACE OF DOOR B 9 S702 S704 45 DEGREE x 1", TYP. GUSSET HINGE PL. DETAIL SCALE: 3"=1’-0" 10 S702 S704 TUBE SUPPORT PL. DETAIL SCALE: 3"=1’-0" 11 S703 S704 HANDLE DETAIL SCALE: 3"=1’-0" 12 S201 S704 THRUST BEARING DETAIL SCALE: 3"=1’-0" 13 S702 S704 A DOOR DETAI LS 3 3/4 " M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 4" 5/ 8" 1" B 5" 1/ 4" 45 DEGREE x 3/4", TYP. 8 3/4 " 4 1/4 " 3" 1/ 2" 5" Dat e: 8 A DESIGNER NOTE: TO BE REMOVED WHEN PREPARING CONSTRUCTION DRAWINGS FOR SITE ADAPTION DESIGN SHEETS S701 - S705 (HIGH SECURITY HASP) AND S701(A) - S705(A) (ILD) IDENTIFY TWO DIFFERENT LOCKING SYSTEMS. THE DESIGNER SHALL VERIFY WITH THE CONTRACTING OFFICIER THE CORRECT LOCKING SYSTEM REQUIRED AND REMOVE THE REDUNDANT SHEETS FROM THE CONSTRUCTION CONTRACT DOCUMENTS FOR THE SYSTEM NOT USED. 5 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 1 Sheet reference number: S-704 Sheet 18 of 24 STANDARD DESI GN DRAW I NGS -FI NAL SHAFT DETAIL 5 45 DEGREE x 1/2", TYP. RSW LOCK BAR DETAIL .500-13UNF-2B THREAD DEPTH = 3/4" 2" 1" DIA. 1/16" RADIUS, TYP. Desi gned by: 30 1" 1" DIA. Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on 1/2 " .219" Dr awi ng code: 3/4 " C Checked by: 1 1/2" DIA. 45 DEGREE x 1/2", TYP. 4" / 3 . SQ AS SHOW N 6 3/4 " JM U 5’-2" Scal e: 3" DIA. Dr awn by: 3/4 " SQ. ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A 3/8 " 2 DECEM BER 2011 C 2 3/4 " Dat e: 3" DIA. 8 7/8 " JM U 2" 2" 3/ 4" 1/2 " U.S.ARM Y CORPS OF ENGI NEERS 1 1/ 2" 2" RADIUS, TYP. *** SAFETY FIRST *** 4 5 3 2 1 3" 3/4" DIA. ROD, MOUNT VERT. AT 44" ABOVE BOTTOM OF DOOR TO CENTER OF HANDLE 1" 4" 3 3/4 " 1" 2 1/8 " 2" DIA. (+0.000/-0.002) 3" SCALE: 3"=1’-0" 45 DEGREE x 1", TYP. GUSSET HINGE PL. DETAIL 2 SCALE: 3"=1’-0" SCALE: 3"=1’-0" S702 S704 4 S702 S704 No. S702 S704 HINGE PIN DETAIL 3 Descr i pt i on 2.015" DIA. DOOR HINGE PL. DETAIL 1 S201 S704 S703 SCALE: 3"=1’-0" 1 1/ 2" 1" 3" HANDLE DETAIL TAP FOR 1/4" GREASE FITTING. PROVIDE GREASE FITTING AND GREASE AFTER ASSEMBLY 1" DRILL 1/4" DIA. Revi si ons 1 1/4 " 4" 4" RADIUS, TYP. D Dat e 4"DI A. 3/8" RADIUS 8" 8" 60 8" 3" 8" FACE OF DOOR Huntsville Center 1 1/4 " 1" D of Engineers 3/4 " 15 8 3/4 " 4 1/4 " 1/ 4" 45 DEGREE x 3/4", TYP. US Army Corps Appr . 3" 1/ 2" 5" Dat e: Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on 1" THRUST BEARING 5" O.D. x 2 1/32" I.D. x 5/8" OIL IMPREGNATED SINTERED BRASS JM U ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 B A B DOOR DETAI LS S702 S704 Dr awn by: 6 Checked by: JM U SCALE: 3"=1’-0" S703 S704 Desi gned by: SCALE: 3"=1’-0" 5 U.S.ARM Y CORPS OF ENGI NEERS TUBE SUPPORT PL. DETAIL THRUST BEARING DETAIL RSW 1" A DESIGNER NOTE: TO BE REMOVED WHEN PREPARING CONSTRUCTION DRAWINGS FOR SITE ADAPTION DESIGN SHEETS S701 - S705 (HIGH SECURITY HASP) AND S701(A) - S705(A) (ILD) IDENTIFY TWO DIFFERENT LOCKING SYSTEMS. THE DESIGNER SHALL VERIFY WITH THE CONTRACTING OFFICIER THE CORRECT LOCKING SYSTEM REQUIRED AND REMOVE THE REDUNDANT SHEETS FROM THE CONSTRUCTION CONTRACT DOCUMENTS FOR THE SYSTEM NOT USED. 5 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 1 Sheet reference number: S-704 (A) Sheet 19 of 24 STANDARD DESI GN DRAW I NGS -FI NAL 6" Dat e: 1/2" THICK PLATE Dr awi ng code: BORE AND TAP FOR 1/4" GREASE FITTING C AS SHOW N 4" Scal e: 5/ 8" C 2 DECEM BER 2011 5" *** SAFETY FIRST *** 5 4 3 2 1 US Army Corps of Engineers Appr . Huntsville Center D 2 DECEM BER 2011 No. Descr i pt i on Revi si ons Dat e D 1. HIGH SECURITY HASPS SHALL CONFORM TO MILITARY SPECIFICATION MIL-DTL-29181C, STYLE 1-HASP (M29181-01) FOR RIGHT HAND SWINGING DOOR AND STYLE 2-HASP (M29181-02) FOR LEFT HAND SWINGING DOOR. HIGH SECURITY PADLOCKS SHALL CONFORM TO MILITARY SPECIFICATION MIL-DTL-43607J. 2. NO MODIFICATIONS AND/OR DEVIATIONS TO THE DOOR CONSTRUCTION SHOWN IN THE STANDARD DRAWINGS IS PERMITTED TO ACCOMMODATE THE HIGH SECURITY HASP UNLESS APPROVED BY THE U.S. ARMY ENGINEERING AND SUPPORT CENTER, HUNTSVILLE (STRUCTURAL BRANCH). HIGH SECURITY HASP A 3. DOOR MANUFACTURER WILL COORDINATE WITH THE GOVERNMENT ON INSTALLATION AND ATTACHMENT DETAILS OF THE HASPS AND PROVIDE THE NECESSARY STIFFENERS AND ADDITIONAL FRAMING (IF REQUIRED) TO ACCOMMODATE THE HIGH SECURITY HASPS. S705 4. SEE DOOR FRAME AND DOOR DETAILS ON SHEETS S701 - S704. A Dat e: RSW Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on Dr awi ng code: Checked by: DESIGNER NOTE: TO BE REMOVED WHEN PREPARING CONSTRUCTION DRAWINGS FOR SITE ADAPTION DESIGN SHEETS S701 - S705 (HIGH SECURITY HASP) AND S701(A) - S705(A) (ILD) IDENTIFY TWO DIFFERENT LOCKING SYSTEMS. THE DESIGNER SHALL VERIFY WITH THE CONTRACTING OFFICIER THE CORRECT LOCKING SYSTEM REQUIRED AND REMOVE THE REDUNDANT SHEETS FROM THE CONSTRUCTION CONTRACT DOCUMENTS FOR THE SYSTEM NOT USED. 5 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 1 Sheet reference number: S-705 Sheet 20 of 24 A STANDARD DESI GN DRAW I NGS -FI NAL HIGH SECURITY HASP NOTES: B HI GH SECURI TY HASP B M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 S705 Dr awn by: Desi gned by: B U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A HIGH SECURITY HASP JM U Scal e: AS SHOW N C JM U Dat e: C *** SAFETY FIRST *** 4 5 3 2 1 US Army Corps of Engineers Appr . Huntsville Center D Revi si ons Dat e D LEFT DOOR 2 DECEM BER 2011 No. Descr i pt i on RIGHT DOOR S705 B INTERNAL LOCKING DEVICE (ILD) NOTES: 1. INTERNAL LOCKING DEVICE IS A U.S. GOVERNMENT DESIGNED AND PATENTED LOCKING SYSTEM. THE ILD SYSTEM SHALL BE PURCHASED FROM A GOVERNMENT APPROVED ILD MANUFACTURER WITH COORDINATION OF NAVAL FACILITIES ENGINEERING SERVICE CENTER (NAVFAC ESC) SECURITY ENGINEERING DIVISION. CONTACT CAN BE MADE VIA PHONE BY CALLING 805-982-1212 OR THEIR WEBSITE https://portal.navfac.navy.mil/portal/page/portal/navfac/navfac_ww_pp/navfac_nfesc_pp/locks/) ( FOR ORDERING INFORMATION. 2. NO MODIFICATIONS AND/OR DEVIATIONS TO THE DOOR CONSTRUCTION SHOWN IN THE STANDARD DRAWINGS ARE PERMITTED TO ACCOMMODATE THE ILD UNLESS APPROVED BY THE U.S. ARMY ENGINEERING AND SUPPORT CENTER, HUNTSVILLE (STRUCTURAL BRANCH). 3. DOOR MANUFACTURER WILL COORDINATE WITH THE GOVERNMENT ON INSTALLATION AND ATTACHMENT DETAILS OF THE ILD AND PROVIDE THE NECESSARY STIFFENERS AND ADDITIONAL FRAMING (IF REQUIRED) TO ACCOMMODATE THE ILD. 4. SEE ILD MANUFACTURERS INSTALLATION DRAWINGS FOR ADDITIONAL INFORMATION NOT SHOWN IN THESE DRAWINGS. 5. SEE DOOR FRAME AND DOOR DETAILS ON SHEETS S701(A) - S704(A). A Dat e: RSW Pr oj ectEngi neer / Ar chi t ect : Jef fCoul st on Dr awi ng code: AS SHOW N Scal e: Dr awn by: Checked by: B DESIGNER NOTE: TO BE REMOVED WHEN PREPARING CONSTRUCTION DRAWINGS FOR SITE ADAPTION DESIGN SHEETS S701 - S705 (HIGH SECURITY HASP) AND S701(A) - S705(A) (ILD) IDENTIFY TWO DIFFERENT LOCKING SYSTEMS. THE DESIGNER SHALL VERIFY WITH THE CONTRACTING OFFICIER THE CORRECT LOCKING SYSTEM REQUIRED AND REMOVE THE REDUNDANT SHEETS FROM THE CONSTRUCTION CONTRACT DOCUMENTS FOR THE SYSTEM NOT USED. 5 4 3 *** SUPPORT VALUE ENGINEERING - IT PAYS *** 2 1 Sheet reference number: S-705(A) Sheet 21 of 24 A STANDARD DESI GN DRAW I NGS -FI NAL A I NTERNAL LOCKI NG DEVI CES SCALE: NTS VIEW FROM INSIDE OF MAGAZINE FOOT & HEAD BOLT SHOWN DISENGAGED DETAILS ARE SHOWN FOR GENERAL INFORMATION ONLY. SEE ILD MANUF. DRAWINGS FOR A COMPLETE SET OF DETAILS AND REQUIREMENTS. S705 M ODULAR STORAGE M AGAZI NE BOXTYPE,STD 4218007 INTERNAL LOCKING DEVICE (ILD) SCALE: NTS VIEW FROM INSIDE OF MAGAZINE FOOT & HEAD BOLT SHOWN DISENGAGED B U.S.ARM Y CORPS OF ENGI NEERS ENGI NEERI NG AND SUPPORT CENTER, HUNTSVI LLE,ALABAM A INTERNAL LOCKING DEVICE (ILD) Desi gned by: JM U Dat e: ILD SYSTEM, SEE MANF. DRAWINGS C JM U C