University of CA, San Diego Confined Space Program

advertisement

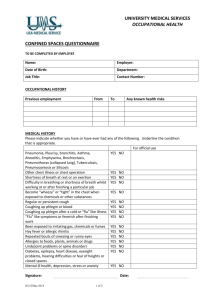

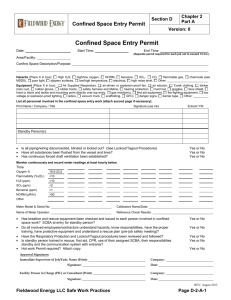

A publication of the Environment, Health & Safety Office University of CA, San Diego Confined Space Program Policy and Procedure for Entering Confined Spaces Intended for Employees and Supervisors Involved in Conducting Work in Confined Spaces Revised April 2002 Office of Environment, Health and Safety (858) 534-3660 UCSD Environment, Health and Safety Publication April 2002 Table of Contents Introduction ……………………………………………………………………………..3 California Regulatory Requirements.…………………………………………………3 Hazardous Atmospheric Conditions.………………………………………………….3 Air Monitoring Instrumentation.………………………………………………………..6 Physical Hazards……………………………………………………………………..…6 Entry Logs and Permits…………………………………………………………….…..7 Pre-entry Procedures……………………………………………………………….…..8 Permit-Required Confined Space Procedures……..………………………………..9 . Emergency Rescue Policy and Procedures………………………………………..10 Employee Training…………………………………………………………………….11 Role of an Employee………………………………………………………………….12 Role of an Entry Supervisor………………………………………………………….12 Role of an Authorized Entrant………………………………………………………..12 Role of an Attendant ………………………………………………………………….13 Role of the Office of Environment, Health and Safety……………………………..13 Identified Confined Spaces at UCSD………………………………………………..14 Contractors……………………………………………………………………………..15 Appendix A Sample Confined Space Entry Permit .……………………………….16 Confined Space Entry Permit Sample (Enhanced Title 8 Version)…17 Appendix B Sample Routine Confined Space Entry Log………………………….18 Appendix C Ventilation and Purge Chart……………………………………………19 UCSD Environment, Health and Safety Publication April 2002 2 Introduction Californians die in confined space accidents every year. Not only is the original victim at high risk, but sixty percent of the fatalities are would -be rescuers who enter the space attempting to retrieve the fallen individual(s), only to be overcome by the hazardous atmosphere and perish themselves. UCSD maintenance and telecommunication employees entering confined spaces on campus may encounter extremely hazardous atmospheric conditions and/or access difficulties, which could bec ome life threatening. Such locations include sewers, tanks, boilers, crawl spaces, acid pits, vaults, storm drains, pipelines, bins, tubs, ducts and vessels which must be entered for repairs, inspection and maintenance. Insufficient ventilation may allow for the accumulation of toxic or flammable gases or the critical depletion of ox ygen necessary to sustain life. Limited access into and exit from these spaces greatly hampers rescue procedures. Confined space means a space that has all of the following ch aracteristics: Is large enough and so configured that an employee can bodily enter and perform assigned work; and Has limited or restricted means for entry or exit (for example, tanks, vessels, silos, storage bins, hoppers, vaults, and pits are spaces that may have limited means of entr y.); and Is not designed for continuous employee occupanc y. California Regulatory Requirements Special confined space occupational regulations have been developed by California Occupational Safety and Health Administra tion (Cal/OSHA). These regulations are contained in Title 8, Sections 5156 -59 of the General Industry Safety Orders and Section 8616 of the Telecommunication Safety Orders of the California Code of Regulations. This program polic y was developed by the Offi ce of Environment, Health and Safety (EH&S) to provide UCSD employees with critical information about these regulations to ensure their safety whenever engaged in confined space operations. Hazardous Atmospheric Conditions The unfavorable ventilation of a confined space can cause the atmosphere in the area to become life threatening, not life -supporting. Processes of biological activity, decomposition of natural materials, oxidation, percolation of vapors and structural leaks can cause the production and accumulation of toxic gases and/or flammable gases. Available oxygen levels may become seriously depleted or displaced through these same processes. W hen the atmosphere becomes contaminated with harmful gases or lack of ox ygen, the effects may not be immediately felt by the exposed worker. A false feeling of euphoria or well -being is a common side effect to such exposure. A number of the gases have no odor or color detectable by the body’s senses. Many who die in confined space accidents simply slip into unconsciousness quietly, never realizing what is happening and never awakening. UCSD Environment, Health and Safety Publication April 2002 3 One cardinal rule prevails in working in confined spaces: “never trust your senses.” Only through using appropriate monitoring instruments, which are capable of analyzing gases in the parts-per-million range can employees be certain that the atmosphere is safe to enter. The following section discusses the harmful effects of exposure to varying toxic gases and ox ygen levels commonly found in confined space atmospheres. Oxygen Depletion Life ceases quickly without enough oxygen. Common sources of ox ygen depletion in confined spaces include aerobic bacterial growth, oxidation or rusting of metals, combustion and displacement by other gases. Oxygen comprises only a small percentage (20.9%) of the air we breathe. W hen levels of ox ygen are reduced below 19.5% (minimal acceptable level), serious health problems begin to occur very quickly. The following provides an overview of those effects at various ox ygen levels: 20.9% ........ Percent ox ygen found in normal air. 19.5% ........ Minimum permissible oxygen level. 15-19% ...... Decreased ability to work strenuously. May impair coordination and may induce early s ymptoms in persons with coronary, pulmonary or circulatory problems. 12-15% ...... Respiration and pulse increase; impaired coordination, perception and judgement. 10-12% ...... Respiration further increases in rate and depth, poor judgment and bluish lips. 8-10% ........ Mental failure, fainting, unconsciousness, ashen -face, blueness of lips, nausea and vomiting. 6-8% .......... 8 minutes - 100% fatalities; 6 minutes - 50% fatalities; 4-5 minutes recover y with treatment. 4-6% .......... Coma in 40 seconds, convulsions, respiration ceases - death. As well as being consumed by organisms, fire or decay proce sses, oxygen may be depleted because other gases have displaced it. Some gases are heavier than air and move downward; others being lighter than air travel upward, displacing the available ox ygen as they fill the space. Toxic Gases There are many different types of toxic gases, which can be found in confined spaces. Their sources and physical characteristics vary, but th ey all share one common thread – potential harm to individuals who come in contact with them in enclosed areas. There are two categories of toxic gases: irritants and asphyxiants. Irritants – many gases, existing in low concentrations in the air, are irritating to the body’s respirator y and nervous system. W hen breathed, they cause swelling of mucous linings of the lungs and sinuses, some times so severe that complete closure of the respiratory tract occurs causing strangulation. Except under extreme conditions, normally the body does recover after exposure to gases has stopped. In higher concentrations, irritants can become asphyxiating g ases. UCSD Environment, Health and Safety Publication April 2002 4 Asphyxiants – any gas which, when present in high enough concentration, causes displacement of ox ygen in the body. Carbon monoxide is one of the most common asphyxiants. It is produced by incomplete combustion of carbon fuels. Carbon monoxide kill s by chemically combining with the hemoglobin in red blood cells. This greatly reduces the ability of the blood to carry ox ygen to the body tissues and brain cells. CARBON MONOXIDE EXPOSURE EFFECTS 25 ppm ................................. Permissible Exposure Limit over 8 hour shift 500 ppm ............................... Slight headache 1000 ppm ............................. Confusion, nausea, discomfort 2000 ppm ............................. Tendency to stagger 2500 ppm ............................. Unconsciousness after 30 minute exposure 4000 ppm ............................. Fatal in less than one hour Hydrogen sulfide is even more toxic than carbon monoxide. It i s produced through the decay of organisms and natural materials. This colorless gas has a characteristic rotten -egg odor at first smell; however, after a short time the gas renders the olfactory nerve (which controls the sense of smell) ineffective. A worker may be lulled into a false sense of security because he/she no longer smells the substance, and yet it causes serious bodily harm in higher concentrations. HYDROGEN SULFIDE EXPOSURE EFFECTS 10 ppm.............. ................... Permissible Exposure Limit over 8 hours 50-100 ppm....... .................. Mild eye and respiratory irritation 200-300 ppm ....................... Marked increase in eye and lung irritation 500-700 ppm ....................... Unconsciousness/death after 30 minute exposure 1000 or more ....................... Death within minutes Search Permissible Exposure Limits for Chemical Contaminants , Table AC1, for current exposure limit data being enforced by Cal/OSHA . Flammable Gases Many of the gases routinely found in confined spaces are combustible unde r the right combination of conditions (including hydrogen sulfide, carbon monoxide, acetylene, and methane). W hen fuel, ox ygen and a source of ignition are present at the same time and in the correct proportions, a serious explosion or fire can result. If a combustible gas and air are trapped in a confined space, only a source of ignition is needed to create an explosion. W elding, sparking tools, smoking or static electricity can easily satisfy this requirement. The lowest concentration (air -fuel mixture) at which a gas can ignite is called its Lower Explosive Limit (LEL). Concentrations below this level are too lean to burn. The highest concentration that can be ignited is its Upper Explosive Limit (UEL). Above that concentration, the mixture is too rich t o burn. A gas is flammable in concentrations between its LEL and UEL. Monitoring instruments analyze air samples and react or alarm at a predetermined concentration level, which is usually less than 10 % of the LEL figure. This early warning provides the worker with advance information concerning the existing potential hazard. Any concentration of flammable gas is reason for concern in a confined space. Overly rich mixtures can collect in an area and reach UCSD Environment, Health and Safety Publication April 2002 5 combustible concentrations when fresh air is int roduced and quickly changing its proportions to levels between the LEL and UEL. Confined space atmospheres containing an enriched oxygen level above 23.5% increase the flammability ranges of many gases, as well as support violent flammable reactions when c ombustion occurs. Oils and grease may unexpectedly burst into flames under such atmospheric conditions. Air Monitoring Instrumentation It is critical that an atmospheric monitoring instrument is used before and during confined space entr y. There are seve ral types of atmospheric monitoring instruments being used by various campus divisions of maintenance and telecommunication personnel. They are capable of continuous sampling of the atmosphere to which the worker is being exposed and have both liquid cryst al digital screens and audible alarms that are preset to activate when certain levels of contaminants are sensed. Each instrument monitors air samples for four categories of hazardous conditions simultaneously: (1) percent of available ox ygen, (2) presence of hydrogen sulfide (toxic gas), (3) percent of flammable gases and (4) presence of carbon monoxide in the air. Other instruments in use at UCSD currently may not be capable of continuous monitoring; rather, they are designed to monitor a single sample of drawn air for certain contaminants. These older models are larger, not worn on the employee’s belt and must be activated each time a new sample is needed. They may or may not have the capability to analyze the sample for more than one type of contaminant at once. At a minimum, every employee performing atmospheric monitoring should have the ability to retrieve sampling information about the oxygen level, as well as presence of both toxic and flammable gases. This may only be possible by utilizing several different instruments. Regardless of the type of instrument being used, each requires periodic maintenance and calibration. Specific manufacturer’s instructions must be followed to ensure each instrument provides reliable service. Replacement parts, incl uding extended probes and carr ying cases, should be purchased directly from the manufacturer. Each of these appliances is a highly sophisticated scientific instrument that must be carefully handled and maintained in order to provide critical, lifesaving information to the user. These instruments are capable of detecting deadly atmospheric conditions far beyond that of human senses. Physical Hazards Confined space areas may also have the following physical hazards which employees may come in contact with: Possibility of engulfment or entrapment by flooding while working in a storm sewer. Pipes, valves and lines carrying harmful substances (steam, natural gas and electricity) should they rupture while being worked on or activated if not locked out. Loud noise reverberating from the use of hammers, hydraulic equipment. Exposure to higher environmental temperatures during work activities. Slips and falls on wet surfaces or resulting from broken or oxidized ladder rungs. UCSD Environment, Health and Safety Publication April 2002 6 Exposure to corrosive substances w hich could cause irritation to unprotected skin Exposure to rodents and other pests living in the area Poor or inadequate illumination Entry Logs and Permits A permit-required confined space fits the definition of a confined space and has one or more of the following characteristics: Contains or has a potential to contain a hazardous atmosphere Contains a material that has a potential for engulfing the entrant Contains inwardly converging walls or a floor that slopes downward and tapers to a smaller cross-section where an entrant could be trapped or asphyxiated Contains any other recognized serious safety or health hazard (e.g. unsafe temperature, electrical shock, corrosive chemicals) An entry log (non-permit) confined space fits the definition of a co nfined space, but does not contain or have the potential to contain any atmospheric hazard capable of causing death or serious physical harm. Most confined space operations at UCSD facilities will require only the use of the Entry Log (Appendix B) form. T hose with special hazards, as listed in the section entitled "Identified Confined Spaces at UCSD," are considered as "permit required confined spaces" and require a supervisor's authorization before entry and full compliance of the Permit-Required Confined Space Program. The purpose of the entry log or permit is to ensure that necessary precautions are taken before entry is made. The following action items are included on UCSD’s Confined Space Entr y Permit (Appendix A) forms: Date, location, job description, time employee(s) entered and exited the permit space and supervisor’s signature Monitoring instrument calibration and battery check Necessity of blocking and blinding all pipes and lines Performance of periodic atmospheric tests; recording of all data results Either the UCSD version or the enhanced Title 8 version of the Confined Space Entry Permit (Appendix A) shall be used when entering Permit -Required confined spaces. Copies of the UCSD Entry Log/Permit form are available through Physical Plant Services, Telecommunications, Housing Services, and EH&S. All logs and permits are to be kept at the job site until the operation is completed. All measurement data from the sampling activities are to be recorded on the log. Logs and permits are to be signed and kept in departmental records for two year. Such records shall be open to periodic inspection by applicable employees, their representatives, EH&S staff, and Cal/OSHA inspectors. Appendix A contains a standard copy of the permit and entry log that shall be filled out upon confined space entr y. UCSD Environment, Health and Safety Publication April 2002 7 Pre-entry Procedures The following four steps must be taken before entry is made into any known or suspected confined space area on campus: STEP 1 - Determine Whether Entry Permit or Log is Required If special hazards are present, as discussed above, obtain supervisor's written approval on the Confined Space Entry Permit form and comply with the safety protocols before entering the space. STEP 2 - Organize the Equipment Obtain the following items: Entry Log or Permit Air monitoring equipment (check the battery and current calibration status) Ventilation equipment and its power supply Arrange for qualified attendant (standby person) and communication equipment Tripod, winch, and full harness (for vertical entry, deeper than 5 feet in a permit space) Only devices designed by the manufacturer and approved for moving humans should be used Barricades, if needed STEP 3 - Securing the Environment Steam Boilers - before entry into one of a battery of boilers or a boiler connected to another source of steam, the valve connection to the steam header or source must be closed and blinded, or there shall be two closed valves with an open bleeder between them. Blow-down valves and other valves on lines through which harmful material might accidentally flow back to the boiler shall be closed, locked and tagged. The key must be kept by the employee entering the boiler. This is not necessary if the lines are blinded. Fire Boxes, Flues and Combustion Chambers - before entry, the pilot light, fuel and steam lines must be blinded, disconnected or have two closed block-valves with an open bleeder between them. Water Tanks – valves, which could admit water must be closed, locked and tagged. The employee entering the space must keep the key. Spaces with Potentially Harmful Electrical Equipment - this equipment must be disconnected with the disconnect switch locked and tagged. The key must be in the possession of the employee entering the space. Spaces with Fire Suppression Systems That Use Toxic or Oxygen-displacing Gas system must be deactivated before entry. Spaces Pedestrians Could Fall Into - must have appropriate barricades. Spaces Where Employees Could Fall - use harness and winch setup to prevent falls. STEP 4 - Initial Monitoring A meter is available 24 hours a day at the Physical Plant Services Central Utilities Plant. UCSD Environment, Health and Safety Publication April 2002 Activate the meter and allow it to warm up. Check its operation condition and charge status of the battery. Perform the initial monitoring evaluation to determine potential hazards in the confined space atmosphere. Follow the manufacturer’s operational and sampling instructions exactly to obtain the best results. Insert the probe into the opening of the manhole lid or other access point and allow the monitor to sample for the manufacturer’s prescribed time period. If the readings for available oxygen, hydrogen sulfide and flammable gases are within acceptable levels, continue to sample the atmosphere by lowering the probe through the lid opening until it reaches near the floor. Allow adequate time for the instrument to draw the sample up the extended hose and conduct the analysis. This sample will analyze for heavier-than-air gases, which would be found near the bottom of the space. Using an extension cable, monitor at various levels and locations, testing for the presence of contaminated atmosphere. Where interconnected spaces are blinded off, each space shall be monitored separately. The most hazardous conditions found in any portion of the area shall dictate the appropriate action to be taken by employees. All monitor readings must be recorded on the Entry Log/Permit form. If unacceptable readings and/or alarms are activated during any monitoring tests, it is an indication that the atmosphere is contaminated and unsafe for employee entry. Ventilate for at least five minutes. Conduct second round of air monitoring. If the atmosphere does not clear, DO NOT ENTER THE SPACE! Contact your supervisor and EH&S. The source of the contamination will be investigated and eliminated before any work is performed. Permit—Required Confined Space Procedures Locations identified as permit-required confined spaces shall be clearly communicated, either by signage or other effective methods, to employees who are likely to enter these spaces. These areas shall be secured to prevent unauthorized entry. Entry Procedures for Permit-Required Space Once the initial tests are completed and determined to be within acceptable limits, work may proceed utilizing the following precautions: UCSD Environment, Health and Safety Publication April 2002 9 At least two employees will be needed for a “Permit-Required” confined space operation. One employee will remain outside of the space to be available in case of an emergency. This individual must be in direct communication with the other worker(s) in the confined space, as well as have the capability to reach emergency response personnel by dialing 911 for the campus areas, (x6111 for the Medical Center) or by having radio contact with someone who can place the emergency call. A portable blower must be used at all times during confined space work activities to purge the area of possible contaminated air. The blower intake must be located outside of the confined space and away from any operating internal combustion engine to ensure that fresh air is being supplied. The blower should be activated before employees enter the space for a minimum of five minutes or as determined from the purge chart. It must remain on the entire time work is being performed. Arrange for quick means of entry and exit from the space. When possible, enter confined spaces from a side opening rather than top access. Side openings are those located within three-and-a-half feet of the bottom. Use of tripod, winch, and body harness is required for vertical entry in permit spaces of five feet or greater of depth. Personnel using the atmospheric meter shall leave the instrument operating the entire time work is being performed, to provide constant atmospheric monitoring. The worker shall have the meter with him/her at all times during confined space entry and results must be recorded accurately on the job permit/log. If at any time, atmospheric conditions change and monitoring devices indicate the presence of toxic or flammable gases, or a decreased level of oxygen, employees are to evacuate the space at once. Workers are to remain outside of the area until the cause of the problem can be determined by supervisory personnel and EH&S. Emergency Rescue Policy and Procedures Fatalities can occur when the rescuers: are overcome by emotio ns, take unnecessar y chances, do not know the hazards involved, do not have a plan of action, and/or lack confined space rescue training. Types of Rescue Operations Self-Rescue – The self -rescue plan provides entrants with the best chance of escaping a permit-required space when hazards are present. W henever authorized entrants recognize their own s ym ptoms of exposure to a dangerous atmosphere, or when a prohibited condition is detected, entrants are still able to escape from the space unaided and as quickly as possible. The advantages to this type of rescue are: rapid evacuation from the hazardous space, able to alert fellow workers, and not endangering anyone else. Non-Entry Rescue – W hen self-rescue is not possible, non-entry rescue can be started right away and prevents additional personnel from being exposed to unidentified and/or uncontrolled confined space hazards. Usually, equipment and other rescue aids are employed to assist in removing endangered entrants. Ensure that entrant(s) of a “Permit Required” space can be retrieved immediately (i.e. s/he wears a harness attached to a retrieval line that can be winched out by the attendant operating the tripod/winch outside). Entry Rescue – It is the most dangerous form of rescue and an entry rescue plan shall be developed prior to assuming this type of rescue responsibility. UCSD personnel are currently not trained to qualify as an emergency entry rescuer and do not have the equipment to provide emergency rescues in confined spaces . Emergency entry rescue services would be provided by San Diego Fire Department. Emergenc y confined space entry rescue personnel shall have current certification and knowledge on: first UCSD Environment, Health and Safety Publication April 2002 10 aid/CPR, Self-Contained Breathing Apparatus/Supplied Air Respirator, use of rescue equipment, and necessary rescue training. A thorough rescue plan shall include: A barricade area for crowd control Additional ventilation options Control or other hazards (cave-ins, traffic, etc.) Protective clothing and equipment Appropriate lighting e quipment (explosion proof) Method of communication A standby rescue team Victim removal procedures and devices Available emergency vehicles Medically trained personnel Employee Training As directed by the UCSD Hazard Communication Program, every employee responsible for working in confined spaces has a right to clearly understand the hazardous properties of the toxic and flammable contaminants which they may encounter in any confined space. They also are entitled to information on methods by which they can protect themselves while working in such areas. It is the responsibility of the departmental supervisors to ensure that appropriate training resources are made available to all employees before assigning confined space entr y tasks; that each employee has available to them all necessary protective equipment needed to conduct the job safely, and that each individual clearly understands how to use such equipment correctly. This includes basis understanding on the operation of appropriated confined space gas meters. It is the responsibility of each employee engaged in confined space activities to follow all procedures and instructions outlined in this polic y. The core training shall include, but not limited to: characteristics of confined space and permit -required confined space; specific duties of the entrant, attendant, supervisor, and non -entry rescuer; atmospheric monitoring and ventilation; communication; self -rescue, nonentry rescue, and emergenc y operations and polic y; hazard communication; hazard recognition and control; injur y and illness prevention program; entry permit s ystem; personal protective equipment, first aid, and CPR; and sings, s ymptoms, and consequences of exposures. Employees should receive training in confined space operations at leas t once per year. Programs may be presented by departmental supervisors, EH&S staff and/or qualified off-campus representatives. Additionally, all new employees assigned to work in confined spaces should receive this information as part of their initial orientation. If employees are assigned to respond as Non -entry rescuer, training on: use and operation of retrieval s ystems, first aid/CPR, communication equipment shall be provided by the department. Documents of such training should be kept with the empl oyee’s department. At minimum, a sign-in roster with employee’s name, signature and date with a copy of an outline of class content need to be documented by the employee’s supervisor. Role of an Employee (an individual who is likely to work in and arou nd confined spaces) UCSD Environment, Health and Safety Publication April 2002 11 Ensures that he/she attends a class on UCSD Confined Space Program before performing work in a confined space. Informs supervisor if he/she needs to enter a confined space to perform work. Obtains necessary air monitoring instrument, safety equipment, entry log/permit, and additional resources before entering a confined space. Follows safety procedures as covered in this booklet. Ensures that all equipment is in proper condition after an entry is completed. If not notify the superv isor. Turns in the confined space entry log or permit to the supervisor. Role of an Entry Supervisor (a person involved in assigning employees to conduct work in confined spaces and has a good understanding of the hazards and liability of tasks completed in confined spaces) Ensures that employees assigned to confined space entry tasks receive necessar y training on health and safety concerns and safe entry procedures outlined in this booklet and other operational procedures, before entering a confined space, Ensures that employees are provided with air monitoring instrument and other equipment needed to work safety in a confined space. Ensures that employees fill out the confined space entry log or permit and the supervisor signs the permit for authoriza tion before a confined space entr y. Ensures that all confined space entry logs and permits are collected from the employees and retained in the department record for two years. Communicates to contractors of jobs involving confined space work and discloses known hazards associated with the jobs. Role of an Authorized Entrant (an employee who has attended a confined space training class and is authorized by his/her supervisor to enter a confined space) Knows confined space hazards, exposure routes, signs, symptoms, and adverse health effects that could result from exposure. Uses adequate personal protective equipment. Uses proper entry equipment. Follows proper entry procedures. Performs assigned job. Is alert to any prohibited condition. UCSD Environment, Health and Safety Publication April 2002 12 Communicates with attendant. Evacuates immediately, if necessary. Role of an Attendant (an employee who has attended a confined space class and understands the specific duties of an attendant) Does not enter the confined spaces. Is prepared to perform non-entry rescue or call for a rescue team. Knows the hazards or potential hazards of the space. Maintains accurate count of authorized entrant in the space Stays alert to possible behavioral changes of entrants Monitors activities inside and outside the space to ensure that it is safe for entrants to remain in the area. Remains outside the confined space until relieved by another attendant and prevents entry of unauthorized personnel. Communicates with entrants. Orders evacuation if prohibited or hazardous conditions arise. Role of the Office of Environment, Health & Safety The Office of Environment, Health & Safety provides the following services to departments, supervisors and employees engaged in confined space activities: Assists departments and employees in the identification of confined space locations. Performs additional on-site atmospheric tests in spaces identified to have hazardous contaminants or conditions existing in the air. Develops this Polic y to provid e all campus personnel with information on safety aspects governing confined space operations. Reevaluates designated confined spaces, as needed. Presents in-service educational programs. Advises on interpretation and compliance measures to ensur e that confined space work is in compliance with all occupational safety requirements and applicable codes. Provides and maintains respiratory protection equipment and provides instruction in its utilization. UCSD Environment, Health and Safety Publication April 2002 13 Identified Confined Spaces at UCSD The following is a list of locations designated as confined spaces on campus property requiring the use of entry logs and permits ( Please note this a partial list and it is by no means a comprehensive list of all confined spaces ): In General - All Locations All manholes, meter vaults, valve boxes, etc., that are not directly connected to the main tunnel system. Normal operations within these spaces require the use of an Entry Log. If welding or high voltage work is to be done, or if it is a blocked sewer, an Entry Permit is required. All acid pits: use Entry Log. All steam generators, boilers and fireboxes: use Entry Permit All condensate, resin or other tanks: use Entry Log. Any confined spaces with machinery that could harm workers if it suddenly turned on: use Entry Permit. Main Campus Revelle Cafeteria Storeroom – crawlspace underneath the Revelle Cafeteria: use Entry Log. Revelle Mudhut tunnel – the dead end section: use Entry Log. SIO Seawater tanks: use Entry Log. Crawlspace in the basement pit of the Coastal Studies Building: use Entry Log. Point Loma Facilities All ship's tanks or sealed compartments: use Entry Logs. If welding or high voltage work is to be done: use Entry Permit. This list contains only those confin ed spaces identified on UCSD property as of January 1993. Other spaces will be included in future revisions of this Polic y as they become known. If you are asked to enter a space, which you believe may be hazardous to your health, please discuss the locat ion with your supervisor/EH&S to determine whether it should be classified as a confined space. UCSD Environment, Health and Safety Publication April 2002 14 Contractors Contractors who enter confined spaces on campus shall be notified of any known hazardous conditions, shall have their own confined space program and shall know how to contact emergency rescue personnel on the campus. Project managers shall communicate this in writing to the contractor and verify training and qualification of those entering confined spaces Appendices Appendix A Sample Confined Space Entry Permit Appendix B Sample Routine Confined Space Entry Log Appendix C Ventilation and Purge Chart UCSD Environment, Health and Safety Publication April 2002 15 Appendix A CONFINED SPACE ENTRY PERMIT For Permit-Required Spaces UCSD To be used for entering tanks, boilers, combustion chambers, spaces with moving machinery and blocked sewers. Also when welding or high voltage work will be performed. UCSD employees are only authorized to enter confined spaces after having received training in specialized entry procedures. Date _______________ Location _____________________ Type of Space/# ______________________ Reason for Entry________________________________________________________________________ Persons(s) Entering _____________________________________________________________________ Form Completed By _____________________________________________________________________ Supervisor's Authorization ______________________________ Permit Expiration Date ______________ PREPARATION 1. If the space is a blocked sewer, contract the job out, if possible. 2. If the space is a boiler or combustion chamber, follow appropriate pre-entry procedures listed in the confined space employee guide. 3. Lock valves or blind/lock pipes in spaces, which could become flooded. 4. Lock and tag all machinery which could be accidentally turned on. 5. Check the air monitor and battery status. 6. Arrange for blower, power supply, standby person and communication resource. ON-SITE MONITORING 1. Test air at top of space through the cover. Record the results. 2. If acceptable, open the cover. Test air at the bottom of the space. Record the results. If the combustibility reading at the bottom is greater than the top of the space, notify your supervisor and EH&S. DO NOT ENTER THE SPACE! 3. If air is not safe, ventilate, purge and retest. If atmosphere does not clear, DO NOT ENTER! 4. Ventilate space according to purge chart on back of this form - 5 minutes minimum. 5. Monitor continuously, recording results every two hours. Retest the air after breaks and lunch. MEASUREMENT Instrument # ____________________ Calibration Date ______________________ TIME 0XY CO H2S COMBUSTIBILITY OTHER Safe Range Safe Range Safe Range Safe Range (19.5-23.5%) (<25ppm) (< 10ppm) (< 10%) ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ If an emergency should occur, first summon help. Call 911 (6111 at Med. Ctr) and request help from the fire department. Tell the operator you have a "manhole rescue situation." If a person is down for no apparent reason, you must assume that toxic gases or oxygen deficient atmosphere conditions exist. DO NOT ENTER THE SPACE - fire department personnel using self-contained breathing apparatus and full protective gear will manage the rescue effort. Date/Time Entered __________________________ Date/Time Exited ____________________________ Keep this log at work site during the operation. Complete the form and return it to your supervisor when finished. UCSD Environment, Health and Safety Publication April 2002 16 UCSD Environment, Health and Safety Publication April 2002 17 Appendix B ROUTINE CONFINED SPACE ENTRY LOG To be used for meter vaults, telecommunications vaults, free-flowing sewers and electrical manholes where no high voltage work will be done. If these conditions change, a PERMIT is required. UCSD employees are only authorized to enter confined spaces after having received training in specialized entry procedures. Date _____________ Location ________________________ Type of Space/# _________________ Reason for Entry______________________________________________________________________ Persons(s) Entering ___________________________________________________________________ Form Completed By ___________________________________________________________________ PREPARATION 1. 2. 3. Check air monitor calibration status and battery condition. Arrange for ventilation equipment and power supply. Arrange for standby person and communication. ON-SITE MONITORING 1. Test air at top of space through the cover. Record the results. 2. If acceptable, open the cover. Test air at the bottom of the space. Record the results. If the combustibility reading at the bottom is greater than the top of the space, notify your supervisor and EH&S. DO NOT ENTER THE SPACE! 3. If air is not safe, ventilate, purge and retest. If atmosphere does not clear, DO NOT ENTER! 4. Ventilate space according to purge chart on back of this form - 5 minutes minimum. 5. Monitor continuously, recording results every two hours. Retest the air after breaks and lunch. MEASUREMENT Instrument # ____________________ Calibration Date ______________________ TIME 0XY CO H2S COMBUSTIBILITY OTHER Safe Range Safe Range Safe Range Safe Range (19.5-23.5%) (<25ppm) (< 10ppm) (< 10%) ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ If an emergency should occur, first summon help. Call 911 (6111 at Med. Ctr) and request help from the fire department. Tell the operator you have a "manhole rescue situation." If a person is down for no apparent reason, you must assume that toxic gases or oxygen deficient atmosphere conditions exist. DO NOT ENTER THE SPACE - fire department personnel using self-contained breathing apparatus and full protective gear will manage the rescue effort. Date/Time Entered _________________________ Date/Time Exited ____________________________ Supervisor's Signature ____________________________________ Date _______________________ Keep this log at work site during the operation. Complete the form and return it to your supervisor when finished. UCSD Environment, Health and Safety Publication April 2002 18 Appendix C Ventilation and Purge Chart UCSD Environment, Health and Safety Publication April 2002 19 Year 2002 Edition Environment, Health & Safety University of California, San Diego (858) 534-3660 http://blink.ucsd.edu/ehs e-mail: ehsweb@ucsd.edu UCSD Environment, Health and Safety Publication April 2002 20