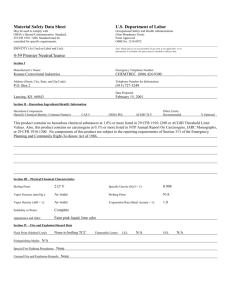

Occupational Safety and Health Admin., Labor Pt. 1910 (d)

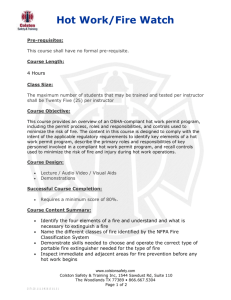

advertisement