Document 12093809

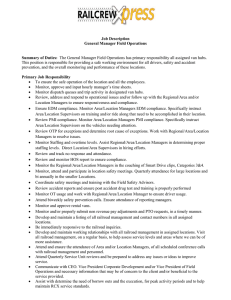

advertisement