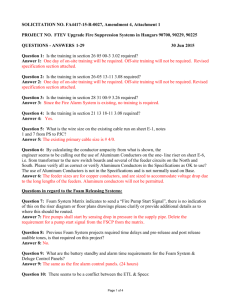

11460 EICO/vrd 01

advertisement