UTILIZATION OF NAVY-GENERATED WASTE OILS AS BURNER FUEL

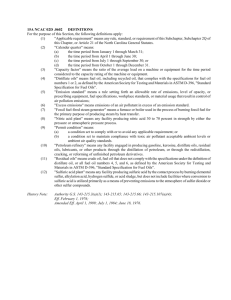

advertisement